Membrane fabric: description and types. Options and performance characteristics of membrane clothing Which membrane is better

The women's demi-season raincoat is part of the new uniform for police officers. The raincoat has a semi-fitting silhouette, with a central inner hidden fastener with five loops and buttons and an additional top button and a through-stitched loop, on an insulated stitched lining. On the yokes in the area of the shoulder seams there are two belt loops and one non-slit loop for attaching removable shoulder straps. Sleeves are set-in, two-seam. Patches are sewn into the lower part of the middle seam of the sleeve, fastened with a loop and a uniform button. Turn-down collar, with a detachable stand. The removable belt is threaded into belt loops located in the side seams and fastened with a buckle with a tongue, the free end of which is threaded into the belt loop. On the right hem there is an internal welt pocket with a leaf. Jacket fabric (100% polyester) with rip-stop weaving threads and water-repellent impregnation. The second layer is the membrane. Filler: Thinsulate 100 g/m. Recommended temperature range: from +10°C to -12°C. Worn with a dark blue muffler or a white muffler. It is allowed to wear a demi-season raincoat neatly folded with the front side out on the left hand. Demi-season raincoats are worn buttoned up. It is allowed to wear demi-season raincoats with the top button undone. Demi-season raincoats are worn with or without removable insulation and a belt fastened with a buckle. This raincoat has removable dark blue shoulder straps and dark blue stripes.

A set of windproof smok (jacket) and a warm lining with Primaloft ® Black insulation, which can be worn separately as a standalone smok jacket: Can be worn with or without a lining High and wide collar. A hood with a visor into which plastic is inserted to give it a rigid shape. For a thorough fit of the hood, it has three adjustments. Front zipper with two locks, unfastened both at the top and bottom. Windproof flap covering the front zipper. Velcro cuffs for smooth adjustment of the wrist girth. Front closure flap and pockets are fastened with Canadian (ribbon stem) buttons. , having greater reliability compared to conventional buttons. The buttons are large, making them easy to work with in thick gloves. Volume pockets on the body have a bendable entrance that protects the contents from falling out. Pockets: 2 volume pockets on the chest, 2 volume pockets at the bottom of the jacket, 2 Napoleon pockets with a zipper on the chest, one flat pocket. on the left sleeve and one inside on the left with a zipper Drawstrings: at the waist and bottom of the jacket, with elastic cords to protect against cold penetration under the clothes Lining: Quilted lining together with insulation, which increases the service life of the clothes (the insulation remains in place during dry cleaning or washing ) Fastening to a smoke jacket and fastening when worn as a separate jacket is done using comfortable American-style lens-shaped buttons. The hood is adjustable to fit the shape of the face. For comfortable wearing, the inside of the hood is lined with fleece Ventilation holes on the armpits Knitted cuffs for comfort Internal pocket on the left with a zipper Product material: Main smoka fabric: Strong rip-stop of high density (different from the analogue used in the summer uniform of Splava), 35% cotton, 65% polyester Smoke lining: thin mixed fabric, 35% cotton, 65% polyester Main lining fabric: 100% polyester Lining insulation: torso - Primaloft ® Black 2 × 133 g/m 2 sleeves - Primaloft ® Black 2 × 80 g/m 2 Product weight: 46/176 size -1969 g 50/176 size -2097 g 54/182 size -2181 g 56-58/188 size -2439 g Also on the site are models of trousers with insulation Primaloft® YOU MAY BE INTERESTED IN: We strongly recommend using front-loading washing machines, but if you own a top-loading machine, we recommend washing clothes and equipment in a special mesh laundry bag to protect against possible damage from parts of the washing machine drum . Before washing, you must fasten all zippers and Velcro fasteners and completely loosen all adjustments. If the outer fabric is membrane, then it is better to wash the product with the lining facing out (turned inside out). Wash on delicate cycle at 30°C with a double rinse cycle (it is better to use two rinse cycles to ensure that all detergent residues are removed from the fabric and insulation) and a medium spin. It is acceptable to use a drying drum at medium temperature (40-60°C) for 30-40 minutes or until completely dry; if the top fabric is membrane, it is better to dry the product with the lining out (turned inside out). You can hang dry the product with the lining facing out. To remove stubborn stains, you can treat the stains with a special solution such as Grangers Performance Wash or Nikwax Tech Wash before washing, allowing the detergent to soak in for 10-15 minutes. It is better to store clothes and equipment with synthetic insulation in a straightened (not compressed) state. How to restore DWR treatment on insulated clothing or equipment DWR is a special polymer applied to the surface of the fabric to give it water-repellent properties. DWR treatment does not last forever. During use of the product, as well as after a certain number of washes, the effectiveness of DWR decreases. If water droplets no longer roll off the surface of the fabric and wet the fabric even after washing, it’s time to restore the splashproof treatment. We recommend using a special spray-on or in-the-machine splash-proofing treatment such as Grangers Clothing Repel or Performance Repel, or Nikwax TX.Direct Wash-In or Spray-On. First, wash the item in accordance with the washing recommendations, then use the selected solution to restore the splash-proof treatment by spraying it directly onto the front of the item while it is still damp, or running a second wash cycle after pouring the required amount of wash-in into the washing machine . The manufacturer's instructions for the splashproof restoration product on the packaging must be followed exactly. Many DWR restoration products require heat activation, so it is best to tumble dry treated clothing and equipment on medium heat (40-60°C) for 40-50 minutes or until completely dry.

Winter jacket for the ground forces, navy and air force reliably protects against wind and snow. The insulation retains heat well, weighs little, does not deform, and does not absorb moisture. The combination of membrane fabric and insulation provides protection from severe frosts. CHARACTERISTICS Cold protection Regular cut For military operations Hand wash only MATERIALS Rip-stop Membrane Fibersoft insulation

Straight silhouette, length to mid-thigh Hood with a detachable edge, adjustable for volume and face shape Insulated with two layers of padding polyester, which is 270 g/m2 Quilted polyester lining together with padding polyester, which increases the service life of clothes (the padding polyester remains in place during dry cleaning or washing) Front zipper with two locks, unfastened both at the top and bottom of the jacket Windproof internal and external flaps covering the front “zipper”; trim on the hood; high collar and hem of the sleeves, adjustable in size using Velcro with an internal knitted cuff, prevent the cold from penetrating under clothing Windproof flap and pockets on the chest are fastened with large buttons, which are convenient to use with gloves Pockets: two pockets on the chest and two on the sleeve two internal pockets four pockets at the bottom of the jacket Drawstrings: along the waist and bottom of the jacket Material: 100% Polyamide with PU coating Product weight: 46/176 size -1140 g 50/176 size -1207 g 54/182 size - 1302 g 58/188 size -1430 g Constructed like a combat jacket, which involved serious checks and tests, having survived bursts of popular worship and periods of cooling, it returned to us calm and confident in its reliability, functionality and durability. Warm, durable, windproof and water-repellent, thanks to the fabric used in its manufacture (100% polyamide with PU coating), “Alaska” provides complete protection from snow, wind, moisture and cold. Insulation – two layers of synthetic fiber padding polyester (270 g/m2), which, unlike down, does not absorb moisture and is not afraid of frequent washing. The polyester lining is quilted along with it, which increases the service life of the jacket (the padding polyester remains in place during dry cleaning or washing). Unlike expensive membrane fabrics and down insulation, these materials do not require special care and do not raise the price of a jacket to sky-high heights. The hood, characteristic of Alaska, with fur trim, in combination with a high collar, covers almost the entire face if necessary, and is adjustable in terms of volume and oval of the face. The trim, made of natural or faux fur (your choice), can be detached from the hood. The inside of the collar and the edge of the hood that touches the face are lined with soft fleece. Serious barriers to wind and cold are also the windproof outer and inner flaps of the front two-way zipper, the belt and the bottom of the jacket that are tightened with a cord. Sleeves with internal knitted cuffs are adjustable with Velcro patches. The length of the jacket (up to mid-thigh) allows you to stay in the cold for a long time, and the loose silhouette does not restrict movement. Large buttons allow you to unbutton the jacket without taking off your gloves. The voluminous, warm front pockets are lined inside with a soft knitted fabric, and large buttons on the top pockets allow you to unfasten them with gloves. In addition to the six front pockets, there are two more pockets on the sleeve and two inside. A warm, comfortable jacket designed for long stays in the cold.

The jacket reliably protects from wind and snow. The insulation retains heat well, weighs little, does not deform, and does not absorb moisture. The combination of the membrane and Fibersoft insulation provides protection from frost down to -40 degrees. CHARACTERISTICS Protection from cold Regular cut Hand wash only MATERIALS Rip-stop Membrane Fibersoft insulation

Plain jackets are recommended as a set for the summer uniform “Security Guard” M4, M5 or M12 in the off-season Elastic knitted elastic band on the cuffs and waist for comfort Metal front “zipper” with an internal windproof valve The website presents a camouflage version of this jacket. Pockets: 2 spacious external pockets and 2 internal ones, 1 with a zipper with a section for a pen on the left sleeve Material: Twill -100% polyester with PU coating Insulation: Synthetic winterizer 150 g/m 2 Product weight: 44-46/170-176 size -631 g 48-50/170-176 size -662 g 52-54/182-188 size -689 g YOU MAY BE INTERESTED IN: If you are still flying in your sleep and can’t take your eyes off from a glider soaring in the sky - you will not pass by this model. Flight jackets, which were meant to combine functionality with simplicity, are reflected in this lightweight and practical urban jacket. The short demi-season Pilot jacket does not restrict movement and is comfortable for a bicycle, scooter or motorcycle. Thanks to the durable, water-repellent, wrinkle-resistant material (Twill (100% polyester with PU coating)) and synthetic padding polyester insulation (150 g/m2), from which the jacket is made, the “Pilot” easily withstands bad weather, is quickly cleaned and retains its original appearance for a long time. Elastic ribbing on the collar, cuffs and waistband provides soft but reliable protection from the wind. A powerful metal front zipper with an internal windproof flap declares reliability by its very appearance. Volumetric side pockets will allow you to place everything you need and will not allow your hands to freeze, and to keep small items safe, the jacket is equipped with two internal pockets and a pocket on the sleeve. Plain jackets are recommended to accompany the summer Security Guard uniform in the off-season. On the camouflage version, false shoulder straps can be used. We strongly recommend using front-loading washing machines; if you own a top-loading machine, we recommend washing clothes and equipment in a special mesh laundry bag to protect against possible damage from the washing machine drum parts. Before washing, you must fasten all zippers and Velcro fasteners and completely loosen all adjustments. If the outer fabric is membrane, then it is better to wash the product with the lining facing out (turned inside out). Wash on delicate cycle at 30°C with a double rinse cycle (it is better to use two rinse cycles to ensure that all detergent residues are removed from the fabric and insulation) and a medium spin. It is acceptable to use a drying drum at medium temperature (40-60°C) for 30-40 minutes or until completely dry; if the top fabric is membrane, it is better to dry the product with the lining out (turned inside out). You can hang dry the product with the lining facing out. To remove stubborn stains, you can treat the stains with a special solution such as Grangers Performance Wash or Nikwax Tech Wash before washing, allowing the detergent to soak in for 10-15 minutes. It is better to store clothes and equipment with synthetic insulation in a straightened (not compressed) state. How to restore DWR treatment on insulated clothing or equipment DWR is a special polymer applied to the surface of the fabric to give it water-repellent properties. DWR treatment does not last forever. During use of the product, as well as after a certain number of washes, the effectiveness of DWR decreases. If water droplets no longer roll off the surface of the fabric and wet the fabric even after washing, it’s time to restore the splashproof treatment. We recommend using a special spray-on or in-the-machine splash-proofing treatment such as Grangers Clothing Repel or Performance Repel, or Nikwax TX.Direct Wash-In or Spray-On. First, wash the item in accordance with the washing recommendations, then use the selected solution to restore the splash-proof treatment by spraying it directly onto the front of the item while it is still damp, or running a second wash cycle after pouring the required amount of wash-in into the washing machine . The manufacturer's instructions for the splashproof restoration product on the packaging must be followed exactly. Many DWR restoration products require heat activation, so it is best to tumble dry treated clothing and equipment on medium heat (40-60°C) for 40-50 minutes or until completely dry.

Winter jacket for the ground forces, navy and air force reliably protects against wind and snow. The insulation retains heat well, weighs little, does not deform, and does not absorb moisture. The combination of membrane fabric and insulation provides protection from severe frosts. CHARACTERISTICS Cold protection Regular cut For military operations Hand wash only MATERIALS Rip-stop Membrane Fibersoft insulation

Universal all-season boots for light trekking and the city. Upper material – genuine leather (th. 2.0 mm) with PU coating + Cordura ®. Easy to care for and resistant to wear. The lining is a practical synthetic material on a Dintex® membrane. Well removes excess moisture from the foot and retains heat. Replaceable molded insole. It is highly resistant to wear. Durable nylon lacing ensures a tight and comfortable fit on the foot. The sole is two-component (heat-resistant rubber + EVA) - well-cushioned and non-slip. The toe part of the boot has a rubber pad that provides additional protection from mechanical impacts when walking. Multi-directional tread ensures optimal grip. surface Stainless steel fittings The red, disheveled sun, yawning, creeps out from behind the distant ridges, looks at itself in every puddle, rings with drops and draws us into a festival of light and air. I would like to forget about the backpack that weighs down my shoulders, take a deep breath and look around, not at my feet. The road is far from simple... it lulls your vigilance, unfolding like a fluffy carpet, and suddenly, capriciously bending, throwing up obstacles and traps. It’s good that trekking boots have already been invented! THB "Berg" boots fix the foot, protect the feet from stones and impacts, “keep” on the terrain, do not get wet and remove excess moisture from the inside. Stability on difficult terrain, the necessary rigidity and elasticity of the boot are provided by a two-component sole (heat-resistant rubber + EVA). EVA (ethylene vinyl acetate) is a lightweight and elastic material, similar to foam rubber, with excellent shock-absorbing properties. It has low heat transfer, does not absorb moisture, and remains flexible at low temperatures. Thanks to the foamed structure of the EVA sole, the shoes spring well, easily restore their shape when deformed, retain heat, and do not allow cold to pass through. The outsole is made of wear-resistant rubber with a deep multi-directional tread that provides reliable traction on a variety of soils in any weather. The upper material combines full-grain leather with PU coating and durable, lightweight synthetic material Cordura ®, which reduces the weight of the boots and improves their breathability and wear resistance. The lining is a practical synthetic quick-drying material on a Dintex® membrane. It breathes, removes excess moisture well from the foot and maintains a comfortable temperature in the boot, protecting the feet from hypothermia. The replaceable, molded, anatomical sockliner is highly wear-resistant and antibacterial to provide arch support and ventilation. The heel supports the ankle, durable nylon lacing secures the foot tightly, and a rubber pad in the toe of the boot protects the toes from impact and increases the grip area on rocky terrain. Light, comfortable boots will make your journey shorter, just be careful and take your time while trying them on. To make it easier for you to “feel” the shoes, our stores have simulators of complex terrain Characteristics: Weight: 550 g (1/2 pair 42 sizes) Size range: 41-46

Warm and durable winter jacket. The most popular model. The website presents a plain version of this jacket. You can use false shoulder straps Quilted polyester lining together with padding polyester, which increases the service life of the clothing (the padding polyester stays in place during dry cleaning or washing) Front zipper with two locks, unfastens both at the top and bottom of the jacket Folds on the back to give additional freedom of movement Windproof flap covering the front zipper, knitted cuffs inside the sleeves prevent the cold from penetrating under the clothes. Stainless steel buttons are used. It is possible to complete the jacket with a hood, collar and lining. Pockets: 2 breast, 2 at the bottom of the jacket and 1 internal. Drawstrings: cord for tightening the belt and bottom of the jacket. Material: Oxford. ) -100% nylon with PU coating Insulation: Synthetic winterizer 300 g/m 2 SIZE SELECTION: Download

MPA-78 Light jacket provides excellent protection from wind, thanks to the stitched lining, removable hood and windproof strip. On the right and left shelves there are patch pockets fastened with textile fasteners. There are also front side welt pockets with a zipper. The sleeves are adjustable in width using tape and plastic patches (Velcro). Along the shoulder line there are false shoulder straps fastened with buttons. On the left side of the jacket lining there is a horizontal zippered pocket. The demi-season jacket of the Ministry of Defense provides excellent protection from wind thanks to the stitched lining, removable hood and windproof flap. On the right and left shelves there are patch pockets fastened with textile fasteners. Appearance. Jacket of a straight silhouette with an insulated stitched lining, with a central side zipper, with an external wind flap, and a drawstring at the waist. The front has a stitched yoke extending to the back, with upper welt pockets with flaps fastened with textile fasteners, side welt pockets fastened with a zipper. Set-in two-seam sleeves with stitched cuffs on an elastic band and plastic patches (Velcro) at the bottom to adjust the width. Along the shoulder line there are shoulder straps with false shoulder straps, fastened with buttons. Stand collar. The hood is fastened with a zipper, consisting of three parts. The hood along the front neckline is adjustable with an elastic cord and clamps. On the left side of the jacket lining there is a horizontal zippered pocket. Characteristics protection from cold protection from rain and wind regular cut Materials rip-stop membrane

Attention! The price of the jacket is indicated without the cost of the edge. You can order the edge separately. Warm but light winter down Alaskan jacket for harsh winters. Features a loose fit that does not restrict movement, a membrane fabric upper with wind- and moisture-proof and breathable properties, a detachable trim made of natural fur, a convenient hood adjustment system (top flap, back and front ties made of elastic cord with clamps) shoulder pads made of synthetic insulation, a high, warm collar trimmed with Polartec ® profiled sleeves central two-lock zipper protected by an insulating strip, duplicated by two Velcro ® flaps braid along the strip prevents fabric from getting into the zipper special strip protects the face from contact with the top edge of the zipper six external convenient pockets under the outer strip and on the right sleeve hidden pockets with zippers four internal pockets warm half-glove cuffs made of Polartec ® with thumb holes windproof skirt waistband elastic cord with fasteners Characteristics Upper fabric: Nylon Supplex Inner fabric: Advance® Classic Insulation: goose down Weight, g.: 1960 Insulation weight, g. : 470 Type of insulation: natural Temperature range, C°: -30 Seam technology: simple Number of internal pockets, pcs.: 4 Number of external pockets, pcs.: 6 Windproof skirt Zipper type: two-lock Hood: non-removable Water resistance, mm. water column: 3000 Vapor permeability, gr.m.sq./24 hours: 3000 Membrane: Nylon Supplex ® Volumetric cut of the elbow area Fill Power indicator (for down products): 670 Windproof flap Duplicate central zipper valve Hood volume adjustment Waist adjustment Internal cuffs Hem adjustment

Plain jackets are recommended as a set for the summer uniform “Security Guard” M4, M5 or M12 in the off-season Elastic knitted elastic band on the cuffs and waist for comfort Metal front “zipper” with an internal windproof valve The website presents a camouflage version of this jacket, allowing the use of false shoulder straps Pockets: 2 spacious external pockets and 1 internal 1 with a zipper with a section for a pen on the left sleeve Material: Twill -100% polyester with PU coating Insulation: Synthetic winterizer 150 g/m 2 Product weight: 44-46/170-176 size -611 g 48-50/170-176 size -721 g 52-54/182-188 size -741 g YOU MAY BE INTERESTED IN: If you are still flying in your sleep and can’t take your eyes off from a glider soaring in the sky - you will not pass by this model. Flight jackets, which were meant to combine functionality with simplicity, are reflected in this lightweight and practical urban jacket. The short demi-season jacket “Navigator” does not restrict movement and is comfortable for a bicycle, scooter or motorcycle. The only difference between the “Navigator” and the “Pilot” jacket is the presence of a patch collar. Thanks to the durable, water-repellent, wrinkle-resistant material (Twill (100% polyester with PU coating)) and synthetic padding polyester insulation (150 g/m2), from which the jacket is made, the “Navigator” easily withstands bad weather, is quickly cleaned and retains its original appearance for a long time. Elastic ribbing on the cuffs and waistband provides soft but reliable protection from the wind. The powerful metal front zipper with an internal wind flap inspires confidence just by looking at it. Volumetric side pockets will allow you to place everything you need and will not allow your hands to freeze, and for the absolute safety of valuable items, the jacket is equipped with two internal pockets and a pocket on the sleeve. Plain jackets are recommended to accompany the summer Security Guard uniform in the off-season. On the camouflage version, false shoulder straps can be used. We strongly recommend using front-loading washing machines; if you own a top-loading machine, we recommend washing clothes and equipment in a special mesh laundry bag to protect against possible damage from the washing machine drum parts. Before washing, you must fasten all zippers and Velcro fasteners and completely loosen all adjustments. If the outer fabric is membrane, then it is better to wash the product with the lining facing out (turned inside out). Wash on delicate cycle at 30°C with a double rinse cycle (it is better to use two rinse cycles to ensure that all detergent residues are removed from the fabric and insulation) and a medium spin. It is acceptable to use a drying drum at medium temperature (40-60°C) for 30-40 minutes or until completely dry; if the top fabric is membrane, it is better to dry the product with the lining out (turned inside out). You can hang dry the product with the lining facing out. To remove stubborn stains, you can treat the stains with a special solution such as Grangers Performance Wash or Nikwax Tech Wash before washing, allowing the detergent to soak in for 10-15 minutes. It is better to store clothes and equipment with synthetic insulation in a straightened (not compressed) state. How to restore DWR treatment on insulated clothing or equipment DWR is a special polymer applied to the surface of the fabric to give it water-repellent properties. DWR treatment does not last forever. During use of the product, as well as after a certain number of washes, the effectiveness of DWR decreases. If water droplets no longer roll off the surface of the fabric and wet the fabric even after washing, it’s time to restore the splashproof treatment. We recommend using a special spray-on or in-the-machine splash-proofing treatment such as Grangers Clothing Repel or Performance Repel, or Nikwax TX.Direct Wash-In or Spray-On. First, wash the item in accordance with the washing recommendations, then use the selected solution to restore the splash-proof treatment by spraying it directly onto the front of the item while it is still damp, or running a second wash cycle after pouring the required amount of wash-in into the washing machine . The manufacturer's instructions for the splashproof restoration product on the packaging must be followed exactly. Many DWR restoration products require heat activation, so it is best to tumble dry treated clothing and equipment on medium heat (40-60°C) for 40-50 minutes or until completely dry.

The jacket runs one size too big!!! If you wear 50 rubles, you need to take 48!!! Jacket from a winter field suit for military personnel of the Russian Armed Forces, model 2010. It differs from the original in its outer wind and waterproof fabric, lightweight non-removable insulation and a more convenient central fastener. Outer fabric is Oxford PU (100% nylon). Unlike the original mixed fabric, it does not get wet, protects from wind and is highly durable. Lining made of light synthetic fabric. Central zipper closure, covered on the outside with a placket with buttons (buttons in the original). Better protection from cold and wind, more convenient to work even with warm gloves. For simplicity and convenience, the insulation (sintepon) is made non-removable. The amount of insulation is less than in the original, the jacket is more demi-season for its intended purpose. Reinforcement of the elbows with pads from the second layer of fabric. Cuffs are fastened with Velcro patches. Shoulder straps with Velcro fastener are sewn onto the shoulders (location of the new sample). False shoulder straps included High wide collar with fleece lining. Fastens with Velcro. The hood is insulated with a layer of fleece and stows away in the collar. Tightens around the face, and in two dimensions at the back of the head. Fastens at the front with Velcro. The waist is tightened with an elastic cord with two fasteners on the inside of the jacket. A hanger loop on the inside of the collar. Pockets: two lower patch flat pockets with Velcro flaps. Chest slit pockets for warming the hands. With an inclined entrance at a convenient angle, insulated with fleece, an internal pocket for documents with a Velcro flap (on the heart side), made of water-resistant fabric. We strongly recommend using front-loading washing machines; if you own a top-loading machine, it is recommended washing clothes and equipment in a special mesh laundry bag to protect against possible damage from parts of the washing machine drum. Before washing, you must fasten all zippers and Velcro fasteners and completely loosen all adjustments. If the outer fabric is membrane, then it is better to wash the product with the lining facing out (turned inside out). Wash on delicate cycle at 30°C with a double rinse cycle (it is better to use two rinse cycles to ensure that all detergent residues are removed from the fabric and insulation) and a medium spin. It is acceptable to use a drying drum at medium temperature (40-60°C) for 30-40 minutes or until completely dry; if the top fabric is membrane, it is better to dry the product with the lining out (turned inside out). You can hang dry the product with the lining facing out. To remove stubborn stains, you can treat the stains with a special solution such as Grangers Performance Wash or Nikwax Tech Wash before washing, allowing the detergent to soak in for 10-15 minutes. It is better to store clothes and equipment with synthetic insulation in a straightened (not compressed) state. How to restore DWR treatment on insulated clothing or equipment DWR is a special polymer applied to the surface of the fabric to give it water-repellent properties. DWR treatment does not last forever. During use of the product, as well as after a certain number of washes, the effectiveness of DWR decreases. If water droplets no longer roll off the surface of the fabric and wet the fabric even after washing, it’s time to restore the splashproof treatment. We recommend using a special spray-on or in-the-machine splash-proofing treatment such as Grangers Clothing Repel or Performance Repel, or Nikwax TX.Direct Wash-In or Spray-On. First, wash the item in accordance with the washing recommendations, then use the selected solution to restore the splash-proof treatment by spraying it directly onto the front of the item while it is still damp, or running a second wash cycle after pouring the required amount of wash-in into the washing machine . The manufacturer's instructions for the splashproof restoration product on the packaging must be followed exactly. Many DWR restoration products require heat activation, so it is best to tumble dry treated clothing and equipment on medium heat (40-60°C) for 40-50 minutes or until completely dry.

Police windbreaker. This statutory police windbreaker thanks to the use of high-quality membrane fabric with a density of 240 g. will be able to protect employees of the Ministry of Internal Affairs from any adverse weather conditions. A big feature of this jacket model is its resistance to wind gusts and moisture resistance. Inside the stand-up collar there is a hood, which can be easily adjusted along the front. Elasticated cuffs, an adjustable waistband, and a durable zipper hidden by a fabric strip with rivets will also provide protection from bad weather. Along the perimeter of the shoulder girdle, the product is complemented by sewn-in red piping. On the shoulder seams there are shoulder straps on the button, intended for attaching distinctive signs. color dark blue main features: uniform MVD material membrane wide size grid CHARACTERISTICS CHARACTERISTICS OF THE SUIT Material: membrane Composition: P/E Density: 240 gr. Cuffs: yes Jacket/pants pockets: yes/no Seasonality: all-season Additional: statutory police windbreaker

Warm and durable winter jacket. The most popular model. The website presents a camouflage version of this jacket. You can use false shoulder straps Quilted polyester lining together with padding polyester, which increases the service life of the clothing (the padding polyester stays in place during dry cleaning or washing) Front zipper with two locks, unfastens both at the top and bottom of the jacket Folds on the back to give additional freedom of movement Windproof flap covering the front zipper, knitted cuffs inside the sleeves prevent the cold from penetrating under the clothes. It is possible to complete the jacket with a hood, collar and lining. Stainless steel buttons are used. Pockets: 2 chest pockets and 2 at the bottom of the jacket. 1 internal pocket. Drawstrings: cord for tightening the belt and bottom of the jacket. Material: Oxford ( Oxford) -100% nylon with PU coating "Tourist" -100% polyacrylic with polyamide coating Insulation: Sintepon 300 g/m 2 SIZE SELECTION: Download

A men's raincoat for employees of the Ministry of Defense with a straight silhouette will provide comfortable service and a presentable appearance at temperatures down to -15 degrees. Jacket fabric with a membrane in combination with insulation works as wind and moisture protection. CHARACTERISTICS Protection from cold Protection from rain and wind Regular cut Hand wash only MATERIALS Rip-stop Membrane Fibersoft insulation

False shoulder straps can be used on camouflage jackets Elastic knitted ribbing on the cuffs and waist for comfort Metal front zipper with an internal windproof valve The website presents a plain version of this jacket Pockets: 2 spacious external and 1 internal pocket 1 with a zipper with a section for a pen on the left sleeve Material: Upper material 45-P Shadow Alpha Industries - Splav: 100% nylon Twill (Twill) -100% polyester with PU coating Insulation: Synthetic winterizer 150 g/m 2 Product weight: 44-46/170-176 size - 611 g 48-50/170-176 size -721 g 52-54/182-188 size -741 g Additional discounts do not apply to products with a red price YOU MAY BE INTERESTED in: We strongly recommend using washing machines with front loading, but if you own a top-loading machine, it is recommended to wash clothes and equipment in a special mesh laundry bag to protect against possible damage from parts of the washing machine drum. Before washing, you must fasten all zippers and Velcro fasteners and completely loosen all adjustments. If the outer fabric is membrane, then it is better to wash the product with the lining facing out (turned inside out). Wash on delicate cycle at 30°C with a double rinse cycle (it is better to use two rinse cycles to ensure that all detergent residues are removed from the fabric and insulation) and a medium spin. It is acceptable to use a drying drum at medium temperature (40-60°C) for 30-40 minutes or until completely dry; if the top fabric is membrane, it is better to dry the product with the lining out (turned inside out). You can hang dry the product with the lining facing out. To remove stubborn stains, you can treat the stains with a special solution such as Grangers Performance Wash or Nikwax Tech Wash before washing, allowing the detergent to soak in for 10-15 minutes. It is better to store clothes and equipment with synthetic insulation in a straightened (not compressed) state. How to restore DWR treatment on insulated clothing or equipment DWR is a special polymer applied to the surface of the fabric to give it water-repellent properties. DWR treatment does not last forever. During use of the product, as well as after a certain number of washes, the effectiveness of DWR decreases. If water droplets no longer roll off the surface of the fabric and wet the fabric even after washing, it’s time to restore the splashproof treatment. We recommend using a special spray-on or in-the-machine splash-proofing treatment such as Grangers Clothing Repel or Performance Repel, or Nikwax TX.Direct Wash-In or Spray-On. First, wash the item in accordance with the washing recommendations, then use the selected solution to restore the splash-proof treatment by spraying it directly onto the front of the item while it is still damp, or running a second wash cycle after pouring the required amount of wash-in into the washing machine . The manufacturer's instructions for the splashproof restoration product on the packaging must be followed exactly. Many DWR restoration products require heat activation, so it is best to tumble dry treated clothing and equipment on medium heat (40-60°C) for 40-50 minutes or until completely dry.

A classic, warm women's down coat for the city. Durable mixed upper fabric with waterproof DWR treatment reliably protects from wind and snow, and is resistant to stains. The optimal balance of style, comfort and reliable protection from frost, weight, strength and wear resistance of this model make it an obvious choice as a practical everyday urban outerwear for cold weather. of the year. Semi-fitted cut allows you to look feminine and at the same time provides more than the necessary freedom of movement Four-layer construction (separate down bag) eliminates the migration of down Length to mid-thigh Comfortable stitched warm hood with height and face adjustments Removable trim made of natural fur Warm high collar Central two-lock scalloped zip Insulated internal safety placket Insulated external placket with snaps Sleeves with warm internal cuffs Articulated elbow cut Pockets: Two warm side pockets with flaps with snap buttons, soft velor burlap One internal chest pocket with zipper Material: Outer fabric: 84% polyester, 16 % cotton, 191 g/m 2 Lining: 100% nylon 20D 36 g/m 2 Insulation: High-quality goose down FP600 Down weight: 44/158-164-181.4 g 50/158-164-221.0 g 54/ 164-170-246.1 g SIZE SELECTION: Download Down production

Straight silhouette, length to mid-thigh Hood with a detachable edge, adjustable for volume and face shape Insulated with two layers of padding polyester, which is 270 g/m2 Quilted polyester lining together with padding polyester, which increases the service life of clothes (the padding polyester remains in place during dry cleaning or washing) Front zipper with two locks, unfastened both at the top and bottom of the jacket Windproof internal and external flaps covering the front “zipper”; trim on the hood; high collar and hem of the sleeves, adjustable in size using Velcro with an internal knitted cuff, prevent the cold from penetrating under clothing Windproof flap and pockets on the chest are fastened with large buttons, which are convenient to use with gloves Pockets: two pockets on the chest and two on the sleeve two internal pockets four pockets at the bottom of the jacket Drawstrings: along the waist and bottom of the jacket Material: 100% Polyamide with PU coating Product weight: 46/176 size -1140 g 50/176 size -1207 g 54/182 size - 1302 g 58/188 size -1430 g Constructed like a combat jacket, which involved serious checks and tests, having survived bursts of popular worship and periods of cooling, it returned to us calm and confident in its reliability, functionality and durability. Warm, durable, windproof and water-repellent, thanks to the fabric used in its manufacture (100% polyamide with PU coating), “Alaska” provides complete protection from snow, wind, moisture and cold. Insulation – two layers of synthetic fiber padding polyester (270 g/m2), which, unlike down, does not absorb moisture and is not afraid of frequent washing. The polyester lining is quilted along with it, which increases the service life of the jacket (the padding polyester remains in place during dry cleaning or washing). Unlike expensive membrane fabrics and down insulation, these materials do not require special care and do not raise the price of a jacket to sky-high heights. The hood, characteristic of Alaska, with fur trim, in combination with a high collar, covers almost the entire face if necessary, and is adjustable in terms of volume and oval of the face. The trim, made of natural or faux fur (your choice), can be detached from the hood. The inside of the collar and the edge of the hood that touches the face are lined with soft fleece. Serious barriers to wind and cold are also the windproof outer and inner flaps of the front two-way zipper, the belt and the bottom of the jacket that are tightened with a cord. Sleeves with internal knitted cuffs are adjustable with Velcro patches. The length of the jacket (up to mid-thigh) allows you to stay in the cold for a long time, and the loose silhouette does not restrict movement. Large buttons allow you to unbutton the jacket without taking off your gloves. The voluminous, warm front pockets are lined inside with a soft knitted fabric, and large buttons on the top pockets allow you to unfasten them with gloves. In addition to the six front pockets, there are two more pockets on the sleeve and two inside. A warm, comfortable jacket designed for long stays in the cold. We strongly recommend using front-loading washing machines; if you own a top-loading machine, we recommend washing clothes and equipment in a special mesh laundry bag to protect against possible damage from the washing machine drum parts. Before washing, you must fasten all zippers and Velcro fasteners and completely loosen all adjustments. If the outer fabric is membrane, then it is better to wash the product with the lining facing out (turned inside out). Wash on delicate cycle at 30°C with a double rinse cycle (it is better to use two rinse cycles to ensure that all detergent residues are removed from the fabric and insulation) and a medium spin. It is acceptable to use a drying drum at medium temperature (40-60°C) for 30-40 minutes or until completely dry; if the top fabric is membrane, it is better to dry the product with the lining out (turned inside out). You can hang dry the product with the lining facing out. To remove stubborn stains, you can treat the stains with a special solution such as Grangers Performance Wash or Nikwax Tech Wash before washing, allowing the detergent to soak in for 10-15 minutes. It is better to store clothes and equipment with synthetic insulation in a straightened (not compressed) state. How to restore DWR treatment on insulated clothing or equipment DWR is a special polymer applied to the surface of the fabric to give it water-repellent properties. DWR treatment does not last forever. During use of the product, as well as after a certain number of washes, the effectiveness of DWR decreases. If water droplets no longer roll off the surface of the fabric and wet the fabric even after washing, it’s time to restore the splashproof treatment. We recommend using a special spray-on or wash-in fabric spatter-reinforcement product such as Grangers Clothing Repel or Performance Repel, or Nikwax TX. Direct Wash-In or Spray-On. First, wash the item in accordance with the washing recommendations, then use the selected solution to restore the splash-proof treatment by spraying it directly onto the front of the item while it is still damp, or running a second wash cycle after pouring the required amount of wash-in into the washing machine . The manufacturer's instructions for the splashproof restoration product on the packaging must be followed exactly. Many DWR restoration products require heat activation, so it is best to tumble dry treated clothing and equipment on medium heat (40-60°C) for 40-50 minutes or until completely dry.

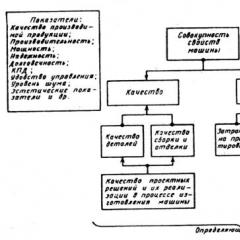

« Membrane- this is either the thinnest film that is laminated (welded or glued using a special technology) to the upper fabric, or a special impregnation that is rigidly applied to the fabric using a hot method during production. On the inside, the film or impregnation can be protected by another layer of fabric.”

From this we can conclude about an important property of membrane clothing - it is very light.

Poreless membranes they work on the principle of osmosis (not space, but osmosis - remember physics and chemistry lessons at school).

The system is as follows: vapors fall on the inside of the membrane, settle on it and, through active diffusion, quickly move to the outside of the membrane. (Again, only if there is a driving force - a difference in the partial pressures of water vapor).

What are the advantages of non-porous membranes? They are extremely durable, do not require careful maintenance, and work properly in a wide temperature range. Such membranes are usually used in top-end (expensive and most functional) products.

What are the disadvantages? At first it may seem that the products are getting wet, but this is precisely the same fumes that accumulate on the inside of the product. That is, they begin to breathe more slowly, but advanced non-porous membranes, “heating up”, sometimes surpass porous membranes in their breathing properties.

Pore membranes- these are, roughly speaking, membranes that work according to the following principle: drops of water that fall on the membrane tissue from the outside cannot pass through the pores of the membrane inside, since these pores are too small. The steam molecules that form when you sweat are freely removed from the inside of the membrane tissue through the pores of the membrane (since a steam molecule is thousands of times smaller than a drop of water, it can freely penetrate through the pores of the membrane). As a result, we obtain waterproof membrane fabric on the outside of the product and breathable (steam-removing) properties from the inside of the product. At the same time, a drop of water will not be able to seep into such a hole. But how (you ask) will clothes with holes withstand the wind? After all, wind molecules are also significantly smaller than a drop of water! In this case, the membrane works differently. The wind, entering long and narrow pores, begins to swirl and does not pass through.

What is the advantage of pore membranes? They "quickly" begin to breathe, i.e., remove evaporation as soon as you begin to sweat (provided that there is a difference in the partial pressures of water vapor inside and outside the jacket. That is, when there is a driving force).

What are the disadvantages? This membrane “dies” quite quickly, that is, it loses its properties. The pores of the membrane become clogged, which greatly reduces the breathability. If washed incorrectly, the jacket may begin to leak. This drawback can manifest itself especially strongly if you are not a particular fan of caring for your things (using special DWR sprays, detergents for membrane fabrics, etc.).

Membrane combination- everything is very cool. The system is as follows: the upper fabric is covered on the inside with a pore membrane, and on top of the pore membrane there is also a thin coating (i.e., a non-porous polyurethane membrane film). This magical fabric has all the advantages of pore and non-pore membranes without the disadvantages. But high technology comes at a high price. Very few companies use this membrane in their products...

How does a membrane “work”?

If you become the owner of membrane clothing, then you should not put it on a cotton T-shirt and go for a run in twenty-degree frost. This is how the membrane does not “work”. The idea is to keep the heat inside by wicking moisture out and preventing it from being absorbed into your clothes.

The classic scheme of protection against moisture and cold consists of three layer elements, and the membrane is only one of them, the very last.

First layer of clothing- this is thermal underwear (special thin clothing that retains the heat generated by the body). Cotton should be avoided, as it greedily absorbs moisture, and, therefore, there can be no talk of any warmth.

Second layer- woolen clothing (with an admixture of synthetic fabrics that wick away moisture) or clothing made from artificial materials such as fleece (Fleece) or Polartec. It is important that the second layer is voluminous and retains heat.

But only third, outer layer- thin membrane jacket.

If the frost is mild, then you can get by with only the first and third layers, which will provide you with mobility and mobility.

And finally, it is important to understand how moisture will be removed outside. Due to the difference between the air pressure under the membrane jacket and outside. Therefore, if you decide to sit motionless in a snowdrift, hoping for a “magic” membrane, there is a real chance of catching a serious cold. However, this does not mean at all that you need to run around like crazy waiting for a pressure difference for the membrane to “work.” It’s enough just to move more or less actively (just in case: walking is also movement).

Characteristics of membrane fabric

A membrane can be characterized not only by its structure and operating principle (with or without pores), but also by its two main parameters: water resistance and the ability to release steam.

Water resistance(or water resistance), waterproofness (millimeters of water column, mm water column, mm H2O) - the height of the water column that the membrane (fabric) can withstand without getting wet. In fact, this parameter indicates the water pressure that can be maintained without getting wet. The higher the water resistance of the membrane, the more intense precipitation it can withstand without letting water pass through it.

Vapor permeability(g/m2, g/m2) - the amount of water vapor that a square meter of membrane (fabric) can pass through. Other terms are also used: Moisture Vapor Transfer Rate (MVTR), moisture permeability. Most often, the value g/(m2.24h) averaged over a long period of time is indicated - the amount of water vapor that a square meter of membrane (fabric) can pass through in 24 hours. The higher it is, the more comfortable the clothing.

The base level is usually 3,000mm/3000g/m2/24 hours.

Mid-range membranes typically have a rating of 8,000mm/5,000g/m2/24hrs or so.

The water resistance of high-end fabrics is usually at least 20,000 mm water column, and the breathability is at least 8,000 g/m?/24 hours.

About gluing seams

Taped seams prevent moisture from penetrating through the seams, and, as a result, you feel dry and comfortable.

Inscription " all seams are sealed

" means that all seams in this product are taped.

If the label says “critical seam sealing,” this means that only the main seams are taped in the product, which may or may not result in leaks in some places. It is worth noting that in products positioned by the brand as semi-urban, this option is very acceptable (usually these are products with insulation). Here, every buyer is free to choose what he wants and what is suitable for him personally.

Water-repellent coating - DWR

Look - the droplets on the fabric are not absorbed, but lie on the fabric, rolling into balls! This is a DWR (Durable Water Repellence) coating that does not allow water to pass even through the top layer of the fabric (that is, to be absorbed into it). On DWR coated fabric, water beads up and rolls easily. DWR, by the way, is not durable, and disappears over time (is washed off), and wet spots appear on the fabric (upon contact with water). This does not mean that the product gets wet, since the membrane will still not allow water to pass through, but some discomfort may be present. The resulting layer of water on top will not allow the membrane to work, no matter how cool it is. In addition, in pore membranes, in this case, water can pass through the membrane. Specially developed products with this same DWR coating (NIKWAX, WOLY, salamander), sold in stores selling extreme clothing, will help you avoid dying of DWR.

Pros and cons of membrane clothing

Pros:

- it is light and comfortable: the child can move outside and enjoy a walk, rather than sitting in a stroller and only being able to move his head.

- you don’t waste a lot of nerves pulling on and fastening another layer of “warmer” clothing

- the child will not cry while you get dressed and go outside.

- protects well from rain and snow, durable and lightweight;

again, your nerves are calm and you don’t have to run home after another fall in a puddle. - it is not blown by the wind and removes body fumes well;

it is suitable for both not very cold windy weather and frosty weather; - You need to wear less clothing underneath than usual.

- Dirt is very easy to remove, you can forget about washing every other day and choose bright colors.

Minuses:

- membrane clothing is quite expensive

- requires special care

- relatively short-lived

- clothes for it must be selected in a special way;

- Not suitable for lovers of everything natural.

The best is the Gore-Tex microporous membrane, developed in the 60s of the 20th century for astronaut suits. For ski clothing, as a rule, two-layer Gore-Tex is used, which is lighter and softer than three-layer, from which jackets for tourism and mountaineering are mainly made.

The water resistance of the two-layer membrane is 15,000 mm, and the moisture evaporation rate is 12,000 g/m2/24 hours.

The non-porous membranes Triple-Point and Sympatex, ULTREX, and other fabrics under the general name hi-pora are kept approximately on the same level with Gore-Tex. Their water resistance ratings are slightly lower - approximately 12,000 mm, but this is quite enough to not get wet even in heavy rain or snowfall. These membranes also breathe very well. Sympatex, in addition to being used in its pure form, is part of the Omni-Tech technology, which includes a membrane, a special water-repellent coating and a windproof layer.

Ceplex and Fine-Tex membranes, which are now very actively used in the production of sportswear, are much cheaper. The main disadvantage of Ceplex is its fragility.

If clothes with Gore-Tex, Triple-Point or Sympatex last 4-5 years with careful handling, then Ceplex rarely withstands more than one or two seasons of active use and begins to get wet. Fine-Tex, on the other hand, does not get wet, but breathes a little better than polyethylene. But these membranes themselves and clothing with them cost an order of magnitude less than their counterparts from Gore-Tex, Triple-Point and Sympatex.

The Ceplex membrane is used in the production of Vaude brand clothing.

Membrane Fine-Tex, Sympatex - in brands Bolik, COOLAIR.

hi-pora membranes - in the brands Commandor (Hi-Pora™/Evapora™), Lowe Alpine (Triple Point Ceramic), Columbia (Sympatex)

Membrane, insulation, outer fabric and weather conditions, let’s sum it up at the layman level by creating review of brands currently represented in Ukraine.

On average, you can start wearing winter membrane clothing from +5+7 °C (for cool children). A membrane overall or set worn by a baby during autumn rain or during a spring thaw will save the mother’s nerves (but not those around her) and will give the child a lot of joy from interacting with water. If no active fiddling around in the puddle is expected, fabric impregnated with DWR will suffice.

It would be very nice if the seams in the product are taped. Reima tec (for cool children, but if the child is active and not freezing, it is better to get by with demi-season clothing), Huppa (jacket without fleece insulation or with 80 g of insulation, fleece-lined trousers) are suitable for such conditions. Under the overalls - a minimum of clothing, ideally - thermal underwear. Because, as practice shows, when there are a lot of puddles around, it is not difficult for a child to walk inactively.

When the thermometer shows 0...-5 °C, you can either add 1 layer, or change outer clothing. As an option - Reima tec (you can add a fleece blouse or a mixed golf shirt to your thermal underwear), Huppa (jacket without insulation on fleece or with an amount of insulation of 80, 130 g, trousers with fleece or bib overalls 100 g), Lenne (products with an amount of insulation no more than 150 g), Bambino, TCM, H&M.

Suitable for temperatures of -5...-15°C are Reima tec (it is advisable to wear thermal underwear or other underwear and a fleece overall under the overalls), Huppa (jackets with insulation amounts of 130, 160, 200 g, bib overalls 100 g, overalls 200 g), Lenne ( products with insulation 150 g, 330 g), at temperatures below -10 °C you can wear a down jacket (O'Hara, Chicco, Geox) or overalls Kiko, Donilo, Gloria Jeans, Lemmi, Shaluny, Gusti, Bambino, TCM, H&M.

15 °C and below - many mothers cancel walks at this temperature. If you are not one of those people, make sure that the child does not sit still on the street (in which case a fur coat will not help much), which means that he is not dressed in thick clothes and can move freely.

15-20 °C will not be scary if the child rides down the slide, sculpts a snow woman, plays snowballs (if you don’t believe me, try it yourself!). Suitable for Reima tec (not for everyone, depends on the child), Huppa (jackets with insulation amounts of 130, 160, 200 g, bib overalls 100 g, overalls 200 g), Lenne (products with 150 and 330 g of insulation), down jacket (O'Hara , Chicco, Geox), overalls Kiko, Donilo, Gloria Jeans, Lemmi, Shaluny, Gustі, Bambino, TCM, H&M.

These recommendations are suitable for small pedestrians. If the baby walks, but still rides in a stroller, you can, after dressing him for a walk, put him in an envelope in the stroller. Then you won’t freeze in the stroller and won’t sweat while running.

For babies in the first year of life, one-piece overalls are well suited - Huppa (200 g), Lenne (baby models or transformable overalls), down jackets (Chicco), overalls Kiko, Donilo, Gloria Jeans, Lemmi, Shaluny, Gusti, sheepskin overalls. You can also choose lighter options, but put a fur envelope in the stroller and enjoy your walk

Like

The membrane resolved a controversial issue. How to get breathable clothes with water-repellent properties. What's the secret? The fact is that each pore of the membrane is so small that it will not allow even a drop of water to pass through, but the pore is large enough to remove steam, which is smaller in structure, from the body. By combining different types of membranes and related fabrics, manufacturers create clothing with unique properties for different applications.

In membrane clothing there are 4 main areas of application:

- for cardio exercises (running, cycling);

- for mountaineering;

- everyday wear, tourism, hunting, fishing;

- for classic winter sports - skiing, snowboarding.

It is this classification that narrows the scope of choice for membrane clothing and allows you not to get lost in the sea of proposals. To find out which group of products to focus on, during the purchase, read the manufacturers' catalogs or take advice from sellers. And proceed to the next stage - selecting the optimal characteristics.

Water resistance and vapor permeability

It is water resistance and vapor permeability that characterize the main properties of the membrane. Water resistance is especially important if you plan to exercise in poor weather conditions. It is calculated using special devices that simulate a water column. The more water pressure the membrane fabric can withstand, the better it will protect its owner.

These 2 indicators can be indicated on clothing labels. Water resistance in mm water column, and vapor permeability in MVTR or RET. More about this below.

In some cases, the manufacturer indicates only the scope of application of the product, without specifying MVTR or RET.

Water resistance

The water resistance indicator is grouped as follows:

- more than 20,000 mm - clothing is suitable for use during a storm, heavy rain with strong winds;

- 10000-20000 mm – withstands heavy rain or downpour;

- 5000-10000 mm – moderate rain;

- 1000-5000 mm – light rain, fog;

- <1000 мм – только ветрозащитные свойства.

Despite the variation in water resistance, manufacturers often offer a membrane with the highest protective properties. In this way, as if guaranteeing their clients comfort during any bad weather.

For lovers of hiking, fishing and hunting, are produced.

Vapor permeability

Vapor permeability in membrane clothing is much more important than water resistance. It is she who is responsible for comfort during active physical activity, when the body produces steam that needs to be removed quickly and efficiently.

To calculate vapor permeability, 2 main methods are used:

- MVTR involves testing samples for the fabric's ability to transmit water vapor. The resulting indicator is recorded as X g/m2/24 hours, with an X value of more than 13,000 - extremely breathable clothing, from 6,000 to 13,000 - excellent breathability, below 6,000 - clothing with a moderate ability to release steam.

- RET- a reverse technique that calculates how the fabric resists the release of steam. It was originally used by Gore-Tex. The vapor permeability scale according to the RET method looks like this: from 0-6 - nothing prevents the escape of steam, extremely breathable fabric, 6-13 - excellent breathability, 13-20 - fabric with moderately breathable properties, more than 20 - the fabric does not breathe.

Vapor permeability indicators calculated using 2 methods are not always identical. This is due to the testing conditions in different research centers.

In view of this, some manufacturers indicate both values on the tag, others - only an indicator calculated using one method, and others may not give specific values to the consumer at all (in order to avoid comparing clothes with competitors’ products based on only one indicator).

What level of vapor permeability to choose

High vapor permeability rates are especially important for active physical activity. If you plan to wear membrane clothing only while walking, a vapor permeability rating of 6-10 RET is sufficient.

Types of membranes by structure and purpose

The membrane is a very thin film with tiny holes. It is able to transmit steam coming from the body and at the same time remain resistant to humidity from the outside, not allowing even small particles of water to pass through.

This is what membrane tissue with pores looks like under a microscope

The structure of the membrane plays an important role in its operation and even its service life.

What types are there?

- Poreless– they work indirectly, since the steam first settles on the inner surface of the membrane and then gradually evaporates under pressure. Poreless membranes are durable and easy to maintain;

- Pore– very well “breathable” membranes, but require careful care;

- Combined– combines the characteristics of both pore and non-pore membranes. This type is used by all leading manufacturers;

- eVent- a new class in membranes, manufacturers have “taught” the pore membrane to repel dirt and fats, thereby giving it greater durability.

Review of druft jacket with eVent membrane

The purpose of membranes also varies:

- Windproof– usually work in conjunction with fleece (polartec) fabric, onto which a layer of water-repellent impregnation is applied. Such clothing is optimal for use in the off-season; it warms well and can withstand light rain. All windproof membranes are durable, inexpensive and easy to maintain.

- Wind- And waterproof– a classic in the membrane industry. They are designed to operate even during bad weather conditions. They have good water-repellent and windproof properties, while maintaining the ability to breathe. These membranes are expensive and difficult to maintain.

Membrane Protective Fabrics

The membrane (due to its thinness) in clothing is always covered by fabric, which must first withstand the impact of wind, rain or snowfall.

The inner lining is in the form of a mesh that protects it.

Its properties are influenced by the following indicators:

- Fiber type- These are synthetic materials nylon or polyester. They have approximately the same properties, but nylon is more durable, and polyester is cheaper and warmer. In rare cases, elastic materials are used in membrane clothing, since the membrane is very sensitive to stretching.

- Thickness and weight of threads– this indicator is designated as Den or D (denier) and is calculated as the weight of 9 km of the designated thread. High denier fabrics are very durable and quite heavy.

- Density– calculated in g/m2. High rates always characterize heavy, dense fabric.

Every manufacturer is always looking for the ideal light, durable and at the same time inexpensive fabric. But in practice, you always have to look for a compromise between the weight of the product and strength.

If you are not planning to conquer mountain peaks, but are choosing clothes to wear in city mode or short hikes, inexpensive membrane jackets are quite suitable. They have sufficient density, moderate weight and reasonable price.

For mountaineering and freeride Only ultra-strong and lightweight materials are suitable, which are tested for resistance to friction and tearing. These fabrics are very expensive, which affects the final cost of the products.

If you are doing long hikes, make sure that the membrane jacket is wear-resistant, since the backpack straps create friction during movement and can damage both the fabric itself and the membrane.

For aerobic exercise Lightweight fabric with moderate strength is ideal. However, it is advisable to move in such clothes on terrain without obstacles.

Methods for connecting membrane to fabric

In order for the membrane and fabric to work together, they are connected. Outer fabric - membrane - inner lining. It turns out to be a kind of sandwich.

How does it work:

- 2-layer materials (2L or 2-layer) - obtained by simply attaching a membrane to the inside of the fabric. This method has a significant drawback - the membrane wears out quickly, since it is not covered with anything from the inside. Sometimes manufacturers add a conventional 3rd layer in this scheme - a lining in the form of a mesh or soft fabric, but it does not serve as full protection for the membrane.

- 2.5-layer materials (2.5L or 2.5-layer) are very similar to 2-layer materials, only the function of covering the membrane is not performed by a mesh, but by a special coating. This membrane fastening scheme allows maintaining the flexibility and durability of the membrane.

- 3-layer materials (3L or 3-layer) are a kind of monolith of fabric, membrane and lining. Clothing with this type of membrane fastening is quite heavy and inflexible, but benefits from a long service life.

A brief educational program on labeling fabrics with heat-saving properties

Designations:

- Soft Shell - especially soft, comfortable, flexible material;

- Windbloc, Windtec - products with these designations provide excellent wind protection, but do not guarantee water-repellent properties;

- Windstopper - an improved line of clothing from Gore with good wind protection;

- Polartec Thermal Pro is a good warming material, essentially a slightly improved Polartec;

- Polartec Wind Pro - warming material with excellent windproof function, can protect against light rain;

- Polartec 200 is one of the most popular heat-saving materials for jackets;

- Resist Techno Soft Shell is the latest material on the membrane clothing market, provides excellent warmth and has increased breathability. Suitable for active sports;

- Rip Stop is a fabric with a special weave structure, therefore durable and wear-resistant;

- Gore-Tex is the world's first patented membrane;

- Sympatex is a German high-tech membrane that is used in clothing and footwear;

- eVent is an advanced pore membrane, ideal for clothing for extreme sports;

- ComforTex is a membrane from an Italian manufacturer with wind- and water-repellent properties.

Pay attention to the cut features

Manufacturers are no less scrupulous about the sewing process than they are about the selection of fabric and membrane type. If the model does not fit perfectly, the whole point of membrane clothing will come to naught.

At the first stage, fashion designers prepare a pattern. It should take into account the main nuances of future physical activity. Everything is important here: from calculating the seam allowance to the width of the elastic bands on the cuffs.

For greater functionality in clothing, the areas most susceptible to wear are sealed, making the base of the product from lighter materials. This allows you to reduce the cost while maintaining the quality and lightness of the finished garment.

On overalls and trousers, the bottom of the legs, knees and buttocks are sealed. In jackets, thickening is done on the elbows, cuffs, and shoulders. It is membrane clothing that is characterized by shifting shoulder and back seams - this allows you to reduce the friction of the backpack during long hikes.

In general, membrane clothing is not the place for modeling frills, so manufacturers produce 3 main types of cut:

- Athletic– designed for intense physical activity (running, cycling). Assumes an ideal fit to the figure (it, accordingly, should also be fit). Clothing of this cut follows the curves of the body as closely as possible; under it you can only wear thin thermal underwear and a fitted fleece jacket.

- Regular cut is more versatile. It allows you to wear thermal underwear and a second, denser insulating layer. It is comfortable to wear this type of clothing for a long time; it does not restrict movement. Suitable for hiking, walking and other light activity.

- Loose fit designed specifically for use in unstable climates. Under such clothes you can wear a different number of insulating layers. It is suitable even for people who do not have an ideal physique. But the main purpose of a loose cut is to be used during expeditions, long hikes and for low-impact sports.

All the subtleties are in the details. An important point when choosing

Membrane clothing is a kind of standard in textile production. She does not tolerate crooked stitches and especially poor fittings. But for its good functionality, a “reliable rear” is needed.

What to look for when choosing. Using the example of a review of The North Face Men Tethian jacket

Sealing seams

Any sewing needle leaves holes in the fabric. And if no one pays attention to them in ordinary clothes, then in membrane clothes moisture can leak through these holes. To eliminate this defect, in all models the seams are sealed, i.e. The top is glued with a special tape.

Ventilation

During active movement, the body quickly heats up. In order to remove the generated heat (steam) as efficiently as possible, manufacturers provide additional ventilation. On jackets in the armpit area, and on trousers along the inner seam, zippers are sewn in. Sometimes an additional folding pocket can serve as additional ventilation, which, however, is only appropriate in lightweight models.

Hood

The upper part of the jacket is one of the most vulnerable places in the entire complex of membrane clothing. The hood should provide protection here. For driving in normal weather conditions, models with a simple cut are suitable. They can handle moderate rain and snow quite well. During extreme travel and mountain hiking, the hood should fit well to the helmet. To do this, it is given a more complex shape and several adjustments are provided.

Lightning

The accessories used in membrane clothing are of the highest quality. Despite the fact that in good zippers the teeth fit together as closely as possible, in heavy rain conditions they can also become vulnerable. In budget clothing, zippers are hidden under a fabric strip for additional protection. In more modern and expensive models they are treated with a special polymer. It prevents water from seeping inside, as it tends to repel it.

Be sure to check all zippers (not just the main ones) before purchasing.

Changing snakes (runners) in membrane clothing is very difficult, since during repairs the tightness of the seams may be compromised and the product will lose its properties.

Check whether it is easy to fasten the zipper while wearing gloves. If it grabs the fabric, be sure to put the item aside. “Playing” with bad lightning during bad weather is not a pleasant experience.

Pockets

These elements in membrane clothing should be both comfortable and functional. Consider what you will need in an easily accessible place and whether the pockets meet these requirements.

The above features of such clothing are the main ones, but not the only ones.

There are other additional options:

- Fleece inserts on the inner surface of the jacket/pants provide additional protection for the membrane;

- a flexible visor on the hood will cover your face from wind, rain or snowfall;

- snow skirt - for severe cold weather and mountaineering, it is not just an additional option, but another main factor of protection.

Who produces

When choosing membrane clothing, the last thing you should pay attention to is the price of the product. By the way, it can be both transcendental and more democratic. It all depends on the “renowned” manufacturer, the quality and type of membrane, the characteristics of the top layer of fabric, etc.

The most famous manufacturers of such clothing:

- The North Face is an American brand widely known throughout the world. The company's developers were directly involved in improving the Gore-Tex membrane. One of the main areas is clothing for mountaineering. Now the company's product list includes almost the entire arsenal of things for sports and tourism.

- Marmot is a North American company with over 50 years of experience. Produces clothing with a PreCip membrane.

- Black Yak, a company originally from Korea, confidently occupies key positions not only in the Asian market, but throughout the world. The main direction is clothing for mountaineering.

- Arcteryx - this Canadian brand is well known to all extreme athletes. The company has many years of experience, established itself in the last century and confidently holds its own in the market.

- Norrona is a European brand that was the first to release a jacket with a Gore-Tex type membrane. One of the most recognizable companies in Scandinavia.

- Decathlon is a French manufacturer of budget sports equipment. Models are easy to select thanks to the available classification. Before going on sale, all products are tested, so the buyer can be confident in the quality of the product. The price of membrane clothing from Decathlon is one of the most affordable.

How to wear it correctly

Membrane clothing suggests the presence of allies. To begin with, it's right. It must correspond to the type of physical activity. If thermal underwear does not cope well with moisture removal, the operation of subsequent layers is also at risk.

The second layer of clothing - also insulating - should work in conjunction with thermal underwear and membrane clothing. Choose a fleece jacket or jumper in accordance with the temperature conditions. If necessary, wear not one, but 2-3 layers (). The membrane clothing itself is the final, 3rd link in the overall complex.

Remember: only a well-thought-out set of clothes will not spoil the overall impression of wearing things with a membrane. If you feel cold or, on the contrary, overheat, try changing your thermal underwear or a second layer.

Having bought membrane clothing, be sure to. This way you will extend the life of things and thereby minimize one of the main disadvantages of the membrane - high cost and fragility.

Membrane clothing has both a large number of its adherents and those who do not recognize it and trust ordinary things. The former are always up to date with new products, and the latter are lured by manufacturers with interesting cuts, bright combinations and even promotional offers. So, this type of clothing is gradually gaining a place in the market, in our closets, and it does so more than confidently, because it is not afraid of either fashion trends, global warming, and especially the weather in the house.

(in everyday speech sometimes called simply membrane ) is a type of fabric that, due to its special structure, has water-repellent or windproof properties and at the same time allows water vapor to pass through it.

The membrane fabric consists of several layers: an upper wear-resistant layer and a lower soft layer. And between them there are several protective layers of fabric and membrane .

The first industrial membrane fabric was Gore-Tex, developed for use in space by Rowena Taylor, Wilbert L. Gore and his son Robert W. Gore. It was initially protected by a patent, but after the patent expired, other types of fabrics with similar properties appeared on the market.

Membrane fabric has found wide application in tourist products: it is used to sew jackets , trousers, do shoes. The reason for the success of this type of fabric is that the membrane fabric allows you to stay dry in the rain, while the body does not dry out due to lack of air.

What is a membrane?

The membrane is either the thinnest film that is laminated (welded or glued using a special technology) to the upper fabric, or a special impregnation that is rigidly applied to the fabric using a hot method during production. On the inside, the film or impregnation can be protected by another layer of fabric.

This is a fabric that has windproof and/or waterproofing properties, while the normalized pore size of the membrane allows the material to effectively allow the evaporation of the human body to pass through (breathe). The opposite of it is the so-called. “Oilcloth”, that is, a completely non-breathable fabric with a polyurethane (PU) coating, usually used in the production of tents and awnings.

Membrane fabric is used in top layer clothing, protecting the lower layers of clothing from getting wet. The structure of the membrane fabric allows your skin to breathe and remove sweat. The higher the technical characteristics of the membrane fabric, the stronger and lighter it is in weight.

Double layer fabric– this is the outer layer of fabric, to which the wrong side is applied in a special way. membrane. This fabric is always used in products with a lining, because... the lining provides adequate protection to the membrane from clogging and mechanical damage.

The three-layer fabric looks like a fine mesh fabric on the reverse side. This is the upper fabric + membrane+ knitted mesh, glued into one structure using a special lamination technology. The knitted mesh protects the membrane from mechanical damage and clogging.