Mauerlat for the roof: what it is and how to make it. Do-it-yourself Mauerlat for a gable roof: we attach the Mauerlat of a gable roof according to the instructions The process of installing a gable roof with your own hands

Any modern roof begins with a Mauerlat. It is a base that is fixed along the perimeter of the top of the external walls. The device serves to support the roof and prevent its windage. Thanks to the uniform distribution of the load over the area, the Mauerlat seems to “tie” the roof to the house.

Mauerlat - what is it and what is it for?

The classic Mauerlat is a dried timber or log fixed on top of the external walls. Fastening is carried out using an armored belt or simply around the perimeter of the house. The structure is the support for the entire rafter system. This is a kind of foundation that unites all the elements of the roof.

Why the device is needed:

- ensuring roof levelness;

- preventing tilts and distortions;

- elimination of windage;

- uniform load distribution;

- tying the roof to the house.

The size of the element is calculated based on the area of the house, roof type, roofing material, climatic conditions, and the presence of an attic.

What materials can it be made from?

The structure is often made of wood, using wooden beams or boards fastened together. Often a steel profile is used. The choice depends on the weight of the roof.

The structure is often made of wood, using wooden beams or boards fastened together. Often a steel profile is used. The choice depends on the weight of the roof.

Wooden beam

The timber is placed under the rafters along the perimeter of the roof. With this arrangement, the load is evenly distributed to each point on the walls of the house. There should be no knots on the timber, and if there are any, their size should not exceed 2/3 of the thickness of the wooden product. When arranging the Mauerlat, knots will interfere with the main structure, so it is better to avoid them. If there are many knots on the beam, then a break may occur in the places where they form.

Boards fastened together

In frame construction, when the roof is light in weight, boards fastened together can be used. This design is not suitable for a heavy structure - the boards will not withstand the high load. This material is suitable for roofing without insulation and additional elements that increase weight. The boards are attached around the perimeter of the building. For the Mauerlat, it is advisable to use durable material that will not crack during use and exposure to external factors.

Steel profile

Instead of wooden products, steel structures are often used. This material is more durable, as it can withstand increased loads. The steel profile is represented by a square section or round metal pipes. The use of steel as a support for the roof implies the presence of metal lining around the perimeter of the external walls. The device is suitable for a gable roof, and beams can also be used. The harness is secured to the outside of the wooden belt.

Mauerlat cross-sectional dimensions SNIP

Recommended parameters in accordance with SNIP rules should be at least 100x100 mm for wooden beams. These are the indicators that are considered average, allowing you to reliably hold the roof on the walls. Builders recommend increasing the dimensions to 150x150 or 100x150 mm to increase the reliability of the structure .

Recommended parameters in accordance with SNIP rules should be at least 100x100 mm for wooden beams. These are the indicators that are considered average, allowing you to reliably hold the roof on the walls. Builders recommend increasing the dimensions to 150x150 or 100x150 mm to increase the reliability of the structure .

There are several requirements for the section:

- the wood must be treated with an antiseptic not only on the cut, but along the entire length;

- individual elements are secured using a direct lock;

- beams are laid over the entire area of the walls.

If you reduce the cross-section of timber or boards, the structure will not be reliable: the roof may not be resistant to adverse weather conditions.

How to attach the Mauerlat

The main requirement when arranging a support is immobility and precise fixation of structural elements. For this purpose, studs, anchor bolts, wire method and wooden plugs are used.

Special metal pins are embedded in the masonry of the walls, then they are used to fix the mauerlat. This method is ideal for lightweight structures. The stud looks like a metal bolt in the shape of the letter “L”, and can also be welded to a square of metal. The studs are immersed in the brickwork to a depth of 45 cm. They protrude vertically from the wall by 3 cm. The studs must be inserted at the stage of laying the walls, in the final or penultimate row. The optimal distance from the outer part of the wall is 5 cm.

Fastening with anchor bolts

To enhance reliability, the Mauerlat is attached to an armored belt using anchor bolts. The manufacture of a reinforced belt is mandatory when using aerated concrete. Such blocks are soft, so it is impossible to screw bolts into them.

To enhance reliability, the Mauerlat is attached to an armored belt using anchor bolts. The manufacture of a reinforced belt is mandatory when using aerated concrete. Such blocks are soft, so it is impossible to screw bolts into them.

When the armored belt is installed in the formwork, threaded anchors are tied to it. They should be aligned exactly along the line - this will ensure a strong fixation. The fasteners themselves must be strictly vertical for the fastening process to take place accurately. There should be as many anchors as there are rafters or more. Anchors should not be located in the places where rafter legs are attached.

How to attach with wire

The classic way is to use wire fastening. To do this, follow a certain sequence of work:

- Pieces of wire are placed 4-5 rows before the end of the masonry.

- The distance between the pieces is maintained at 60 cm.

- The ends of the wire rise up 20-30 cm.

- The ends of the wire material are hidden in the solution.

- The other end of the wire is used to tie timber or boards to the wall.

This option is used everywhere in construction. It is suitable for houses made of brick or other stone, as well as where mortar is used for walls.

Using Wooden Plugs

For small structures, for example, for country houses, wooden plugs are used as fastenings. They also securely fix the Mauerlat. The plugs are the size of a traditional brick; each element is treated with an antiseptic and covered with roofing felt. Sometimes plugs are made from timber impregnated with bitumen for strengthening. The cork is laid below the level of the rafters or at the same level at a distance of 50-70 cm from each other.

Methods for attaching the Mauerlat

The device for tying the roof to the walls can be attached using a reinforced belt, as well as without its use. In the second case, an oblique cut or other materials are used, depending on the raw materials of the erected walls.

Fastening without armored belt

To begin with, it is important to determine what the walls are made of - brick, expanded clay, aerated concrete, gas silicate, foam block or cinder block. Next, use one of the options.

Attaching to a brick wall

First, the preparatory stage is carried out: the bricklaying is completed with a flat horizontal surface or ledge. In the first case, the device for tying the roof is placed on the inside, and at the end it is insulated with blocks of expanded clay. Fastening is carried out in one of the following ways:

First, the preparatory stage is carried out: the bricklaying is completed with a flat horizontal surface or ledge. In the first case, the device for tying the roof is placed on the inside, and at the end it is insulated with blocks of expanded clay. Fastening is carried out in one of the following ways:

- embedded studs;

- wooden plugs;

- wire;

- anchors.

At the final stage of masonry, a waterproofing layer is installed. Roofing felt, roofing felt, waterproofing or linochrome are used as waterproofing.

Fastening to expanded clay blocks

The most reliable method of fastening to expanded clay blocks is chemical anchors. Due to the special structure of expanded clay, other options may lead to its fracture and the structure will not withstand.

Chemical anchors are special compounds that are made on the basis of chemicals. They harden quickly, have a long service life and increased adhesion.

Chemical anchors come in ampoule and polymer types. Ampoules are represented by a small capsule inserted into the block. The substance fills the voids, then an anchor is inserted into the hole. Polymers are placed into the cavity using a dispenser gun.

Fastening to aerated concrete

It is possible to secure the Mauerlat to aerated concrete using steel wire. To do this, perform the following actions:

- A few rows before the end of laying the blocks, a wire 6 mm thick is placed.

- The ends of the wire are placed hanging on both sides of the block.

- The length of the ends should be such that the timber can be tied loosely.

- The number of segments is selected based on the perimeter of the walls.

Then a beam is applied and tied with a twist. This method is optimal, since aerated concrete has a soft stone structure and other options will not work.

Fastening to gas silicate

To fix the Mauerlat on a gas silicate wall, you will need galvanized studs. With a block size of 375 mm, studs with a diameter of 12 mm and a length of 33 cm are needed. The ends of the studs must have a reinforced washer. To ensure reliable fastening, the studs are installed with the same pitch and depth strictly vertically. Holes are drilled in the timber according to the diameter of the pin, then the wooden product is put on them. For precision fastening, you can make a template from a board, in which you need to make a hole and insert a pin there. 12mm fasteners require a 14mm hole.

Attaching to foam block

Before attaching the support to the wall, ensure reliable waterproofing. The best method of fastening is to use wire. On the last row of foam block laying, a steel wire folded in several layers is threaded. Its ends come out freely, and the middle is placed under the block. The length of the material should be such that it can be threaded through the beam and the ends twisted. The number of wire fastenings must be no less than the number of rafters.

Before attaching the support to the wall, ensure reliable waterproofing. The best method of fastening is to use wire. On the last row of foam block laying, a steel wire folded in several layers is threaded. Its ends come out freely, and the middle is placed under the block. The length of the material should be such that it can be threaded through the beam and the ends twisted. The number of wire fastenings must be no less than the number of rafters.

Attaching to cinder block

If the house under construction is small, then you can use the method of fixing it with embedded studs. If the house has a large perimeter, using anchors is suitable. Metal pins should protrude from the structure by 20 cm, their pitch should be no more than 80 cm. The distance between the anchors is marked in advance, then the bolts are screwed in and the Mauerlat is installed. Before fastening, an insulating layer similar to roofing felt is used.

Attaching to armored belt

If the house is built from panel boards or cellular structures, then the installation of a reinforced belt for the Mauerlat will be mandatory. Before fastening the roof, it is important to find out the optimal thickness, manufacturing methods and connection with the armored belt.

The thickness of the armored belt under the Mauerlat

The thickness of the reinforced belt ensures the reliability of the structure. The minimum indicators are 15 cm, the optimal ones are 20 cm. The thickness should not exceed the width of the wall. The minimum cross-section of the reinforced belt is 250 by 250 mm. The structure must be continuous and also have the same strength. The concrete belt is often monolithic and is completed in one pour, then a reinforcing layer with a diameter of at least 10 mm is inserted.

According to SNiP, the reinforcing belt should be one third the size of the wall thickness.

How to make an armored belt correctly

The technology for constructing an armored belt consists of the following stages:

The technology for constructing an armored belt consists of the following stages:

- Installation of formwork: wooden boards, side supports or threaded rods are used. The length and width of the belt should be the same. The upper edge of the formwork is aligned in a horizontal plane using a water level.

- Installation of reinforcement cage. The reinforcement mesh consists of longitudinal rods with a diameter of 10-12 mm. The distance between them is from 20 to 40 cm.

How to attach to an armored belt

The Mauerlat is fixed using the same methods - with studs or anchors. Sequence of stages:

- holes are drilled in the timber;

- the Mauerlat is placed on studs or anchors;

- perform isolation;

- secure the bolts with washers and nuts;

- secure the connections with locknuts.

The remaining elements are cut using a grinder.

Features of the Mauerlat device depending on the type of roof

Depending on the type of roof - gable, three or four slopes, as well as hip or single slope, the Mauerlat will have fastening nuances.

For a pitched roof

The support beam for the rafter system of this type of roof requires increasing the height of one wall, since there is no slope. To do this, use the formula for calculating a right triangle. The thickness of the Mauerlat depends on the angle of the pitched roof. First, the top layer of the wall is covered with roofing felt, then the beam is fixed to the wall with anchors. The horizontal position is measured with a level, then the bolts are tightened.

For gable roof

In this case, the device is always fixed on two opposite walls - the roof will rest on them. When building a house from timber or logs, such a device will not be needed. If the house has a load-bearing wall in the center, then the Mauerlat captures 3 points of support - parallel and load-bearing. The distance from the outer edge of the wall should be at least 5 cm.

For a gable roof

The support beam in this design is also installed around the perimeter with support on the load-bearing wall. The device involves distributing the load of the roof onto the walls. A timber with a cross section of 100x100 mm or 150x150 mm is suitable here. Coniferous lumber is used as timber. Before installation, it is treated with an antiseptic. Floor beams are installed on top of the Mauerlat.

Mauerlat for a hipped roof

The hipped roof has a rectangular envelope design or 4 identical triangles. The main goal is to prevent the roof from moving away from the axes of the Mauerlat. The structural elements are fixed on 4 sides of the walls. This is done with studs, anchors or wire, sometimes wooden plugs are used - depending on the material of the walls. A hipped roof is considered the most resistant to wind, but its design still requires the installation of a support beam.

Mauerlat for hip roof

The roof support beam is installed around the perimeter of the walls, as well as on the load-bearing elements of the partitions, if present. To relieve the load on the walls and increase rigidity, a diagonal jumper is installed between two adjacent elements of the Mauerlat. The support beam must have a cross-section of 100x150 mm. In hip roofs it is better to choose a soft roof.

The roof support beam is installed around the perimeter of the walls, as well as on the load-bearing elements of the partitions, if present. To relieve the load on the walls and increase rigidity, a diagonal jumper is installed between two adjacent elements of the Mauerlat. The support beam must have a cross-section of 100x150 mm. In hip roofs it is better to choose a soft roof.

Installation and fastening of rafters to the Mauerlat

After arranging and fixing the support beam, the rafters are installed and secured. There are several rules for this:

- Formation of cuts that ensure a tight fit of the elements to each other.

- Linings should not be used at the junctions with the rafter legs - over time they become thinner and deformed.

- To fix the rafters, metal corners, plates, brackets, bolts, nails, and threaded rods are used.

To ensure the sliding of the rafter legs to the mauerlat, a “sled” is used.

Waterproofing and insulation

The work includes two necessary stages - laying waterproofing under the support beam, as well as insulating it from the inside.

Insulation of the roof mauerlat from the inside

The insulation of the support beam is carried out from the inside of the attic. A layer of vapor barrier is laid in the lower part under the beam. This will prevent vapors from escaping from the room. The support beam itself is massive, so it will be warm in the attic.

When purchasing insulation, pay attention to its moisture resistance, non-toxicity, fire resistance and speed of installation.

Expanded clay, pressed sawdust, mineral wool, polyurethane foam and expanded polystyrene are suitable for insulation.

Waterproofing under the Mauerlat

Protection from moisture occurs at the stage of fixing the support beam. Before attaching it in any way, a waterproofing layer is placed on the wall. This way the cold will not penetrate through gaps in the roof structure. Rolled roofing felt or other materials are used as protection.

Mauerlat is used to prevent the roof from sailing, as well as to tie it to the walls. It is attached with or without an armored belt using studs, anchors, wire or wooden plugs. Depending on the type of roof, the fixation features will vary. The Mauerlat is made from timber, steel profile or boards. The support beam must be insulated and a layer of waterproofing laid.

Everything with your own hands

Do you need a Mauerlat?

I somehow omitted this question when writing an article about beams and, as it turned out later, it was in vain! Let's figure out what's what.

In general, the Mauerlat has two main purposes.

The first is to take the load from the beams and distribute it evenly onto the wall. And in the second case, transfer the loads from the “thrust” of the rafters. This is when building a simple roof, when the rafters on top rest against each other, and the bottom is cut into the mauerlat, and there are no additional contractions or tightening. In general, not my case. Therefore, I am considering here the first purpose of the Mauerlat.

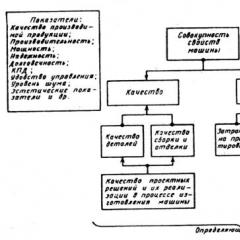

The roof mass is huge! It is necessary to take into account everything: floor beams, the entire rafter system, the ceiling, insulation, sheathing, the roof itself, the mass of rubbish that will be stored in the attic, the snow on this roof. In general, it runs up quite a bit, and all this puts pressure directly on my gas silicate, trying to push it through and destroy it.

When I started building the roof, I roughly figured out what was what.

- 8 cubic meters of wood (dry pine weight 650-700 kg) - 5600 kg,

- about 70 OSB sheets (about 16 kg each) - 1120 kg,

- soft roof 210 square meters (weight of one square roof 8.5 kg) - 1615 kg,

- insulation 22 cubes (37 kg each) - 814 kg

Here, I think, it’s worth understanding a little. We look for SNiP with any search engine. I’m not providing the link because it’s harmful, but because today the link is SNiP, and tomorrow I don’t know what. Paragraph 5.2 of SNiP says: the calculated value of the weight of snow cover Sg per 1 m 2 of horizontal surface of the earth should be taken depending on the snow region of the Russian Federation. This is not the area of the roof, but the area of the horizontal surface of the roof. In other words, this is the area of land that the roof covers. For example, if you cover 100 m 2 of area with a roof

and make a gable roof at an angle of 60 degrees, then the roof area will increase exactly 2 times, and the area of the horizontal surface of the earth under this roof will remain 100 square meters.

And snow will fall on this roof as much as 100 square meters of land. This seems to have been sorted out.

The dimensions of my house are 12x13.5, the roof protrudes 30 cm on each side. The horizontal surface is 12.6 x 14.1 = 177 m 2. Using map number 1 (Zonation of the territory of the Russian Federation according to the estimated weight of the snow cover of the earth), we look for our settlement, find out the snow region,

put it in the table.

The number in brackets, in my case 180, will indicate the load per 1 m 2. We multiply 177x180, we get almost 32 tons. If you add everything up (both the snow and the roof), you get an impressive colossus - weighing 41 tons. My poor blocks...

We look at the picture and count the points where the beam lies on the block. I counted 126 points.

Our block has a width of 20 cm, the width of the beam is 5 cm. We multiply one by the other, we get the area of \u200b\u200bone point of 100 cm 2. We divide 41,000 kg by the number of points, we get 325 kg of pressure on each point or 3.25 kg per cm 2.

We find out the compressive strength of the material. In my case, according to the manufacturer, destruction occurs at a load of 27 kg/cm 2, which, you see, is much more than 3.25? It is for this reason that I decided that I did not need a Mauerlat.

Beautiful and reliable do-it-yourself gable roof

What does a gable roof consist of?

In order to understand how to make a gable roof, you need to find out what structural elements it consists of. To do this, below is a list of these components and a description of what they are needed for.

Mauerlat and rafter legs

Rafter legs are boards measuring 50 mm x 100 mm or 100 mm x 100 mm. Outline the outline of the future roof. They distribute the load throughout the Mauerlat, and it, in turn, transfers it to the walls. Keep the roof from falling off during bad weather. The pitch of the rafter legs should be approximately 80 - 100 cm; if the material placed on the sheathing is heavy, then reduce it to 50 - 60 cm.

Skate, fillies and bed

The fillies continue the rafter legs and provide an overhang for the roof. They are used when the length of the rafters is less than necessary to form an overhang. The overhang, in turn, protects the walls from rain.

When building a gable roof with your own hands, do not forget about the roof. This is a beam that is placed on the internal load-bearing wall. It also participates in uniform load distribution.

Stands and ties

Tie-rods are components of the hanging parts of rafters. They do not allow their legs to move in different directions.

Strut and sheathing

The final stage in forming a gable roof with your own hands is attaching the sheathing. Attached perpendicular to the rafter legs. Roofing sheets are laid and screwed onto it.

Building a roof without a Mauerlat can lead to the following disadvantages:

- loss of rigidity, which is necessary for attaching rafter legs,

- will require increased material consumption.

Mauerlat influences mechanical strength and is the basis of the future roof. It is advisable to mount it to the walls using anchors.

When it has become approximately clear what components will be needed to make a gable roof frame, you should proceed to installation.

Installation of a gable roof

Calculation of frame position

If the construction of a gable roof takes place in an area with heavy rainfall, the slope should be made at 45°. This will ensure that snow and rainwater slide off unhindered.

How to lay a mauerlat for a gable roof

If the house is made of timber, then the last upper beam will serve as the mauerlat.

A waterproofing layer of roofing felt must be laid underneath it. It is connected to the wall using studs for a wooden house; for a brick house, knitting wire and fittings are used.

Installation of rafters

The better the fastening, the less susceptible the roof will be to demolition during strong winds.

The top piping of the gable roof stiles is made by installing them “on the miter”. The ridge beam is laid after installing and fastening the outer rafter legs to the wall of the building.

After the rafters have been leveled, it is recommended to check each leg again using a level. The rafter legs must rest firmly on the mauerlat.

After the rafters are aligned and the mauerlat is securely reinforced, it is recommended to proceed to assembling the roof truss.

Roof truss

What the beams are attached to when building the roof of a house is important. It is recommended to use self-tapping screws, nails, and fastening boards.

Before installing the pediment, it is necessary to check the perpendicularity of the structure and ensure that the rafters are of the same height. A ridge beam is attached to the top of the gable.

It is necessary to sew up the gable after finishing the roofing work and laying the sheets on the sheathing.

To make the pediment, a board measuring 50 x 100 is used. The cladding is carried out vertically or horizontally.

After the base for the roof is ready, beams measuring 400 x 400 are laid on the rafters in a perpendicular position. They tighten the rafter legs and at the same time serve as the base to which the profile sheet or metal tile will be screwed.

There are two types of lathing:

To insulate the roof, insulation in the form of mineral wool is used. It is mandatory to lay a waterproofing film between the rafters and sheathing beams. This will protect the roof from condensation collecting inside. And condensation, if it is a frequent guest, can lead to the death of wooden products, their swelling, and mold. Create favorable conditions for the development of pathogens for the tree.

It is recommended to place a cornice strip on the bottom batten of the sheathing before laying the roofing material. It will serve as a guide for rainwater to flow into the drain.

Positive aspects of a gable roof

If all instructions for the construction and operation of the roof are followed, it will serve the owner of the house:

- protection from rain and snow,

- cold and heat,

- snow and water will easily come off it,

- the wind will never tear off a properly laid roof,

- the roof will last for many years.

If the owner does not have enough knowledge on roof construction, then it is recommended to contact specialists.

Rafters without mauerlat

Good afternoon.

I'm generally an inexperienced builder, this is my first time building. I built a box out of bricks. The stage of roof construction has arrived. Household block at the dacha. Half a brick. 4x10. I'm going to make a 45 degree gable roof covered with flexible tiles.

Tightening - boards 50x150. Rafters 50x100. What kind of fasteners do you recommend for rafters and tie-downs? I’m going to fasten the rafters in the ridge area with triangles made of 16-18mm plywood, but I’m thinking about bolting the rafters and tightening them, but not at an angle as is usually shown on the internet, but vertically.

RUS34 wrote:

Is this possible or is it wrong?

And if you post a sketch (a photo of the sketch in pencil), then it’s possible and correct.

Here's a drawing I sketched. Vertical cylinder - a bolt recessed into the rafter and tightening.

RUS34 wrote:

Is this possible or is it wrong?

This is not clear. Do you have a half-brick wall 10 meters long? What's the height? It smells like extreme sports, though.

The building is 4 meters wide and 10 meters long. There are 2 main partitions that overlap with the main walls. For a summer kitchen with a bathhouse, a dressing room, a barn and a toilet, I don’t see the point in building a more massive building. So no extreme

Height 2.5 meters.

Here's a clearer picture of the structure

RUS34 wrote:

So no extreme

The spirit of adventurism hovers near the bolt at a height of 2 and a half meters.

Sorry, I did not understand

2RUS34 like this is possible.

Plus overlays

RUS34 wrote:

made of plywood 16-18mm

on nails, maybe it will be easier?

But it would be better to throw a 150*50 beam like a Mauerlat.

Yes, I initially wanted to use overlays, but after looking at the prices for them here, I didn’t want anything. Due to the fact that this is still a rarity in our country, their prices are high. For example, 1 corner costs about fifty dollars

But I can’t imagine using a Mauerlat on a half-brick building (for example, how to secure it)

If your linings are expensive, then you can make a plank knot at the hanging rafters.

The maurlat, or in your case the backing leveling board, together with the rafter truss, must be tied to the wall with soft (laminated) steel wire. The wire had to be laid in the masonry. If you haven’t laid it, drill the wall either right through and insert wire or hammer in anchors and tie them to them. The span is 4 meters, this is not much; you get 2 m slopes, and even at an angle of 45° there will be no snow on them. You need to fight the wind, and this is only by tying the truss.

Samar, Arkan60 Thank you very much! I'll do it according to your advice.

You only attach the wire lower to the wall, otherwise a strong wind can tear off the roof along with the brick of the wall if you attach it high. The wall thickness of half a brick is very small, resulting in little weight.

Okay, I didn't think about that by the way. Thank you!

By the way, is there still a need for a bolted connection when using a plank assembly?

I will note a few more nuances. It is correctly noted here that it is worth throwing a beam as a power plate. I would even do it differently in this case, around the entire perimeter I would cast a reinforced concrete armored belt about twenty centimeters thick, four 8x reinforcement bars with viscous “square” wire with embedded bolts, I would tie antiseptic boards to it (an alternative is to antisepticize the boards in advance, punch 200 of them with nails and at the time of casting the concrete, put them on top through a “cushion” of lime mortar. But these boards would already be attached in a completely ordinary way, using nails or self-tapping screws. I think it is absolutely necessary to make some kind of roof overhang. That is, your diagram binding is unsuccessful. Nowadays they sell tin corners with drilled holes everywhere, I forgot what they are called, they are convenient for fastening wood. IMHO, make the height at the ridge three meters or a sloping roof at 2.30. It will be more convenient to insulate the ceiling, you will simply walk on top of the rough flooring and fill it with expanded clay concrete or fill it with sawdust concrete Naturally, you need to leave the windows in order to secure the block for lifting the concrete mixer and materials. Take your time, but be quick. The rainy season has already begun, in principle there will still be three weeks of Indian summer, and then the season of heavy snow will begin. It is very unpleasant to work in semi-darkness in the November light rain.

We build a simple roof for a house, garage or bathhouse with our own hands

In this article we will look at common options for roofing structures and talk about the important features of their selection and installation.

Types of simple roofs and their main elements

Any roof consists of a supporting frame and a protective roofing covering.

The frame includes the following elements:

- Rafters - inclined beams (serve as the load-bearing basis of the roof).

- Ridge beam (connects the upper connecting points of the rafters).

- Lathing is a flooring made of boards or OSB slabs, laid on the rafters and serving as a base for the roofing material.

- Counter-lattice - used when installing a warm roof (creates an air gap for ventilation of the insulation).

- Mauerlat - wooden beam (mounted on longitudinal walls). The lower parts of the rafters (rafter legs) are attached to it.

- Vertical posts, horizontal ties and struts (used to strengthen the truss structure).

- Fillers are boards nailed to the lower ends of the rafters to create a roof overhang.

The design of a simple roof for a house is determined by several factors:

- width of the covered span,

- purpose of the attic space (residential or non-residential, walk-through or non-through-passage),

- type of interfloor covering (wooden beams, reinforced concrete panels).

If the width of the building is small (up to 4.5 meters), and there are no plans to arrange living space in the attic, then you can choose the option of a pitched roof. It is economical and easy to install.

The rafters of such a roof can be supported directly on the walls. To do this, one of them needs to be made higher than the other. This will create the slope necessary for rainwater to drain.

If you decide to install a pitched roof on walls of the same level, then to create a slope, you need to include wooden posts in its design. After installation is completed, they are sheathed with siding, OSB board or blockhouse.

For asbestos-cement slate, the roof slope must be at least 22 degrees. For metal tiles, ondulin, and bitumen tiles, the roof slope should be at least 15 degrees. When calculating a simple pitched roof, remember that snow load is a serious factor. To reduce it, it is recommended to make the slope steeper. Otherwise, you will have to increase the cross-section of the rafters and sheathing, which will lead to an increase in the cost of the structure.

If the span width is from 4.5 to 6 meters, then the rafters need to be reinforced with braces (inclined racks made of timber). They will reduce the deflection of the rafter legs under the influence of snow load. The lower ends of the braces are embedded in the masonry, and when using vertical support posts, they are attached to them using staples, nails or jagged metal plates.

Shed roofs are most often used for small structures such as garages, sheds, bathhouses or gazebos. A gable structure with a large elevation angle is the best option for arranging an attic space.

Main docking points

The main condition for the strength of any roof is the proper joining of all its parts. Therefore, when drawing up a sketch drawing, you need to pay attention to the nodes (connection of the Mauerlat to the wall, rafters to the ridge and floor beams).

The installation of a simple roof begins with laying a horizontal wooden beam - a mauerlat, on which the rafters will rest. It is attached to the masonry through threaded steel anchors (in brick walls) or to studs concreted in an armored belt (gas silicate masonry, expanded clay concrete, foam block).

The floor beams are fixed to the wall using anchor pins, and the Mauerlat is attached to them with nails or long screws.

We also note that the roof of a small house, barn or garage can be installed without a Mauerlat, fixing the lower ends of the rafters directly to the floor beams.

The next important unit is fastening the upper ends of the rafters to each other and connecting them to the ridge beam.

There are several ways to create this node. The rafter beams can be connected with a bolt and tightened with a nut (node 1). You can use a piece of OSB board (node 2) or secure them with a metal toothed plate (node 3). For closer contact of the rafters with the ridge beam, notches are made on them.

It should be noted that ridge beams, which increase structural rigidity, are most often used on large roofs. It is also installed in buildings with gables made of brick, block or logs, which serve as supporting walls for it. When building a small bathhouse, garage or country house, you can do without this element. A small roof will be provided with sufficient rigidity by lathing or decking made from OSB boards.

If you are planning to make a simple roof with your own hands, you should familiarize yourself with the recommended sections of rafter legs (Table No. 1).

The cross-sectional dimensions of other elements of a simple roof can be taken from table No. 2

Features of constructing a simple roof

The installation of the roof begins after the completion of the walls, installation of beams or floor slabs. Having aligned the outer rafters, they are attached to beams or mauerlat and fixed with temporary ties. After this, a beacon cord is pulled between them. Ordinary rafters are placed along it and secured one by one using lathing.

If there is a capital pediment, installation is simplified, since the ridge beam laid on it serves as a support and beacon for installing the rafters.

Installing a roof frame at height is a labor-intensive task. When erecting a small roof, it is more convenient to assemble roof trusses on the ground. In this case, on the walls you will only have to connect them using lathing into a single structure. Having assembled one truss, it can be used as a template for marking and cutting rafters, tie rods and beams.

When preparing to build a roof, be sure to make a detailed diagram indicating the dimensions of all elements and detailed elaboration of the components. It will be useful to you for calculating the purchased lumber and will help you complete the installation efficiently and quickly.

If the attic space is residential, then the roof structure needs to include not only insulation, vapor barrier, but also a counter-lattice - a wooden block with a cross-section of 30x50 mm. It is nailed to the rafters on top of the vapor barrier film to create a ventilation gap, and the main sheathing is attached on top. Without this “trifle,” the insulation will become wet from diffusion moisture in the cold season, and the wooden parts of the structure will begin to rot.

If a solid OSB board deck is used when installing an insulated roof, then a counter-lattice is placed under it.

To protect the walls from rainwater, any roof needs overhangs. For a lean-to structure, they are made not only in the lower part, but also in the upper part. If the length of the rafter legs is not enough to form eaves overhangs, then they are extended by nailing “filly” boards.

The minimum size of roof overhangs must be at least 20 cm. To protect the gables from moisture, the length of the roof on each side is increased by 20-30 cm, creating front overhangs. The ends and lower planes of the overhangs are sheathed with wind boards.

And as it turned out later - in vain! Let's figure out what's what.

In general, the Mauerlat has two main purposes.

The first is to take the load from the beams and distribute it evenly onto the wall. And in the second case, transfer the loads from the “thrust” of the rafters. This is when building a simple roof, when the rafters on top rest against each other, and the bottom is cut into the mauerlat, and there are no additional contractions or tightening. In general, not my case. Therefore, I am considering here the first purpose of the Mauerlat.

The roof mass is huge! It is necessary to take into account everything: floor beams, the entire rafter system, the ceiling, insulation, sheathing, the roof itself, the mass of rubbish that will be stored in the attic, the snow on this roof. In general, it runs up quite a bit, and all this puts pressure directly on my gas silicate, trying to push it through and destroy it.

When I started building the roof, I roughly figured out what was what.

- 8 cubic meters of wood (dry pine weight 650-700 kg) - 5600 kg;

- about 70 OSB sheets (about 16 kg each) - 1120 kg;

- soft roof 210 square meters (weight of one square roof 8.5 kg) - 1615 kg;

- insulation 22 cubes (37 kg each) - 814 kg

Here, I think, it’s worth understanding a little. We look for SNiP with any search engine. I’m not providing the link because it’s harmful, but because today the link is SNiP, and tomorrow I don’t know what. Paragraph 5.2 of SNiP says: the calculated value of the weight of snow cover Sg per 1 m 2 of horizontal surface of the earth should be taken depending on the snow region of the Russian Federation. This is not the area of the roof, but the area of the horizontal surface of the roof. In other words, this is the area of land that the roof covers. For example, if you cover 100 m 2 of area with a roof

and make a gable roof at an angle of 60 degrees, then the roof area will increase exactly 2 times, and the area of the horizontal surface of the earth under this roof will remain 100 square meters.

And snow will fall on this roof as much as 100 square meters of land. This seems to have been sorted out.

The dimensions of my house are 12x13.5, the roof protrudes 30 cm on each side. The horizontal surface is 12.6 x 14.1 = 177 m 2. Using map number 1 (Zonation of the territory of the Russian Federation according to the estimated weight of the snow cover of the earth), we look for our settlement, find out the snow region,

put it in the table.

The number in brackets, in my case 180, will indicate the load per 1 m 2. We multiply 177x180, we get almost 32 tons. If you add everything up (both the snow and the roof), you get an impressive colossus - weighing 41 tons!!! My poor blocks...

We look at the picture and count the points where the beam lies on the block. I counted 126 points.

Our block has a width of 20 cm, the width of the beam is 5 cm. We multiply one by the other, we get the area of \u200b\u200bone point of 100 cm 2. We divide 41,000 kg by the number of points, we get 325 kg of pressure on each point or 3.25 kg per cm 2.

We find out the compressive strength of the material. In my case, according to the manufacturer, destruction occurs at a load of 27 kg/cm 2, which, you see, is much more than 3.25? It is for this reason that I decided that I did not need a Mauerlat.

Roof installation is a fairly complex construction process. To independently assemble and install a rafter system, you need to know how to correctly connect the elements, what the length of the rafters should be, at what angle they should be tilted and, most importantly, what materials the roof is assembled from. Without special knowledge and skills, making a complex roof will be problematic. In this case, you can choose the best option - a gable roof with your own hands.

Design features of a gable roof

A gable roof is based on a triangle, which gives it rigidity. It contains the following elements:

- Mauerlat- these are beams laid directly on the outer walls along the entire perimeter of the house. Fastening of these elements is most often done using anchor bolts. The recommended material for the manufacture of elements is coniferous wood. The cross-section of the beams has the shape of a square with sides of 100*100 mm or 150*150 mm. It is on the Mauerlat that the rafters rest, and the load from the entire system is transferred to the external walls.

- Sill- this is a beam of a certain length into which the racks rest. It is laid in the direction of the internal load-bearing wall. The element is used when arranging the roof of large houses.

- Struts- these are elements made from small bars. They are installed at an angle between the post and the rafters. This arrangement helps strengthen the rafters and increase the load-bearing capacity of the roof.

- Racks- these are roof elements located vertically. Through this element the load from the ridge beam is transferred to the walls. The racks are located between the rafters.

- Puffs They are beams that connect the rafters at the bottom. This element is the base of the truss triangle. Like braces, these beams make wooden roof trusses stronger and more resistant to various loads.

- Rafter legs They are boards of a certain length, having a cross-section of 5*15 cm or 10*15 cm. The elements are connected to each other at an angle, forming the vertex of a triangle. Two connected rafter legs are called a truss. The number of such structures is determined by the length of the house. In this case, the distance between the farms can be no more than 1.2 meters and no less than 0.6 meters. When calculating the pitch of the rafter legs, the total weight of the roof, wind and snow load should be taken into account.

- Horse is located at the highest point of the roof and is a beam that serves as a connection for the slopes. This element is supported from below by vertical posts, and the ends of the rafters are attached to it from the sides. In some cases, instead of timber, two boards are used, connected at a certain angle and nailed to the top of the rafters on both sides.

A do-it-yourself gable roof involves making sheathing from boards or timber, which are nailed onto the rafters in a perpendicular direction. Depending on the roofing material, the sheathing can be continuous or with gaps.

What is the difference between layered and hanging rafter systems?

Before assembling a gable roof, you need to know some features of its structure. A hanging rafter system is installed when the house is small in size and there is no internal load-bearing wall. In this case, the rafters are connected at a certain angle, making appropriate cuts at their ends; nails are used for connection.

When installing such a rafter system, the posts and ridge are not made, and the support of the lower ends of the rafters falls on the external load-bearing walls. To make the structure more durable, the top tightening should be located no further than 0.5 meters from the top. Sometimes floor beams are used as tie-downs. The absence of racks frees up the attic space, which allows it to be used for arranging the attic floor.

If the house has an internal load-bearing wall, then it is more effective to use a layered rafter system. In this case, the bed is laid, support posts are fixed on it, onto which the ridge is nailed. This method is considered simpler and more financially profitable. When designing ceilings at different levels, the studs can be replaced with a brick wall, which will divide the attic space into two parts. A gable roof can also be made with different slopes along the length, which is also very beautiful and practical.

The process of installing a gable roof with your own hands

To answer the question of how to properly make a gable roof with your own hands, you need to follow the sequence of actions.

Installation of a roof of this type involves working according to the following plan:

- Preparatory stage.

- Fixing the Mauerlat.

- Truss assembly.

- Installation of trusses on floors.

- Skate device.

- Stuffing the sheathing.

Preparatory stage

Before starting work, you should prepare a set of necessary tools and materials:

- Hammer and hacksaw.

- Square and level.

- Fastening elements.

- Boards, beams and roofing felt.

All wooden materials should be treated with antiseptic solutions and fire retardants and dried thoroughly.

Mauerlat installation

In houses made of wooden logs or timber, the role of the mauerlat is played by the top row of the frame, this makes the process simpler. A groove is cut out on the inside of the log into which the rafter leg is installed.

In brick or block houses, the Mauerlat is laid as follows:

- When laying the last rows, threaded metal studs are installed in the masonry. They should be located around the entire perimeter of the house at a distance of about 1.5 meters from each other.

- The upper part of the walls is covered with roofing felt in several layers, piercing it with studs.

- Holes are drilled in the beams in accordance with the location of the studs.

- Lay the beams, putting them on the studs. At this stage, it is important to ensure that the beams are laid exactly horizontally and that the opposing elements are parallel to each other.

- The nuts are tightened on the studs, pressing the Mauerlat. Read also: "".

The result of this stage should be a rectangle of the correct shape, located on the same horizontal line. This design makes the structure more stable and facilitates subsequent work. The completion of the work is cutting out the grooves in accordance with the size of the rafters.

Installation of a hanging rafter system

The length of the rafters is determined by the distance between the external load-bearing walls and the angle of connection of the rafter legs. The optimal length is considered to be 4-6 meters, taking into account the eaves overhang of 50-60 cm. These parameters should be taken into account when solving the problem of how to make a large roof.

At the top, the rafters are fastened in different ways: end-to-end, overlapping or “in the paw” with grooves cut out. The rafters are fixed with bolts or using metal plates. A tightening is mounted a little lower and the finished truss structure is lifted to the installation site.

First, trusses are installed along the edges, checking their verticality using a plumb line. At the same time, the amount of overhang is adjusted. The rafters are attached to the mauerlat using bolts or steel plates. Sometimes temporary struts are used to support the truss during installation. When inserting the remaining rafters, maintain the same distance between them. After installing and fixing all the trusses on both sides of the upper slope, I nail boards with a section of 5*15 cm.

Methods for fixing hanging rafters to the Mauerlat

Hanging rafters can be attached to the Mauerlat in several ways:

- A groove is cut out on the rafters, and a metal pin is driven into the wall at a distance of 15 cm from the top edge. The rafter is placed on the mauerlat, tied with wire and pulled to the wall. The wire is wrapped around the pin.

- The second method involves laying out a brick stepped cornice. The Mauerlat is laid along the inner edge of the wall and a groove is made in it for the rafter leg.

- When using the third option, the rafters rest against the floor beams, which extend beyond the perimeter of the house up to half a meter. The beams are cut at an angle and secured with bolts. Using this method, you assemble a roof without a Mauerlat with your own hands.

How to install layered rafters

Layered rafters are installed in the following order:

- The load-bearing wall, located in the center of the house, is covered with waterproofing material.

- A bench is laid on top and secured with bolts or metal brackets.

- Racks made of beams with a cross section of 10*10 cm are placed on the bench.

- Purlins are nailed on top of the racks in a horizontal direction, strengthening the structure with temporary spacers.

- Install the rafters and fix them.

After installing the main structural elements, the wooden surfaces are treated with fire retardants.

How to make a sheathing correctly

Before laying the sheathing, the rafters are covered with a layer of waterproofing, protecting it from getting wet. Waterproofing is laid in a horizontal direction, starting from the eaves and going up. The strips are laid with an overlap of 10-15 cm, the joints are sealed with tape.

There must be a ventilation gap between the sheathing and the waterproofing; for this, slats with a thickness of no more than 4 cm must be placed on each rafter leg.

Now you can sheathe the rafter system. The sheathing can be made from timber 5*5 cm or boards having a thickness of no more than 4 cm and a width of more than 10 cm. The sheathing begins from the bottom of the rafters, maintaining a certain step.

After installation, the sheathing begins to cover the gables and overhangs. Depending on the construction budget and the desires of the homeowner, you can make a gable roof with your own hands with gables made of plastic, corrugated sheets or wooden boards. Knowing how to sheathe the gable of a house with corrugated sheets, you can carry out the installation yourself. The sheathing is attached to the sides of the rafter using nails or self-tapping screws. Overhangs can be hemmed with all kinds of materials.

As a rule, a continuous reinforced reinforced concrete belt is poured under such load-bearing structural elements. However, some amateur builders, apparently for reasons of saving time and materials, are trying to find ways to attach the Mauerlat to aerated concrete without an armored belt. Let's see how possible this is, and whether it is worth resorting to such a solution at all.

A few words about the importance of the Mauerlat

What is a Mauerlat and why is it needed? To a person inexperienced in matters of construction, this tricky word often means nothing at all. Meanwhile, we are talking about one of the most important load-bearing parts of the building structure.

Probably everyone knows what a foundation is. So, in terms of its functionality, the Mauerlat can be compared with a foundation strip. True, it is responsible for the loads transmitted from the entire building as a whole, and the Mauerlat is only responsible for those that are formed during the operation of the entire roof structure - the rafter system, the roofing covering, the insulating “pie”, the internal lining of the slopes (if there is one) and etc.

And the loads here can be considerable, and what is most dangerous is to have an expansive direction perpendicular to the surfaces of the walls, that is, to work towards their destruction. It's all about the angles of the roof slopes - this is what gives such a decomposition of the vectors of application of forces, both from the gravity of the roof structure itself, and from external loads - snow and wind.

Such bursting point loads transmitted from rafter legs are especially dangerous for walls made of piece material - brick or masonry blocks (which includes aerated concrete). This means that it is necessary to distribute the resulting load as evenly as possible along the entire length of the wall. And, again, by analogy with the foundation tape, a powerful wooden beam that rests tightly along its entire length against the end of the wall can cope with this.

The second remarkable quality of the Mauerlat is that it significantly simplifies the installation work when installing the rafter system. Agree that attaching each rafter leg to a main wall is much more difficult than, as they say, “tree to tree.” The presence of a Mauerlat opens up very wide possibilities for using various connection schemes, from “blind” to moving, using a variety of fasteners.

A wooden beam with a cross-section of 100×100 mm and higher is usually used as a Mauerlat (as a rule, depending on the massiveness of the roof structure, another 100×150, 150×150, 150×200 mm is chosen). Very often they rely on an unspoken, in principle, but effective rule - the thickness of the mauerlat should be at least twice the thickness of the rafter legs.

Width - depending on the thickness of the wall on which it is installed. At the same time, they try to position the beam so that it is not flush with the surface of the wall, either outside or inside. This way it will be easier to protect the wood from the negative influence of the external environment and to insulate this rather complex unit in terms of ensuring normal thermal insulation. This rule is not mandatory, but if you read the advice of the masters, they almost unanimously advise leaving at least 50 mm from the edge on each side.

It is possible to make a Mauerlat from logs, but this solution does not seem optimal - the operations of attaching to the wall, and then inserting rafter legs, will become much more complicated and, accordingly, will require increased skills in carpentry.

It is clear that due to the high responsibility of this element of the roof structure, for such purposes they try to choose first-class dried wood that does not have curvatures, pronounced knots, cracks, signs of biological decomposition, and other defects.

For Mauerlat, selected hardwood is generally recommended. But finding such material is not easy, so most often they use high-quality pine, but only subjecting it to a very picky choice: saving on quality in this case is completely unacceptable.

By the way, the Mauerlat may not be made of wood. For example, if you plan to create a rafter system from prefabricated or welded metal trusses, then a steel beam will be used as a Mauerlat - usually a channel or I-beam. However, in the practice of private construction, such solutions are rarely resorted to - wood remains a “classic”.

Mauerlat may not be used on walls made of timber or logs (its role will be played by the last row - the top trim), and on frame houses - for the same reason. Sometimes a Mauerlat is abandoned when the walls are built from a durable material that is resistant to point and thrust loads (for example, concrete), and the roof design involves fastening the rafters to the external extension of the floor beams. For walls made of piece materials, it will not be possible to do without a Mauerlat in any case.

It is clear that in order for the Mauerlat to fully perform its functions, the reliability of its mounting on the wall should not cause any concern. With concrete, stone, and brick walls it is simpler, since there are many ways to securely fix the beam at the end of the wall. For example, when laying ceramic or sand-lime bricks, backfills are made from wooden blocks. This makes it possible to then use ordinary steel brackets to fasten the Mauerlat. But making such fillings with aerated concrete is an absolutely futile task; you don’t even have to try, since no reliability will be ensured. We have to look for other methods, which will be discussed later in the article.

On walls made of aerated concrete, it is recommended to make the Mauerlat in a “closed pattern”, that is, in the form of a frame that completely encircles the entire perimeter of the building - this way, maximum structural reliability is achieved. However, this is not always possible - for example, in the case when pediments are laid out from the same foam blocks. This means that the more securely the timber should be fastened to the end of the wall.

How is a gable rafter system calculated?

In the course of the presentation, we have already once referred the reader to the size of the rafter leg - the cross-section of the Mauerlat depends to a certain extent on this. But, taking into account the steepness angles and all the resulting loads - read in the special publication of our portal.

How can you attach a Mauerlat beam to a gas silicate wall without an armored belt?

First of all, a builder who is faced with a similar problem must clearly answer the question for himself - “Do I really not have the opportunity to pour a reinforced concrete belt so as not to have problems in principle?” Why? – yes, because any of the options proposed below is not without certain disadvantages. And besides, the very possibility of installing a Mauerlat without an armored belt is quite doubtful, and is accepted with many reservations.

No matter how much you search, it is unlikely that you will be able to find clear criteria when experts clearly say - yes, you can do without a concrete reinforced belt on this gas silicate wall. There are only a lot of “ifs” under which, it seems, one can hope for the success of such an installation.

Prices for aerated concrete

aerated concrete

- If the house or outbuilding is small (alas, there are no evaluation criteria).

- If the roof has a not too complex and heavy structure (let’s assume that we are talking about simple ones made of, for example, corrugated sheets or metal tiles - all other roofing materials, together with their sheathing, will be heavier).

- If the climatic conditions of the construction region do not require a large snow load and wind pressure (and where is the guarantee that a weather anomaly will not occur?).

- If the design of the rafter system minimizes thrust loads. This can be provided by:

— Using hanging stops, rigidly tightened with horizontal ties.

- Using layered rafters, with mandatory support at the point of the ridge connection, if at the point of connection of the rafter legs with each other on the ridge there is a hinged connection, and the attachment point to the power plate involves the use of movable, sliding connections.

In a word, the list of conditions for trying to do without an armored belt (and then without complete confidence in success) is quite large. And you probably need to think ten times before choosing this particular path.

However, the Internet offers several methods for installing Mauerlat timber directly on a gas silicate wall without pouring an armored belt. Let's try to understand them.

Fastening the Mauerlat with wire

One of the simplest methods, which is often used when constructing brick walls. In this case, approximately 4–5 rows before the end of the masonry, bundles of steel wire with a diameter of approximately 3 mm (3–4 wires in a bundle) are laid between the rows, so that they look out from both the outside and the inside of the wall. The length of the release of these “braids” is made such that it ensures coverage of the Mauerlat timber installed at the end of the masonry and allows for trouble-free twisting and tightening of the wire loop. The spacing of such support bookmarks is usually chosen equal to the spacing of the rafters, so that the Mauerlat fastening points are located between adjacent rafter pairs.

When the wall is ready, it is laid on its end. Then a beam is installed on top, leveled, and then a wire loop is created and tightened. Tightening is usually carried out using a crowbar (mount), ensuring that the timber is pressed as tightly as possible against the wall.

It would seem that this is the simplest solution. However, take a closer look: all the examples shown are only on a brick wall. They write that this method works quite well with gas silicate blocks, only the laying of wire “braids” is carried out approximately two rows before the end of the laying.

They write, but not a single reliable proof of the reliability of this method with gas silicate walls could be found on the Internet.

According to personal feelings, won’t the wire, under heavy loads, and even more so under possible vibration, for example, in strong winds, work like a “hacksaw blade”, gradually biting into the gas silicate block (which can be sawed with a hand hacksaw)? After all, this is both a violation of the integrity of the masonry and a weakening of the fixation of the Mauerlat on the wall, with all the ensuing consequences.

In a word, not everything is so obvious and simple...

Fastening timber using anchors or dowels

It would seem that this is the simplest and most reliable method, tested by practice and time. Everything is true, but only if we are not talking about gas silicate. The increased fragility of this material may well present a surprise when, when tightening an anchor or screwing in a dowel, a crack or even a chip forms.

Of course, nowadays you can find on sale a considerable assortment of fasteners designed specifically for aerated concrete walls. But, you see, it’s one thing to fasten furniture, interior items or even a frame for wall insulation - and a completely different thing is a powerful one, which becomes the basis for the entire roof structure.

Considering that the holding properties of gas silicate are small, you will have to purchase anchors of maximum length - about 300÷500 mm, so that, taking into account the thickness of the Mauerlat beam, you can more or less reliably “catch” to the wall. But the cost of such long, powerful anchors is considerable, so this also needs to be kept in mind.

The work of installing the Mauerlat on the anchors is carried out approximately in the following sequence:

| Illustration | |

|---|---|

| First of all, it is necessary to ensure reliable waterproofing between the gas silicate and the timber being laid. Otherwise, a source of dampness and, as a result, biological decomposition will inevitably appear at the point of contact between wood and other building materials. |

| A strip of high-quality roofing material is quite suitable for a waterproofing barrier - it is laid so that it completely covers the entire end of the wall. If it comes in a little on the sides, it’s not a big deal, since it’s easy to cut it off later. The strip can be laid dry, that is, without the use of bitumen mastic. |

| After this, the mauerlat is laid on the end of the wall. In this example, a high-quality board 50x150 mm is used for it, which, by the way, looks a little thin in terms of thickness. But this does not change the principle of fastening. |

| The timber is laid exactly in its place, as provided for by the project, and leveled. |

| The necessary markings are carried out. In principle, in this case it comes down to marking the areas for installing the rafter legs - then the anchors for fastening the Mauerlat can be placed between them - and there will be no mutual interference. |

| The location for attaching the rafter leg is marked. The anchors can be positioned arbitrarily, repeating the pitch of the rafters. |

| Here it is, the anchor bolt. Let’s make a reservation right away - in this example, an armored belt is poured on top of the gas silicate wall, so the master uses relatively small anchors, 12 mm in diameter and 150 mm in length. In mature concrete, such fastening will provide the required reliability. But if there is no armored belt, you will have to install the longest possible fastener - up to half a meter. |

| Next, a feather-shaped wood drill (in this case with a diameter of 12 mm) is installed in the drill, and through holes are drilled in the Mauerlat beam, right up to the end of the wall. It is recommended to immediately sweep away the sawdust so that it does not fall back into the channel. |

| After this, a hammer drill with a 12mm drill is used. A channel for the anchor into the wall material is drilled directly through the hole in the wood. |

| Once the hole is ready, the anchor is inserted into it. Next, the anchor must be driven in with a hammer to its entire length, until the washer under the nut stops in the wood. |

| And the last step is to tighten all the anchors using the appropriate wrench, thereby tightly pressing the mauerlat beam to the end of the wall. |

Will such a connection be reliable? With concrete - definitely yes. Directly dealing with gas silicate is a difficult question, even with a long anchor length. In any case, it was not possible to find any research or results of studying experience on this issue on the Internet - neither positive nor negative.

Let us focus on one more point. Often the length of the timber is not enough to lay the mauerlat along the wall in one piece, and you have to resort to splicing. Experienced carpenters can make very interesting and reliable interlock connections, but for a non-professional it will be enough to make a “half-tree” connecting knot. A prerequisite: at this place it will then be necessary to provide a fastening - an anchor or a pin to tighten the connection.

Prices for corrugated sheets

corrugated sheet

A similar approach is used in the corners where the beams of adjacent walls join - a locking connection followed by tightening with the selected fasteners.

In addition, in order to connect all sides of the Mauerlat into the most rigid frame possible, reinforcement of the connection using steel brackets is practiced at the corners. One of the diagrams above shows this well.

Another tip - if you have to join two sections of timber on a wall, you should strive to ensure that they are approximately the same length. For example, on a wall length 8,5 meters it is better to use beams not 6 + 2,5 , and, for example, 4,2 + 4,3 m.

Technological innovations – chemical anchors

A dozen years ago, few people had heard about these innovative methods of fastening parts in various materials. Today, chemical anchors are widely available for sale, although it is not yet possible to call them generally available in price.

By the way, many home craftsmen carried out similar fastening technologies without special chemical anchors - we are talking about those cases when a mixture of epoxy and hardener was poured into the hole made, and then the part was inserted - after a day a reliable connection was obtained.

The advertising accompanying such chemical anchors attributes to them the highest strength qualities. True, you can already come across consumer complaints, although perhaps they are related to the fact that there are a lot of low-quality counterfeits of such chemicals on the market. And if we talk about reputable manufacturers of such materials, then you should focus on the brands “Sormat”, “Hilti”, “Nobex”, “Fischer”, “Tox”, “Tecseal”, “Tecfix”, “Technox”, “KEW” and some others.

Chemical anchors themselves may differ in the principle of their use.

- So, one variety has a capsule (ampoule) layout.

An ampoule is inserted into the hole drilled for the anchor, which contains a one- or two-component composition, which begins to quickly harden after mixing and contact with air.

After placing the ampoule, the anchor itself (pin) is inserted into the hole and driven to the required depth. When clogged, the anchor destroys the ampoule, sucking and filling the entire space of the canal. Including between the walls and threads of the stud. At normal air temperatures, after 25–45 minutes the composition completely polymerizes, hardens, and ensures reliable retention and immobility of the anchor even under considerable load.

- Another type of chemical anchors involves the use of cartridges (tubes) with a polymer composition (usually two-component) and a special dispensing gun. The gun is similar in design to the one we usually use with silicone sealants or “liquid nails”. And some types of chemical anchors are directly designed for such simple pistols.

In addition, depending on the wall material, additional devices may be used. For example, let's look at how to install a chemical anchor designed specifically for porous concrete.

| Illustration | Brief description of the operation performed |

|---|---|

| The illustration shows the possible components of a set of Fisher chemical anchors - these are the cartridges themselves with compositions of different hardening rates, and dispensing guns. The channel for any chemical anchor always needs to be thoroughly cleaned of dust - for this purpose there is a special pump for purging and pumping out, and brushes of different diameters. A drill with a special attachment allows you to make conical holes (just what you need for porous concrete). And, finally, various adapters, guide adapters, mesh bushings for hollow walls, and the stud anchors themselves of various lengths. |

| In this case, we are interested in the topic of the article precisely in the gas silicate wall - porous concrete. |

| Drilling of the channel for the anchor begins. For this purpose, a special drill with a round stop-limiter and a spherical nozzle is used. |

| First, drill a straight hole until it touches the stop. |

| The limiter rests against the wall, and thanks to the spherical shape of the nozzle, the hole begins to take a conical shape - as shown in the illustration. |

| When the channel is ready, the drill is placed straight and carefully, so as not to accidentally break the narrowed top of the cone, and removed from the hole. |

| After this, take a hand pump - you need to thoroughly clean the channel from dust. Purge begins with the pump probe completely immersed in the hole. |

| Then the pump probe is gradually removed from the channel without stopping the blowing. If necessary, use a round brush of the appropriate diameter. This blowing operation should be repeated at least four times - the presence of dust sharply reduces the reliability of the chemical anchor. Ideally, you should strive to keep the channel completely clean. |

| After cleaning, a plastic sleeve is inserted into the hole. It will “ennoble” the edge of the hole and, most importantly, ensure that the inserted anchor (stud) is positioned perpendicular to the wall surface. |

| Chemistry is getting ready for work. The cartridge is inserted into the gun and the mixer spout is screwed on. A small release of the composition is made onto any surface - you need to make sure that all components are completely mixed - this will show the even color of the resulting mixture. |

| After this, the spout is inserted into the coupling that limits the hole, and the cavity begins to be filled with a composite composition. |

| Typically the cavity is filled to approximately ¾ of its volume. |

| Next, a stud anchor of the required length is taken and carefully screwed (in the literal sense of the word) into the plastic mass that fills the conical cavity - for this, finger force is sufficient at this stage. It is important to ensure that the stud is in a position perpendicular to the wall - the guide sleeve will help with this, but it still doesn’t hurt to check. The pin is screwed all the way to the wall. |

| All you have to do is wait just 45 minutes - and at normal temperatures (about +20 °C) the anchor will be ready for load testing. |

What else do they say about the advantages of chemical anchors:

- The fastening is considered to be highly durable and durable - its service life is estimated at 50 years.

- The polymer composite used is completely inert to atmospheric, biological, and chemical influences.

- When installing such an anchor, there are no thrusting loads inside the porous concrete, that is, the risk of cracks or chipping is practically eliminated.

- At the same time, the penetration of the composite into the pores of aerated concrete adjacent to the drilled channel ensures the maximum degree of adhesion of the chemical dowel to the wall material.

Well, now – about the shortcomings. There are few of them, but judge for yourself:

- The cost of chemical dowels is high, and attaching the Mauerlat will cost a very impressive amount. Moreover, our task requires very deep channels with their complete filling with a composite - so a fair amount of cartridges will be required.

- Chemical anchors are not resistant to high temperatures. It is clear that on the Mauerlat there is basically nowhere to get temperatures above 100 degrees, but nevertheless...

- No reliable data on the timing and results of using chemical anchors for fastening the Mauerlat to aerated concrete without an armored belt has been identified. That is, there are assumptions that it should turn out well, but there are no results of the tests yet. Maybe you want to be the first?

Video: demonstration of working with a Hilti chemical anchor

Fastening the Mauerlat to embedded studs

If, even before attaching the Mauerlat, studs stick out from the end of the wall at the required distance from each other, the installation process is simplified to the limit.

- The location marks of the studs are transferred to the beam - to do this, just lay the Mauerlat on top and tap a little - the studs will leave marks that will become centers for drilling holes.

- Next, a strip of waterproofing is “pricked” onto these studs.

- Then a beam with drilled holes is strung.

- Wide washers are put on the studs, nuts are attached - and a completely understandable procedure occurs for pressing the Mauerlat to the end of the wall.

Everything is very simple, except for one thing - how to embed studs into an aerated concrete wall. This is where the difficulties begin.

There is such advice - a deep, about 500 mm, hole with a diameter of about 3-4 mm larger than the diameter of the stud is drilled in aerated concrete masonry. Then the channel is filled with masonry adhesive or cement laitance. After this, a pin is inserted into it all the way - and left in this form until the solution completely sets.

It would seem easy, but some craftsmen who have tried this method are clearly not happy with it - the solutions can shrink, it is difficult to avoid void areas, and the quality of such a unit is still not the highest. Some fasteners may become loose due to dynamic load or vibration, and this is fraught with a general weakening of the structure, the appearance of cracks on gas silicate blocks - with all the ensuing dire consequences.

Another option for installing studs in advance. In this case, they are welded perpendicular to metal plates, which will be placed in the masonry seam before installing the last row of gas silicate blocks. The shape of the plates does not play a big role - for example, they can be as shown in the illustration.

The main thing is that the plates provide support for the stud and at the same time work against the pulling load. With this approach, holes are drilled in the blocks of the top row in advance, before they are installed in the masonry, then pins are inserted there, and if necessary, the edges of the block are “straightened” so that it does not become warped due to the thickness of the plate. After this, the masonry is done - and when the wall is ready, there is immediately a row of embedded studs for mounting the mauerlat.

The plates are hidden in the masonry seams, and the studs become a convenient aid for securely fixing the Mauerlat.

The plates are hidden in the masonry seams, and the studs become a convenient aid for securely fixing the Mauerlat. And yet, the most reliable installation of embedded studs is ensured only when pouring a reinforced belt.

Is it reasonable to refuse to fill the armored belt?

And now, on the contrary, a direct question to the reader - how serious are your reasons for refusing this simple, but very reliable, proven operation of pouring an armored belt that guarantees the strength of the roof structure being created? Let's take another look at how simple and clear it all is before making a final decision.