Homemade soldering iron for 12 volts. DIY soldering iron at home in different ways. Making a soldering iron from a resistor

Among the large assortment of soldering equipment on the radio engineering market, it is worth paying attention to mini electric soldering irons with a 12-volt power supply. The small-sized instrument attracts many radio technicians with its miniature size and decent characteristics.

Where is a low-voltage soldering iron needed?

When working with printed circuit boards filled with small radio components, special dexterity is required in handling a standard soldering tip. This creates certain inconveniences. In this case, a low-voltage soldering iron (LV) is simply irreplaceable.

Areas of use

A miniature 12 volt electric soldering iron is designed to work with small parts. NP is convenient for soldering leads of various microcircuits, headphone wires, electronic components of watches and much more.

Important! DIYers use a micro-soldering iron to create various compact homemade electronic devices. For example, you can make your own USB charger for smartphones or other gadgets.

Basic properties

The main properties of a micro-soldering iron include:

- small sizes, ensuring the accessibility of the soldering iron in inconvenient places on printed circuit boards;

- economical energy consumption;

- the ability to use various batteries as a power source;

- universal power supply, both from alternating and direct current;

- the simplicity of the design of the NP allows it to be repaired.

Power restrictions

You should pay attention to how much power the mini-soldering iron has. Work safety depends on this. For example, a 40 W SS at a voltage of 36 volts will require a current of more than 1 A. For a 12 volt 30 W soldering iron, a current of more than 2 A will already be consumed. Therefore, when choosing current-carrying conductors, it is necessary to take into account their cross-section corresponding to these characteristics.

Connecting a 12 V soldering iron

It is very important that the connection of the power cord to the power source is as safe as possible. To do this, use various connectors that fit tightly into the sockets of the power units.

Depending on the design of the NP, the required characteristics of the supply current, and the types of power sources, plugs, clamps, clamps, pin lugs or plugs for a car cigarette lighter are used.

Since mini-soldering irons do not have automatic heating control, they must be turned off periodically. Otherwise, the device will malfunction. To quickly turn off the soldering iron, the power connectors should be convenient in this regard.

Soldering iron selection

To make the right choice of soldering iron, you need to clearly understand what kind of work it will be used for. Power up to 40 W is quite sufficient for a 12 volt NP to solder connections for radio components.

When purchasing a soldering iron, you need to check the strength and reliability of the handle, body and tip. If the seller is not able to check the melting of lead-tin solder or the heating temperature of the tip, then it is better to refuse the dubious purchase.

Note! A low-power tool is of little use for soldering wire connections in a car. A large cross-section of electrical equipment cables of a car will actively “take” heat from the tip. In addition, it will be impossible to use NP in cold weather.

DIY soldering iron

There are many ways to make homemade low-voltage soldering irons. It is quite possible to make a 12-volt device with your own hands, practically without any special financial costs. Before you start making a soldering tool, you need to prepare the appropriate materials and tools.

Materials

- copper wire 40 x 1.5 mm;

- a tube made of thin tin or a body of a metal 4-color ballpoint pen;

- nichrome wire;

- a wooden handle with a hole equal to the outer diameter of the tube;

- PCB substrate or copper foil;

- electrical cord;

- stationery silicate glue;

- talc or baby powder.

Tool

- pliers;

- napkins or rags;

- tweezers;

- needle file;

- wire cutters;

- putty knife;

- step-down transformer 220/12 V;

- a household heater with an electric coil or a kitchen gas stove.

Procedure for assembling a soldering iron

- The end of a piece of copper wire is ground with a needle file on both sides in the form of a cone with an angle of 400.

- The cheeks of the point are tinned.

- Silicate glue is mixed with talc to obtain a viscous adhesive electrical insulating mass.

- The tip is wrapped in copper foil so that a wire tip 10 mm long remains.

- The resulting copper tube is coated with an adhesive mass.

- Then the electrical insulating coating is subjected to heat treatment over a heater or gas burner flame. You can get by with a hot air gun.

- After ceramization of the insulation, the rod is wrapped with nichrome wire in dense turns in one layer.

- The process of coating with a viscous substance is repeated.

- One end of the conductor is wrapped to the opposite end of the tube. It is also coated with an adhesive compound and heated until completely hardened.

- The cylinder is threaded into the casing so that it is held tightly in the body of the soldering iron.

- In turn, the casing is secured in a wooden handle by threading the leads of a nichrome spiral through it.

- The power cord, on one side, is connected to a nichrome wire, on the other hand, it is attached to the terminals of a step-down transformer or other 12 V current source.

- The transformer plug is inserted into the socket. All that remains is to wait until the tip warms up to the melting temperature of the solder.

Additional Information. In order for a 12-volt soldering iron to work from the cigarette lighter in the car, a plug from a car lighter is attached to the power cord.

Remaking an old soldering iron

An old 220 V soldering iron can be converted to a 12 V NP. To do this proceed as follows:

- Unscrew two screws on the body and remove the tip.

- Remove the handle and separate the twists of the power cord and heater wires.

- Using a knife, pry off the bushing and remove the heating element from the housing.

- Remove the thermal fabric, mica shells, and wind up two layers of nichrome thread. Subsequently, only the heating wire of the top layer will be needed.

- At the front end of the tube (from the tip side), a copper wire is secured with a ring, one end of which is twisted with a nichrome thread.

- A heating coil is wound around the tube, the end of which is twisted with another piece of copper wire.

- The spiral is covered with a mica shell.

- Bend the front copper wire to the tube and cover the rod with a second layer of mica.

- The leads of the copper wires are connected to the power cord.

- The heating element is wrapped in thermal cloth and inserted into the soldering iron casing.

- The tip is inserted and secured with screws.

- On the other hand, put on the handle.

- The cord plug can be removed. Instead, connect a contact connector corresponding to the power supply sockets.

- The 12 volt soldering iron is ready for use.

Making a soldering iron from a resistor

A simple mini-device for soldering small parts is made from a simple resistor. To make it you will need the following:

- domestic resistor (25 Ohm / 2 W);

- small wooden plank;

- two pieces of copper wire in a PVC sheath;

- AC adapter or 12 volt screwdriver battery.

Assembly:

- One of the resistance leads will serve as a sting. It is cleaned and left 1 cm long.

- The second end of the resistor should be no shorter than 1.5 cm.

- The front cap of the radio component is wrapped with a bare ring of one of the pieces of copper wire.

- After 50 mm, a loop is made on the wire and fixed with a screw on a wooden batten.

- The tip of the second segment, cleared of insulation, is soldered to the long terminal of the resistor.

- The free ends of the wires are stripped and connected to a 12 volt power source.

- The mini-soldering iron tip heats up to the melting temperature of the solder in a few minutes.

- A wooden strip is used as a soldering iron handle.

What you need to know about a 12 volt soldering iron

A 12V soldering iron has a small tip, which is convenient for soldering the thinnest pins of microcircuits. The NP case does not obscure the full view of radio components on the printed circuit board or circuits of various gadgets. When in contact with a heat-sensitive component, the mini-soldering iron tip will never overheat it.

Various batteries are used as power sources for the NP: from a car battery, a screwdriver battery, a block of 18650 batteries to an ordinary 220/12 V adapter.

The low-voltage soldering iron is so easy to manufacture that it will not be difficult for a home radio technician to make it himself. At the same time, you can purchase a reliable instrument at the best price on the radio market.

Video

Home (and not only) craftsmen are encouraged to assemble a soldering iron with their own hands, first of all, by economic considerations. It is, of course, better to buy a simple 220 V soldering iron for ordinary small soldering work. However, it is also possible to modify it without disassembling it in order to extend the life of the tip. But a 150-200 W “axe”, which can be used to solder metal water pipes, costs not 4.25, but ten times more. And not Soviet rubles, but evergreen conventional units. The same problem arises if you need to solder outside the reach of the power supply from a 12 V car or a pocket lithium-ion battery. How to make a soldering iron yourself for such cases, and not only such, is discussed in today’s publication.

What is smd

Sub Micro Devices, subminiature devices. You can clearly see the SMD by opening your mobile phone, smartphone, tablet or computer. Using SMD technology, tiny (perhaps smaller than the cut of a match) components without wire leads are mounted by soldering onto contact pads, called polygons in SMD terminology. The polygon may have a thermal barrier that prevents heat from spreading along the traces of the printed circuit board. The danger here is not only and not so much in the possibility of the tracks peeling off - the heat may cause the piston connecting the mounting layers to break, which will render the device completely unusable.

A soldering iron for SMD should not only be micro-power, up to 10 W. The heat reserve in its tip should not exceed that which the soldered part can withstand. But long-term soldering with a soldering iron that is too cold is even more dangerous: the solder still doesn’t melt, but the part heats up. And the soldering mode is significantly affected by the outside temperature, and the more, the lower the power of the soldering iron. Therefore, soldering irons for SMD are made either with a limitation of time and/or amount of heat transfer during soldering, or with operational adjustment of the temperature of the tip during the current technological operation. Moreover, you need to keep it 30-40 degrees above the melting temperature of the solder with an accuracy of literally 5-10 degrees; this is the so-called permissible temperature hysteresis of the tip. This is greatly hampered by the thermal inertia of the soldering iron itself, and the main task in designing one is to achieve the lowest heat time constant possible, see below.

It is possible to make a soldering iron at home for any of these purposes. Incl. and powerful for soldering steel or copper water pipes, and a fairly accurate mini for SMD.

Note: Actually, in a soldering iron, the tip is the working (tinned) part of its rod. But, since there are other different rods, for clarity, we will consider the entire rod to be a sting. If the working part of the soldering iron is mounted on a rod, it is called a tip. Let us assume that the tip with the rod is also a sting.

Simplest

Let's not get into the complications for now. Let's say we need a regular 220V soldering iron without any fuss. We go to choose and see that the difference in prices reaches 10 times or more. Let's figure out why. First: heater, nichrome or ceramic. The latter (not “alternative”!) is practically eternal, but if the soldering iron is dropped on a hard floor, it can break. The tip of ceramic soldering irons is necessarily non-replaceable, which means you need to buy a new one. And a nichrome heater, if the soldering iron is not forgotten to be turned on at night, lasts more than 10 years; with occasional use - over 20. And in extreme cases, it can be rewound.

The difference in price has now been reduced to 3-4 times, what else is the matter? In a sting. Nickel-plated copper with special additives is poorly dissolved by solder and burns very slowly in the soldering iron holder, but is expensive. Brass or bronze heats up worse, and it is impossible to solder SMD with it - the temperature hysteresis cannot be brought back to normal due to the thermal conductivity of the material being much worse than that of copper. The red copper tip is eaten by solder and swells quite quickly from copper oxide, but it is cheaper.

Note: a tip made of electrical copper (a piece of winding wire) is unsuitable for a conventional soldering iron - it quickly dissolves and burns. However, for SMD such a sting is just right, its thermal conductivity is the highest possible, and thermal inertia and hysteresis are minimal. True, you will have to change it often, but the sting is about the size of a match or less.

Burning and swelling of the red copper tip can be dealt with simply by being careful: after finishing the work and allowing the soldering iron to cool, take out the tip, peel off the oxide, tapping it on the edge of the table, and blow out the channel of the soldering iron holder. Solder dissolution is worse: sharpening the tip is often inconvenient and it quickly wears out.

You can make a soldering iron tip from ordinary red copper many times more resistant to the action of molten solder by not sharpening its working end, but by forging it to the desired shape. Cold copper can be forged perfectly with an ordinary metalworker's hammer on the anvil of a bench vise. The author of this article has had a forged tip in the ancient Soviet EPSN-25 for more than 20 years, although this soldering iron is in use, if not every day, then certainly every week.

Simple from resistor

Calculation

The simplest soldering iron can be made from a wire resistor; this is a ready-made nichrome heater. It is also easy to calculate: when the rated power is dissipated in free space, the wirewound resistors heat up to 210-250 degrees. With a heat sink in the form of a sting, the “wireworm” maintains a long-term power overload of 1.5-2 times; The temperature of the tip will not be lower than 300 degrees. It can be increased to 400, giving a power overload of 2.5-3 times, but then after 1-1.5 hours of operation the soldering iron will need to be allowed to cool.

Calculate the required resistor resistance using the formula: R = (U^2)/(kP), where:

R – required resistance;

U – operating voltage;

P – required power;

k – the above power overload factor.

For example, you need a 220 V 100 W soldering iron for soldering copper pipes. The heat transfer is large, so we take k = 3. 220^2 = 48400. kP = 3*100 = 300. R = 48400/300 = 161.3... Ohm. We take a 100 W resistor 150 or 180 Ohm, because There are no “wireworms” at 160 Ohms, this rating is from the range of 5% tolerance, and “wireworms” are no more accurate than 10%.

The opposite case: there is a resistor with a power p, what power can you make a soldering iron from it? What voltage should it be powered from? Let's remember: P = U^2/R. Let's take P = 2 p. U^2 = PR. We take the square root of this value and get the operating voltage. For example, there is a 15 W 10 Ohm resistor. The power of the soldering iron is up to 30 W. We take the square root of 300 (30 W * 10 Ohm), we get 17 V. From 12 V, such a soldering iron will develop 14.4 W, you can solder small things with low-melting solder. From 24 V. From 24 V – 57.6 W. The power overload is almost 6 times, but occasionally and for a short time it is possible to solder something large with this soldering iron.

Manufacturing

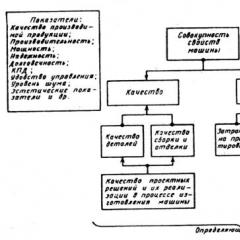

How to make a soldering iron from a resistor is shown in Fig. higher:

- We select a suitable resistor (item 1, see also below).

- We prepare the parts of the tip and fasteners for it. Use a file to select a groove on the rod for the ring spring. Threaded blind holes are made for the bolt (screw) and the tip, pos. 2.

- We assemble the rod with the tip into the tip, pos. 3.

- We fix the tip in the resistor-heater with a bolt (screw) with a wide washer, pos. 4.

- We attach the heater with the tip to a suitable handle in any convenient way, pos. 5-7. One condition: the heat resistance of the handle is not lower than 140 degrees; the resistor terminals can heat up to this temperature.

Subtleties and nuances

The soldering iron described above made from 5-20 W resistors was made by many (including the author in his pioneer days) and, having tried it, they were convinced that it could not be used seriously. It takes an unbearably long time to heat up, and it only solders small things with a poke - the ceramic layer interferes with the heat transfer from the nichrome spiral to the tip. This is why the heaters of factory soldering irons are wound on mica mandrels - the thermal conductivity of mica is orders of magnitude higher. Unfortunately, it is impossible to roll mica into a tube at home, and rolling 0.02-0.2 mm nichrome is not for everyone either.

But with soldering irons from 100 W (resistors from 35-50 W) the matter is different. The ceramic thermal barrier in them is relatively thinner, on the left in the figure, and the heat reserve in the massive tip is an order of magnitude greater, because its volume grows by the cube of its dimensions. It is quite possible to qualitatively solder a joint of 1/2″ 200 W copper pipes with a resistor soldering iron. Especially if the tip is not prefabricated, but one-piece forged.

Note: wirewound resistors are available for dissipation power up to 160 W.

Only for the soldering iron you need to look for resistors of old types PE or PEV (in the center in the figure, still in production). Their insulation is vitrified and can withstand repeated heating to light red without losing its properties, only darkening as it cools. The ceramic inside is clean. But the resistors C5-35V (on the right in the figure) are painted, and so are the insides. It is completely impossible to remove paint from the channel - ceramics are porous. When heated, the paint becomes charred and the tip sticks tightly.

Soldering iron regulator

The example with a low-voltage soldering iron made from a resistor is given above for good reason. A PE (PEV) resistor from trash or from an iron market most often turns out to be of an inappropriate rating for the current voltage. In this case, you need to make a power regulator for the soldering iron. Nowadays it is much easier even for people who have the vaguest idea about electronics. The ideal option is to buy from the Chinese (well, Ali Express, otherwise) a ready-made universal voltage and current regulator TC43200, see fig. on right; it's inexpensive. Allowable input voltage 5-36 V; output - 3-27 V at a current of up to 5 A. Voltage and current are set separately. Therefore, you can not only set the desired voltage, but also regulate the power of the soldering iron. There is, for example, a 12 V 60 W tool, but now you need 25 W. We set the current to 2.1 A, 25.2 W will go to the soldering iron and not a milliwatt more.

Note: for use with a soldering iron, it is better to replace the standard TC43200 multi-turn regulators with conventional potentiometers with graduated scales.

Pulse

Many people prefer pulse soldering irons: they are better suited for microcircuits and other small electronics (except SMD, but see below). In standby mode, the tip of a pulse soldering iron is either cold or slightly warmed up. Solder by pressing the start button. In this case, the tip quickly, within a fraction of a second, heats up to operating temperature. It is very convenient to control the soldering: the solder has spread, the flux has been squeezed out of a drop, the button has been released, and the tip has cooled just as quickly. You just need to have time to remove it so that it doesn’t get soldered there. With some experience, the danger of burning a component is minimal.

Types and schemes

Pulsed heating of a soldering iron tip is possible in several ways, depending on the type of work and the requirements for workplace ergonomics. In amateur conditions, or for a small individual entrepreneur, a pulse soldering iron will be more convenient and affordable to make one of the traces. schemes:

- With a current-carrying tip under industrial frequency current;

- With an isolated tip and forced heating;

- With a current-carrying tip under high frequency current.

Electrical circuit diagrams of pulsed soldering irons of the indicated types are shown in Fig.: pos. 1 – with a current-carrying tip of industrial frequency; pos. 2 – with forced heating of the insulated tip; pos. 3 and 4 – with a high-frequency current-carrying tip. Next, we will analyze their features, advantages, disadvantages and methods of implementation at home.

50/60 Hz

The circuit of a pulsed soldering iron with a tip under industrial frequency current is the simplest, but this is not its only advantage, and not the main thing. The potential on the tip of such a soldering iron does not exceed a fraction of a volt, so it is safe for the most delicate microcircuits. Until the induction soldering irons of the METCAL system appeared (see below), a significant part of installers in electronics production worked with industrial-frequency pulsers. Disadvantages - bulkiness, significant weight and, as a result, poor ergonomics: shifts last longer than 4 hours. workers got tired and started making mistakes. But there are still a lot of industrial-frequency pulsed soldering irons in amateur use: Zubr, Sigma, Svetozar, etc.

The device of a 50/60 Hz pulse soldering iron is shown in pos. 1 and 2 fig. Apparently, for the sake of saving on production costs, manufacturers most often use transformers on type P cores (magnetic cores) (item 2), but this is far from the optimal option: in order for a soldering iron to solder like EPCN-25, the transformer power needs 60-65 W. Due to the large stray field, the P-core transformer gets very hot in short-circuit mode, and the heating time of the tip reaches 2-4 s.

If the P-core is replaced with an SL from 40 W with a secondary winding made of a copper busbar (items 3 and 4), then the soldering iron can withstand hour-long work with an intensity of 7-8 solderings per minute without unacceptable overheating. To operate in periodic short-term short-circuit mode, the number of turns of the primary winding is increased by 10-15% compared to the calculated one. This design is also advantageous in that the tip (copper wire with a diameter of 1.2-2 mm) can be attached directly to the terminals of the secondary winding (item 5). Since its voltage is a fraction of a volt, this further increases the efficiency of the soldering iron and extends its operating time before overheating.

With forced heating

The circuit diagram of a soldering iron with forced heating does not require any special explanation. In standby mode, the heater operates at a quarter of the rated power, and when you press start, the energy accumulated in the capacitor bank is released into it. By disconnecting/connecting containers to the battery, you can quite roughly, but within acceptable limits, dose the amount of heat generated by the tip. The advantage is the complete absence of induced potential on the tip if it is grounded. Disadvantage: using commercially available capacitors, the circuit can only be implemented for resistor mini-soldering irons, see below. It is used mainly for occasional work on hybrid assembly boards that are not saturated with components, smd + conventional printed circuit boards in through-hole pins.

At high frequency

Pulse soldering irons at high or high frequencies (tens or hundreds of kHz) are very economical: the thermal power at the tip is almost equal to the nameplate electrical power of the inverter (see below). They are also compact and lightweight, and their inverters are suitable for powering constant-heat resistor mini-soldering irons with an insulated tip, see below. Heating the tip to operating temperature in a fraction of a second. Any thyristor voltage regulator 220 V can be used as a power regulator without modifications. They can be powered with a constant voltage of 220 V.

Note: for power over approx. A 50 W HF pulse soldering iron is not worth making. Although, for example Computer power supply units can have a power of up to 350 W or more, but it is almost impossible to make a tip for such power - either it will not warm up to operating temperature, or it will melt on its own.

A serious drawback is that the operating frequencies are affected by the influence of the tip’s own inductance and the secondary winding. Because of this, an induced potential of over 50 V may appear on the tip for a time of more than 1 ms, which is dangerous for CMOS components (CMOS). Another significant drawback is that the operator is exposed to a flow of electromagnetic field (EMF) power. You can work with a pulsed HF soldering iron with a power of 25-50 W for no more than an hour a day, and up to 25 W for no more than 4 hours, but no more than 1.5 hours at a time.

The simplest way of circuit implementation of a 25-30 W pulsed HF soldering iron inverter for ordinary soldering work is based on a 12-volt halogen lamp network adapter, see item. 3 fig. with diagrams. The transformer can be wound on a core of 2 K24x12x6 ferrite rings folded together with a magnetic permeability μ of at least 2000, or on an W-shaped magnetic core made of the same ferrite with a cross-section of at least 0.7 square meters. see Winding 1 - 250-260 turns of enameled wire with a diameter of 0.35-0.5 mm, windings 2 and 3 - 5-6 turns of the same wire. Winding 4 - 2 turns in parallel of wire with a diameter of 2 mm (on a ring) or braid from a television coaxial cable (pos. 3a), also paralleled.

Note: if the soldering iron is more than 15 W, then it is better to replace the MJE13003 transistors with MJE130nn, where nn>03, and put them on radiators with an area of 20 square meters or more. cm.

An inverter option for a soldering iron up to 16 W can be made on the basis of a pulse starting device (IPU) for an LDS or the filling of a burnt-out energy-saving light bulb, respectively. power (do not hit the flask, there is mercury vapor!) The modification is illustrated by pos. 4 in Fig. with diagrams. What is highlighted in green may be different in the IPU of different models, but we don’t care about it. We need to remove the starting elements of the lamp (highlighted in red in position 4a) and short-circuit points AA. We get a diagram of the poses. 4b. In it, a transformer is connected in parallel to the phase-shifting inductor L5 on one of the same rings as in the previous one. case or on W-shaped ferrite from 0.5 sq. cm (pos. 4c). Primary winding - 120 turns of wire with a diameter of 0.4-0.7; secondary – 2 turns of wire D>2 mm. The tip (pos. 4g) is made of the same wire. The finished device is compact (item 4d) and can be placed in a convenient case.

Mini and micro on resistors

A soldering iron with a heating element based on an MLT metal film resistor is structurally similar to a soldering iron made from a wire resistor, but is designed for a power of up to 10-12 W. The resistor operates with a power overload of 6-12 times, because, firstly, the heat dissipation through the relatively thick (but absolutely thinner) tip is greater. Secondly, MLT resistors are physically several times smaller than PE and PEV. The ratio of their surface to volume resp. increases and heat transfer to the environment increases relatively. Therefore, soldering irons with MLT resistors are made only in mini and micro versions: when you try to increase the power, the small resistor burns out. Although MLTs for special applications are produced with a power of up to 10 W, it is realistic to make on your own only a soldering iron on the MLT-2 for small discrete components (scattered) and small microcircuits, see for example. video below:

Video: micro soldering iron using resistors

Note: the MLT resistor chain can also be used as a heater for a stand-alone cordless soldering iron for ordinary soldering work, see next. video clip:

Video: Cordless mini soldering iron

It is much more interesting to make a mini soldering iron from an MLT-0.5 resistor for smd. The ceramic tube - MLT-0.5 body - is very thin and almost does not interfere with heat transfer to the tip, but will not allow a thermal impulse to pass through at the moment it touches the landfill, which is why SMD components often burn out. Having selected a tip (which requires quite a lot of experience), you can solder SMD with such a soldering iron slowly, continuously monitoring the process through a microscope.

The manufacturing process of such a soldering iron is shown in Fig. Power – 6 W. Heating is either continuous from the inverter described above, or (better) with forced heating with direct current from a 12 V power supply.

Note: how to make an improved version of such a soldering iron with a wider range of applications is described in detail here - oldoctober.com/ru/soldering_iron/

Induction

The induction soldering iron is currently the pinnacle of technical achievements in the field of metal soldering with eutectic solders. In essence, an induction-heated soldering iron is a miniature induction furnace: the HF EMF of the inductor coil is absorbed by the metal of the tip, which is heated by Foucault eddy currents. Making an induction soldering iron with your own hands is not so difficult if you have a source of HF currents at your disposal, for example. computer switching power supply, see e.g. plot

Video: induction soldering iron

However, the quality and economic indicators of induction soldering irons for conventional soldering work are low, which cannot be said about their harmful effects on health. In fact, their only advantage is that the tip stuck to the holder in the body can be torn out without fear of tearing the heater.

Induction mini-soldering irons of the METCAL system are of much greater interest. Their introduction in electronics production made it possible to reduce the percentage of defects due to installer errors by 10,000 times (!) and lengthen the work shift to a normal one, and the workers left after it cheerful and capable in all other respects.

The structure of a METCAL type soldering iron is shown at the top left in Fig. The highlight is the ferronickel coating of the tip. The soldering iron is powered by RF at a precisely maintained frequency of 470 kHz. The thickness of the coating was chosen such that at a given frequency, due to the surface effect (skin effect), Foucault currents were concentrated only in the coating, which gets very hot and transfers heat to the tip. The tip itself turns out to be shielded from EMF and induced potentials do not arise on it.

When the coating warms up to the Curie point, above which the ferromagnetic properties of the coating disappear in temperature, it absorbs EMF energy much weaker, but still does not allow RF into the copper, because maintains electrical conductivity. Having cooled below the Curie point on its own or due to heat transfer to the soldering, the coating again begins to intensively absorb EMF and heats up the tip. Thus, the tip maintains a temperature equal to the Curie point of the coating with an accuracy of literally one degree. The thermal hysteresis of the tip is negligible, because determined by the thermal inertia of the thin coating.

To avoid harmful effects on people, soldering irons are produced with non-replaceable tips, tightly fixed in a cartridge of a coaxial design, through which they are supplied to the RF coil. The cartridge is inserted into the soldering iron handle - a holder with a coaxial connector. Cartridges are available in 500, 600 and 700 types, which correspond to the Curie point of the coating in degrees Fahrenheit (260, 315 and 370 degrees Celsius). Main working cartridge – 600; The 500th is used to solder especially small smds, and the 700th is used to solder large smds and scatterings.

Note: to convert degrees Fahrenheit to Celsius, you need to subtract 32 from Fahrenheit, multiply the remainder by 5 and divide by 9. If you need to do the opposite, add 32 to Celsius, multiply the result by 9 and divide by 5.

Everything is great about METCAL soldering irons, except the price of the cartridge: for “(company name) new, good” – from $40. “Alternative” ones are one and a half times cheaper, but are produced twice as fast. It is impossible to make a METCAL tip yourself: the coating is applied by spraying in a vacuum; Galvanic at the Curie temperature instantly peels off. A thin-walled tube mounted on copper will not provide absolute thermal contact, without which METCAL simply turns into a bad soldering iron. Nevertheless, making an almost complete analogue of the METCAL soldering iron yourself, with a replaceable tip, although difficult, is possible.

Induction for smd

The design of a homemade induction soldering iron for microcircuits and SMD, similar in performance to METCAL, is shown on the right in Fig. Once upon a time, similar soldering irons were used in special production, but METCAL completely replaced them due to better manufacturability and greater profitability. However, you can make such a soldering iron for yourself.

Its secret is in the ratio of the shoulders of the outer part of the tip and the shank protruding from the coil into the inside. If it is as shown in Fig. (approximately), and the shank is covered with thermal insulation, then the thermal focus of the tip will not go beyond the winding. The shank will, of course, be hotter than the tip of the tip, but their temperatures will change synchronously (theoretically, thermohysteresis is zero). Once you have set up the automation using an additional thermocouple that measures the temperature of the tip tip, you can then solder in peace.

The role of the Curie point is played by a timer. It is reset to zero by a signal from the thermostat for heating, for example, by opening the key that shunts the storage tank. The timer is started by a signal indicating the actual start of the inverter operation: the voltage from the additional winding of the transformer of 1-2 turns is rectified and unlocks the timer. If you do not solder with a soldering iron for a long time, the timer will turn off the inverter after 7 seconds until the tip cools down and the thermostat issues a new heating signal. The point here is that the thermal hysteresis of the tip is proportional to the ratio of the times of switched-off and switched-on heating of the tip O/I, and the average power on the tip is proportional to the reverse I/O. Such a system does not maintain the temperature of the tip up to a degree, but it provides +/–25 Celsius with a working tip of 330.

Finally

So what kind of soldering iron should you use? A powerful wirewound resistor is definitely worth it: it costs nothing at all, it doesn’t require eating, but it can help out a lot.

It is also worth making sure that you have a simple soldering iron for SMD from an MLT resistor on your household. Silicon electronics is exhausted, it is at a dead end. The quantum one is already on its way, and the graphene one is clearly looming in the distance. Both do not interface directly with us, like a computer through a screen, mouse and keyboard, or a smart phone/tablet through a screen and sensors. Therefore, silicon frames in future devices will remain, but exclusively SMD, and the current scattering will seem something like radio tubes. And don’t think that this is science fiction: just 30-40 years ago, not a single science fiction writer thought of a smartphone. Although the first samples of mobile phones were already available then. And an iron or a vacuum cleaner “with brains” would never have occurred to the dreamers of that time even in a bad dream.

(1

ratings, average: 5,00

out of 5)

Many people use homemade soldering irons. There are quite a lot of implementation options, since these tools are sculpted from what is at hand or can be easily found. The most labor-intensive process is to make a soldering iron, similar to a factory one, but of low power. Here is an example of what and how to make a miniature one at home. It is assumed that the soldering iron will receive power not directly from the network, but through a 220/12 V transformer.

You will need the following materials:

- copper wire with a diameter of 1.5 mm - about 40 mm long

- copper foil - a small rectangle 30x10 mm or a little larger

- nichrome wire 0.2 mm – 350 mm

- a tin tube or piece of tin to make a casing for the heating element

- silicate glue (liquid glass)

- talc for the production of an insulating layer with the addition of silicate glue

- handle made of heat-resistant plastic

- electrical cord with plug

Some auxiliary things will also be required:

- heat source (electric or gas oven)

- standard tools (nippers, tweezers, pliers, file)

- non-standard devices (something in the form of a narrow small spatula - wooden or plastic)

- a lot of rags (remove very sticky insulating mixture from hands and tools)

Sequence of actions for assembling the tool

The description of the process is given schematically, since implementation usually does not cause difficulties.

Important! The finished soldering iron can be connected, as already mentioned, to the network via a transformer or to a 12-volt power supply rated for a current of 1 A.This soldering iron can work with microcircuits, but care should be taken to protect against static electricity.

An alternative option to such a soldering iron is of interest to those who are unpretentious about the appearance of the device that they will have to work with. The trick of this solution is that a PEV-10 or PEV-7.5 resistor is used as a heating element. All that remains is to insert the tip, which is fixed in a copper tube tightly seated inside the resistor, and take care of good fixation of the resistor contacts, which cannot withstand certain mechanical loads.

Video on how to make a mini soldering iron with your own hands

The following video will help you figure out how to make a homemade mini soldering iron:

A soldering iron designed for 12 Volts from your own autohorse can be made in an hour or two, which can be very useful for a home craftsman. The basis of the heating element will be... you won’t believe it - a resistor PEV-10 or PEV-7.5!

A soldering iron designed for 12 Volts from your own autohorse can be made in an hour or two, which can be very useful for a home craftsman. The basis of the heating element will be... you won’t believe it - a resistor PEV-10 or PEV-7.5!

This design is just an example, and the flight of fancy of crazy hands is unlimited here. The main thing here is to have two copper rods of different diameters and the PEV resistor itself.

I found a description of such an original design on the Internet. Damn, live forever and learn! For how many years I have been interested in electronics and various crafts, but I have never heard of this and would not have thought about it myself.

In fact, if you are not in the garage, you will need to solder something into some device in your car, because you will not have 220 volts at hand. So such a homemade soldering iron, made with your own hands in an hour, can really help you out in such a situation. And if you have a powerful old transformer with a 12-volt output lying around, then this miracle soldering iron will also work at home!

PEV resistors

These resistors come in high power. I remember at the factory when I worked as a radio assembler, we had soldering irons at 36 volts and they were regulated in a primitive way: through the sequential connection of such huge resistors into their power circuit, similar to these, but only with cylindrical regulation. For this, resistors of the PPG-25G type were used. As the temperature decreased, part of the energy was dissipated on this resistor, and given that we had 40-watt soldering irons, these resistors got really hot.

These resistors come in high power. I remember at the factory when I worked as a radio assembler, we had soldering irons at 36 volts and they were regulated in a primitive way: through the sequential connection of such huge resistors into their power circuit, similar to these, but only with cylindrical regulation. For this, resistors of the PPG-25G type were used. As the temperature decreased, part of the energy was dissipated on this resistor, and given that we had 40-watt soldering irons, these resistors got really hot.

What Russian ingenuity! In fact: resistors are made of ceramics, designed for enormous heating (I know, I’m telling you as a practitioner), they are made firmly, reliably - it can be used as a heating element of a soldering iron. The number in the name means the power of the resistor, if you haven’t guessed.

The design of a homemade soldering iron

Well, now all that remains is to fix the soldering iron tip inside the PEV-10 (PEV-7.5) resistor, and attach a handle to its terminals. And, as I mentioned, the conclusions, like everything else in these resistors, are made for centuries - you’ll tear them off!

This is roughly how a sting is made, together with a body that transmits heat, from two copper rods, inserted inside the resistor.

This is roughly how a sting is made, together with a body that transmits heat, from two copper rods, inserted inside the resistor.

In the large rod, recesses are drilled on both sides: for the tip itself and for the mounting bolt. Then threads are cut into them. The thread is also cut on the tip of the future soldering iron.

On the large rod you need to make a groove for the steel retaining ring, then put it on.

After which the structure of the tip and the heating element of the soldering iron are assembled together.

After which the structure of the tip and the heating element of the soldering iron are assembled together.

Hehe, cheap and cheerful! 🙂 Similar? Hände hoch!

I’ll add on my own that after assembly, the resistor can be wrapped with asbestos cord to reduce heat loss.

The author made the handle from two identical halves of a textolite plate. Material with a thickness of 3-5 mm is suitable. Grooves are made in the plates for the supply wire.

The author made the handle from two identical halves of a textolite plate. Material with a thickness of 3-5 mm is suitable. Grooves are made in the plates for the supply wire.

The weak point of the soldering iron is the resistor contacts. They are not made of steel, but of copper, unfortunately. Therefore, they have a certain flexibility, and the author of the design speaks about this. So when soldering, don’t press too hard! But if desired and skillful, you can strengthen the fastening by putting two round clamping brackets over the resistor in the contact area, clamping the resistor itself with brackets in this way. And screw their ends to the plates. The brackets can be sealed with fluoroplastic tape.

Well, the finished design!

PEV resistor resistance for soldering iron

For a 40 W soldering iron powered by a car battery, the resistance of the resistor should be about 5.1 Ohms (it will produce about 30 W of power). This takes into account the resistance of the wires (approximately 1 ohm). With this resistance, the soldering iron is normally heated up if the battery voltage is above 12 V and does not overheat at the maximum (14.4 V).

If the soldering iron is supposed to be connected through an automatic temperature regulator (with a thermocouple mounted on the tip), then the resistance of the resistor can be reduced to 3.6...4.7 Ohms. Then it will heat up faster - not 2...3 minutes, but only 40 seconds. And domestic PEVs are practically insensitive to current overloads. For other supply voltages, the resistor resistance should be different, as can be seen from the table.

For soldering electronic circuits, it is often necessary to take special care when heating the terminals of semiconductor elements. They can be very picky about temperature.

In addition, sometimes when debugging a circuit you have to solder with the power connected. In this case, using a regular soldering iron powered by a 220 Volt network is dangerous. For such cases, it is better to use an electric soldering iron that operates on a voltage of 12 volts.

A soldering iron designed for 12 Volts can operate on both AC and DC power.

A soldering iron operating on direct current can even be connected to the car’s on-board network, provided that its power does not exceed the rated power of the car’s electrical wiring.

There are many designs of soldering irons on sale that use low voltage. They can be distinguished by the obligatory inscription on the body and packaging.

This voltage must also be indicated in the technical specifications of the tool. If you have an unnecessary 220-volt soldering iron, you can make a 12-volt one yourself.

Remaking an old soldering iron

In order to remake a standard soldering iron, you need to disassemble it and remove the heating element. Instead, you need to wind a nichrome thread with a thickness of 0.02-0.20 mm on a mica substrate. The thread can be removed from any used electrical appliance, for example, a hair dryer.

The length of the filament is selected experimentally depending on the thickness and the required degree of heating of the soldering iron. When winding the thread, you must ensure that the turns do not touch each other.

The sequence of work is as follows:

- after selecting the length of the wire, the turns are fixed using some heat-resistant glue;

- The thread is connected at both ends by wires to the power source. It could be a 12-volt converter, a power tool battery, or a car battery;

- The body of a new 12-volt soldering iron must be assembled and it will be no different from the previous one.

In order not to accidentally connect the tool to a 220 volt network, it is recommended to make a catchy, clearly visible inscription on the handle - “12v”.

From a resistor

You can make a miniature homemade soldering iron for 12 volts using permanent metal film resistors, for example, MLT-2 with a power of 2 W.

They work even with an overload of up to 6-10 times, so it is not difficult to achieve power output of up to 12-20 W from them. But a significant part of it will be wasted on heat exchange with air due to the relatively large surface area of the resistor. For manufacturing you will need a resistor with a nominal value of 24-27 Ohms.

One of its fairly thick leads will serve as a soldering iron tip, the second – as a contact for the power wire.

The resistor body near the tip contact must be cleaned of paint and tightly wrapped with a second supply wire. The working circuit of the soldering iron is ready.

The resistor body near the tip contact must be cleaned of paint and tightly wrapped with a second supply wire. The working circuit of the soldering iron is ready.

All that remains is to place it in a case that will be convenient to use. To do this, the resistor is wrapped in a heat-resistant heat-insulating material, for example, fiberglass, and placed in a plastic tube of a suitable diameter.

Car use

There are few components and parts left in modern cars that can be repaired independently, outside of a garage or workshop. Most likely, these could be damaged wire harnesses at the bends.

Such malfunctions are easy to fix on the road. It is enough to remove excess insulation and twist the wires, then protecting the twist with insulating tape.

But the car's wiring works in very difficult conditions. It is subject to vibrations, frequent changes in temperature and humidity, especially in winter.

Under such conditions, contact in the twist may be lost, and when using a conventional single-wire electrical circuit, loss of contact can have an unpredictable effect on the behavior of the vehicle.

To prevent this undesirable phenomenon, it is recommended to solder the twist. For this you will need a car soldering iron powered by a cigarette lighter.

Almost all car cigarette lighters are powered by a line of wires rated for a current of up to 15 A. This is quite enough to connect a soldering iron with a power of up to 100 Watts. And more is unlikely to be needed. The cigarette lighter itself is also converted into a socket. It turns out to be a miniature infrared hair dryer.

In older vehicles, soldering may be necessary to repair relay and fuse mounting blocks, or to solder terminals to wires that have been broken during use.