Harrow for walk-behind tractor - types, functions and independent production. Do-it-yourself homemade harrow on a walk-behind tractor Do-it-yourself needle harrow

In order to increase the yield on the field, they always plowed and harrowed the soil. This is what our ancestors did, and modern farmers do the same. But in order to do this work, horses were harnessed in the old days, and today the harrow is attached to walk-behind tractors (for small farm plots, private summer cottages) or to a tractor (this is for large farms in large areas). Based on the foregoing, a do-it-yourself harrow for a walk-behind tractor is an important tool for any summer resident, below we will take a closer look at the manufacturing process and how to do proper harrowing with a walk-behind tractor.

Do-it-yourself harrow for a walk-behind tractor

What is a harrow made of?

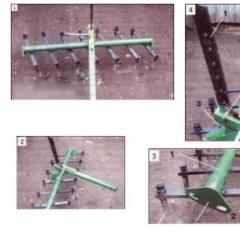

Metal strips are welded to the bottom of the square pipe, at the ends of which teeth are bolted in two rows (photo 3). These strips are placed at an angle of 30⁰ to each other, the stakes of the earth that slip between the teeth of the first row (front) are broken against the teeth of the second row.

The drawbar ends in the boiled bushing, through which the harrow is fixed with the help of a “finger” to the walk-behind tractor. The lifting height is adjusted by the harrowing depth stand (photo 4).

An adjustment screw for the angle of attack is welded to the drawbar next to it - it is he who allows you to adjust the design so that the rear and front teeth fall into the same depth.

Features of using a harrow on a walk-behind tractor

Sometimes, during operation, the harrow becomes clogged. It is very easy to clean it, without even bending over. When raising the handle of the walk-behind tractor, we tear off the harrow from the soil surface, take it to the side and discard with our feet all the debris that has accumulated on the teeth. Then we return the tool to its original place, lower it and continue moving.

The principle of robots and the device of a harrow for walk-behind tractors

The first harrow that a man made with his own hands looked like spruce logs tied together. They were made not very long so that it would be possible to maneuver in the fields, but the mass of the harrow was too large, which made it possible to break up blocks of earth after plowing and retain natural moisture in the ground.

To date, this unit is used both independently and with other types of devices such as seeders and cultivators. The harrow copes not only with earthen blocks, but also covers the soil leaving moisture inside it. The technical characteristics of the harrow allow it to still collect dry plant residues and pull out the roots of weeds.

This is a device that has passed centuries and has managed to modernize so much that when using it, a minimum of human effort is required. Harrows are of several types:

- disk

- rotary

- dental

The technical characteristics of the harrow comply with generally accepted standards and are calculated based on the mass that falls on one disc or tooth. Accordingly, based on this classification, there are heavy, medium and light harrows. And their use can be special or general.

Types of harrows for motoblocks and tractors

First, consider a rotary harrow for a walk-behind tractor, it removes the top layer of soil very well. With the help of a rotary harrow, after harvesting crops, the land is cultivated. It is also a good option for leveling the soil. Thanks to her, there is no need to mow the grass. The working depth is set based on what tasks are set. It usually fluctuates from 5 to 7 centimeters.

For a tractor, it absolutely does not matter what kind of harrow it will be, here it is more important and more valuable to take into account the dimensions necessary for tillage. If this field is several hundred hectares in size, then the wider the harrow, the better.

A large harrow is made specifically for walk-behind tractors, so making it yourself will not be difficult. It is attached to the walk-behind tractor on the hitch.

The farmers concluded that for good efficient work in the field, the harrow, or rather its blades, must have an oblique shape. The teeth should be located at an angle to the plane of the ground, this allows you to cut easily, and thereby leveling the soil.

disc harrow

The second type of disc harrow, the use of dry soil. A disc harrow performs all the same functions as a rotary harrow, only differs in design: it uses discs, each of them stands on a separate axis. But, unfortunately, this type of harrow breaks more often.

The classic tooth harrow is used in places where an even and loose soil layer is required. The teeth are evenly spaced in the frame, their length ranges from 25 mm to 45 mm. The size of the teeth depends on the weight of the harrow, the more weight, the more teeth. The disadvantages include the speed of the efficiency of the walk-behind tractor, the power should be significantly high, and be at least 12-14 km / h.

If you are faced with a choice, then for work in small areas, a rotary harrow for a walk-behind tractor is perfect.

Proper harrowing with a walk-behind tractor

A good, well-made rotary harrow for a walk-behind tractor can be used as a cultivator. Everything that is done manually in the absence of equipment will be done quickly and efficiently, when you have a walk-behind tractor and a harrow for it in your arsenal, then by properly harrowing with a walk-behind tractor you will increase the yield of the planted crop, and significantly reduce the level of seed losses and ensure the delivery of fertilizers to desired depth.

A harrow for a walk-behind tractor helps to level the topsoil, when fertilizers are poured onto the ground, its work ensures that they fall under the topsoil 5-7 cm deep.

Tip: when working with a harrow using a walk-behind tractor, do not exceed the speed of the mechanism by more than 4 km / h.

Related Posts:

Do-it-yourself disk hiller for a walk-behind tractor photos and drawings

Do-it-yourself disk hiller for a walk-behind tractor photos and drawings

What happens and how to choose attachments for the Salyut walk-behind tractor

What happens and how to choose attachments for the Salyut walk-behind tractor

how to make a plow for a walk-behind tractor with your own hands, drawings, description, photo

how to make a plow for a walk-behind tractor with your own hands, drawings, description, photo

We make attachments for walk-behind tractors with our own hands, photos and drawings

We make attachments for walk-behind tractors with our own hands, photos and drawingsA harrow for a walk-behind tractor allows you to level large clods of soil that invariably remain after plowing. In addition, harrowing helps to retain moisture in the ground.

This ensures uniform saturation of the soil with nutrients, which ensures high germination of crops. Due to the design features, with the help of a harrow, it is possible to clear the field from plant residues of weeds.

This type of attachment is available in several modifications, given that the harrow does not include complex components, some craftsmen make equipment on their own.

Varieties

All commercially available harrows for walk-behind tractors are divided into three categories. The subdivision occurs according to the method of cultivating the land. This is what the garden equipment market offers to summer residents.

Tooth harrows

This is a type of trailer. Such models are a metal frame with teeth located on it.

On sale there are harrows, with a zigzag arrangement of working elements or rectangular structures. The number of teeth and the width of the covered area depends on the power of the power plant of the walk-behind tractor.

Tooth harrows are able to go deep into the ground by 15 centimeters. Some models are equipped with spring springs, this contributes to uniform processing of the field surface.

Disc models

In such units, spherical steel disks are used instead of teeth. The cutting elements are located on a metal frame, the angle of attack is adjustable.

This allows the discs to enter the soil at an optimal angle, evenly crushing clods of earth and grinding plant residues. It is worth noting that disc harrows can be mounted on the front or rear hitch of a walk-behind tractor.

Power harrow for walk-behind tractor

Such models process the soil relatively shallowly - up to 7 centimeters, but they are optimally suited for pre-planting soil preparation. Active rotors are installed instead of a tiller or undercarriage, so these models show good performance in virgin soil.

Rotary harrows are not suitable for all models of walk-behind tractors. In order for the equipment to work with maximum efficiency, the walk-behind tractor must have a gearbox and a powerful power plant. The cutting elements of rotary models are made in the form of metal plates with different sharpening angles.

Almost all units for harrowing can be made independently. The exception is the rotary harrow. Here, the wrong sharpening angle will lead to an uneven distribution of the load on the motor shaft, which can cause a breakdown of the power plant.

Homemade construction

A do-it-yourself harrow for a walk-behind tractor is made from any improvised materials that are available on the farm. Let's figure out how to make a tooth harrow yourself. Here is an example assembly algorithm.

For the base, you can use a piece of metal pipe of square or round section. The length of the pipe depends on the width of the covered area and the engine power.

Steel plates are welded to the bottom of the pipe, the edges of the strips should protrude evenly in both directions. Please note that the plates should be at an angle of 25-30 degrees relative to each other.

This design has the following advantage: the teeth are staggered, if a lump of earth slips through the first row of working elements, it invariably breaks against the second.

A sleeve is welded in the middle of the structure. A hitch with a walk-behind tractor and an adjusting device will be attached to it.

Harrow teeth are installed on the edges of the plates. For the manufacture of working elements, we recommend using hardened steel. The teeth are best fastened to the plates with a threaded connection. If welding is used, the teeth will often fly off the plates.

A harrow drawbar is mounted to the welded bushing. We recommend using the rigid hitch option to connect the harrow to the walk-behind tractor. An adjustment screw is located next to the bushing, which will help to set the optimal harrowing depth.

Advantages

Experienced farmers know that if harrowing is excluded, it will not be possible to obtain high yields in autumn. The harrow helps to evenly cover the seeds with a layer of soil, which ensures uniform receipt of moisture and ultraviolet light.

In addition, with the help of harrowing, fertilizers can be evenly applied to the soil. Please note that high-quality harrowing is impossible at high speed, therefore, when performing such work, the speed limit should not exceed 3 km / h.

TELL YOUR FRIENDS

In contact with

To increase the efficiency of work, and therefore increase the yield, such attachments as harrows are used. Previously, horses were used to perform work on the ground, but today a harrow is hung on a walk-behind tractor (if the area is small) or to a tractor (if the area of the cultivated area is impressive). Therefore, a harrow for a walk-behind tractor is a very important device for any knowledgeable landowner, and if it is made by hand, then it is a source of pride. Let's tell you in more detail how harrowing is performed using a walk-behind tractor, and how to make this device yourself.

Types of harrows for a walk-behind tractor and their device

There are several types of harrows that differ structurally and have a number of special features.

- Rotary

- Disk

- Tooth

power harrow

As for the rotary harrow for a walk-behind tractor, its main advantage is the good removal of the top layer of soil (soil). Leveling the soil with it is also not a problem. The depth of processing with a harrow varies from 4 to 8 centimeters, the depth can be adjusted based on the specifics of the work.

The width of the harrow is also important, here not only the power of the walk-behind tractor is taken into account, but also the size of the cultivated area. Usually, this value is from 800 to 1400 mm. Such dimensions are due to be able to work comfortably, maneuvering in a small area.

Rotary harrows from honest manufacturers are made of high-quality metal alloy, allowing the equipment to operate for decades (with proper care and maintenance).

On high-quality harrows, the blade has an oblique shape, and the teeth are located at an angle to the soil, having an optimal angle of attack, for better cutting through the ground, leveling it and removing weed roots.

disc harrow

A disc harrow is used on dry soil, functionally, it performs the same work as a rotary harrow, but it is fundamentally different in design. Here, the main processing elements are discs shaped like stars. They are mounted on the same axis at a certain angle, providing maximum penetration into the ground.

tooth harrow

A tooth harrow is a frame on which teeth are located at an equally spaced distance. The standard length of the teeth is 25-50 mm. An example of such a harrow can be seen in the video below.

Do-it-yourself harrow for a walk-behind tractor drawings

In order to make a harrow for a walk-behind tractor with your own hands, first of all, you need to study the design of the device, drawings and determine the dimensions.

What is a harrow made of?

The design of the harrow is quite simple, the frame is made of a metal square profile, the coupling device, which is credited to the harrow to the walk-behind tractor, and the teeth are mounted on the frame. It is recommended not to weld the teeth, but to fix them with bolts, then in case of breakage one of them will be easier to replace.

Below are drawings of harrows, giving an idea of the required dimensions, attachment points and the general layout.

Homemade harrow

An example of a homemade harrow made from two smaller harrows and rigidly connected to each other. For longitudinal travel, a hinge from a GAZ 53 car was used. In addition to the hinge and a standard hitch, the harrow clings with two rods to ensure better performance.

Harrow for motoblock Neva

One of the leaders among small agricultural machinery. A harrow for the Neva is no different from harrows for other devices, and you can buy them everywhere.

Here is an example of a rotary harrow for the Neva and other walk-behind tractors, whose shaft diameter is 30 mm.

Rotary harrow RB-1.4 (two sections, 0.7 m each) for the Neva walk-behind tractor.

Designed for pre-sowing and post-harvest tillage.

Capture width - 1.4 m;

Diameter - 350 mm;

Bushing bore diameter - 30 mm;

Depth of tillage - up to 100 mm;

Weight of one section - 9 kg;

Videos harrow

Rotary harrow mounted on the Neva walk-behind tractor in operation

Video about the device of the harrow, its dimensions and use with the SCH walk-behind tractor

Proper harrowing

For the operation of any attachments with the Neva walk-behind tractor, it must be connected to the unit. There is a special device for this - a hitch. There are several types, let's look at the features of each of them.

Hitch for APM adapter (for working with a plow and hillers)

![]()

This hitch is designed to connect to the adapter of various attachments. Such as plows, potato diggers and hillers. The design of the hitch allows you to securely fix the equipment to the Neva walk-behind tractors with just three bolts.

This type of hitch allows you to adjust the angle of inclination of attachments using a bolt mechanism. This function allows you to tilt the Neva walk-behind tractor, and the plow will go perpendicular to the ground.

Since this hitch is mainly intended for the use of plows and hillers, it is possible to install a double or triple hitch so that several working elements can be connected to it at once.

This is a modification of the universal hitch for the Neva walk-behind tractor. Its main difference is that you can not only adjust the height of the dive, but also change the angle of inclination in all planes. The maximum tilt angle in the horizontal plane is ± 20°, and in the vertical plane ± 27°.

This hitch is special in itself, since it was produced by the Mobil K LLC plant exclusively for hitching with their OH-2 and Krot equipment. The factory thought out a separate type of clutch, which is not supplied in the kit, but is purchased separately.

Is it possible to make a hitch for a walk-behind tractor with your own hands?

When making a do-it-yourself hitch, it would be most correct to choose a universal option, since 90% of attachments work with this type of clutch.

It must be taken into account that there will be a lot of pressure on the hitch. Therefore, you should choose exceptionally strong materials from large sheet metal.

The universal hitch is based on a U-shaped mount. For its manufacture, a square channel is best suited, it should be 40x40 mm in size.

Holes are made in this channel, which will serve to fix the hitch with a pin. Therefore, you should initially make a pin from high-quality steel, and then drill holes in the mount to fit the size of the pin.

For further installation of attachments, the bracket must be connected. Its long part should be directed downwards or upwards so that the connected equipment does not interfere with movement. It should not be made too long to prevent contact with the ground.

Owner reviews

Here is what people write on the forums about the hitch for the Neva walk-behind tractor:

![]() Stepan writes:

Stepan writes:

“It took a long time to choose which hitch to use. After all, they have a similar device. I thought about doing it myself, but I didn’t bother and bought a universal hitch H. It seemed to me to be the most effective, versatile and compatible with all the equipment that I have. Plus, it comes with an official warranty. Since then, there have been no complaints at work"

![]() Vasily writes:

Vasily writes:

“I bought a Mole plow for work. Since it was one of the cheapest options, and I did not want to overpay. Still, they are similar and functionally the same. What was my surprise when at home I could not connect it to my hitch. The next day I went to the store to find out what the problem was. To which the seller told me that he forgot to mention the special hitch of this plow. I had to buy an extra clutch. Here's a proverb for you that a miser pays twice clearly ... "

Harrows

The harrow is intended for mixing the topsoil (for uniform fertilization, moistening or aerating the soil) and bringing it into a homogeneous state (removes the crust on the ground, breaks clods, removes weeds). On the official website of the manufacturer of motoblocks Neva, one official model of the harrow is presented.

Harrow BD 850M (cultivator)

The harrow breaks large pieces (lumps) of soil into smaller ones, thanks to which the soil additionally absorbs moisture and oxygen. These two factors are indispensable for growing crops.

The harrow is equipped with 8 stainless steel discs. They are interchangeable and, if desired, old ones can be easily changed to new ones. The discs are sharpened at the factory using a special technology, thanks to which they do not become dull over a long period of operation.

Disks are mounted on the axle. These axles are mounted on heavy-duty Teflon bearings.

The furrow angle can be changed depending on the conditions:

- A slope of 10° is used for aggressive furrowing;

- A slope of 15° is used for standard furrowing;

- An inclination of 20° is used for soft furrowing.

If hard rock is being processed and the discs slip, then a weighting agent can be used to sink them into the ground. For this, there is a special well-thought-out platform on top.

To achieve maximum furrowing results, two furrows connected in series can be used. In this case, the first unit dumps the earth inward, and the second outward.

Is it possible to make a harrow with your own hands?

If desired, the harrow can be assembled independently, there is nothing complicated in this design.

The easiest way is to make a toothed harrow. It is slightly less efficient than disk, but the device is much simpler.

To do this, you only need a square pipe, teeth and bolts.

It is necessary to cut the pipes and connect them to each other at an angle of approximately 30 °. And at the place of their connection, insert the teeth and fasten them with bolts.

To connect to a walk-behind tractor, you can use an ordinary chain or make a clutch device using an ordinary metal pipe.

But only this design will often jump out of the ground, it needs to be additionally weighted with something. The ideal solution to the problem would be cinder blocks or any heavy metal structures. But you should not overdo it, because the connecting elements must withstand the weight of the entire structure.

Video review

The video shows the manufacturing process of such a harrow:

And here is a video of the harrow in action and the result of the work done:

What the owners say

And here are a few opinions of people who have already worked with harrows on Neva walk-behind tractors.

![]() Alexey writes:

Alexey writes:

“I decided to make the harrow myself, because its design was intuitive to me. Therefore, after a little brainwashing, and gathering information on the forums, I was able to do it without any problems. All that was needed was the pins and pipes for their fastening. Simplicity is the key to success)

Weights

Weights are used to give the structure more weight. This is necessary in cases where the equipment "jumps over" the soil and works intermittently.

Weighting agents can be both for the walk-behind tractor itself, and for attachments to it.

Weights for motoblock Neva

The official manufacturer offers to buy weighting on his website. They are of two kinds.

Load-weighting agent "Neva" Load-weighting agent

The first are made in the form of disks, they are designed to weight the wheels or axles of the walk-behind tractor. The discs improve soil-catching properties, the weight of one disc is 10 kg.

The latter are made in the form of a cylinder, which is attached only to the pin of the walk-behind tractor. Thus burdening its frame, the weight of one such cylinder is 17 kg.

But do not immediately buy a weighting agent. It's not a piece of equipment, after all. Its task is to weight the structure. Maybe you just have a cinder block, a metal dumbbell or something else weighing about 10 kg at home? So just hang it on a walk-behind tractor, and the result will be the same.

But these manipulations should be carried out correctly, because otherwise there is a high risk of the weighting agent jumping off the mount and causing injury to a person.

Video reviews

Here is an example of how you can make and install a weighting agent for the Neva walk-behind tractor yourself:

And this video talks about how to properly install the disk weight directly on the wheels themselves for the Neva walk-behind tractor: