Water deep pumps for home plumbing. Which Grundfos water pump is suitable for home plumbing. Which pump to choose - manual or automatic

It is not often possible to organize the inclusion of a private house, cottage or cottage in the centralized water supply system. Usually their owners have to decide on an autonomous water supply system for their homes.

But, even if it is possible to connect to a city or village water supply system passing near the house, having an independent source of water on the site is not a bad idea both from an economic point of view, for example, using it for irrigation, and as a guarantee against sudden shutdowns of the central system.

The autonomous water supply system of a private house consists of several components:

- water source:

- - artificial working-mine dug to collect underground groundwater in the surface aquifer to a depth of 10 ~ 15 m and reinforced from shedding.

- . They are performed by drilling and are of several types:

- Non-pressure: "on sand" - up to 50 m, "on limestone" - up to 150 m.

- Artesian- over 150 m.

- Abyssinian and etc.

- artificial reservoirs. Tanks for collecting melted, rainwater. With a nearby spring or spring, you can organize a deep diversion of its channel.

- natural reservoirs. Streams, rivers, lakes.

When designing an autonomous system, the first question that arises is the selection of a pump for the water supply of a private house, as one of the most important and, if we talk about the quality of work and durability, the most expensive part of hydraulic equipment. AND its choice is determined, first of all, by the type of water source on the site, and then - the selected water supply scheme.

Structural differences

Hydraulic pumps are of the following design types:

- Piston. Now they are practically not used for small pumping stations due to bulkiness, low efficiency, low life resource.

- Centrifugal. One of the most popular and in demand due to the simplicity of design, economy and high reliability.

- Turbine. Similar to centrifugal, but not with a lateral, but with an axial arrangement of the blades. More powerful and productive. They are mainly used in industrial hydraulic structures.

- Rotary or so-called screw pumps. They differ in small dimensions in diameter, therefore they are most suitable for lifting water from wells.

- Vibrating or membrane. Cheap but inefficient. Known for a long time produced for summer residents models "Brook", "Kid".

Views by type of accommodation

According to the method of placement, water supply hydraulic pumps are divided into two classes:

According to the method of placement, water supply hydraulic pumps are divided into two classes:

- surface type. Located away from the source of water, it is sucked in through a pipe lowered into a well or well.

- Submersible. Fully descend into the water to a certain depth.

Sometimes in a separate class allocate pumping stations, which in fact are a compact self-sufficient water-pressure complex, consisting of a surface pump, a storage membrane tank-hydroaccumulator, and a control circuit.

Which is better to choose?

Before choosing a water pump for your home, you should compare the advantages and disadvantages of their two main types:

| Surface pumps | Submersible |

|---|---|

| Installed permanently. Easier to maintain. | For repair and maintenance work, they require lifting from a well or well to the surface. |

| They need two pipelines: suction and discharge. | They work only for injection. |

| The maximum suction height is 10 m. The real one, taking into account losses in the pipeline and the margin for lowering the water level in the well, is no more than 7~8 m. | Climbing from a depth below 10 m. |

| They need to be filled with liquid before the first start-up or after repair work. | Ready to go immediately after diving. |

| There is a danger of the motor overheating during prolonged operation. | The pump immersed in water is cooled both by external water from the outside and pumped from the inside. |

| The need for conservation for the winter for the summer version of the water supply. | For the winter it is enough to drain the water from the system. |

| Work is noisy. | Noiseless. |

Thus, it is easier to use a surface pump or pumping station to lift water from a well, and a submersible rotary or centrifugal pump from a well.

Calculation example

The main necessary data for choosing a suitable model of a surface pump for water supply at home:

- Maximum flow rate in l/min or m³/h.

- Suction lift- the difference between the levels of the inlet pipe of the pump and the surface of the water in the source.

- Delivery height- the difference between the levels of the highest point of the pipeline and the outlet pipe of the pump.

- Initial pressure, for a non-pressure well or well equal to atmospheric.

- final- the required pressure in the domestic plumbing system.

- Pressure loss in pipelines depend on the flow rate of the liquid and the quality of the surfaces of the inner walls of the pipelines, which create friction for its movement.

Suction height of surface type hydraulic pumps cannot exceed 10.33 m- the height of the water column, which creates equal atmospheric pressure.

To simplify calculations it is rounded up to 10 m, and the pressure created is equated to one technical atmosphere, 1 at = 1 kgf / cm², or approximately 1 bar ~ 0.98 at.

The discharge height, or head, is determined technical parameters and power of the unit.

Often the value of pressure is confused with pressure, calling one another. These quantities are equivalent, but not exactly equal to each other. The pressure at the outlet of the pump depends only on its technical characteristics, and pressure - from the totality of external conditions: flow rate and flow rate of the liquid, its temperature, height above sea level, etc.

When calculating all system pressures in pascals, bars, atmospheres and other units lead to equivalent head values in meters.

Let's give an example, taking the geodetic level of the pumping station as zero:

- The fluid flow provided by the hydraulic pump is 40 m³/h. This is quite a sufficient value of consumption for the needs of the household.

- The water level in the well is below zero by 4 m.

- The highest point of water rise is 15 m above it.

- The total losses in the inlet and outlet pipelines can be found in the tables for a specific type of pipe, but they are usually calculated based on the fact that for every 10 m of the pipeline, 1 m of pressure is lost, therefore we will take them equal to (15 m + 4 m) / 10 = 1 .9 m

- The final pressure at the top point is assumed to be 1 bar ~ 9.87 m.

The total pressure of the hydraulic pump will be equal to:

4 m + 15 m + 1.9 + 9.87 = 30.77 m.

If the water pumping station is installed not in a caisson located next to the well, but in a house, you should also take into account the pressure loss along the length of the supply pipeline.

For each pump there is an operating characteristic, showing the pressure drop depending on the flow and having something like this:

When choosing a specific pump model, you should calculated values of parameters with passport values for the selected implement instance at the desired operating point.

The hydraulic power of the pump can be found by the empirical formula:

P (W) = 2.725 x Flow (m³/h) x Head (m).

For our example, we get: 2.725 x 40 x 30.77 = 3.354 kW.

For more information on the calculation and selection of a pump for the water supply of a country house, see this video:

Inclusion in the water supply system

As stated above, more convenient to install and operate ready-made pumping stations, the technical characteristics of which are suitable for the water supply of a small house for a family of 2~3 people or a summer house.

Connecting them comes down to a few simple steps:

- Choice of location.

- Preparing a solid foundation.

- Bringing the necessary pipelines.

- The suction pipe lowered into the well must be equipped with a strainer and a check valve. It should be lowered to a depth of not more than 1 m from the surface of the water.

- Connecting the electrical network and protective grounding.

Attention! All water electric pump units must have protective grounding or zeroing, without which their operation is unacceptable. Connecting them to the power switchboard must be done through the RCD and the maximum current machine.

Weaknesses of pumping stations and major breakdowns

Industrially produced pumping stations, or so-called self-priming pumps, attract:

- affordable price, less than with a separate purchase of all components;

- compact size;

- ease of installation and maintenance;

- readiness for operation immediately after purchase.

However, there are also disadvantages in their use:

- Suction lift limited to 7~8 meters. It can be increased by a couple of meters by placing the unit in a recessed caisson next to the well.

- The need to equip a special insulated soundproof room.

- Small hydraulic accumulator capacity 20~50L.

- Noise at work.

Malfunctions of pumping stations can be caused by the following reasons:

- A sudden power outage is often accompanied by water hammer, which can cause irreparable damage.

- Pollution and poor quality of water lead to increased wear of the blades of the centrifugal hydraulic pump and siltation of the tank.

- Inconsistency of operating conditions with technical parameters.

For example, one of the common breakdowns is associated with excessive water consumption when the frequency of switching on / off the station significantly exceeds the passport. This leads to a rupture of the membrane in the accumulator tank.

For example, one of the common breakdowns is associated with excessive water consumption when the frequency of switching on / off the station significantly exceeds the passport. This leads to a rupture of the membrane in the accumulator tank.

At the same time, the station cannot create the required pressure in the system and the frequency of switching on increases even more. Checked by pressing the nipple on the back of the tank: if water leaked from there, the membrane needs to be replaced.

Another common malfunction is a breakdown or incorrect adjustment of the pressure switch, which leads to continuous operation of the station without shutdowns.

The relay is regulated by two springs of different sizes. Large set the lower threshold, and small - the difference between the upper and lower.

Residents of city houses or apartments rarely think about the fact that, approaching or simply opening it, they include in the work perfected for its creation by centuries of scientific discoveries, inventions and engineering solutions. huge and complex system of extraction of water resources, their delivery and distribution.

Those who have to create such a system in miniature for their home truly value the value of this truly irreplaceable source of life - water.

When purchasing suburban housing or a summer cottage, almost all owners face the problem of the lack of a central water supply. To solve this problem, wells are drilled, but even if you find an artesian well on your site, you will not be able to provide the house with water. For normal life, a home pumping station is installed, thanks to which water rises to the surface, passes through filters and is fed into the house.

Is it possible to get by with just a pump?

When there is a source of water on the site, you need to choose the right equipment to ensure that it is lifted and transported to the house. The most common way to do this is to install a submersible water pump for wells. The principle of its operation is that it will start and supply liquid with each use of plumbing fixtures. If the water in the source is below the level of the pump or a power surge occurs, the unit will not turn on and the liquid will not flow to the plumbing.

To make your stay outside the city more comfortable and equip a permanent water supply, a household pumping station will help, consisting of a pump and a tank for accumulating a spare volume of water. If the unit is unable to pump water from the well, the water pumping station will connect the membrane tank to the water supply.

What is the advantage of the station

In addition to the fact that the kit (factory or assembled) includes a storage tank, a pumping station for private use contains a surface unit, not a submersible one. This makes it possible to draw water even from a source of small diameter. It is only necessary to lower a pipe with a check valve into the source, and forward movement to the surface will begin. This is true for cottages, in cases of inappropriate drilling of a large well.

In temporary residences, where there is no need for a constant and large volume of water, it is recommended to use household stations.

If water enters only 1-2 points of intake or only for irrigation of the site, it is worth drilling a well-needle. Only a surface unit is also mounted in such a source, since a conventional submersible simply will not enter (the smallest diameter of the downhole unit is 8 cm). Such household pumping stations for water supply a strong pressure to the pipeline even to the second floor of a country estate.

The principle of operation of pumping stations: pumping water as needed into a special tank - a hydraulic accumulator

However, in addition to the obvious advantages, water supply pumping stations also have disadvantages, which consist in installing devices in rooms where the temperature does not drop to negative values, and systematic maintenance. The water pumping station can pump water from a well up to 8 meters deep. However, there are units equipped with an ejector, which gives them the ability to pump water from great depths.

Types of water supply installations

When you come to a specialized store for a pumping unit for a private house, you will certainly meet with a variety of their types. What is the difference between devices?

According to the type of water absorption, household water pumping stations are classified:

Remote ejector devices

Pumping liquid from a depth of 50 meters. In this case, the ejector must be lowered into the source. The low noise level of the unit allows it to be placed in the house. If the water source is located deep, this type of station becomes indispensable. The weak point of the device is sensitivity to impurities, as they clog and spoil the ejector. It is also worth considering that the deeper the well, the lower the throughput of the installation.

Stations with built-in ejector

Pumped only from a depth of up to 8 meters. Can be used for contaminated fluid and sand wells. The main disadvantage is high noise, so they are mounted in caissons or extensions.

By storage type

According to the type of liquid supply, a pumping station for private use is equipped with a storage or membrane tank. In the first case, the tank is mounted in the upper part of the house, the pump pumps liquid into the tank, and from it the water flows through the pipeline. The advantages of such a system include efficiency, since they turn on only when the tank is empty to a certain level. However, the installation has much more disadvantages - low water pressure in the pipeline, the risk of flooding the house, large overall dimensions.

Today, hydraulic installations are more in demand, that is, equipped with a membrane tank or a hydraulic accumulator. Such systems are small-sized and can be installed in basements or separate outbuildings, since the pressure in the accumulator is regulated. The installation also has disadvantages: a small supply of liquid in the membrane tank and such an installation costs more.

By installation method

Pumping stations for water supply according to the type of water intake source are:

- Surface - a water pump for supplying liquid is installed at the top, and a pipe attached to it is lowered into the source. Such a mechanism is easier to control and maintain. Such a system should be installed if water is taken from a depth of eight meters or less.

- Submersible models are more economical and easier to install, but also more expensive. Such a unit has a waterproof housing and is completely immersed in water.

How not to make a mistake when choosing a system?

Having decided to install a pumping unit for a country house, many find it difficult to choose the right equipment. What should be emphasized? When choosing a system, it is necessary to take into account the following technical characteristics:

- Pump power - as a rule, is in the range from 0.6 to 1.5 kW. They are selected depending on the number of water intake points, the distance from the well to the pump and the volume of water that enters the well per unit of time.

- System performance - is selected taking into account the productivity of the source specified in the documents. For a private house, a unit with a capacity from 3000 l / h to 6000 l / h can provide a continuous supply of water, and for a summer residence 600 -1000 l / h.

- The volume of the storage tank is selected based on how much spare water will be needed in case the electricity is turned off or the liquid rises in the source fails.

- The accumulator material is cast iron, plastic and steel. The most affordable are plastic, but they have a short service life. The best option in terms of price and quality is steel containers.

- Protecting the system from overheating and idling - its presence in the device will significantly increase the price, however, with increased fluid intake, this is justified. Controlling the idling and elevated temperature of the device involves stopping the device in the absence of fluid in the well and saving the device from damage.

- Control method (automatic, remote or manual) - thanks to automatic control, the station turns on without additional intervention when the storage tank is empty and stops when the tank is full. This is an additional convenience for uninterrupted work in private homes.

Household pumping stations for summer cottages, when liquid pumping is needed only seasonally, preferably with manual control.

Pumping stations for water supply at home and summer cottages are simply indispensable for ensuring a comfortable life. Such devices are used for irrigation, and for the operation of sewerage systems, and for providing residents with drinking water. When solving fluid supply issues, it is important to make the right choice, otherwise a mistake can turn into a loss of comfort, money and time.

VIDEO: Calculation of a pump for water supply

Weaknesses and frequent breakdowns

As mentioned earlier, factory-made household water pumping stations have a large number of advantages:

- the price, which in the case of the purchase of the whole set will cost less than when buying each element separately;

- compact dimensions, allowing you to install it anywhere;

- simple installation and easy maintenance, unlike submersible models that have to be pulled to the surface each time;

- ready for use immediately after purchase - nothing needs to be separately assembled or twisted.

But there are a number of disadvantages that put users in a difficult position regarding the choice:

- low height of the water column (no more than 8 meters)

Some users come up with a way out by digging a caisson to install equipment.

- the room where the device will be installed must be insulated - in frost -15 ° C it simply cannot be started;

- insulation of pipes running along the surface on the same grounds is required;

- the maximum capacity of the accumulator is 50 liters;

- noisy work.

And if the shortcomings are rather conditional and easy to fix, then breakdowns must also be taken into account before choosing.

- In the event of a power outage, a water hammer follows, usually critical enough for the installation.

- The quality of water from a well does not always meet the standards, which leads to failure of the blades and pollution of the storage tank.

- Water consumption is not up to standard. The device passport provides for a certain number of on / off cycles. If this indicator is exceeded by 50%, a membrane rupture in the accumulator follows.

It is easy to check the health of the membrane - press the nipple on the back of the accumulator. If there is a leak, it needs to be changed.

- Failure of the pressure switch, which increases the number of on / off cycles. This, in turn, leads to rupture of the membrane (see above).

In apartments, people don't think much. How exactly does the water come in? It is enough to open the tap and it is already flowing. In a private house where a well works, everyone knows the price of water and what difficult work needs to be done to ensure its uninterrupted flow.

VIDEO: Water supply station. Main malfunctions, causes and recommendations for selection

The simplest classification of water pumps can be built on the basis of the position of the unit relative to the water source. And according to this principle, the range of pumps can be divided into two groups:

- A segment of submersible units, which will include pumps lowered into a well or well.

- A segment of surface units, which will include pumps that come into contact with water through an intake pipe.

Moreover, within the segment, structural differences between the units are minimal. But between themselves, submersible and surface pumps differ a little more than completely. Therefore, further in the text we will consider each type of pumps in more detail.

Submersible pumps for wells and wells

Such pumps "dive" directly into the source. Therefore, the diameter of the cylindrical body of such units ranges from 90 to 150-200 millimeters. That is, a submersible pump can be placed in a well with a ring diameter of 90-100 centimeters and in a well outlined by a 10-cm casing pipe.

At the same time, water intake is possible both from shallow depths - 7-9 meters, and from a deeper level - 30-40 meters. The pressure of the unit (the height of the water column pushed to the surface) ranges from 20-40 to 80-100 meters. But here it must be borne in mind that every 10 meters horizontally is equal to one meter vertically.

Structural differences of submersible pumps concern only the design of the aggregate part. Such equipment is powered by a centrifugal or vibration mechanism for pumping water. At the same time, centrifugal pumps provide good performance, pumping hundreds of liters of water per minute, and vibration units can get liquid from the greatest depth and do not respond to the degree of contamination of the pumped medium.

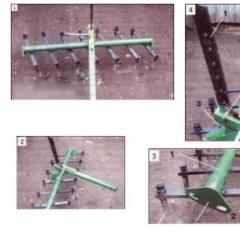

Installation of the submersible unit takes place according to a simplified scheme. We simply lower the pump into the water well (or into the well), hanging it in the shaft on a stainless steel cable. In practice, this operation looks like this:

- You unpack the pump and connect a pressure pipe to the outlet fitting, through which the liquid will flow. The length of the pipe is equal to the depth of the well minus half a meter - the unit will “float” at this level. The pipe diameter is selected according to the pump passport.

- Next, you unwind the power cord and attach it to the intake pipe with polymer zip ties, which you can buy at a "computer" store. The length of the power cord in branded models is usually equal to the pump head. Therefore, you will not have problems with the outlet.

- After that, you need to fix the pump on a cable, which is threaded into special ears in the upper part of the unit housing. And the mount must be secure. Therefore, it is supplemented with a bolt clamp or simply “riveted” the free end of the cable in a copper tube.

- The next step is to fix the cable on the console laid across the neck of the source shaft.

- In the final, you lower the pump into the shaft, holding it only by the cable. Manipulations with the pipe or power cable are strictly prohibited!

At the same time, you need to understand that the pump "sank" in the well not forever. It will have to be removed to the surface to clean the working chamber or during the disinfection of the walls of a well or well.

As a result, it can be argued that submersible pumps will be useful to both owners of shallow wells and owners of artesian wells. Moreover, the performance of such a unit is sufficient for pumping liquid over a fairly significant distance - up to 100 meters. In addition, a submersible pump can work for a long time: after all, the body of such a unit cools the water of a well or well. Therefore, submersible pumps work longer than surface units.

If you own a deep well, a considerable distance from home, then the submersible pump will be the ideal option for a pressure unit for your autonomous water supply.

Surface water pumps and stations

Such a pump is mounted in a caisson (a well above a well or well shaft), a building above a source, a basement of a house or an extension to it. It is not recommended to install surface pumps in the house itself (or rather, in the residential part of the building) - they are quite noisy during operation.

Water intake, in this case, is possible from a depth of 8-16 meters. Moreover, only pipes with an ejector are immersed to the bottom mark - a special nozzle that increases the pressure in the intake branch. Without an ejector, the pump will only lift water from a depth of 5-6 meters. Therefore, surface pumps and stations are sold either with a built-in ejector or with an external (remote) unit. Well, if this device is not included in the package, then you can always buy it separately.

The strength of the surface pump is the physical accessibility of the unit. The connection of the pumping station to the water supply and the well / well is carried out on the surface. Therefore, you can clean the working chamber even without dismantling the plumbing fittings. Even a child can replace filters.

The weak side of surface units is complicated commissioning. The pump can only be started when the suction pipe is full connecting the working chamber and the well.

As a result, when installing surface pressure equipment, it is customary to adhere to the following procedure:

- First prepare the supporting surface. A small podium is poured on the floor, and a special bracket is mounted on the wall.

- Next, the pump or station is installed on a support surface remote from the power source (socket) by the length of the cord. Moreover, a typical pump is equipped with a two- or three-meter cable. Fixation of the equipment is carried out with the help of bolts, laying anti-vibration pads between the base and the supporting surface.

- After that, you need to connect a tee with a vertical outlet closed by a shut-off valve to the pump inlet. When starting the pump through this valve, you will have to fill the suction pipe and the working chamber of the unit.

- To the free side branch of the tee, a filter is mounted in a glass housing. Moreover, the filter element may need to be changed frequently. Therefore, its body must be collapsible.

- A coupling accepting the intake pipe is connected to the free outlet of the filter. And since most external pipes are made of plastic, the coupling must be either a crimp or welded with a metal insert.

- The intake pipe is led out to the shaft of a well or well along a trench, after which it is lowered into the well, provided with a sinker - a rubberized ball. The immersion depth of the intake tube cannot be more than 8-10 meters. Well, at the end of the intake fittings, before immersing it, you need to install a strainer and a check valve that prevents the water from draining back into the well after the pump is turned off.

If the pump is equipped with an external ejector, then it must be installed in front of the filter and the check valve, connected to the pressure pipe of the unit by a separate pipeline. Therefore, two pipes go from such pumps to the well - an intake line (through which water is pumped to the surface) and pressure fittings (through which pressure is supplied to the ejector). Of course, this somewhat complicates the installation, but the performance gain covers all these inconveniences.

As a result, we can say that surface pumps will be of interest only to owners of shallow wells or wells punched to the second aquifer. But given the simplicity of the installation process and easy maintenance, these units are no less popular than their submersible counterparts.

Pumps that increase the pressure in the water supply

In addition to submersible and surface pumps in domestic water supply systems, you can find another type of unit - a pressure booster pump. Indeed, with a sufficiently branched network, one can observe a lack of power of the main pressure equipment, unable to push the required volume of liquid through the pipes.

In this case, the pressure "rescues" the booster pump for the water supply - a circulation unit that cuts into the pipeline in front of the central or intermediate manifold.

At the same time, such a pump is mounted only in tandem with a storage tank that accumulates a supply of water necessary to “accelerate” the pressure. Otherwise, the working chamber of the pump will fill up with air very quickly, and the device itself will burn out. That is why such "amplifiers" of pressure must be used with great care.

The installation process of a booster pump is obscenely simple: you simply cut the unit into the pipeline behind the manifold using a pair of valves and adapter fittings. The pump is fixed to the supporting wall using standard clips. That is, you cut the pipe, mount fittings on the free ends to which you attach the valves, and connect the ends of the fittings to the inlet and outlet fittings of the pump, orienting the unit in the direction of fluid flow in the pipeline.

Let's summarize. If you have a deep well, buy a submersible pump. If you have a shallow well, buy a surface unit. There is not enough pressure - purchase an additional device to increase pressure. That's all the secrets.

One of the primary issues in the arrangement of a private house or cottage due to its remote location from the central water supply is water supply. Most owners of cottages or country houses, when choosing household water pumps, are faced with the problem of a wide variety of pump devices for supplying water directly to plumbing fixtures in the house. What should be the best pumping station for a summer residence or a cottage?

It provides the ability to pump water into the house from any available source: a river, a well, a well, a central water supply. A pump for domestic water supply will provide a constant required pressure in an autonomous water supply and an uninterrupted supply of water to plumbing fixtures. Let's look at the principles that should be followed before choosing a pump for water supply to a summer house or a house.

The design and principle of operation of water stations

Before choosing a pump for water in a private house, it is worth studying its design and the principle of operation of an automatic pumping station.

So, automatic pump stations for home and summer cottages consist of the following nodes:

- pump;

- hydraulic accumulator;

- control and automation groups.

For its uninterrupted operation in a summer cottage, an uninterrupted supply of electricity is required. The device itself is autonomous and does not require additional third-party intervention: water is supplied at constant pressure - there are small differences, but they are so small that they are not felt by either the equipment or the consumers.

The best pumping stations are equipped with hydraulic accumulators, which are a cylindrical container, which is divided into two parts with an elastic membrane. One of the parts of this container is filled with gas at the factory. A certain pressure is created in this chamber.

When the electric pump is turned on, water enters the second part of the accumulator. With the gradual filling of the container, the membrane is stretched, the gas in the second part is compressed even more. Thus, pressure is created in the water supply system of a summer house or a private house. Its control is carried out by means of pressure relay sensors. When the extreme value (about 2-4 atmospheres) is reached, the sensors give a signal to turn off the pump.

When the taps in the plumbing system are closed, the pressure is stable and the pump does not work. As soon as a tap is opened somewhere, water begins to flow into it from the accumulator. As the water flows, the pressure in it decreases. As soon as the pressure reaches the lower mark of its limit, the second sensor turns on, giving the command to turn on the pump and the water begins to fill the tank again, thereby equalizing the pressure.

After the tap is closed, the water pumping station for the well or well continues to work for some time, after which it turns off. Due to the stable pressure in the system, it is possible to connect any household appliances to the water supply - a water heater, a washing machine and a dishwasher. If necessary, it can also be included in the automatic watering system of the site or lawn.

The internal design of individual pumps also has its differences. It is from this factor that the noise level during operation depends:

- Vortex. Suction occurs due to the blades, which are located inside the body. These pumping stations for providing water to the house are quite quiet or even almost silent. But they can only lift water from a shallow depth. They are recommended to be installed in residential buildings due to the fact that this equipment is extremely sensitive to temperature changes, and when freezing, it can even break completely.

- Centrifugal pumps create a fairly high noise level during operation, but have such significant advantages as lifting water from a sufficiently large depth and insensitivity to temperature changes, thanks to this quality, a centrifugal device can be installed in specially equipped rooms.

Most of the stations that are supplied by manufacturers already assembled are equipped with surface pumps. They are mounted on the same frame with a hydraulic accumulator and a control group. The pump is equipped with a pipeline descending into the water source. The advantage of this option is that it is possible to use a pumping station for a private house even in rather narrow wells, where the pipe diameter can reach 32 mm, which is the norm even for the narrowest well. But such a system can lift water from a depth of about 7-10 meters.

For a deeper well, a submersible pump or an installation with an external ejector will be required. In this case, the ejector must be lowered into a well or well by connecting two hoses to it. The rest of the device remains on the surface. With this type of system, water can be raised from a depth of about 40-45 meters. The disadvantage of this system is the sensitivity to the presence of air in the hoses (pipes), which is why starting the system is a rather responsible and troublesome task.

What to look for when choosing?

Before choosing the type of pumping station, you should definitely take into account several conditions in which the installation will operate. Given these nuances, equipment is selected that can provide uninterrupted water supply.

The main parameters of the pumping station that affect its operation are:

- electric motor power;

- station performance;

- maximum storage capacity;

- the height to which the station can raise water.

At the same time, it is worth remembering that the manufacturer indicates the limiting capabilities of the station, which in no case will coincide with the actual required parameters. For example, the passport indicates the value of 3 m3 / h. This characteristic indicates the maximum possible volume of pumped water; at the moment this value is reached, there will be no pressure.

Or a maximum head parameter of 40 meters is indicated, which indicates that the water supply source is at the level of the pumping station, while water flow is not provided. Under these conditions, the pump will give the indicated pressure value, but will be absolutely useless.

In order to obtain accurate data on the relationship between flow rate and pressure at the pressure of the pumping station, it is recommended to use the data in the tables and graphs indicated in the equipment passport. As a rule, the manufacturer indicates the true characteristics of the pump, giving the consumer the opportunity to choose a water pump with matched parameters for specific purposes.

You can also choose a pump housing. The materials for its manufacture are stainless steel, cast iron, and high density polypropylene. The polypropylene housing is quite cheap, while it is not susceptible to corrosion and does not transmit noise during operation. But even with increased density, you should not forget that this is plastic, and if handled carelessly, it can be easily damaged (for example, during transportation).

Second in price is a steel casing, but in combination with a centrifugal pump, this casing transmits noise and even sometimes resonates. So the working process of this pump is characterized by an increased noise level.

A similar pump operating in a cast iron housing is noticeably quieter. But in acidic water, cast iron is subject to a high level of corrosion, which is not a positive quality: usually the iron content in water is already in excess. The case made of stainless steel can be considered the best, but its price is correspondingly the highest.

Rating of the best water pumps for a private house

Usually, water consumption in a country house is characterized not only by domestic needs, but also by irrigation of a personal plot. Sometimes water is taken from sources with a high content of various impurities in the form of sand grains or other suspensions, given this feature, it is strongly recommended that an additional filter be installed at the inlet.

In the case when it is necessary to operate the station in a permanent residence, then you will need to choose a completely different equipment. Which will significantly affect its cost.

In order to realize an uninterrupted supply of water in a country house with a large volume consumed and maintaining a stable supply, equipment with improved parameters is used. Of course, their cost is much higher, but the benefits received are more than worth the money spent.

TOP 10 pumping stations for a country house or cottage:

- NeoClima GP 600/20 N (Russia-China) - from 5600 rubles

- Quattro Elementi Automatico 801 - from 6000 rubles

- AL-KO HWF 1000 - from 6200 rubles

- GARDENA 3000/4 - from 9990 rubles

- JILEX Jumbo 60/35 Ch-24 - from 8500 rubles

- JILEX Water cannon PROF 55/90 House - from 25,000 rubles

- VMtec Altera Auto 5/5 - from 27,000 rubles

- Wilo HMP 603 1 - from 29,000 rubles

- Grundfos CMB-SP SET 3-47 (PM 1-22) - from 29500 rubles

- Espa Tecnoplus 25 4M - from 75,000 rubles.

Pay attention to how much this or that pump for water costs.

The choice of the intended unit directly depends on the water supply system being created and the conditions of its operation. Small country houses and an irrigation system are quite capable of getting by with inexpensive models that can provide an initial level of water supply.

In order to provide a reliable water supply system with a stable water supply for a dwelling with permanent residence of people, it is recommended to pay attention to the presence of an automatic operating mode in the selected unit, which is able to maintain a constant water pressure with the specified parameters.

How to install pumping equipment?

When installing a pumping station, you must follow the installation rules.

For the operation of the pumping station, it is mandatory to supply electricity. This is one of the main criteria during the installation site: it would be better to mount the station near the power supply, or the most successful solution would be to extend the power line from the source to the station installation site. But besides this, there are some nuances:

The equipment must be installed taking into account the distance over which water can be supplied. If you plan to use the system in the winter, then the room where the unit will be installed will need to be insulated - household pumping stations for the house and cottage are extremely negative about frost. In addition, the room must be provided with good ventilation to prevent the accumulation of condensate.

If the pump makes a loud enough noise during operation, and its installation is most convenient in the house or not far from it. In this case, to prevent this inconvenience, it is recommended to enclose it in a soundproof box.

Often the most successful solution is the construction of a caisson - a small room, equipped at a depth of 2.5 meters. In the case of water intake from a well, the casing pipe is cut slightly above the bottom of the caisson. A self-priming or conventional pumping station is lowered into the well, supplying water to the accumulator.

The equipment must be mounted below the freezing depth of the ground, this will help prevent it from freezing: inside the temperature does not fall below zero. Due to this factor, it is also more convenient to lay pipes below the freezing level, and to carry out their output already under the house in a non-freezing zone and supply water to the comb.

If for a house where people constantly live, the arrangement of a caisson is a justified cost, then for a summer residence it is very doubtful. In this case, they equip a simplified version: they make a small box or pit, where they install a water pump for a summer residence or a private house for the spring-summer period, and in winter, taking it to a heated room.

Before purchasing a pumping station that best suits your parameters, it is recommended to study the technical data of the pump, expansion tank, and in addition to this, the equipment installation conditions - in this case, the operation of the system will not be interrupted by unforeseen malfunctions, and the water supply will be stable and uninterrupted.

(18

ratings, average: 4,03

out of 5)

Water is considered to be the main natural resource. Despite the fact that the age of advanced technologies is now outside the window, not everywhere it is possible to use the central water supply. The best solution in this situation is an autonomous water supply using a pump. Water pumps for domestic plumbing transport water under pressure.

Water is considered to be the main natural resource. Despite the fact that the age of advanced technologies is now outside the window, not everywhere it is possible to use the central water supply. The best solution in this situation is an autonomous water supply using a pump. Water pumps for domestic plumbing transport water under pressure.

To date, the domestic market has various types of water pumps, differing not only in production and operational capabilities (power is especially important), but also in the price range.

It is quite difficult for an ordinary consumer, inexperienced in this matter, to make the right choice due to the huge variety of modifications. The water pump is in particular demand and popularity among the owners of summer cottages, suburban areas or owners of private houses. Using the pump, it is possible to pump water from reservoirs nearby to the site for economic and domestic needs. This device helps to effectively solve the problem of watering the garden, while saving time and physical strength of a person.

Varieties of water pumps

A huge variety of existing models, you can conditionally divided into 2 main categories:

- household (used on their own sites);

- professional (used on an industrial scale in production).

When buying a water pump for the home, it must be remembered that the functionality and productivity of the purchased equipment must correspond to the working conditions and tasks.

Based on parameters such as operating conditions and location relative to the water source, the pump can be:

- submersible;

- surface.

At the heart of the productive activity of pumping devices, regardless of their modification, the general principle is used. During operation, a vacuum is created, as a result of which the liquid is sucked into the vacuum chamber and, under high pressure, is pushed out of the tank into the pipeline, heading to the end user. The force with which the liquid will come out depends on how much pressure is present in the central system. Its indicator must be high enough so that the water can easily overcome the hydraulic resistance.

At the heart of the productive activity of pumping devices, regardless of their modification, the general principle is used. During operation, a vacuum is created, as a result of which the liquid is sucked into the vacuum chamber and, under high pressure, is pushed out of the tank into the pipeline, heading to the end user. The force with which the liquid will come out depends on how much pressure is present in the central system. Its indicator must be high enough so that the water can easily overcome the hydraulic resistance.

Structurally, water supply devices can differ significantly from each other, depending on which mechanism is used to create pressure in the device, the device for pumping liquid is made in the following variations:

- centrifugal;

- vortex;

- vibration.

Each of the above types has its own advantages and disadvantages.

Centrifugal equipment

The centrifugal water pump is actively used both at the household level and for water supply on an industrial scale. Functioning is carried out due to the creation of centrifugal force inside the apparatus, under the influence of which the liquid begins to move. The power plant, rotating the blades and wheels, first draws in water, and then pushes it through the outlet into the central line.

The use of quality materials in the manufacture of pumps guarantees the final product excellent operational capabilities, reliability, practicality and high performance. Such centrifugal equipment can work continuously for a long time. Special engineering solutions are implemented in their design, so the equipment can be safely used in the most aggressive climatic conditions.

The indisputable advantage is ease of maintenance, affordable price range and good efficiency. However, in addition to the positive aspects, it is also necessary to note the disadvantages that are inherent in centrifugal devices.

The following deserve special attention:

- air entering the pipe stops the pump;

- voltage drops affect the continuous and stable operation of the device;

- Before each start-up of the pump, its body must first be filled with water.