Neva mb 1 reviews. Motoblock Neva with attachments to help the gardener. Common breakdowns and methods for their elimination

With a mass of 75 kilograms, the MB-1 walk-behind tractors are highly maneuverable and easy to operate. Their main purpose is the cultivation of land plots with medium-heavy soils (mainly loam, including those that have not been cultivated for a long time). The unit of this line will be useful in small, especially reclaimed, areas.

Neva MB-1 is equipped with four engine options:

- MB1B MA (RS950)- The 4-stroke power unit "RS950" of the American company "Briggs & Stratton" has a maximum power of 6.5 hp.

- MB1B-6.0FS- here is the motor (of the same brand) "I / C6.0" with a power of 6 hp. and equipped with an electric starter.

- MB1N MA (GP200)- here is the Honda GP200 engine, which has a power of 5.8 hp.

- MB 1C-6.0- the fourth modification is equipped with a 6-horsepower engine from Subaru.

Among the advantages of all these power units are quick starts, including in cool weather, stable operation throughout the entire rev range and economy.

The engines run on 92nd and 95th gasoline (the capacity of the fuel tank is enough to process several acres of land).

The maximum speed of a walk-behind tractor placed on a support wheel or aggregated with a trailer can reach 11 km / h.

The difference between "MB-1 MA", from other modifications of this line, is the "MultiAGRO" reducer - an own development of the engineers of the manufacturing company. Thanks to him, the walk-behind tractor has an extended set of gears: three front ones at once. For some types of work, a second set is provided, which is connected by rearranging the belt on a two-strand pulley. Due to the rich choice of gear ratios, it is possible to choose the optimal mode of operation of the unit for any task.

We note the convenient control of the walk-behind tractor with the help of a simple but functional steering wheel. It also has a gear lever. The steering wheel is adjustable both in height and angle of rotation.

The set of attachments with which the Neva MB-1 can be used is extensive. When cultivating the plot, the working width is adjustable from 86 to 127 centimeters. The plow can cultivate the earth to a depth of 20 centimeters. Hiller, potato digger, mower, and other equipment are also available. As an additional option, you can purchase a support wheel, which greatly facilitates the work with a walk-behind tractor.

A trolley with a carrying capacity of up to 500 kilograms is connected to the MB-1 through an adapter. The procedure for hanging, as well as replacing wheels with cutters, is simple and not labor-intensive.

The walk-behind tractor will also cope with cleaning a small area from snow - for this, a snow blower, a brush and a blade are included in the list of attachments.

There is a complete set with a powerful headlight for work in the dark.

In the Russian market, Neva MB-1 walk-behind tractors in 2017 are offered at a price of 36,500 rubles.

With the advent of spring, all summer residents begin to think about their allotments of land. There are so many things to do before planting a new crop: dig up the ground, remove all the weeds that have already grown, remove all the garbage accumulated over the winter, and much more. If the land area is large, then it will be very difficult for one to cope with all the work that needs to be done. The Neva walk-behind tractor MB 1 will come to the aid of the owner - a modern unit capable of much.

Motoblock - what is it ...

Motoblock is a very good thing for the economy. Need a device that can help you perform almost all earth operations? Motoblock "Neva" MB 1 will help with this. What then is this miracle machine? A walk-behind tractor is similar in nature to an ordinary mini-tractor, only the design is somewhat different. Both the tractor and the walk-behind tractor are designed for a different amount of work, but the principle remains the same.

What is a walk-behind tractor capable of?

In order to somehow make their lives easier, people began to slowly replace manual labor with mechanized labor. Motoblock "Neva" MB 1 will come to the aid of those who need it. Need to work on the ground? No problem. The technical characteristics of the Neva MB 1 walk-behind tractor allow it to dig up the ground, weed, hill up, work with a rake, remove weeds and do much more. Also, this device is capable of transporting heavy loads, such as water, working tools, fertilizers and more. It can remove snow and debris from the site, in general, do everything you need to maintain cleanliness and order in your country house. By purchasing a walk-behind tractor, a person saves money that could be spent on other similar, but inefficient devices. Motoblock "Neva" MB 1 - this is versatility and reliability, which helps in housekeeping.

The history of the Neva motoblock MB 1

Motoblocks have always been in demand. At the Krasny Oktyabr plant, the MB 1 unit is also produced. By the way, this enterprise is the all-Russian leader in the production of walk-behind tractors and agricultural machinery. "Neva" MB is a whole series of walk-behind tractors. MB 1 is the progenitor of all subsequent models and modifications (Neva MB 2, Neva MB 3, and so on).

Surprisingly, almost all domestic-made walk-behind tractors currently on the market are developments from the eighties. Since then, no new models have been released, only existing old ones will be improved.

In general, the Neva MB 1 and Neva MB 2 walk-behind tractors are very similar. In appearance, they almost do not differ. They only change the filling. The newer the model, the more efficient and powerful it is.

Motoblocks "Neva" have the marking "MB". What is "MB"? This very combination of letters is an abbreviation that stands for the word motoblock. Why put it on? In order not to confuse similar devices that are marked with MK, that is, motor cultivators. 1,2,3 is the number that defines the model itself.

For whom is a walk-behind tractor demanded?

Mechanized labor is always more efficient than manual labor, so it’s better to purchase a MB 1 walk-behind tractor for your summer cottage. You can’t dig a field on such a unit, but a large garden is not a problem for him.

It is difficult to dig up twenty to thirty acres of land alone, but with such an aggregate it is still easier. A six-strong Neva MB 1 walk-behind tractor is enough to dig this entire garden.

Motoblock "Neva" MB 1: safety instructions

After buying for joy, do not forget about simple safety rules. The unit must be handled with care so as not to cause any injury or serious damage.

Motoblock "Neva" MB 1: instruction manual

When working with a walk-behind tractor, it is best to always follow the instructions and try not to bring it to a malfunctioning state. Due to the lack of engine cooling as such, the Neva MB 1 walk-behind tractor very often overheats. The operating instructions say that on too hot summer days it is best to simply turn off the engine for a while. This will help him somehow avoid harmful overheating.

Also, high-quality oil should always be filled in, because the unit itself plows in very difficult conditions. Many rubbing parts will simply wear out very quickly and become unusable if there is a lack of oil or its marriage.

Motoblocks of old brands, developed and produced in the 80s, to which Luch MB-1 belongs, are distinguished by the maximum simplicity of design and the elementary nature of all engineering solutions. This, of course, very far from ideal, light agricultural machinery was still made of very strong and high-quality steel. And it is distinguished by amazing reliability and durability (which cannot be said about most modern walk-behind tractors). "Luch MB-1" is a device on which you can cultivate your garden for almost a lifetime. With proper care, the number of breakdowns and repairs is minimized.

The Luch MB-1 motoblock is in the same line with several more modifications of such equipment, which differ only in names, but are very similar both in appearance and in the design of all parts and assemblies. And the factory index is the same for everyone - “MB-1” (there is also an absolutely identical version, which differs only in the shape of the fuel tank - “MB-5040”).

Names for their products were chosen by manufacturers, many of which belonged to the military-industrial complex and the aviation industry. The manufacturer of the Luch MB-1 walk-behind tractor was the Sverdlov Perm Production Association "Motorostroitel" (now - JSC "UEC" Perm Motors "), a manufacturer of aircraft engines.

The eighties and nineties of the twentieth century became the time for this plant when its products "descended from heaven to earth." The line of manufactured equipment was replenished with new models of gas turbine equipment designed to work as part of gas pumping units of compressor stations of main gas pipelines, gas turbine power plants.

And also, in the light of the general "fashion for conversion" - consumer goods, among which, since 1985, there was Luch MB-1. In previous years, it made no sense to produce walk-behind tractors in the Soviet Union: there was no market demand for them. Personal gardens were plowed and cultivated by collective farm tractors, either free of charge or for a moderate fee. There was always a lot of gasoline and diesel fuel on the farms, and they cost mere pennies. The years of the destruction of the former system of agriculture throughout the country - the second half of the 80s and all of the 90s - became the time for the spread of production and the use of domestic walk-behind tractors.

The main products of the plant "Perm Motors".

At present (more precisely, since the beginning of the 2000s), Luch walk-behind tractors and other non-core "small" equipment have been removed from the lists of products manufactured by the Perm plant: it again makes only turbojet aircraft engines and industrial gas turbine mechanisms. This is also an all-Russian trend: the production of walk-behind tractors was abandoned everywhere at such enterprises.

However, many of the Luch MB-1 walk-behind tractors sold in the last century are not only in working condition, but also work season after season without serious breakdowns; pass from hand to hand, are considered a familiar household helper for families from different regions of Russia and the CIS. Not every mechanism is able to demonstrate such durability in use.

The design of this technique is so universal that analogues of the Luch MB-1 walk-behind tractor are still produced by the Chinese, as well as several enterprises in Russia, which, under the guise of their own production, make these walk-behind tractors from the same Chinese parts and components.

Motoblock "Luch MB-1" is a compact, relatively lightweight unit for tillage in household plots and gardens, as well as for some other agricultural work. It is as simple as possible in design and quite convenient to use. Maintenance and repair are also not something complicated, requiring special knowledge or training. It will be enough just to read the instruction manual. Spare parts are available and inexpensive.

Initially, the Luch MB-1 walk-behind tractor was equipped only with a soil cutter-cultivator designed for loosening and turning the earth. But, complete with other additional attachments purchased separately, this walk-behind tractor can not only cultivate, but also plow light "garden" soils; harrow; cut and clean furrows, hill up and weed rows; dig up potatoes and other root crops; mow; transport goods.

The compatibility of the walk-behind tractor with additional mounted implements is good, but when using them with the MB-1, of course, you must carefully consider the instructions set out in the instruction manual for each mounted implement. The powerful and economic four-stroke engine allows to use the motor-block in various economic works.

Structurally, this walk-behind tractor consists of the following main parts: engine; clutch mechanism; reducer; handles with controls; two tire wheels (or four cultivators). About the engine details - later in the text. the clutch mechanism is designed to transfer the energy of the crankshaft torque from the engine to the gearbox and consists of two belts; forward pulley; reverse pulley; drive pulley; reducer pulley, rods; forward and reverse levers, and springs.

The gearbox is designed to change the gear ratio and transfer the rotational energy from the gearbox pulley to the wheels and working equipment. The chain reducer consists of two body halves; chains; switching shaft; shift knobs; three blocks of sprockets and an output shaft.

The controls located on the handles are used to change the engine operating modes and the direction of movement of the walk-behind tractor. They consist: in fact, from the steering wheel; motor control lever; gear shift knobs. The steering wheel is attached with four bolts to the reducer squares, and it is equipped with height adjustment.

The engine control lever is screwed to the right handlebar, which is connected by a cable through a lever and a spring to the throttle valve of the regulator. On the left handle of the steering wheel, on top, there is a forward lever, which is connected to the forward pulley through a linkage, chain and spring. And below, on the same left handle, there is a reverse lever, which is connected through a chain, rod and spring to the lever on which the reverse pulley is installed. The transmission provides operation in 2 forward and 2 reverse gears.

The wheels on the Luch MB-1 walk-behind tractors are both pneumatic and molded rubber, size - 4.00 × 10 ″. The outer part of the tread, most often, is made in the form of a traditional "Christmas tree", and when installing such wheels on a walk-behind tractor, they must be placed at the corners forward. And to get the best results when plowing, hilling and digging up root crops, it makes sense to replace rubber wheels with metal ones with lugs. Instead of wheels, a cultivator can be installed on the output shaft of the gearbox.

The walk-behind tractor is equipped with a DM-1 engine. This is a four-stroke single-cylinder air-cooled carburetor gasoline engine with a working volume of 316 cubic centimeters and a power of 3.7 kW (5 horsepower). Piston diameter -76 mm; piston stroke - 70 mm. Engine lubrication system - by splashing and in the oil sump; ignition system - non-contact, electronic, with a candle "A17B" (AII-I GOST 2043-75).

Start is carried out by the built-in manual starter. The direction of rotation of the crankshaft is counterclockwise (view from the side of the crankshaft pulley). The permissible tilt angle of the engine is no more than eight degrees.

The arrow indicates the screw for adjusting the fuel supply to the carburetor of the Luch MB-1 walk-behind tractor.

Modern Chinese analogues of the MB-1 are equipped with Lifan, Lianlong, Vanguard, Briggs & Stratton engines. As well as the KADVI 168F-2A engine (Kaluga Engine), which is produced in Kaluga from foreign components and is similar in its technical characteristics to the DM-1. In general, for its time, the DM-1 was a very progressive engine option for compact agricultural machinery. Many walk-behind tractors of those years were equipped not with four-, but with two-stroke engines.

The engine oil should be changed after the first five hours of operation. Then - every 25-30 hours of operation. For the engine of the Luch MB-1 walk-behind tractor, automotive mineral motor oil for carburetor engines is suitable. The oil in the walk-behind tractor transmission is changed every 100 hours of operation.

The transmission of the Luch, like all old walk-behind tractors, is worm-toothed. This is the simplest option, but it is he who is the most reliable and durable.

The clutch on the walk-behind tractor is manual, with driving V-belts. Transmission from the engine to the gearbox (forward and reverse), and from the engine to mounted implements - V-belt. Chain reduction gear: I gear - 1:17, II gear - 1:7.

Specifications in numbers

- The mass of the walk-behind tractor is 100 kg.

- The speed of movement is from 3.6 to 9 km / h.

- Overall dimensions: length - 1.5 m; width - 60 cm; height - 1.15 m.

- Ground clearance - 140 mm.

- Working track width - 570 mm; transport track - 310 mm;

- The minimum turning radius is 1.1 m.

- Traction force - not less than 100 kgf.

- The width of the equipment cultivator is adjustable, from 725 to 1200 mm; diameter - 360 mm.

- The average fuel consumption is from 1.5 to 2 liters of gasoline per hour.

- The volume of the fuel tank is 3.6 liters of fuel.

GENERAL REQUIREMENTS

The MB-1 walk-behind tractor is designed to work on household plots with light soils in gardens and vegetable gardens for individual use on hayfields located in fine-grained forest and swampy areas in the suburban area.

The walk-behind tractor is small in size and easy to operate. The powerful and economic four-stroke engine allows to use the motor-block on various agricultural works. Complete with attachments, it can plow, loosen the soil, harrow, make and clear furrows, hill and dig up root crops, mow grass, spray plants and irrigate, transport goods and remove snow.

Working on a walk-behind tractor does not require special training, but it should be borne in mind that certain skills are needed when working with each attachment.

At the factory, the walk-behind tractor is equipped with a cultivator, which is designed for loosening and turning the soil. When using other attachments for the walk-behind tractor, you must follow the additional instructions set out in the instruction manual for each attachment.

TECHNICAL DATA

Engine DM-1 ...... Four-stroke, single-cylinder, gasoline

Engine power, kW (l. e.),not less than ..........3.7 (5)

crankshaft speed, min-"........... 3200

Piston diameter, mi......76

Piston stroke, im ........ 70

Working volume, cm 3 ...... 316

Engine lubrication system....splash and oil sump, us:.) M10GI or M12GI TU 38 10148-75

Ignition system ....... non-contact, electronic, spark plug A17B or AII-I GOST 2043-75

Cooling system ...... forced, air

Starting system ........ built-in manual starter

Power system ....... carburetor, gasoline L-76 GOST 2084-77

Direction of crank rotationshaft ........... counterclockwise (view from the sidecrankshaft pulley)

Permissible angle of inclination of the engine, deg., not more than ..... 8

Chassis

Reducer .......... lowering, chain 1st gear 1:17, 2nd gear 1:7

Gear lubrication system. . . splashing in the oil sump.transmission oil according to GOST 23652-79 (TAD-17I, TAP-15V, etc.).

Transmission from engine to gearbox(forward and reverse) . . . V-belt

Transmission from engine to attachmentstools ......... V-belt and from the output shaft of the gearbox

Clutch ..........manual, V-belt drive

Wheels...........pneumatic, 4.00x10"

Motoblock weight, kg, no more. . . 100safety requirements

During all adjustment, installation and other work with the walk-behind tractor, as well as when washing and cleaning it, the engine must be turned off (throttle control lever on the right handle in the “STOP” position).

Operate the walk-behind tractor only in accordance with this manual.

Rice. 1a, 1b: 1 - steering wheel; 2 - forward lever; 3 - reverse lever; 4 - casing; 5 - wheels; 6 - front handle; 7 - gas tank; 8 - air filter; 9 - silencer; 10 - engine; 11 - cultivators; 12 - starter; 13 - gearbox; 14 - bracket; 15 - gear shift knob; 16 - throttle lever; 17 - limiter; 18 - latch; 19 - wheel stopper; 20 - pin.

Not allowed:

1. Storage and transfer of gasoline and oil in an open container.

2. Smoke and use open fire in the room where gasoline and oils are stored and when working with them.

3. Start the engine indoors.

4. When cranking or running the engine, touch the ignition wire or spark plug elbow.

TRANSPORT AND STORAGE

When transporting; disconnect the wire from the spark plug. Carry the walk-behind tractor by the front handle and control handles. When carrying the walk-behind tractor must be in a horizontal position.

Drain gasoline from the gas tank and oil from the crankcase of the engine and gearbox during long-term storage of the walk-behind tractor and long-term transportation.

For long-term storage: lubricate all unpainted parts of the walk-behind tractor with protective grease, after washing them and drying them. Before starting work, wash off the protective grease, fill in oil and crankcase of the engine and gearbox and carry out all adjustment work according to the operating manual.

PREPARATION AND ASSEMBLY OF MOTOBLOCKS

Connect the tool holder with the pins. Connect the stopper (depth adjuster) using the lock inserted from the left side.

The height of the handles is adjusted by moving two vertical supports. The walk-behind tractor must be installed parallel to the ground.

Connect the clutch control rods to the control levers on the left handlebar. The forward drive link (A), which is longer, is attached to the upper arm. The reverse link is attached to the lower control arm.

The motor and gearbox are filled with oil at the factory.

ENGINE STARTING

Fill the gas tank with clean A-76 gasoline.

The engine is equipped with a special manual starter.

Make sure that you are at a sufficient distance from the rotating parts of the walk-behind tractor. Check that the power drive is disabled before starting.

1. Open the petrol cock.

2. Close the carburetor choke by turning its lever down to about a horizontal position.

3. Set the throttle lever to the middle position of the sector. Grab the starter handle and pull hard. If necessary, repeat these operations with less throttling. A warm engine does not need to cover the choke: set the throttle lever to the middle position, pull the starter handle.

4. After starting the engine, return. air damper to its original position.

To stop the engine, move the throttle lever on the right handle to the "STOP" position.

The movement is controlled by two levers on the left handlebar: forward - lever A, backward - lever B. When these levers are released, the walk-behind tractor stops instantly.

It is forbidden to press two levers at the same time, because the belts can burn out, the walk-behind tractor will fail.

If the clutch slips, it is adjusted by shortening the chain.

Change of speed of the movement is made by means of the throttle control handle located on the right handle.

The chain reducer has two gears high and low. I - all the way in - low gear. II - middle position - neutral position. III - all the way out - high gear.

Stir the large pulley by hand when switching the handle to the desired position.

Switching should be done with the engine switched off. Before starting the engine, the shift lever must be in the neutral position.

REMOTE THROTTLE CONTROL SETUP

Set the throttle lever to the "STOP" position. Loosen clamping screw A. Move shell B until throttle lever C touches the switch. The throttle lever must be in the "STOP" position. Tighten the clamping screw. Check the operation of the remote control by moving the throttle lever.

ADJUSTING THE CARBURETOR

1. Turn screw 1 at full throttle and screw 2 at low throttle as far as it will go.

2. Loosen both screws 1 1/4 turns.

3. Start the engine and warm it up.

4. Set the throttle control lever to the position corresponding to the minimum speed (before turning off the engine), set the minimum stable idle speed with screw 3.

5. Use screw 2 to set the maximum idle speed.

6. Use screw 3 to adjust the minimum stable idle speed.

7. Repeat the last two operations until a stable, trouble-free operation of the engine idling at the lowest possible speed is obtained.

8. Move the throttle control lever to the maximum engine speed position.

9. In case of interruptions in the operation of the engine, unscrew or tighten the screw 1 at full throttle until stable operation is obtained (the total unscrewing of the screw 1 from the fully screwed position should be no more than 2 3 / 4 turns).

AIR FILTER

The outer porous element B must be cleaned and oiled every 10 hours of operation or every day in dusty conditions.

Unscrew the top nut A, remove the cover B. Remove the porous element C from the dry element E. Wash the porous element in kerosene, gasoline or soapy water. Soak it in M12GI oil, squeeze out excess oil.

Wash dry element E in soapy water, then rinse with clean water. Air dry the element thoroughly. Assemble the air filter in reverse order.

The dry element must not be impregnated with oil.

OIL CHANGE

The oil level in the crankcase should be checked every 5 hours of operation. Install the engine horizontally. The oil level must be up to the level of the filling hole. Add oil if necessary.

Change oil after the first 5 hours of operation. To fill the oil, install the engine horizontally. Using a screwdriver, unscrew the filler plug. Pour oil into crankcase

M10GI or M12GI (capacity 1.3 liters). Close the cork. Then change the oil every 25 hours of operation. Start the engine

and warm it up. Unscrew the oil drain plug and drain it. Close the drain plug and fill with fresh oil.

Disconnect the wire from the spark plug before carrying out a repair or service operation.

1.5 liters of transmission oil according to GOST 23652-79 (TAD-17I, TAP-15V, etc.) are poured into the walk-behind tractor gearbox at the factory. Check the oil level before starting the engine for the first time and each time before operation. Tilt the walk-behind tractor so that the gearbox is in a horizontal position. In this position, the oil level should be just below the filler hole.

The gearbox oil is changed every 50 hours of operation, at the same time as the engine oil is changed.

CHANGING THE BELT

Remove the cover covering the belts. Dismantle the belt guide C. Loosen the guide roller B, remove the reverse belt A. When changing the forward belt D, loosen the two screws d,

holding the guide plate. Pull the plate back and remove the belt. Assembly is carried out in the reverse order. Do not overtighten the guide plate fixing screws as the motor housing is made of aluminum alloy.

The spark plug should be cleaned and adjusted every 100 hours of operation. The distance between the electrodes should be 0.5. . .0.6 mm. After cleaning, rinse the candle with gasoline or thinner.

CLEANING THE COOLING SYSTEM

To avoid overheating of the motor and its failure, it is necessary to regularly remove the fan housing and clean the motor fins from dirt.

FAULT IDENTIFICATION

The engine does not start.

Check:

Is there gas in the tank. Is there an air passage through the hole in the gas tank cap. Is the throttle working? Check the gap between the flywheel magnet and the stator, which should be 0.1. . . 0.15 mm. Is the spark plug damaged and connected.

The engine doesn't pull well.

Clean, rinse and dry the spark plug. Blow out the cylinder by turning the crankshaft several times with the starter. Set the candle in place. Check spark plug.

Check the cleanliness of the cooling system.

Adjust the remote control system to maximum speed.

INSTALLATION OF CULTIVATORS

Remove the wheels from the output shaft of the gearbox and install the cultivators in their place, locking them with locks. The cutting edges of the cultivators should be directed towards the movement of the walk-behind tractor.

OPERATION OF THE MOTOBLOCK WITH THE CULTIVATOR

Before starting the operation of the walk-behind tractor, it is necessary to carry out its adjustment. Poor or incorrect setting causes great fatigue for the worker and reduces the quality of tillage.

The walk-behind tractor with a cultivator must be installed parallel to the ground.

The setting of the cultivator includes the correct setting of the depth limiter, which is carried out after selecting the working depth of soil cultivation. The depth of soil cultivation in one pass is 10. . .15 cm. If deeper tillage is required, cultivation is carried out in 2. . .3 passes, each time increasing the cultivation depth. At the same time, the soil structure becomes more homogeneous - crumbly, without lumps. The cultivation of stony soil should be carried out with the maximum speed of the cultivator blades in order to avoid their breakage.

When working, the cultivator should move easily, without effort.

When processing loose soil, the depth limiter acts as a skid.

When cultivating hard soil, the working depth limiter acts as a brake and makes it possible to till the soil in layers.

Thanks to the powerful engine, soil cultivation can be carried out at a medium throttle position. When working, it is necessary to take into account the dependence of the throttle position and the use of high or low gear. When cultivating light soils, up to 8 cultivator blades can be installed.

ATTENTION!

It is forbidden for outsiders to be in the working area of the cultivator. When turning the walk-behind tractor with a cultivator, it is necessary to maintain the same distance to the knives as when moving forward.

It is forbidden to move the walk-behind tractor towards yourself.

When transporting a walk-behind tractor from site to site, it is necessary to remove the cultivators.

CONTENTS OF DELIVERY

|

p.p. |

No. of parts according to the drawing |

Name of parts |

Qty |

|

005.45.0100 |

| Motoblock | ||

|

Note: To facilitate packing and transportation, the following parts of the walk-behind tractor are dismantled and applied in a separate package. |

|||

|

005.45.0090 |

Steering wheel (with control levers) | ||

|

005.45.0103 |

thrust | ||

|

005.45.0103-1 |

thrust | ||

|

005.45.0140 |

Target | ||

|

005.45.0113 |

Earring | ||

REPLACEMENT KIT

SPARE PARTS applied to the walk-behind tractor

TOOL attached to the walk-behind tractor

|

p.p. |

according to the drawing |

Name, designation |

Qty |

|

D8-14-001 |

Socket wrench 19X22 | ||

|

D6-00-104 |

Key 18 | ||

|

Key 8X10 7811-0003 NS 1X9 GOST 2839-80 | |||

|

Key 10X12 7811-0004 NS 1X9 GOST 2839-80 | |||

|

Key 12X13 7811 0007 NS 1X9 GOST 2839-80 | |||

|

Key 14X17 7811-0022 HC1X9 GOST 2839-80 | |||

|

Screwdriver 1.2 X 6 7810 0969 X9 GOST 17199-71 |

General requirements. .....

Technical data.....

Safety requirements...

Transportation and storage.....

Preparation and assembly of the walk-behind tractor....

Engine starting.......

Remote Throttle Setting.

Adjusting the carburetor......

Air filter.......

Oil change.........

Belt change..........

Cleaning the cooling system.....

Troubleshooting.....

Installation of cultivators......

The work of a walk-behind tractor with a cultivator ....

Contents of delivery.......

Replacement equipment kit....

Spare parts attached to the walk-behind tractor.

A tool attached to a walk-behind tractor.

Hard rural work can greatly facilitate the Neva walk-behind tractor. The wheel mechanism for tillage is completed only with a cultivator. But a device with a powerful engine is adapted to work with mounted implements for cultivating the land, mowing grass, and even a cart for transportation.

Advantages of a walk-behind tractor

The spring working day in the peasant farmstead becomes almost round-the-clock. Heavy manual work on digging up the array for sowing takes most of the time. By the way, mechanical horses appeared - Mole, Neva and the like. In 2 hours on the Neva walk-behind tractor, you can dig up 10 acres of land, free up 3 days for others. The mole is small and nimble, even women's hands can do it, but it is low-powered, traction is rather weak. A gift for the villagers was a more powerful universal unit.

Motoblock Neva, is the brainchild of St. Petersburg machine builders. It was created at the Krasny Oktyabr-Neva enterprise. Manufacturers have created a simple, unpretentious all-weather machine for rural work. Engine power 5.5-7.5 liters. With. powered by reliable motors

- American model "Briggs & Stratton";

- "Honda";

- Subaru.

The walk-behind tractor is equipped with a double air filter, which makes the work more stable. When turning, the drive of one wheel is turned off and turned “on the heel”. The ability to use other tools for agricultural work makes the walk-behind tractor a universal assistant to the villager.

The walk-behind tractor is equipped with a double air filter, which makes the work more stable. When turning, the drive of one wheel is turned off and turned “on the heel”. The ability to use other tools for agricultural work makes the walk-behind tractor a universal assistant to the villager.

You can buy and repair the unit in the most remote regions. The price of the Neva walk-behind tractor is affordable even for people with a low level of income. There are 250 shops selling agricultural equipment and 160 service centers in the country. Online stores deliver purchased goods to any corner of the country using mailing lists. Manufacturers produce equipment with a guarantee, but 1% of the marriage is still inevitable, then the equipment is replaced or a unit is sent for installation. There are no problems with acquiring the necessary spare parts for the Neva walk-behind tractor.

Motoblock models

The first unit was assembled with a domestic model of the DM-1K engine. The cylinder liner of the engine was cast iron, which significantly increased the life of the motor. The development of heavy soils and even virgin lands was within the power of the apparatus. Until now, in the rural courtyard you can find the Neva MB-1 walk-behind tractor.

The modernized model of the walk-behind tractor is in great demand. Changes:

- installed gear-chain reducer;

- used imported engine;

- the ability to unlock the left wheel for easy turning on a small area;

- increased idle speed to 12 km / h.

The carrying capacity of the Neva MB-2 walk-behind tractor became 300 kg, and this made it possible to use a trailer cart. After the modernization, the walk-behind tractor began to be in high demand, despite a significant increase in cost. Experts appreciated the improvement in the performance of the model:

The carrying capacity of the Neva MB-2 walk-behind tractor became 300 kg, and this made it possible to use a trailer cart. After the modernization, the walk-behind tractor began to be in high demand, despite a significant increase in cost. Experts appreciated the improvement in the performance of the model:

- increase in the width of the strip processing in one pass;

- gearbox with gear shifting - 4 forward, 2 back;

- pulley for transmitting power to attachments;

- the presence of a steering wheel;

- increase in carrying capacity on a dirt road to half a ton.

The root tool that comes with the block is reciprocating cutters for loosening the topsoil. With an increase in power, their grip will double with a loosening layer depth of 35 cm. See how easy the Neva walk-behind tractor works in the video:

There are models MB-23 and MB-3. Model 23 performs the same functions as MB-2, but a 10 hp engine is installed. With. and the body became heavier. MB-3 is a light cultivator without attachments.

The first model has been discontinued. Which of the proposed assistants to choose a tiller depends on the area of \u200b\u200bthe land and the nature of the work.

The first model has been discontinued. Which of the proposed assistants to choose a tiller depends on the area of \u200b\u200bthe land and the nature of the work.

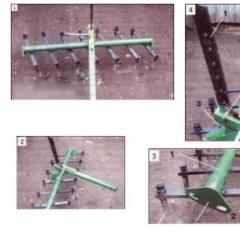

Various attachments for the Neva walk-behind tractor

Initially, the product is a frame structure. It is equipped with rubber wheels with deep and textured grooved tread for good grip on slippery surfaces. The kit includes saber cutters on the axle, which replace the wheels during cultivation. For year-round use, various attachments are offered for the Neva walk-behind tractor.

That is why the technique is called a block, with the help of sheds it replaces a hay mower and hiller, a cart for transporting up to half a ton of garbage, and in winter it turns into a snow blower. You can buy additional canopies one by one or in a set.

Mowers and lawn mowers

Using a mounted tool instead of a hand scythe will save time and effort. Depending on the profile and evenness of the site, a segmented or rotary mower is chosen.

Using a mounted tool instead of a hand scythe will save time and effort. Depending on the profile and evenness of the site, a segmented or rotary mower is chosen.

The segmented mower for the Neva walk-behind tractor is a frame equipped with shearing knives. Blades in the form of two plates with teeth receive an oscillatory movement from the drive and work like scissors, cutting grass in a horizontal area. Working width 110 cm, mower speed 4 km/h. When the technique will provide invaluable assistance

The device has hard alloy teeth and bites even occasional twigs up to 1 cm in cross section. For safety reasons, the instrument belt is covered with a casing. The canopy can be removed and installed quickly, and it will not be difficult to replace the toothed plate in case of breakage of the cutting device.

It is important to note that the mowing is of high quality even in uneven places, since the field is cleared in two passes. At the end of the console there is a skid that prevents the mechanism from lowering to the ground. Rotary mowers for walk-behind tractors are produced by several factories in the country, type KN 1.1.

The rotary mower for the Neva walk-behind tractor in rural areas has become more widespread. The device is a disk or two mounted on a frame in the center. When the cutting surfaces of the disk rotate, everything that gets in the way is demolished. The device is intended:

The rotary mower for the Neva walk-behind tractor in rural areas has become more widespread. The device is a disk or two mounted on a frame in the center. When the cutting surfaces of the disk rotate, everything that gets in the way is demolished. The device is intended:

- to mow a dense herbage;

- work on uneven surfaces;

- mow, overgrown with shrubs, inconvenience.

The cutting mechanism consists of 4 knives fixed on the disc with cotter pins. Knives come out of the disc slot under the action of torque, retract into place when stopped. Grass is laid in even swaths. The mower for the Neva walk-behind tractor of the Zarya type is equipped with two discs rotating towards each other. The cutting height is adjustable. But knives quickly become dull or fly out when they hit the terrain. The productivity of rotary tools is lower, the swath width is 80 cm.

For use in a summer cottage in crowded conditions, a mounted rotary mower Neva-KR-05 for a walk-behind tractor is more suitable. Equipment for its own walk-behind tractor is produced by the Krasny Oktyabr plant. The cutting width of only 56 cm allows you to tidy up the boundaries and mow tree trunks.

For use in a summer cottage in crowded conditions, a mounted rotary mower Neva-KR-05 for a walk-behind tractor is more suitable. Equipment for its own walk-behind tractor is produced by the Krasny Oktyabr plant. The cutting width of only 56 cm allows you to tidy up the boundaries and mow tree trunks.

The use of any type of mower imposes on the contractor the responsibility for the safety of others and his own. Therefore, it is necessary not only to check the strength of the attachment of the cutting tool and the tension of the belt, but also the condition of the mowing field.

Cans, stones and other foreign objects can damage the blades and cause injury to the mower. Care must be taken to remove children and animals from the risk zone. Work in closed clothes and goggles.

During operation, periodically check the condition of fastening and tension of the belts. If it is necessary to repair or replace the blade, knife, walk-behind tractor must be de-energized.

Why do I need an adapter for a walk-behind tractor

The adapter for the Neva walk-behind tractor is a frame structure with a towing mechanism. On top of it, a seat for an employee or a box for transporting goods can be installed. With front driving rubber wheels and driven rear wheels, a controlled self-propelled mechanism on 4 wheels is obtained. The minitractor can be used for various chores.

The adapter for the Neva walk-behind tractor is a frame structure with a towing mechanism. On top of it, a seat for an employee or a box for transporting goods can be installed. With front driving rubber wheels and driven rear wheels, a controlled self-propelled mechanism on 4 wheels is obtained. The minitractor can be used for various chores.

Since the Neva walk-behind tractor has 2 hitches, a driver's seat is attached to one of them. Another node may be equipped with a hiller or other similar tool. Garden work can be carried out in more convenient conditions.

Varieties of the adapter include the AM-2 model, equipped with a special frame and a canopy mechanism with a lifting lever. The result is a mechanism with a driver, idling at a speed of up to 10, in the working position - 3 km / h.

Varieties of the adapter include the AM-2 model, equipped with a special frame and a canopy mechanism with a lifting lever. The result is a mechanism with a driver, idling at a speed of up to 10, in the working position - 3 km / h.

Other options:

- assembled dimensions - 1600*750*1270 mm:

- adapter weight - 55 kg;

- wheel track - 65 cm;

- clearance - 27.5 cm.

The APM-350-1 model is used as a seat, or another set of equipment is installed instead of a chair. And then the cultivation of the land can be carried out immediately with two hillers, two plows. It is on this adapter that the body mount is provided for the transportation of heavy compact units.

Okuchniki used in sheds to walk-behind tractor

The most time-consuming work is cutting furrows for planting and growing plants. A hoe in the hands of a gardener is a universal tool. Okuchnik for the Neva walk-behind tractor was created before other mounted implements. The difference between the disk and plow hiller used in the canopy lies in the principle of their operation. The hiller, created from shaped parts connected to each other as an arrow, makes it possible to break up the soil on both sides with a sharp end with an oval through a curved profile. Distinguish devices:

The most time-consuming work is cutting furrows for planting and growing plants. A hoe in the hands of a gardener is a universal tool. Okuchnik for the Neva walk-behind tractor was created before other mounted implements. The difference between the disk and plow hiller used in the canopy lies in the principle of their operation. The hiller, created from shaped parts connected to each other as an arrow, makes it possible to break up the soil on both sides with a sharp end with an oval through a curved profile. Distinguish devices:

- unregulated;

- adjustable;

- Dutch.

The non-adjustable hiller is a design with a fixed working width. This is the simplest device that creates uniform camber during operation due to fixed wings. Such a hiller can work on furrows where the planting was carried out taking into account its profile. Such a tool works in furrows up to 30 cm wide and is unable to hill rows of potatoes. Canopies are used with light cultivators, on bars up to 12 mm thick. The device is energy-intensive due to its profile, it is used on moderately moist soil. On a powerful walk-behind tractor, its use is unjustified.

The non-adjustable hiller is a design with a fixed working width. This is the simplest device that creates uniform camber during operation due to fixed wings. Such a hiller can work on furrows where the planting was carried out taking into account its profile. Such a tool works in furrows up to 30 cm wide and is unable to hill rows of potatoes. Canopies are used with light cultivators, on bars up to 12 mm thick. The device is energy-intensive due to its profile, it is used on moderately moist soil. On a powerful walk-behind tractor, its use is unjustified.

Hillers with variable grip are the most common tool in private farmsteads, since the principle of its operation resembles a chopper. This tool can be rebuilt for any row spacing. A double hiller is also used. When passing, part of the soil rolls over into the furrow again, making the ridge lower. However, it regulates not only the collapse, but also the depth of hilling.

The Dutch type hiller is a compromise between the first and second options. The stroke height and narrow furrow are obtained by raising the flaps to the desired height. When folded, they are almost double. Rise, like the wings of butterflies scoop. Due to the high wing, the earth does not fall into the furrow, the crest is high.

The Dutch type hiller is a compromise between the first and second options. The stroke height and narrow furrow are obtained by raising the flaps to the desired height. When folded, they are almost double. Rise, like the wings of butterflies scoop. Due to the high wing, the earth does not fall into the furrow, the crest is high.

For the Neva walk-behind tractor, the disk hiller is considered the best canopy. Two disks installed at a certain distance are set at the desired angle of run-off. The fastening system is verified, forming the desired row size and stroke height. Such devices cost several times more than winged ones, but they work more efficiently, and there is less load on the walk-behind tractor.

When working with a hiller, you should use a reduced speed and replace the rubber wheels with metal ones for better grip on the soil. After work, clean all fastening parts from the ground and coat with thick grease - lithol or grease.

The use of a potato digger with a walk-behind tractor

The principle of operation of equipment for collecting potatoes is based on the extraction of tubers from the ground and sifting. Harvesting is done by hand. For each pass of the walk-behind tractor, potatoes are removed from one row.

The principle of operation of equipment for collecting potatoes is based on the extraction of tubers from the ground and sifting. Harvesting is done by hand. For each pass of the walk-behind tractor, potatoes are removed from one row.

The potato digger for the Neva walk-behind tractor of the KKM-1 vibration type is used on light, dry soils with low humidity. At the same time, there should be stones in the ground less than 9 t / ha. The device consists of a cutting plowshare and a grid on which the earth is separated, and the potatoes remain on the surface. The device is single-row, with a capacity of up to 0.2 ha / hour. A strip 37 cm wide and 20 cm deep is captured, cut and passed through the grate. There are other modifications based on the same principle of vibratory screening of the undercut stroke.

The vibrating device called Poltavchanka has a similar effect. The potato digger has a larger grip, but a smaller recess. The device is designed to work in medium moisture and composition soil.

The vibrating device called Poltavchanka has a similar effect. The potato digger has a larger grip, but a smaller recess. The device is designed to work in medium moisture and composition soil.

Overview of the Neva walk-behind tractor - video