Home gas heating system. The scheme of heating a private house with a gas boiler. Single and double circuit boilers

When designing a country cottage, several engineering systems are laid down to provide the owners with the benefits of civilization. The question that worries everyone is the comfort in their own home, which is difficult to imagine without a stable operation of the heating system.

In urban conditions, heating of a dwelling is carried out in two ways, using central or autonomous (local) heating. For the vast majority of owners of suburban areas, only the second option is available, and all they need to do is choose the best method for heating their homes. Heating can be carried out in different ways, the most common of which is gas heating of a private house.

Gas boilers are easy to operate and maintain

Features of water heating: system requirements

The dominance of water heating in the private sector is explained by its advantages:

- System reliability. The process is ideally simple and debugged: the water heated from the boiler circulates in pipes in a closed circuit, gives off heat and returns back.

- Heat capacity (and heat transfer) of water. It is sufficient to efficiently and evenly heat a residential building. The rest of the coolants (including antifreeze) have the worst performance.

- Cheap. Water is a cheap and environmentally friendly coolant.

- Expensive installation pipeline.

- Constant flow funds for heating the system (and where is it not constant?).

- thermal inertia. The effect after turning on the water heating is not immediately felt (compared to air heating).

- Care. It is necessary to monitor the condition of the system: metal elements are subject to corrosion, heating radiators must be kept clean (dust reduces heat transfer).

- Features of functioning. Turning off the heating for the winter can lead to an accident (water will freeze and burst pipes). Summer cottage owners should consider replacing the water with antifreeze (or replacing the system).

If water flows from the tap, the system is not airy

Before the water runs through the pipes, giving off heat and uplifting, it must be heated. The heating method (type of heating) is selected based on several criteria:

- Availability of fuel (its price and the possibility of uninterrupted supply).

- The cost of installing the system (the cost of labor, equipment and materials).

- Maintenance and repair costs.

System Components

Before the start of work, a draft of the future heating system is drawn up. The heating scheme of a private house with a gas boiler takes into account the size and location of the building, on the basis of which the components are selected:

1. Heat generator

The type of heating system is determined by the selected fuel. Depending on the fuel used, there are:

- Gas boilers. Gas can be obtained centrally or create your own storage.

- Diesel.

Economical and reliable way of heating - gas boiler

- On solid fuel. The raw material is coal, firewood, peat, fuel briquettes or pellets (wood fuel pellets).

- Electrical. Electrolysis (electrode), induction devices, as well as boilers on heating elements are used.

- Combined. Popular options are combinations of gas with solid or liquid fuels.

- Universal. The design has several fireboxes for different types of fuel.

2. Pipes

Installation of gas heating in a private house involves the use of several types of pipes:

- Steel. There are ordinary and galvanized products that are connected both by welding and mechanical (threaded) method. Can cause an accident (rupture) if water is allowed to freeze.

- Polymer(plastic). They are not subject to corrosion, are silent, tolerate frost without problems. The pipes have a significant coefficient of thermal expansion and do not cope well with high temperatures (only metal pipes are suitable for arranging the chimney and piping the boiler).

Copper pipes in the distribution of heating a private house with a gas boiler

- Metal-plastic. Composite (multilayer) products, reliable and durable. Installation is carried out using fittings.

- Copper. They are not afraid of freezing because of their plasticity, they have high thermal conductivity (higher than that of steel products). Copper pipes are subject to electrochemical corrosion and are also expensive.

3. Expansion tank

Water has a significant thermal expansion (when heated to 90°C, its volume increases by 4%). If in an open (not sealed) system this is not critical, then in a closed (with forced circulation) it is fraught with equipment damage. In order not to spoil the system and compensate for the pressure in the pipes, an expansion tank (hydraulic accumulator) is built into it.

The expansion tank is a sealed steel (sometimes stainless) cylinder, consisting of two compartments. A flexible membrane is built between the compartments, separating the hot coolant and the pressurized gas.

Expansion tank action algorithm

4. Radiators

Manufacturers produce batteries for different heating systems; they differ in the material of manufacture (cast iron, steel, aluminum, bimetallic radiators) and in the number of sections. There are several types of heating radiators:

- Sectional. Old cast iron radiators and modern tubular steel varieties.

- Panel. All-forged steel, with heating and convection plates, on which the heat output of the radiator depends.

- vertical(towel dryer).

- Convectors.

- Underfloor heating systems.

5. Devices and accessories

The water heating system needs to be controlled. For this are intended:

- manometers;

- control and safety valves (shut-off valves and thermostatic valves).

The pressure gauge on the expansion tank monitors the pressure in the heating system

Gas heating: types of supply

There are two ways to bring gas to the house - centralized and autonomous; The choice depends entirely on the location of the property.

- Main gas. Continuous gas supply is more functional and environmentally friendly, but not without drawbacks. Gas pipes are usually laid underground, which prolongs operation, but is more expensive. The remoteness of the gas pipeline also affects the cost of work; to coordinate the connection, it is necessary to prepare and coordinate a package of documents. The unreasonably long connection times and the high cost of work force us to pay attention to an alternative method of gasification.

- Gas holder. Under the big name is a storage tank for liquefied natural gas. When there is no main gas pipeline nearby, a gas tank will become the exit, the principle of operation resembling a huge lighter and suitable for any type of boiler. Autonomous gas heating of a country house is a frequent occurrence in Europe, where a thrifty owner would not even think of pulling a branch for several kilometers. A well-chosen gas tank (taking into account fuel consumption by the household) is replenished 2-3 times a year.

Gas tank - autonomous gasification

Advantages and disadvantages of gas heating

The use of gas as heating has many advantages:

- Price. Gas heating is beneficial due to the best price-performance ratio compared to other fuels.

- Safety. Thanks to automation, there is no need for constant attention to the process. The work is monitored by sensors, the task of the owners is to adjust the temperature in the house.

- Dimensions. The gas boiler has small dimensions, which allows it to be placed in a small room. A room for storing fuel is not needed (which cannot be said about firewood, coal or diesel fuel).

- Profitability. Modern gas boilers are able to heat large areas; some models (two-circuit) additionally supply hot water.

- Independence. The gas holder allows the household not to depend on utilities.

Economy of gas heating

- Environmental friendliness. Fuel is stored in a gas tank, combustion products go through the chimney (no need to remove the ash, there is no unpleasant smell).

Heating a house with gas has some negative points:

- The installation of boiler equipment operating on natural gas is coordinated with the Gaztekhnadzor service, which is accompanied by the preparation of a project, an agreement and the collection of permits (licenses).

- For the safe operation of the system, a separate room with good ventilation, a separate exit to the street and a chimney is required. You also need automation that monitors gas leaks. Open (atmospheric) burner systems are potentially fire hazards.

- A change in gas pressure in the pipeline can lead to boiler failure. Some models are adapted to such force majeure.

- Some systems require electricity.

Boiler room with an open burner needs a high chimney

Design schemes for heating a country house

Design features allow you to divide the heating wiring diagrams by type:

- Single and double circuit(one- and two-pipe). The scheme depends on the type of boiler; single-circuit is used only for heating, double-circuit is also capable of heating water.

- Passing and dead end. Varieties of two-pipe wiring. In the first case, the movement of the hot and cooled flows occurs in the same direction, and the water turnover time for each radiator (and their heating rate) is the same. The dead-end scheme assumes the oncoming flow of flows; at the same time, radiators located closer to the boiler heat up faster.

- Vertical and horizontal. Conditional division according to the position of pipes (risers) supplying water to radiators. For one-story private houses, a horizontal scheme is used. In dwellings with 2-3 floors, it is used if vertically located tubes do not fit into the design (horizontal ones are easier to hide).

Scheme of radiator heating of a two-story house; horizontal two-pipe wiring

Schematic diagrams of gas heating

Installing gas heating is a profitable solution for a country house. The connection of gas heating systems takes place according to two principal (suitable not only for gas) schemes:

With natural circulation

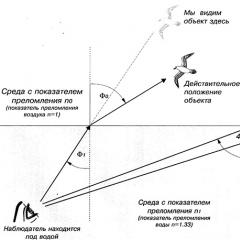

They are often referred to as gravity or gravity systems; the principle of operation is based on the physical properties of the coolant. Heated water has a lower density than cold water. The reverse pressure of the cooled liquid (passed through the pipes and gave off heat) displaces the hot liquid from the boiler. It rises along the heating riser, filling horizontal pipes and radiators.

Installation of heating boilers in a private house

In order for the system to work efficiently and the water does not stagnate, the installation of heating pipes is carried out with a slope of 3-5 °, and the boiler is installed as low as possible (for example, in the basement). The scheme has obvious advantages:

- Simplicity. During installation, it is necessary to fulfill only one condition - to organize the slope of the pipeline.

- Independence. The scheme with a gas heating boiler does not need electricity.

- Silence. The scheme does not include devices (circulation pumps) that create background noise.

- Practicality. The service life is 25-30 years without major repairs.

There are also disadvantages:

- Contour length limitation. For the system to function effectively, the length of the closed circuit should not exceed 30 m, which is feasible only in small houses.

- Service. Gravity structures are prone to clogging; periodic flushing is required.

Video description

About choosing a heating scheme in the following video:

With forced circulation

The circuit includes water pumps, forcing water to circulate forcibly. The pump circuit does not restrict the use of heating circuits; upper and lower pouring of the coolant, one- and two-pipe scheme are possible. The circulation pump is often installed in front of the boiler and allows you to do without the organization of the slope of the pipeline.

The main condition for a forced circulation circuit is an uninterrupted power supply for the entire heating period. The disadvantage of the system is its airing (usually at the beginning of the heating season).

Comparison of schemes with natural and forced circulation

Combined system

Combines the previous types, with its own characteristics:

- The wiring of metal pipes is mounted with a slope.

- The pump is connected using a bypass pipe (bypass).

If the power grid is intermittent, the heating of the house is due to natural circulation; the pump turns on if you need to quickly warm up the house.

Selection Options

The principle of operation of gas boilers is simple: when gas is burned, energy is released, which is accumulated by water, and then released in residential premises, heating them. There are several criteria that help evaluate the benefits of a particular model of a gas device. In addition to the manufacturer and the price of the device, most of the criteria are interrelated; this makes a comprehensive assessment possible.

When designing gas equipment systems for heating a private house, medium-sized boilers are often located in utility rooms

Power is a key factor in keeping the system running smoothly. When assessing the required power, the area and parameters of housing (ceiling height, number of windows), as well as winter temperatures at the location of the house, are taken into account. For normal operation (long and without breakdowns), the boiler must have a power reserve.

This parameter depends on:

- Place of installation. Specifies the instrument layout type. Wall-mounted (saves space) or floor-mounted (more powerful, reliable and expensive).

- Burner type. Open or closed. The design of the burner determines how the products of combustion are removed (natural draft chimney or forced ventilation).

- contours. The choice of the owners - whether the boiler will only warm the house, or also provide the family with hot water.

- Profitability. It depends on the efficiency of the boiler and for the latest models it is 90-95%.

Controller for heating system maintenance

- Equipment. The programmer (temperature controller) purchased together with the boiler can save 20-25% of heating costs. Operational safety can be improved with the help of additional elements: a flame sensor (if the flame goes out, the gas supply is interrupted automatically), a draft control sensor, a boiler blockage sensor (when the gas is turned off).

To select a suitable device according to the described criteria, you must:

- Determine the required power taking into account the size of the dwelling. On average, a consumption of 1 kW per 10 m2 is taken.

- If you need a double-circuit boiler(not only warm, but also provide hot water), a boiler is selected with a power margin of at least 25%.

- If power outages- a harsh reality, a device with mechanical automation is selected. In combination with natural circulation, you get a practical and reliable, if somewhat old-fashioned, system.

- If there are no electrical problems, a modern unit with electronic automation and forced (by default) circulation is purchased.

Video description

How to choose a gas boiler in the following video:

Purchase of a gas boiler

When buying, you should choose an organization that not only sells boilers and related equipment, but also installs them. This approach allows:

- Get expert advice not only when buying, but also when installing, debugging and operating equipment.

- Be confident in the quality of the boiler and its service (timely delivery of spare parts).

- Be sure that there are no problems with warranty service (which may appear if the installation was carried out by a third-party master).

Professional installation of gas heating - efficient operation of the system

The procedure for arranging a gas heating system in a private house

The procedure can be described as follows:

- Drawing up a project and its approval (when connected to the main line), conclusion of a contract with the installation team.

- Purchase of gas equipment (project requirements do not limit the choice of model).

- Installation of a gas tank or tie-in and connection to a common line.

- Installation and connection of the boiler.

- Trial run, technological checks.

Video description

About the installation of a boiler room with a double-circuit boiler in the following video:

gas fireplace

Many owners of country houses use a gas fireplace as an alternative to gas water heating; they find this method practical - the fireplace decorates the interior and saves money. The fireplace copes with the task if the housing area is small (up to 60 m2); it is mainly used as a source of additional or backup heating.

Gas fireplaces have a lot to offer - economy, convenient regulation and clean combustion

Buyers are offered fireplaces of different sizes, designs and types of installation (there are built-in, wall and island models). Structurally (automatics, burners) they coincide with gas boilers. Fireplaces, unlike the boiler, are located in the living room and directly heat the air; they meet high environmental and fire safety standards.

Gas heating of a private house is a modern way to ensure the comfort of the family; autonomous heating will allow achieving independence from accidents and preventive scheduled repairs of main networks. Particularly convenient are automated systems that monitor fuel economy, change the temperature according to a schedule and control the safety of the process.

When creating engineering communications for a country house, the most important point for any owner is the right choice of a building heating system. As heat generators installed in a dwelling, furnaces and boilers operating on solid and liquid fuels, gas and electricity are used. Today in Russia, gas heating of a country house is considered the most convenient and affordable, the options for which will be discussed in this publication.

Classification of gas heating systems

Natural gas is an energy carrier that is supplied to the consumer:

- under pressure through a centralized line;

- in a liquefied state, by filling specialized containers - gas tanks or cylinders.

In the first case, the gas flows through the central pipe directly to the switchgear, which equalizes the pressure between the domestic gas supply system and the main. Only after that, natural gas enters the dwelling directly to the heat generator. In the second variant, the gearbox plays the role of a switchgear. It is this device that equalizes the pressure between the container and the point of consumption.

Regardless of the type of system, the most popular among our compatriots is the following gas equipment for heating a private house: a gas heating boiler, a convector. Next, the design features, advantages and disadvantages of a centralized and autonomous heating system for a country house with natural gas will be considered.

Autonomous gas heating of a country house is used if the main gas pipeline does not pass near the building or the gas pressure in it is too low for the normal operation of heating devices.

Equipment

To store liquefied gas, you need to install a gas tank. It is a tank that is mounted underground. The underground gas pipeline transports fuel from the reservoir to the points of consumption.

If a temporary system of autonomous gas supply is assumed, then the ground location of the tank is also allowed.

Installation of a gas tank cannot be called a budget solution. That is why it is common in Europe to jointly install one underground storage tank for liquefied gas, which is used by several homeowners. In this case, the cost of installing the tank is reduced several times. For those who cannot afford the creation of a “blue fuel” storage facility in their backyard, the only option left is gas heating of a private house with cylinders filled with liquefied gas.

The operation of a gas tank with insufficient quality of its installation is extremely dangerous and harmful: damage to the tank can provoke a gas leak.

With an autonomous heating system, heating boilers with a specialized burner for liquefied gas, gas convectors and infrared reflectors are used as heat generators. The first, when burning fuel, heat the coolant, which, circulating through the system, gives off its heat to the air. Radiators are used to increase the heat exchange area.

Convectors are devices for local heating. The principle of operation of these installations is to heat the radiator, which gives off heat to the air in the heated room. To control the operation of convectors, thermostats are used, on which the upper and lower values are set for each heated zone.

Infrared reflectors are heating devices that reflect thermal radiation from heated ceramic plates. Therefore, infrared radiation heats interior items and, as a result, the room in which the device is installed.

Traditional heating scheme

Among Russians, the most popular is the traditional gas heating scheme in a private house, in which the boiler, by burning blue fuel, heats the coolant. Most often, ordinary water acts as a coolant, which moves through the system using a pump or natural draft. The principle of operation of such a system is simple: the boiler heats the water circulating through the heat exchanger. Further, through the pipeline, water enters the radiators. In them, the coolant loses some of the heat, after which it returns to the boiler and heats up again. The use of a pump allows more complex heating systems, such as the combination of underfloor heating with radiators. The figure below shows a standard diagram of a traditional autonomous heating system for a country house.

With natural circulation of the coolant, a simplified diagram of the heating system looks like this:

Regardless of the choice of one or another heating scheme for a country house, the calculation and installation should be carried out by professionals.

Advantages and disadvantages

The main advantage of autonomous gas heating is stable pressure in the gas pipeline, which cannot be said about main fuel. Heating the cottage with gas from cylinders allows year-round living in a country house with a high level of thermal comfort and full automation of the heating system and hot water supply.

Now, a few words about the shortcomings. Gas purchase costs. In economy mode, for heating a small two-story country house, 6-10 bottles of liquefied gas will be required monthly. And this, we repeat, in the mode of maintaining the temperature in the premises at 16 ° C from 23:00 to 5:00 daily; from 9:00 to 17:00 on weekdays. On weekends and in the evenings, the room temperature is kept around 22°C. The required amount of gas will be accurately calculated in the project documentation, based on the power of the heat generator and the consumption of "blue fuel".

If you have to use cylinders for gas heating, then for their storage it is necessary to allocate a separate room created in accordance with all fire safety rules, or make a fireproof, better insulated cabinet.

Central gas heating

The presence of main gas in a country house allows you to use it with virtually no restrictions. The only brake for the homeowner and the inhabitants of the house may not be the volume of the tank for storing blue fuel, but the size of the wallet.

As heat generators, as in the case of autonomous heating of a house, hot water boilers, a piping system, radiators and valves are used. The only difference between an LPG boiler and natural blue fuel heaters is the design of the burner. Most modern heating boilers are equipped with burners for burning both natural and liquefied gas.

Gas heating boilers differ:

- According to the installation method. Today, in the market of climatic equipment in a wide range there are floor and wall-mounted boilers. Due to the fact that floor-standing heat generators are not limited in weight, they are often equipped with a durable cast-iron heat exchanger. Wall-mounted units, as a rule, have less power, but are equipped with highly efficient heat exchangers made of non-ferrous metals or stainless steel.

- By functionality. Boilers are single-circuit and double-circuit. In other words: the former serve only to heat the coolant that is used in the home heating system; the second type of device is used for heating and creating hot water at home.

- By type of traction. In boilers with an open combustion chamber, the exhaust gases are removed by. The suction of air necessary for the combustion of fuel is carried out from the room. In heaters with a closed combustion chamber, forced draft is created through the use of an air turbine. All combustion products are removed, and fresh air is supplied through or a separate smoke exhaust system.

Today, convection and condensing gas heating boilers are very popular with the Russian consumer, the efficiency of which, unlike the usual 75%, varies at around 95-99%.

The structure of the gas heating system

Any gas heating scheme that involves the use of a liquid heat carrier includes: a heat generator, its piping, one or more heating circuits. The boiler piping includes the necessary shut-off valves, blast valves and an expansion tank, pressure or non-pressure. If the system is circulating, then the pump must also be included in the boiler piping. Directly, the contours can be made according to a single-pipe or two-pipe scheme.

A single pipe configuration is when the coolant bypasses the radiators in order from the installation. With this scheme, there is a significant savings in pipes, but it is almost impossible to achieve uniform heating of all rooms.

With a two-pipe configuration of the system, the heated coolant is simultaneously supplied to all radiators. When using such a scheme, it is possible to control and change the heating temperature in each room, through the use of mechanical regulators on each radiator.

With a two-pipe configuration of the system, the heated coolant is simultaneously supplied to all radiators. When using such a scheme, it is possible to control and change the heating temperature in each room, through the use of mechanical regulators on each radiator.

The figure shows a typical gas heating scheme for a two-story private house.

Advantages and disadvantages of heating a house with natural gas

The advantages of gas heating are obvious:

- Availability. Trunk gas in Russia is the cheapest fuel, even in relation to pallets and other types of solid fuel.

- The ability to create a high level of thermal comfort in the home.

- Environmental friendliness. In modern low-temperature boilers, emissions of fuel combustion products into the atmosphere are minimized.

- Efficiency. The use of modern heating devices allows increasing the efficiency of natural gas combustion up to 99%.

Despite the many obvious advantages of gas heating, there are also disadvantages. Gasification of a country house is a procedure that requires not only colossal financial, but also time costs. And this is only the cost of tie-in to the highway. Further, huge investments will be required for the calculations of the necessary regulatory device, which equalizes the pressure between the main and the household system; the creation of a competent strapping that disfigures the facade of the house, and other types of work. The cost of a gasification project for a private house can amount to tens of thousands of rubles and an unlimited time frame.

Despite this, gas heating is the cheapest and most trouble-free system that allows the owner to comfortably live in a country house and use "blue fuel" at any time of the year.

You can heat the room in different ways, but due to the significant economic benefits and if there is a central gas main near the house, heating schemes with a gas boiler are chosen. This method heats apartments, cottages and non-residential premises. There are several scenarios for the heating device: you can entrust the entire range of activities to one organization, perform some of the work yourself, or completely carry out heating on your own.

Characteristics of gas boilers and their varieties

Wall-mounted gas boilers can not only heat rooms, but also provide yourself with hot water for household needs. The fuel for them is natural or liquefied gas. Depending on the power of the energy source, it is possible to heat rooms from 30 to 300 sq. m. You can connect the device yourself, choosing the equipment taking into account the characteristics of a private house: the level of water pressure, the presence of underfloor heating, etc. The correct choice of the heating scheme will provide the optimal temperature for each room.

Gas boilers differ in purpose:

- Single-circuit. Perform only heating function. They are connected to the heating system to heat the coolant. Additional electric water heaters or gas water heaters are used for water heating.

- Double-circuit. They perform two functions: they heat the room and provide hot water supply, since an additional circuit for heating water is installed inside the devices. But it happens alternately. Priority is water heating, during which the heating is turned off. However, if the boiler is equipped with two heat exchangers, it can serve both circuits at once.

According to the method of combustion, boilers are divided into devices with an open and closed chamber. The former have a natural draft: they take the oxygen necessary for combustion from the room where the device is located. Therefore, they require equipping the boiler room with high-quality ventilation.

Devices with a closed combustion chamber have a special coaxial type chimney. It consists of two nested pipes. Combustion products are removed from the inside, fresh air is taken from the street through the gap between the pipes.

Boiler room - basic requirements

Gas equipment is a fire and explosion hazard, so in a private house it is necessary to allocate a separate room for its installation. With a boiler power of up to 30 kW, its size will be sufficient, about 8 cubic meters. m, from 30 to 60 kW - 14 cubic meters. m and above, the ceiling height is not less than 2.5 m.

In the boiler room, it is necessary to provide for a window with a window, a door with a width of more than 80 cm. Be sure to equip the supply ventilation, which provides a complete change of air about 3 times per hour in order to minimize the gas content in the room. The interior decoration is made of non-combustible fireproof materials with a temporary fire resistance limit of at least 45 minutes.

Strong refractory partitions are installed between the boiler room and living rooms. The layout should prevent the rapid spread of fire to residential premises. From the appliance to the floor, the distance is made at least 80 cm, to the ceiling - 50 cm, free space is left under the boiler, non-combustible material of 1x1 m is laid on the floor.

For exhaust, a chimney is installed. It is impossible to use ventilation ducts for this purpose, since the exhaust gases contain combustion products harmful to humans.

It will be easier to connect closed-type heating devices to the chimney with your own hands, as they are equipped with special coaxial pipes, which in private houses lead out through the wall to the street. The required thrust is created by a built-in fan, so the height of the suspension is not important. Open-type gas boilers are connected to an individual chimney made of materials that are resistant to high temperatures, mechanical wear, and the effects of combustion products. The chimney pipe is connected with a slight slope towards the heater.

Heating system diagrams

Before installing a heating device that uses gas, it is necessary to check the housing for compliance with technical conditions, to obtain permission from the relevant authorities to carry out work. Connecting gas heating includes the installation of gas pipes, tie-in to the central gas main, installation of the boiler itself, the chimney, connecting the power supply and checking the performance of the heating system.

The heating scheme of a private house with a gas boiler consists of the following elements:

- gas pipeline;

- radiators or other heating devices;

- heat source - gas boiler;

- additional equipment;

- stop valves.

If the system is with forced circulation, a pump is installed as an accessory. When using a double circuit, a manifold is needed, with the help of which pipes are routed.

An expansion tank is required. When heated, the liquid increases in volume, therefore, in order to avoid rupture of pipes when pressure increases, a container is included in the network, where excess water is collected.

In the latest models of boilers, additional equipment is already built into the device. Heating schemes using a gas boiler are divided according to the parameters:

- by the number of circuits for single and double circuits;

- in the direction of wiring to horizontal and vertical;

- by type of circulation into natural and forced;

- by type of wiring for one-, two-pipe and beam.

Single- and double-circuit systems differ only in operational features. In a two-circuit scheme, when the DHW is turned on, the heating is turned off.

In the vertical wiring, risers are installed through which the coolant is supplied to the heating devices. It is more suitable for multi-storey cottages. To pump fluid, the presence of a circulation pump is required. In one-story houses, horizontal wiring is done.

With natural circulation, the pipeline is mounted at a slight slope, which makes it possible for the coolant to drain under its own weight. In the case of forced circulation, a pump is installed to move it.

The one-pipe scheme is the simplest option. It is a single pipe coming out of the boiler, bypassing the heating devices and returning the cooled coolant to the boiler. The temperature of the heat carrier at the beginning of the circuit and at the end is different. The advantage of this scheme is the ease of installation, the minus is the inability to disconnect parts of the circuit from heating.

In the two-pipe scheme, a return is provided - the second pipe designed for the cooled coolant. In this case, the house warms up evenly, the presence of control valves allows you to create the optimal temperature regime for individual rooms. The downside is the difficulty of installation.

With beam wiring, at least one collector is provided, from which a separate pipe is supplied to each device. This is the best option for a cottage, but the most expensive and time-consuming.

Installation begins with mounting the heater on a special bracket. The adjoining of the gas boiler to the wall is unacceptable. After installation, it is necessary to connect the device to three systems: plumbing, electrical and gas.

Connecting the hydraulic decoupling and electrical network

The heating system can be single-pipe and two-pipe, depending on this, the installation will be carried out using a different number of pipes. But with any option, the plugs from the boiler nozzles are first removed. To prevent contamination from the heating system from entering it, a strainer is installed at the return inlet. In case of hard water or non-compliance of its other characteristics with the requirements of heater manufacturers, the system is equipped with filters. Connections are carefully sealed with tow and paint, sealants or special thread seals.

The water circuit is connected in the same way as the heating pipeline. The differences relate to the diameter of the pipes used and valves. A filter must be installed at the inlet of the cold water supply so that contaminants that can damage the appliance do not get into the boiler. Taps for shutting off water are equipped with detachable connections. They simplify installation and facilitate the replacement of a worn or failed crane. Pipes for hot water supply to the gas boiler are connected on the left side relative to the center, for cold water - on the right.

Modern gas wall-mounted boilers are equipped with sophisticated automation, so they need to be connected to the mains. To do this, they are equipped with either a cable for connecting directly to the machine, or a conventional plug. The socket is made next to the heating device, but not from below, in order to avoid a short circuit in the event of a coolant leakage. A gas boiler requires mandatory grounding, which is installed next to the house or in the basement.

It is impossible to make grounding on gas pipes or heating devices - this is a violation of the rules for the operation of gas equipment.

Experts recommend including a stabilizer in the electrical network in order to avoid power surges that can damage boiler automation. To prevent shutdown of heating in the event of power outages, uninterruptible power supplies are installed.

Connection to the gas pipeline

It is recommended to use steel pipes to connect the boiler to the central gas pipeline. Connection is made with a pipe. To ensure the necessary tightness, threaded connections are sealed with tow and covered with paint.

A filter is installed on the valve that shuts off the gas, which protects against the ingress of small debris and condensate. Further, the gas pipeline is connected to the filter using a flexible connection or pipe. Do not use a rubber hose, as over time it cracks and gas seeps through the cracks. Corrugated hose is the best choice for flexible connection. It is made of stainless steel, strong, durable, resistant to high humidity.

At the last stage, the connection to the central gas line is made using a union nut with a paronite seal. Tightness is determined using a soapy solution, which is applied to the joints. A sign of a gas leak is the presence of bubbles. The correct connection of the gas system is checked by a representative of the gas service.

Before the first start-up of the heating system, water is pumped into it. The procedure should be carried out slowly so that the existing air comes out of the pipes. Filling ends when the liquid pressure in the line reaches two atmospheres. At the same time, the tightness of the water supply is checked, all leaks are immediately eliminated. Found faults are eliminated and the system performance is checked. The first start-up must be supervised by a gas service representative.

There will be no comfort in any home without enough heat. It can be provided in many ways, but the most common option is gas. About how gas heating should be organized in a private house and what is needed for this, read in our today's review.

Types of gas heating

Depending on the region and the conditions of gasification in it, you can choose one of three heating methods:

- liquefied gas from cylinders;

- liquefied gas from a gas tank;

- natural fuel from the main pipeline.

The first two are used in non-gasified settlements and differ only in the way gas is supplied and stored.

When choosing heating with liquefied gas, check the feasibility of this method. In some regions, this may not be cost effective compared to other heating options.

Bottled liquefied gas is supplied in containers of 50 liters. If this volume is enough in summer to service the stove for a period of more than a month, then in winter, with the inclusion of heating from a domestic cylinder, there will be little sense, it will need to be changed every 2-7 days, depending on the outside air temperature. A gas tank gas storage system is much more profitable, high costs will be only at the installation stage. Wholesale purchase of gas during the period of operation is much more profitable than the purchase of cylinders.

A gas tank is a gas sealed storage with a volume of two thousand liters or more. This amount of gas is enough to heat a country house with an area of 120-150m² with gas. For a cottage of 300 "squares", where gas consumption is several times higher, a capacity of approximately eight thousand liters will be required. If the village in which your house is located is gasified, then the best option would be to connect to the highway. Gas heating in a private house in this case will be costly only at the stage of its installation.

Benefits of gas heating

The advantages of heating a private house with gas are obvious.

- Low price of fuel: in our country, "blue" fuel is one of the cheapest (taking into account logistics costs).

- In modern gas boilers, high efficiency, which allows economical fuel consumption.

- A large selection of boilers with different capabilities, including heating water for household and household needs.

- Ability to heat large rooms.

- Environmental friendliness.

Flaws

There are also disadvantages in heating a private house with a gas boiler, one way or another they are all related to safety. If you carefully monitor the gas equipment, then nothing terrible will happen.

How to choose a heating gas boiler

A person who first encountered the problem of choosing a gas boiler may be confused and confused in the variety of modern models. Where do you need to start? The first thing you need to pay attention to before buying is the power of the device. It should provide heating for the house, depending on its area. In this case, you need to purchase a model with a margin of about 20% of the required volume. This will be required to heat the house in a particularly cold period. Next, consider the issue of hot water supply. If your house has or plans to install an electric boiler or other water heater, then you need a single-circuit gas boiler.

In the event that you plan to heat water for domestic and household needs through a boiler, purchase a two-circuit model. There are two options to consider here:

- A simple flow circuit when the hot water consumption is low.

- A heating system with a built-in boiler will not only heat the home, but also provide a sufficient amount of hot water.

Modern gas boilers can be designed to operate with natural or artificial draft. In the first case, it will be necessary to install additional pipes for exhaust gases and air inflow. The second option provides for the presence of forced ventilation. According to the placement, the boilers can be floor and wall. Floor-standing boilers are characterized by increased power and large dimensions, often for their installation it is required to allocate a separate room. If your private house is small, then a compact wall model would be the best option.

Heating scheme

The most common scheme for heating a private house with a gas boiler is water, in which a special non-freezing liquid can serve as a coolant in addition to water. Such a coolant is especially appropriate for houses in which people do not live permanently, but come for a while, for example, to give. According to the way the liquid moves through the heating pipes, modern systems can be divided into three types:

- gravity;

- forced;

- combined.

In the first case, the heating device provides for the natural circulation of water in the pipes due to the height difference. This can be done by placing the boiler at the lowest point of the house. The heated water will rise up the pipes, and when cooled, it will roll back to the boiler. This requires the use of large-diameter pipes and an increased amount of coolant in them. The disadvantage of the system is the uneven heating; at the end of the line, the batteries warm up much worse than at the beginning.

In a forced heating system, the liquid moves through the pipes under the action of a circulation, “circulating” pump. The heating of the coolant and heating devices in this case is uniform. There is only one drawback - dependence on the supply of electricity.

For non-stop operation of the circulation pump, you can use uninterruptible power supplies with powerful batteries, similar to those used for computer equipment.

Combined systems are a gravity version with an integrated pump. Here, even in the event of a power outage, the liquid will move due to the natural slope of the pipeline. The wiring from a gas boiler around the house can be single-pipe, two-pipe or beam. The first option is the most economical and easiest to install. Heating radiators in this case are connected in series with one pipe. A single-pipe system can only be used in small houses, the difference in temperature at the inlet and outlet is very large. A two-pipe system is built from two circuits: supply and return. In this embodiment, two pipes enter each radiator: one is supplied with water from the boiler, along the “return” it flows to its lower circuit. By installing taps at the radiators, you can adjust their heating as you wish.

Beam wiring is mounted using a collector, from which each battery has its own pipe. The most expensive option, requiring a large number of pipes, but very effective in terms of uniform heating of the premises.

Calculation of gas consumption for heating a house

In order to accurately calculate the need for the amount of heat, complex engineering calculations will be required, taking into account not only the area or volume of the room, but also the heat capacity of wall finishing materials, the average temperature in the region by months of the year, and other factors. For simplicity, we will use a simple assumption that one kilowatt of energy per hour is required to heat 10 m² of a room. Taking into account the fact that the boiler does not work all the time, but turns off as it heats up to a certain temperature, you can divide the resulting value in half. So, for a house of 100m², you need to consume 100 * 24/2 = 120 kW per day, 150m² - 180, 200m² - 240. The heating season in the middle lane lasts about 7 months: from October to April, so the annual energy demand will accordingly be:

- 100m² - 25200 kW;

- 150m² - 37800 kW;

- 200m² - 50400 kW.

To provide such an amount of energy, it is necessary to burn a certain volume of gas, depending on its calorific value, that is, the amount of energy released during its combustion. For natural gas, which mainly consists of methane, this figure is 9.3 kW/m³. Liquefied, which includes propane, ethylene and some other hydrocarbons, has a higher calorific value - 6.55 kW / l.

By dividing the amount of energy by the calorific value of the fuel, we get the total gas consumption depending on the area of the premises:

- 100m² - 2709 cubic meters of natural or 3847 liters of liquefied gas;

- 150m² - 4064 cubic meters m or 5771 l;

- 200m² - 5419 cubic meters m. or 7695 l.

Installation of gas heating

Gas heating in a private house is carried out in stages.

First of all, you should contact the district gas service to agree on a decision and draw up a gas supply project. Further actions are carried out according to the following scheme:

- The calculation of the necessary materials and equipment is made.

- The necessary accessories are purchased.

- The heating system is being installed. These works can be done with your own hands, in contrast to the "gas" installations.

- A gas tank or cylinder storage tank is being installed if a liquefied gas supply scheme is selected.

- A tie-in is made into the main gas pipeline or storage tank and the pipe is inserted into the room.

- Gas pipes are being laid inside the house.

- Gas equipment is installed and connected to the heating system.

- The coolant is poured.

- The operation of the system is checked in different modes.

It is best to entrust the installation of the gas pipeline and devices to a team from the operating gas service. In this case, there will be fewer problems with maintenance later.

The use of gas for heating is the best option for creating comfort and coziness in the premises of a private house. This solution is especially effective if there is a main gas pipeline in the village. At the same time, you should always remember that gas is a source of increased danger and it is unacceptable to neglect the recommendations of gas and fire services. If the installation of other systems in the house can be carried out independently, then it is better to entrust the installation of gas and all the work associated with this to a professional with appropriate training and permits.

A private house can be called comfortable and cozy only if the homeowner was able to solve all problems with heating. Today, there are various options for heating suburban buildings, which allows you to simultaneously ensure the convenience of living and reduce the cost of paying utility bills. The heating scheme of a private house with a gas boiler is very popular, which is ideal for buildings for various purposes.

- depending on the type of wiring, it can be radial, one- and two-pipe;

- in direction - horizontal and vertical;

- depending on the number of circuits - single and double circuit;

- according to the type of circulation - natural or forced.

Show all

Equipment Description

The popularity of autonomous heating boilers on gas is explained by the availability and low cost of this type of fuel. Today, many villages and individual development areas have a central gas supply, which makes it possible for homeowners to completely solve the problems with heating buildings. The use of natural gas allows you to reduce the cost of heating a private house by 2 times compared to solid fuel installations.

Such equipment, subject to the use of high-quality equipment and proper installation, will be completely safe in operation, and thanks to automation, the autonomy of the operation of heating installations is ensured. If in the past the operation of a gas heat generator presented certain difficulties, today there are reliable boilers that can completely solve problems with heat both in a small cottage and in a building with an area of 200-300 square meters.

Such equipment, subject to the use of high-quality equipment and proper installation, will be completely safe in operation, and thanks to automation, the autonomy of the operation of heating installations is ensured. If in the past the operation of a gas heat generator presented certain difficulties, today there are reliable boilers that can completely solve problems with heat both in a small cottage and in a building with an area of 200-300 square meters.

The heating and water supply scheme from a gas boiler will be an excellent choice for a private house with year-round use. This is the most economical option that will simultaneously solve problems with hot water and heating. At the same time, the cost of such equipment with two circuits will be lower than purchasing a gas boiler and an electric boiler separately.

The best heating system for a private house!

Working nodes

The system of gas heating and water supply of a private house in each case is planned individually, depending on the characteristics of the structure, the mode of operation of the equipment, as well as the climate in the region. The standard scheme includes the following elements:

In double-circuit systems, an insulated tank is additionally installed, in which water heated in the boiler is stored. Subsequently, the liquid is used for the technical needs of homeowners. Boilers can be additionally equipped with safety and temperature valves, control pressure gauges and have appropriate shut-off and control valves.

Gas removal can be carried out either using a standard chimney or through a hole cut in the wall along a coaxial pipe. An open fired boiler draws air directly from the room. If the heater has a closed combustion chamber, then a coaxial chimney is installed, which is responsible for the supply of oxygen and smoke removal.

Heating of a private house 1/1 / Heating of a private house from A to Z

Gas heating boilers

Modern gas heating boilers are fully controlled by automation, this is a reliable and safe equipment to use. The heat generator can be wall and floor. Boilers powered by natural gas are economical, allow you to quickly heat up the room, and the equipment itself, thanks to a high degree of automation, can be fully integrated into the "smart home" system.

Heaters differ in their power, respectively, you can choose options for both a small country house with an area of \u200b\u200b50–60 square meters, and floor installations that can cope with heating country cottages with an area of 300–400 square meters. In each case, the equipment is selected based on the size of the room, the required degree of automation, gas supply parameters, as well as the financial capabilities of the homeowner.

Heating appliances

Heat from the coolant heated in the boiler is transferred to the room through radiators, which can vary in the number of sections and dimensions. Most widespread Today we received the following types of batteries:

Traditionally, cast-iron batteries are popular, which hold heat well, are durable and are offered to customers at an affordable cost. The disadvantages of such radiators are usually attributed to their high inertia, so they heat up for a long time, and it is difficult to make effective compact models of radiators from cast iron.

The most efficient and expensive are copper and bimetallic radiators. They are compact, have excellent efficiency, allow you to quickly heat up the room after turning on the heater. In recent years, owners of private houses and apartments often change old cast-iron batteries to new aluminum, bimetallic and copper ones, which significantly increases the efficiency of the autonomous and central gas heating system of a private house.

Expansion tank and pump

In the classical heating scheme with cast-iron radiators, the circulation pump is installed on the return pipe, through which cooled water or antifreeze returns to the heater. Additionally, the pump is equipped with a filter that increases the reliability of the equipment used.

In underfloor heating systems, a coolant with a temperature of up to + 50 ° C circulates, which allows you to install the pump directly at the inlet to the distribution manifold. This simplifies installation work, while increasing the efficiency of heating equipment.

In high-temperature heating systems, it is mandatory to install an expansion tank, the main purpose of which is to relieve excess pressure. Depending on their type, tanks are made with a closed and open design. In the latter, hot steam and air are released directly into the boiler room through a special valve. The expansion tank is installed at the highest point of the heating circuit. This allows you to ensure the complete safety and efficiency of the heating system at home.

In high-temperature heating systems, it is mandatory to install an expansion tank, the main purpose of which is to relieve excess pressure. Depending on their type, tanks are made with a closed and open design. In the latter, hot steam and air are released directly into the boiler room through a special valve. The expansion tank is installed at the highest point of the heating circuit. This allows you to ensure the complete safety and efficiency of the heating system at home.

Heating circuit pipe

The choice of pipes and the laying of a thermal circuit presents certain difficulties, since it is required not only to correctly calculate the optimal layout of the riser, but also to complete this work even before the completion of repairs in the house.

Heat circuit pipes can be made from the following materials:

If earlier metal pipes were the most popular, today homeowners are increasingly choosing polypropylene or cross-linked polyethylene. Such materials are thermally stable, durable and not subject to corrosion.

For underfloor heating systems, it is recommended to use cross-linked polyethylene or metal-plastic. Such a heating system has the necessary strength, it is not afraid of high temperatures, and the pipes inside the screed will retain their thermal efficiency for a long time, easily transferring heat to concrete, heating the floor and the whole house.

How to connect a heating boiler wiring diagram

Optimal wiring diagram

Depending on the power indicator of the heating installation, the area and number of storeys of the house, the wiring diagram of the thermal circuit may differ. They are usually divided into several main parameters:

Ideally, the choice of a gas heating scheme in a private house should be performed by a specialist with extensive practical experience. This is the only way to ensure the maximum possible efficiency of the heat generator and the absence of problems with heating.

The optimal wiring option can be indicated in the project documentation for a private house with a detailed description of the heating equipment used.

Beam, one- and two-pipe configuration

The simplest scheme for heating a private house is a single-pipe wiring, when a circuit departs from the boiler, to which the batteries are connected in turn. This option will be an excellent solution for a country house or a small country house. In the two-pipe circuit laying circuit, there is a “return”, which is responsible for returning the cooled coolant to the boiler. The disadvantages of this pipe laying technology include an increase in the cost of arranging engineering communications in the house, as well as the structural complexity of the entire system, which negatively affects its reliability and durability.

For a country house and a spacious cottage, the best option would be beam wiring, which implies at least one collector node, from which an individual pipe with a hot coolant goes to the battery. This allows you to ensure the highest possible heating efficiency of the building. The disadvantage of beam wiring is the difficulty of installation and the high cost of arrangement.

Forced and natural circulation

With natural circulation, the pipeline is mounted with a barely noticeable slope, which helps the coolant to move by gravity from the boiler through the pipes, heating all the batteries and subsequently returning to the heat generator.

In schemes with forced movement of the coolant, one or several pumps are used at once, which are responsible for maintaining the required pressure in the system.

Heating the house with a gas boiler with natural circulation will be an excellent choice for a small area. If it is required to heat a full-sized cottage, then an additional “return” is carried out, on which powerful pumps are installed, which quickly drive the coolant through the radiators, effectively heating the room.

One or two circuits

There are no fundamental differences between the single-circuit and double-circuit wiring diagrams. Such equipment has only operational features. When the hot water supply is turned on, the heating is immediately turned off. Therefore, when arranging a two-pipe scheme, it is necessary to provide for the inertia of the system, which should remain warm for a long time even when heating is stopped.