Heavy welded reinforcement mesh. Other requirements of Gosstandart are important! Scope of application of reinforcing steel mesh

Today, welded mesh is one of the most popular types of metal products. Among these meshes, the most common are welded reinforcing mesh. The wire in them is welded using the contact method spot welding in accordance with the requirements of GOST 14098 at right angles at intersections. To increase service life, an anti-corrosion coating is applied to the mesh.

Figure 11 - Hoses with spirals or steel hoops. Steel reinforcement mesh for concrete foundations. Steel reinforcement mesh for concrete foundations. Mesh Reinforcement for Concrete Foundations Introduction. Steel reinforcement mesh for concrete foundations is also called concrete reinforced mesh, concrete reinforcement mesh, welded steel mesh, concrete steel mesh.

Steel reinforcement fittings for reinforcement reinforced concrete structures longitudinal and transverse are located at a given interval and at right angles to each other, all intersections are welded. Reinforcing steel mesh for concrete foundations Material.

Welded reinforcing mesh is divided into two large classes:

- masonry (arm belt) and road;

- for glass reinforcement and thermal insulation.

Requirements for the range of reinforcing mesh are determined by the standards:

- GOST 8478-81 “Welded mesh for reinforced concrete structures. Technical specifications";

- GOST 23279-85 “Welded reinforcement mesh for reinforced concrete structures and products. General technical conditions".

These meshes are intended for reinforcing reinforced concrete structures in construction and road surfaces.

It has smooth uniform mesh surface, high stability and great corrosion resistance. 1-Electrode galvanized mesh. 2-hot galvanized mesh. Galvanized welded mesh has good corrosion resistance. Reinforcing steel mesh for concrete foundations Specification.

Width: 1m, 1.5m, 2.0m, 2.4m, 3m or as your requirement. Length: 1m, 2m, 4m, 6m, 8m, 12m or as your requirement. Surface treatment: Galvanized galvanized or hot-dip galvanized. List of specifications for steel reinforcement for concrete foundations.

They are made from low-carbon reinforcing wire of class VR-1 and V-1 in accordance with GOST 6727-80 and are supplied in rolls or cards.

To increase the corrosion resistance of the mesh, one of the following types of zinc coating is used:

- galvanized, then welded (electrolytic zinc coating with a layer of about 10 g/m2);

- welded, then galvanized (electrolytic zinc coating with a layer of about 20 g/m2);

- hot-dip galvanized, then welded (hot zinc about 50 g/sq.m.);

- welded, then hot-dip galvanized (hot zinc about 130 g/sq.m).

The amount of zinc on the mesh is directly proportional to the service life of such a product.

Reinforcing steel mesh for concrete bases Color. All kinds of flowers can be coated according to customers' special requirements. Reinforcing steel mesh for concrete foundations Variety. Reinforced steel mesh for the benefit of concrete foundations.

Steel reinforcement mesh for the benefits of concrete foundations. Reduce project costs. Speed up construction progress. Ensure project quality. Anti-cracking, etc. Reinforcing mesh for typical concrete foundations. Steel reinforcement knitting for concrete foundations Material.

Range of welded mesh for glass reinforcement and thermal insulation

This type of mesh is intended for glass reinforcement and thermal insulation. The material is low carbon wire. A special feature of this mesh is the presence of transverse threads of the mesh fabric, which have double corrugation (No. 25) or single corrugation (No. 125) in each cell. The range and technical requirements for this mesh are determined by TU 14-4-713-97 and TU 14-4-714-97. The mesh is produced from wire with a diameter of 0.5 mm and 0.6 mm, with a pitch of 12.5 mm and 25 mm, web width from 600 mm to 2000 mm.

One light weight. Anti-corrosion and durability. G. easy to cut. Easy to install and easy to maintain. Reinforcing mesh for concrete foundations Note. Steel mesh reinforcement for concrete foundations Note. Reinforcement mesh can be designed according to project requirements, improve efficiency and bond with concrete to meet special needs. It is widely used in airports, tunnels, bridges, roads and piers, as well as in the construction of building, wall, roof and balcony.

Reinforced steel mesh for concrete foundations. Reinforcing mesh for concrete foundations Application. Reinforced steel mesh for use in concrete foundations. It is widely used in industry, agriculture, aquaculture, construction, communications, transportation and mining, etc. It also finds application in sinks on machines or equipment, wire fence for livestock or flowers and trees, window protection fence, walkway fencing, bird cage, egg storage basket, grocery basket, paper basket or decorative fields at home or in the office.

Technical characteristics of variable-section wire VR-1

To increase the adhesion of the mesh to the reinforced material, ribbed wire of variable diameter VR1 is used in accordance with GOST 6727-80. It is made from wire rod manufactured according to OST 14-15-193-86. After appropriate mechanical processing, the wire acquires the following appearance:

Reinforcing steel mesh for concrete foundations Packaging. Steel mesh reinforcement for concrete foundations packaging. It is inside with plastic film and packed with waterproof paper, then by pallet bag or according. Reinforcing steel mesh for concrete bases packed with mother-of-pearl.

Concrete reinforcement steel for concrete roller stands Packing with waterproof paper. Get documentation Request a price contact the manufacturer. Galvanized welded mesh used for reinforcement of plaster or interior plasters, as well as for exterior backboards. Also used as reinforcing mesh for repairing cracked walls and as reinforcement for external insulation systems. Also available on request in stainless steel. Available in three square mesh options, five yarn plies and two roller lengths.

Example of size ratio for BP1 wire with diameter (d) 3.8 mm:

- dent depth (h) 0.2 mm;

- dent pitch (s) 2.5 mm;

- protrusion length (b) 0.8 mm.

Technical requirements for welded reinforcing mesh

One of the main requirements for reinforcing mesh is their strength. The strength of the mesh depends on its design: what smaller size cells, the stronger the mesh, and the higher its ability to withstand heavy loads. You can check the quality of the mesh by its weight: the larger it is, the greater the load the mesh can withstand. To do this, weigh the roll of masonry mesh and calculate the weight of 1 square meter. m. and compare with the theoretical (reference) weight. If the difference in weight is more than 5%, then you should check other parameters of this roll.

Other specifications product. Depending on the height, our mesh panels are made with 2-4 times the reinforcement, each 100mm wide for even greater rigidity. For simplicity. Stiffer mesh is more stable than flexible mesh. The color evaporates and plasticizes, providing high resistance to wear and corrosion to keep the color intact for many years.

For your security and safety project, choose a rigid fence in welded mesh panels for your private property, tertiary site or community. A palisade with a modern look, with a wide range of colors and a long shelf life thanks to the quality products we offer. Indeed, we only sell products that we also represent to professionals for companies, town halls, the Drôme and Ardèche industries.

GOST 23279-2012 (85) regulates the production of welded mesh (flat or rolled), which are manufactured in factories producing products for construction organizations. Meshes are used to reinforce prefabricated or monolithic concrete or reinforced concrete structures. They can also be used for the construction of various small structures, such as greenhouses, outbuildings, gazebos, and so on.

Rigid fencing panel

Why choose our rigid panels

Personalize, decorate, plaster your fence to suit your tastes! In addition to having reinforcing layers and security pins, rigid panels are extremely difficult to remove once they have been installed. Increased need for security Select two-wire panels typically offered for industrial use. Easy to install, which is done with advancement and without accessories. The panel hangs in the grooves of the pole. The latter is identical whether it is intermediate, angled or at the end. No installation tool required. Help with installation and follow-up of your project.- Rigid and modern fence.

- High-quality panels that last over time.

- Our fences are made in France of high quality and are guaranteed for 10 years in finishing.

- Wide selection of colors at no extra charge.

- An excellent deterrent against the risk of invasion.

Welded mesh is made using reinforcing steel (rods or wire), with a thickness of 3 to 40 mm. The most popular are products with cell sizes of 50×50 and 100×100 mm.

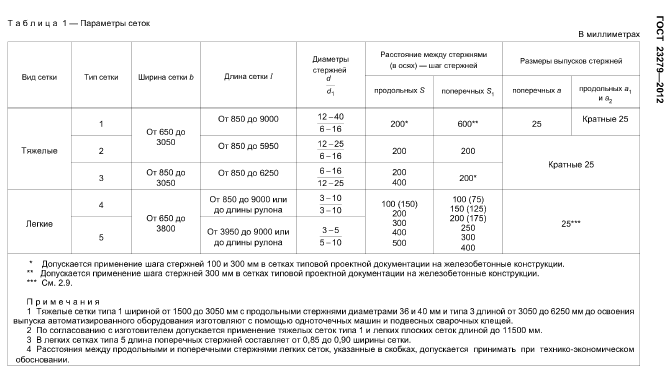

1 Classification

Reinforcing mesh is divided according to GOST 23279-2012 (85) in accordance with the following characteristics:

- diameter (section) of rods or wire;

- structural arrangement of reinforcement.

Depending on the diameter of the reinforcement used in production, This parameter is divided:

Click on the picture to enlarge. Reversible panel fence, aesthetically pleasing and economical for homes, garden and grounds, residences or communities. I had to change the galvanized wire mesh. Glad you chose rigid panels. The access to my house really looks nice! Reversible, aesthetic and economical fencing panels for homes, gardens and gardens, communities or industries. I don't need a tight stitch, but I do need larger threads.

Fence with reversible panels and aesthetic for home or garden and garden. Reversible panel fence, durable and aesthetically pleasing for home, garden and grounds, residences or communities. Reversible panel fence, durable and aesthetically pleasing for home, garden and grounds, communities or industries. Fence with highly durable and aesthetic panels for home, garden and garden, communities or industries. These high-strength, tamper-proof fasteners are self-closing and are used with large manual or, more commonly, pneumatic staplers.

- lightweight - have transverse and longitudinal rods from 3 to 10 mm;

- heavy - rods located in one direction and having a diameter of 12 mm.

Another subgroup, which is determined by the direction of the reinforcement:

- working fittings located in one direction (transverse or longitudinal), and distribution fittings in the other;

- working fittings are located in both directions.

1.1 Characteristics

Reinforcing mesh according to GOST 23279-2012 (85) has the following types:

This tool weighs approximately 8 kg and must be connected to a source of compressed air. Bar 2 or 3 m long, equipped with 2 handles and numerous hooks that snap into the grids of vertical electric welded panels. Temporarily tightens the gabion during filling.

Mesh mesh side edge and edging with double twist hexagonal mesh

Wires are larger in diameter than wire mesh and reinforce the twisting of the mesh. The bracket is parallel to the wires and is woven simultaneously with the wire mesh. After weaving, a side border is added perpendicular to the mesh. A metal structure in plumbing was used to temporarily close double torsion box gabions while they were being filled.

- type 1 (heavy) - the diameter of the working fittings is larger than that of the distribution fittings;

- type 2 (heavy) - there is working reinforcement in both directions;

- type 3 (heavy) - the working fittings are located in the transverse direction and their diameter is larger than that of the distribution fittings;

- type 4 (light) - transverse rods are located across the entire width of the mesh;

- type 5 (light) - has offset transverse rods.

Meshes are produced in accordance with GOST 23279-2012 (85), in flat or roll form.

Rectangular parallelepipedal rectangular structure made of electroscrub mesh or hexagonal double torsion mesh in various sizes. A gabion cage is usually divided evenly into inner cells by one or more diaphragms. Gabion boxes, gabion soles, mattress gabions and multi-cell gabions are available.

Vertical gabion walls. There is front and back view and both ends. Top part closes the gabion. The cover may be part of the structure or may be separate. Dark brown rust, Dark brown rust. Definition of hexagonal mesh type as a function of cell size.

2 Options

The pitch of the rods in the same direction is the distance between them and it should be the same over the entire area. For heavy meshes of the first type, it is allowed to have an additional step of transverse rods at the edge of the product, which can be equal to 100, 200 and 300 mm.

A rectangular panel of electro-welded wire mesh or twin-screw hexagonal mesh used to evenly divide a gabion cage into internal cells. The nominal mesh size is the axle-to-axle distance between two successive wires for electric welded panels and between the torsion axis for woven gabions with hexagonal meshes. In the case of woven gabions with a two-turn hexagonal mesh, the mesh size is an average distance of more than 10 meshes, measured at right angles between the twisted sides of the mesh.

Lightweight reinforcing mesh can have an additional step in the longitudinal direction at the edges or cutting points (cutting is carried out using special scissors, which can be read about separately). The additional pitch of the rods located longitudinally can have dimensions from 50 mm to a given cell size (50 × 50, 100 × 100 mm), while at the edge it should be a multiple of 10 mm, and in places of cutting 50 mm.

The second indicator is indicative. A hexagonal-shaped mesh formed by twisting two or two adjacent threads alternately to the right and then to the left. A type of woven mesh in which the wires are twisted together. Spiral winding of two wires around each other at an angle of rotation of the two wires of 180°. The wires only rotate in one direction. Visually, some people think there are three swirls.

The resulting sheet is stopped at each edge by a border consisting of a wire with a diameter larger than the diameter of the wire used for the entire screen. Method for manufacturing gabion panels. We are talking about welded mesh or electric welded panels. The wires or rods are connected by spot welding. This production method allows the use of very small and large wires, which allows the panels to be very stable and more rigid. The grids are square or rectangular and can vary from one side of the panel to the other.

The transverse components of the reinforcing mesh can have an additional step from 50 to 250 mm, with a multiplicity of 10 (50×50, 100×100 mm).

Lightweight reinforcement made in one strip, may be with release of longitudinal rods from 25 to 250 mm (multiples of 5). For transverse values, values of 15, 20 and 30 mm, or from 25 to 100 mm (with a multiple of 25) are allowed. Such outlets are suitable for cells with dimensions of 50×50, 100×100, 100×250 mm.

Larger diameter wire used to outline the mesh, perpendicular to the production direction and double twisted, by mechanically winding the mesh wires with at least 2.5 windings around each mesh. Steel wire coated with zinc, zinc-aluminum alloy or organic coat or stainless steel wire and used to assemble and join empty gabions and to close and join adjacent gabion cages in a structure, replacing spirals or staples.

Ligature wire can also be used as ties to prevent cladding from deforming. Metal wire used for bordering toast sheets, in the direction of the mesh production and parallel to the double twist, by continuously weaving the mesh.

2.1 Dimensions

These parameters are presented in the following form: 50x50x4, 100x100x5. From the numbers you can determine that the cell is a square, the sides of which are 5 (10) cm, and the diameter of the rod is 4 (5) mm, according to the examples above.

2.2 Weight

2.3 Technical requirements

Welded metal mesh from reinforcing steel is manufactured in accordance with GOST 23279-2012 (85) and specific working drawings, as well as accompanying technological documentation.

Working reinforcement in heavy meshes is made of class A-III steel with a rod cross-section of 10-40 mm. In some cases, the use of steel is allowed A-I diameter 10-32 mm.

Heavy mesh distribution fittings (type 1) are made from steel A-I II (6-16 mm), and in type 3 - steel A-III (10-16 mm) and steel A-I (6-16 mm).

For light meshes, steel class B500C (4-5 mm), reinforcing wire made from steel class BP-1 (3-5 mm) and reinforcement made from steel grades A-III and A-I (6-10 mm) are used.

Distribution fittings can be steel B500S with a diameter of 4-5 mm and wire B-l diameter 3-5 mm.

The connection of the rods at their intersections is carried out using resistance spot welding, the operating modes of which must comply with regulatory documents.

In products made using steel grades A-I, V mandatory, all intersections of the rods must be fastened. When assembling a product from rods and wires, connection of intersections by welding is allowed through one or two in a checkerboard pattern. In this case, the two rods running along the edges of the product must be fastened without fail.

A maximum of two non-welded intersections (using clamps) per area of 1 m² is allowed out of the required number of connections.

2.4 Labeling, transport and storage

Data on the product packaged in bags or rolls must be indicated on two metal or plywood tags, which are attached on two different sides.

The total weight of one packaged unit must not exceed three tons. The nets in the bags are tied with soft wire in four places, and the rolls in three.

The information on the tags indicates the following:

- name (trademark) of the enterprise that manufactured the product;

- type ( symbol) products;

- number of units in the package;

- package (roll) weight in tons;

- production date and batch number.

During transportation and loading and unloading operations, rules must be followed safety precautions, and also observe precautions aimed at protecting the product from mechanical damage.

Storage is permissible in indoor areas with distribution by grade and in stacks, the height of which does not exceed 2 meters. Rolls can be folded into tiers, the number of which does not exceed 3. When forming a large number of stacks, a free passage must be left between them, the width of which is at least 0.5 m.

2.5 How is reinforcing mesh produced? (video)