Weight of jumpers. Reinforced concrete lintels - description, technical characteristics - gk rosatomsnab

Reinforced concrete lintels are construction material rectangular, mounted above window or door openings. Used to strengthen vulnerabilities and distribute the load. Most often used in brick buildings. It is impossible to build a strong and reliable structure without reinforced concrete supports.

How are they made, types and characteristics

Concrete lintels are necessary to evenly distribute the load created by the wall or floor over the opening. The weight is equally distributed along the edges of the reinforced concrete support. Manufactured in different sizes and brands in factories. You can make them yourself. For the production of lintels for overlapping openings, reinforcement and concrete of class B15 and higher or grades M200 and M250 are used. In any case, the density of concrete products must be at least 2200 kg / m 3. Smooth or corrugated reinforcement with anti-corrosion coating is used to increase the characteristics of concrete, or rather, the strength of the entire material. Steel increases the degree of bending.

Reinforced concrete lintels of different sizes and brands are manufactured as follows:

1. A frame made of reinforcement fits into the mold.

2. Concrete is poured.

3. The mold with the mixture is left to harden.

Reinforced concrete lintels can be used not only as a support for window or doorways, but also in other structures (for the construction of pavilions, pavilions, stairs). Also, with the help of them, territories and sites are landscaped, garage and assembly openings are made. Reinforced concrete supports are used in buildings or structures made of bricks, artificial or natural stone, foam, slag, aerated concrete or other similar materials.

Depending on the purpose, reinforced concrete lintels are divided into the following types:

- bar;

- slab;

- beam;

- front.

The width of reinforced concrete supports of the first type does not exceed 25 cm. Slab lintels, on the contrary, are produced with a width of 25 cm. All reinforced concrete supports have reinforcement loops or holes. Thanks to them, their loading, transportation and installation are greatly simplified.

Reinforced concrete bar bulkheads are the most demanded in the construction of buildings. They have an almost square cross-section, which cannot be more than 25 cm. They are used both in private and capital construction. Used as a support for structures made of brick, stone, aerated concrete or wooden beams... Squared reinforced concrete window lintels are not afraid of low temperatures and are resistant to moisture. They are used not only for openings, but also for fences and supports.

Slabs are used for structures made of brick, concrete, aerated concrete, monolith and other materials. Just like the previous type of supports, these have a rectangular section. But unlike bar reinforced concrete lintels, slab supports are made with a width of more than 25 cm.

Beam lintels have an additional protruding quarter - a recess on one side. Other floors are laid on it. Used for construction, residential and industrial buildings.

Labeling and cost

Reinforced concrete lintels differ among themselves not only in strength, but also in their ability to withstand low temperatures. Therefore, you need to choose a material for construction not only because of the planned load, but also according to weather conditions and seismic activity. There are reinforced concrete supports that can withstand earthquakes up to 7 points, and are also resistant to aggressive chemicals.

Jumper markings:

- PB - squared;

- PP - slab;

- PG - beam.

The first number in the marking means the number of the cross-section, the letters behind it - the type, the next number - the length in dm (approximate). The number after the hyphen is the bearing capacity kN / m. The lowercase letter p means the presence of mounting loops, and - the outlets of the fittings. The cost of reinforced concrete supports is influenced by their type and dimensions.

A table with prices at which you can buy jumpers of different sizes and brands:

| Name | Jumper sizes, mm | Price for 1 piece, rubles |

| 2PB 10-1p | 1030x120x140 | 270 |

| 2PB 22-3 p | 2200x120x140 | 450 |

| 2PB 29-4 p | 2850x120x140 | 640 |

| 3PB 13-37 p | 1290x120x220 | 440 |

| 3PB 18-37 p | 1810x120x220 | 680 |

| 3PB 30-8 p | 2980x120x220 | 1230 |

| 5PB 21-27 p | 2070x250x220 | 1680 |

| 5PB 27-37 p | 2720x250x220 | 2400 |

| 5PB 36-20 p | 3630x250x220 | 3500 |

| 8PB 10-1-p | 1030x120x90 | 180 |

| 8PB 17-2-p | 1680x120x90 | 250 |

| 9PB 13-37-p | 1290x120x190 | 400 |

| 9PB 21-8-p | 2070x120x190 | 530 |

| 9PB 27-8-p | 2720x120x190 | 1080 |

| 10PB 21-27-p | 2070x250x190 | 1270 |

| 10PB 27-37-p | 2720x250x190 | 4090 |

| 2PG-39-31 | 3890x250x440 | 6200 |

| 2PG-43-31 | 4300x250x440 | 7000 |

| 3PG-60-73 | 5950x380x585 | 19200 |

| 2PP-23-7 | 2330x380x140 | 1620 |

| 5PP-14-5 | 1420x510x140 | 1450 |

| 10PP-30-13 | 2980x510x190 | 4280 |

Before you buy lintels for window and door openings of any brand, size and weight, you need to pay attention to their condition and damage. There should be no cracks or chips in them. Damaged concrete will not be able to withstand heavy loads, which can cause part of the building to collapse. Also, you should not purchase concrete products of any weight and brands at prices that are significantly lower than from other suppliers, since it is highly likely that low-quality components or cement of a lesser grade were used for their production.

It is necessary to install reinforced concrete supports only in accordance with all the rules and observing safety technology. Lintels for buildings with brick walls and other structures are heavy and must be handled with extreme care to avoid injury or damage to building materials.

It is necessary to store reinforced concrete supports stacked in stacks no more than 2 m high. A gasket must be placed between the rows so that they are not damaged due to their own weight.

Table 7

|

OKP code |

Jumper mark |

Jumper main dimensions, mm |

Consumption of materials |

Bulkhead weight (reference) kg |

Type designation |

|||||

|

Length |

Height |

Protruding height |

Support area length |

Concrete, m 3 |

Steel, kg |

Project documentation Series 1.038.1-1 |

||||

|

58 2821 0842 |

4PF8-2 |

770 |

0,014 |

0,53 |

35 |

|||||

|

58 2821 0843 |

4PF9-2 |

900 |

1,96 (200) |

0,017 |

0,58 |

43 |

||||

|

58 2821 0844 |

4PF10-2 |

1030 |

90 |

90 |

130 |

0,020 |

0,63 |

50 |

||

|

58 2821 0845 |

4PF13-3 |

1310 |

2,94 (300) |

0,026 |

0,80 |

65 |

||||

|

58 2821 0846 |

4PF14-4 |

1420 |

3,92 (400) |

0,029 |

0,95 |

73 |

||||

|

58 2821 0847 |

5PF16-5 |

1550 |

4,90 (500) |

0,050 |

0,83 |

125 |

||||

|

58 2821 0848 |

5PF17-5 |

1680 |

190 |

90 |

130 |

0,055 |

0,99 |

138 |

||

|

58 2821 0849 |

5PF19-6 |

1940 |

5,88 (600) |

0,064 |

1,40 |

160 |

||||

|

58 2821 0850 |

6PF22-8 |

2200 |

0,071 |

3,23 |

178 |

Edition 7 |

||||

|

58 2821 0851 |

6PF23-8 |

2330 |

190 |

90 |

195 |

7,85 (800) |

0,076 |

3,74 |

190 |

|

|

58 2821 0852 |

6PF25-8 |

2460 |

0,080 |

4,26 |

200 |

|||||

|

58 2821 0853 |

6PF 30-8 |

2980 |

0,098 |

7,09 |

245 |

|||||

|

58 2821 0854 |

6PF22-12 |

2200 |

0,071 |

4,61 |

178 |

|||||

|

58 2821 0855 |

6PF23-12 |

2330 |

190 |

90 |

195 |

11,77 (1200) |

0,076 |

5,15 |

190 |

|

|

58 2821 0856 |

6PF25-12 |

2460 |

0,080 |

6,28 |

200 |

|||||

|

58 2821 0857 |

6PF30-12 |

2980 |

0,098 |

10,07 |

245 |

|||||

|

58 2821 0858 |

7PF40-10 |

4020 |

0,181 |

11,89 |

453 |

|||||

|

58 2821 0859 |

7PF43-10 |

4280 |

290 |

90 |

260 |

9,81 (1000) |

0,193 |

13,67 |

483 |

|

Notes to Table 1-7.

1. In the case of application as prestressing longitudinal reinforcement of reinforcing steel class A-V instead of Ат-V or А-IV instead of Ат-IVС in the brand of prestressed jumpers, the designation of reinforcing steel should be replaced, respectively, АтV with AV or АтIVС with AIV.

2. The calculated bulkhead load is based on the bulkhead's own weight.

3. Steel consumption for a prestressed bulkhead is given for the nominal length of prestressed reinforcement bars equal to the length of the bulkhead. This consumption of steel should be clarified taking into account the actual length of the prestressing reinforcement, taken depending on the method of tensioning the reinforcement and the design of the grippers.

4. In the case of installation in the lintels of the outlets of fittings and embedded products that are not provided for in the standard project documentation series 1.038.1-1, the steel consumption for the lintel should be changed accordingly.

5. The weight of the lintels is given for heavy concrete with an average density of 2500 kg / m 3 .

1.8. Jumpers are marked with brands in accordance with the requirements of GOST 23009-78.

A jumper mark consists of alphanumeric groups separated by hyphens.

The first group contains an Arabic numeral denoting the ordinal number of the transverse lintel cross-sections, designation of the jumper type and its length in decimeters (the value of which is rounded to the nearest whole number).

In the second group, the value of the calculated load on the lintel in kN / m (rounded to the nearest whole number) and the class of prestressing reinforcement (for prestressed lintels) are given.

In the third group, if necessary, indicate:

The presence of mounting loops, outlets of fittings and embedded products in the lintels, indicated by lowercase letters (for example, the letter "a" - the presence of anchor outlets in the bar lintels for fastening balcony slabs; the letter "p" - the presence of mounting loops in the bar lintels);

Additional characteristics that ensure the durability of the jumpers under operating conditions. For example, for lintels of buildings with a design seismicity of 7 points and higher - resistance to seismic effects, denoted by the capital letter C; for lintels used in conditions of exposure to aggressive media - characteristics of the degree of concrete density (P - high density, O - extra dense).

An example of a symbol (brand) of a jumper of the PB type, 2460 mm long, cross-section No. 5 (according to Table 1), for a design load of 37.27 kN / m, with mounting loops:

5PB25-37-n

The same, type PP, 1810 mm long, cross-section No. 8 (according to Table 6), for a design load of 70.61 kN / m, with prestressing reinforcement of class AT-V:

8PP18-71-ATV

The same, type PB, 2070 mm long, cross-section No. 10 (according to Table 5), for a design load of 27.46 kN / m, with anchor outlets for fixing balcony slabs, with mounting loops:

10PB21-27-an

The same, type PF with a length of 1940 mm, cross-section No. 5 (according to Table 7), under a design load of 5.88 kN / m:

5PF19-6

2. TECHNICAL REQUIREMENTS

2.1. Jumpers should be made in accordance with the requirements of this standard and technical documentation approved in the prescribed manner, according to standard design documentation series 1.038.1-1.

2.2. Jumpers must meet the requirements of GOST 13015.0-83:

Factory readiness;

Strength, stiffness and crack resistance;

According to the indicators of the actual strength of concrete (at design age, transfer and release);

For concrete frost resistance;

The quality of the materials used for the preparation of concrete;

For concrete as well as for preparation materials concrete lintels intended for operation in an environment with an aggressive degree of impact on reinforced concrete structures;

To the shape and size of reinforcement and embedded products and their position in the lintel;

To steel grades for reinforcement and embedded products, including for mounting loops;

By the deviation of the thickness of the concrete cover to the reinforcement;

Corrosion protection;

On the use of forms for making jumpers.

2.3. Bulkheads should be made of heavy concrete (average density more than 2200 to 2500 kg / m 3 inclusive) of the compressive strength classes or grades specified in the design documentation for these bulkheads.

2.4. The normalized transfer strength of concrete of lintels with prestressing reinforcement should be 70% of the class or grade of concrete in terms of compressive strength. The transfer of the compression forces to the concrete (release of the tension of the reinforcement) should be carried out after the concrete has reached the required rated strength.

2.5. The normalized tempering strength of concrete of the lintels should be (as a percentage of the class or grade of concrete in terms of compressive strength):

70 - upon delivery of jumpers during the warm season;

90 - the same, in the cold season.

2.6. Reinforcing steel should be used as prestressing longitudinal reinforcement of lintels:

Thermally hardened classes AT-V and AT-IVC according to GOST 10884-81;

Hot rolled classes A-V and A-IV according to GOST 5781-82.

2.7. Reinforcing steel should be used as non-tensioned longitudinal lintel reinforcement:

Hot rolled class A-III in accordance with GOST 5781-82;

Thermomechanically hardened class AT-IIIC in accordance with GOST 10884-81;

Reinforcing wire of class Вр-I in accordance with GOST 6727-80.

2.8. Transverse reinforcement should be made of hot rolled reinforcing steel grades A-I and A-III in accordance with GOST 5781-82 or reinforcing wire of class Вр-I in accordance with GOST 6727-80.

2.9. Tensioning of prestressing reinforcement should be done electrothermally or mechanically on stops.

2.10. The values of stresses in prestressing reinforcement, monitored after the end of its tension on the stops, must correspond to those given in the design documentation for the lintels.

The values of actual stress deviations in prestressing reinforcement should not exceed 5% when tensioned by a mechanical method, and values

MPa ![]()

Where is the length of the tensioned bar (the distance between the outer edges of the stops), in meters.

2.11. Values of actual deviations geometric parameters jumpers should not exceed the limit specified in table. eight.

Table 8

Mm

|

Geometric parameter deviation name |

Geometric parameter name |

Prev off |

|

Deviation from linear dimension |

Jumper length: |

|

|

Up to 2500 |

6 |

|

|

St. 2500 "4000 |

8 |

|

|

" 4000 |

10 |

|

|

Lintel width and height |

5 |

|

|

Position of tabs, grooves and holes |

5 |

|

|

Position of embedded products: |

||

|

In the plane of the lintel |

5 |

|

|

From the lintel plane |

3 |

|

|

Deviation from straightness |

Straightness of the profile of the front surface of the lintel: |

|

|

Length up to 2500 at a given length 1000 |

3 |

|

|

The length of St. 2500 to 4000 over the entire length of the lintel |

3 |

|

|

The length of St. 4000 over the entire length of the lintel |

4 |

2.12. The following categories of lintel concrete surfaces are installed:

A3 - bottom and side surfaces;

A7 - other surfaces.

Requirements for the quality of surfaces and the appearance of the lintels are in accordance with GOST 13015.0-83.

2.13. In the concrete of the lintels supplied to the consumer, cracks are not allowed, with the exception of:

Shrinkage and other surface technological cracks, the width of which should not exceed 0.1 mm;

Cracks from concrete compression in prestressed lintels, the width of which should not exceed the values specified in the design documentation for these lintels.

3. RULES OF ACCEPTANCE

3.1. Acceptance of jumpers should be carried out in batches in accordance with the requirements of GOST 13015.1-81 and this standard.

3.2. Acceptance of lintels in terms of their strength, stiffness and crack resistance of concrete, frost resistance of concrete, as well as water resistance and water absorption of concrete of lintels intended for operation in an environment with an aggressive degree of exposure should be carried out according to the results of periodic tests.

3.3. Acceptance of lintels in terms of concrete strength (class or grade of concrete in terms of compressive strength, transfer and tempering strength), compliance of reinforcement and embedded products with design documentation, strength of welded joints, accuracy of geometric parameters, thickness of concrete cover to reinforcement, width of technological crack opening, the categories of the concrete surface should be made according to the results of acceptance tests and control.

3.4. In cases where it is established during verification that the actual tempering strength of concrete is lower than the required tempering strength, then the delivery of lintels to the consumer should be made after the concrete reaches the strength corresponding to the class or grade of concrete in terms of compressive strength.

3.5. Acceptance of lintels in terms of accuracy of geometric parameters, thickness of the concrete cover to reinforcement, category of concrete surface, width of technological crack opening should be carried out according to the results of a one-stage selective inspection.

4.1. The control and assessment of the strength, stiffness and crack resistance of the bridges should be carried out in accordance with GOST 8829-85.

Loading tests of lintels to control their strength, stiffness and crack resistance should be carried out when the concrete reaches the strength corresponding to its class or grade in terms of compressive strength.

4.2. The concrete strength of the lintels should be determined in accordance with GOST 10180-90 on a series of samples made from a concrete mixture of the working composition and stored under conditions in accordance with GOST 18105-86.

When testing lintels by non-destructive methods, the actual transfer and tempering compressive strength of concrete should be determined by the ultrasonic method in accordance with GOST 17624-87 or mechanical devices in accordance with GOST 22690-80, as well as other methods provided for in the standards for concrete testing methods.

4.3. Frost resistance of concrete should be determined in accordance with GOST 10060-87 on a series of samples made from a concrete mixture of the working composition.

4.4. The water resistance of concrete lintels intended for operation in an environment with an aggressive degree of exposure should be determined in accordance with GOST 12730.0-78 and GOST 12730.5-84 on a series of samples made from a concrete mixture of the working composition.

4.5. The water absorption of concrete of lintels intended for operation in an environment with an aggressive degree of impact on reinforced concrete structures should be determined in accordance with GOST 12730.0-78 and GOST 12730.3-78 on a series of samples made from a concrete mixture of the working composition.

4.6. Methods of control and testing of reinforcement and embedded products - according to GOST 10922-90.

4.7. Measurement of stresses in prestressing reinforcement, controlled at the end of tension, should be carried out in accordance with GOST 22362-77.

4.8. Inspection and testing methods for the raw materials used for the manufacture of bulkheads shall be in accordance with established standards or technical conditions on these materials.

4.9. Dimensions, deviation from straightness, concrete cover thickness to reinforcement, position of embedded products, quality of concrete surfaces and appearance jumpers should be checked by the methods established by GOST 13015.0-83, GOST 13015.1-81 - GOST 13015.3-81 and GOST 13015.4-84.

5.1. Jumper marking - in accordance with GOST 13015.2-81. Markings and signs should be applied to the end or top sides of each bulkhead. On the front side of jumpers with slinging holes (instead of mounting loops), the mounting sign "Top of the product" must be applied in accordance with GOST 13015.2-81.

It is allowed, by agreement of the manufacturer with the consumer and the design organization - the author of the project of a specific building, instead of marks, to put on the lintels their abbreviated legend adopted in the design documentation of a particular building.

5.2. Requirements for the document on the quality of jumpers supplied to the consumer are in accordance with GOST 13015.3-81.

In addition, the document on the quality of lintels should indicate the grade of concrete for frost resistance, and for lintels intended for operation in an environment with an aggressive degree of impact, the water resistance and water absorption of concrete (if these indicators are specified in the order for the manufacture of lintels).

5.3. Jumpers should be transported and stored in accordance with the requirements of GOST 13015.4-84 and this standard.

5.3.1. The lintels should be transported and stored in containers sorted by grade and stacked in working position.

It is allowed to transport and store lintels stacked without containers.

5.3.2. Washers and gaskets between the rows of lintels must be at least 25 mm thick and located vertically one above the other at a distance of 200-250 mm from the end of the lintel.

5.3.3. The height of the lintel stack should be no more than 2 m.

5.3.4. Lifting, loading and unloading of bulkheads should be carried out in packages with a crane using special load-gripping devices, and individual bulkheads should be gripped by mounting loops or provided slinging holes.

5.3.5. During transportation, the lintels should be laid in vehicles in working position, longitudinal axis in the direction of traffic.

APPENDIX

Mandatory

CONCRETE BRANDS FOR FROST RESISTANCE

|

Estimated winter outdoor temperature * |

The minimum grade of concrete for frost resistance for buildings of the class according to the degree of responsibility |

||

|

I |

II |

III |

|

|

Below minus 40 ° С |

F200 |

F150 |

F100 |

|

Below minus 20 to minus 40 ° С incl. |

F100 |

F75 |

F50 |

|

Below minus 5 to minus 20 ° С incl. |

F75 |

F50 |

Not standardized |

|

Minus 5 and above |

F50 |

Not standardized |

Also |

_________

* The estimated winter temperature of the outside air is taken as the average air temperature of the coldest five-day period, depending on the construction area in accordance with SNiP 2.01.01-82.

CONTENT

1. TYPES, BASIC PARAMETERS AND DIMENSIONS

Jumper type PB

Jumper type PP

Jumper type PG

Jumper type PF

2. TECHNICAL REQUIREMENTS

3. RULES OF ACCEPTANCE

4. METHODS OF CONTROL AND TESTING

5. MARKING, STORAGE AND TRANSPORTATION

APPENDIX (required). CONCRETE BRANDS FOR FROST RESISTANCE

Specialization: facade decoration, interior decoration, construction of summer cottages, garages. The experience of an amateur gardener and gardener. He also has experience in repairing cars and motorcycles. Hobbies: playing guitar and much more, for which there is not enough time :)

Jumpers for window openings are important detail any building, on which the strength and durability of the entire structure depends. Therefore, their arrangement must be approached no less responsibly than, for example, the construction of the foundation and the laying of walls. In this article I will try to tell you in detail about all the nuances of the manufacture and installation of jumpers in private construction.

Jumper Requirements

So, window lintels, in fact, are beams that are laid on top of window openings when erecting walls. Therefore, they perform several functions at once:

| Functions | Peculiarities |

| Strengthening the wall and opening | The lintel must support the weight of the wall located above it and transfer it to the one below wall structure... In addition, this detail strengthens the opening, preventing the walls from collapsing. |

| Opening formation | The lintel participates in the formation of the window opening, since it is top... Moreover, with its help, you can even set the shape of the opening, for example, make it arched or even. |

| Creates the basis for subsequent construction | Further wall masonry is erected on the beam or ceilings are laid, i.e. it forms the basis for the wall above. |

In this way, the main requirement for jumpers is their strength... Therefore, reinforced concrete lintels in accordance with GOST R 51263-99 are made of concrete grades not lower than D300-D600.

In addition, they must meet some other requirements:

- high precision of the form;

- the length of the supporting sections must be at least 25 cm on each side;

- durability.

Types and production

Currently, in private construction, as a rule, the following types of jumpers are used:

V wooden houses, made of a bar or log, lintels as such are not made, since their function is performed by the crown of the wall located above the opening. Moreover, in some cases, the openings are cut out after the walls have been erected.

Reinforced concrete

Reinforced concrete lintels in Lately are the most popular due to the following advantages:

- have high strength, which allows them to be used in construction even multi-storey buildings from heavy materials;

- you can pour it yourself or use ready-made beams made at the precast concrete plant, which allows you to speed up the construction process. True, the advantage of self-pouring is the ability to make a beam of any size. The finished products are sized according to GOST 948-84;

- you can give the product any shape, but, again, with self-filling;

- long service life - the concrete lintel will last as long as the entire wall structure.

At self-production concrete lintels, the following rules must be observed:

- longitudinal reinforcement rods must have a diameter of at least 10-12 mm;

- transverse reinforcement rods must have a diameter of at least 6 mm, in addition, they are installed with a step strictly no more than ¾ of the beam height. In places where the beam rests on the wall, the step should be at least 1/3 of the lintel;

- the depth of support should be at least one third of the height, but not less than 20 cm.If the height of the lintel does not exceed 50 cm, the depth of its support is brick house must be at least the length of one brick.

Concrete beams for windows are poured in the same way as any other monolithic structures- first, the formwork is installed, after which the reinforcement is performed and then the formwork is poured with concrete. I will not describe this process in detail, since it has already been mentioned many times on the pages of our portal.

Metallic

In private construction, concrete beams are often replaced with metal beams, which, as a rule, are made from a corner. Also for these purposes, I-beams or channel profiles can be used.

Among the advantages of such structures are the following points:

- the metal is able to withstand enormous tensile loads and pressures on it. Therefore, the strength of metal structures is quite sufficient in private construction;

- simplicity and speed of installation;

- it is possible not to perform the calculation, since the safety margin is sufficient, especially during construction brick walls... The only thing is that the thickness of the corner steel should be 8-9 mm, and the width of the opening should not be more than 1500 mm.

In order for the corners to work together, and not lie by themselves, after laying on the wall, they should be connected with several jumpers. As the latter, you can use reinforcement rods.

In some cases, when designing a building, it is necessary to calculate the lintels. Therefore, further we will consider how to calculate the strength of a metal beam.

The calculation is carried out according to the following formula:

Мр = 1.12 * W * R, where:

The installation of lintels for window openings from a corner is quite simple - corners or other types of profiles must be brought to a depth of at least 20-25 cm, like any other lintels. In this case, the length of the profiles is adjusted to the masonry seams. I must say that the walls for such lintels do not have to be reinforced with reinforcement.

The only thing under the lintels, as a rule, is a pillow made of concrete or brick. In the process of making the cushion, it is extremely important to ensure the horizontal position of the jumper. In fact, these are all the nuances of installing metal beams.

Brick

Brick lintels are used when arranging openings in brick buildings... Moreover, they are most often used for small houses.

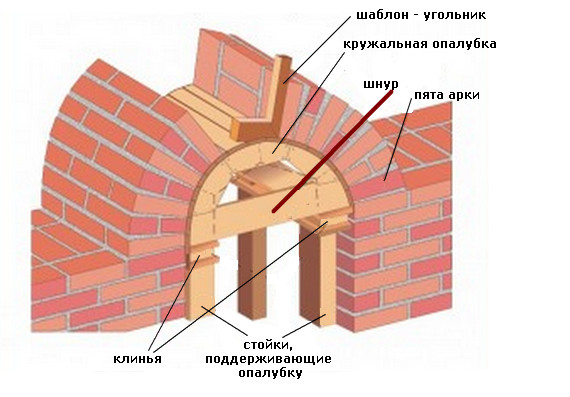

The principle of such bridges is based on the use of a particularly strong mortar, as well as reinforcing rods that are laid inside the masonry. The main advantage of this technology is that it allows you to create spectacular vaults. In this case, the masonry is carried out by laying the bricks in a wedge-like manner.

I must say that brick lintels are strong enough to withstand heavy loads. However, in order for them to keep their shape until the solution hardens, spacers, usually wooden, are necessarily used. Actually, it fits on them brickwork, which subsequently gains strength.

If the opening has an arched shape, you can order plastic arched windows for it. As a result, the design of the facade will look very impressive.

Brick lintels must meet the following requirements:

- if the width of the window opening does not exceed two meters, you can lay out the bricks in rows. In this case, they must be reinforced with rods;

- mortar for laying bricks must be 25th grade or even higher;

- rows of bricks should be placed strictly horizontally;

- the length of the brick lintel should be 50 cm greater than the width of the opening;

- if the width of the opening exceeds two meters, then brick cannot be laid with wedges;

- all joints must be thoroughly filled with mortar.

Now let's look at how to make a lintel over a brick window. The work is carried out in the following sequence:

- when the brick walls are erected to the height of the window opening, you can proceed with the formwork (spacers). As a rule, boards with a thickness of about 5 cm are used for this. The bottom board should be located strictly horizontally;

- then a solution with a thickness of about 2-3 cm should be poured into the formwork and carefully leveled;

- then reinforcement rods with a diameter of 6 mm must be pressed into the solution. There should be at least two rods under each brick. The ends of the reinforcement should be brought out 25 cm outside the opening, moreover, they should be bent in the form of a hook, therefore, it is necessary to calculate the dimensions of the rods in advance and prepare them;

- after that, bricks are laid on the reinforced base;

- when the mortar hardens, the formwork can be disassembled.

The supports for the formwork must be installed so that after the mortar has solidified, the horizontal plank can be lowered evenly.

From aerated concrete blocks

Window lintels for aerated concrete are most often made of U-shaped aerated concrete blocks. Since aerated concrete itself is lightweight materials, such blocks do an excellent job. The principle of their manufacture is that the inner space of the blocks is reinforced and filled with concrete.

The instructions for arranging the jumper in this case are as follows:

- before making a lintel over the aerated concrete window, a horizontal spacer should be installed, which will support the blocks until the solution hardens;

- then blocks are laid on the spacer with a support on the wall of at least 25 cm;

- further, reinforcement should be done before pouring concrete into the U-blocks. For this, four rods of the A400-A500 d12-d16 class are used. Of these, spatial is performed.

In this case, the transverse support reinforcement should be located with a step of 40-50 cm. It should be noted that the dimensions of the tray in the blocks may be different. If its width does not exceed 12 cm, you can perform reinforcement with two rods, which should form the upper and lower reinforcing belt;

- the resulting formwork from aerated concrete blocks is poured with concrete.

The blocks must be installed so that their thick wall faces the street.

Here, in fact, is all the information on how the lintels are performed over the windows in a house made of aerated concrete. After the mortar has solidified, the spacer can be dismantled.

Conclusion

Lintels for windows are made from different materials. The choice of construction depends, first of all, on the materials from which the walls are erected. In addition, nuances such as installation speed and even facade design are often important factors.

The video in this article contains more information. If you have any questions regarding the arrangement window lintels, ask them in the comments, and I will be happy to answer you.

October 14, 2016If you want to express gratitude, add clarification or objection, ask the author something - add a comment or say thank you!