Wall cladding with facing bricks. Important details of installation work. The process of doing work.

![]()

Brick cladding of the facade of the house is done quite often. It's worth saying this species finishes are not always suitable. Mainly in terms of scope. After all, here you need to have a reliable foundation and not in all rooms it is. Today we will tell you how to decorate the facades of brick houses. This issue can be solved completely independently and avoid unnecessary costs.

Requirements for a brick

The meadow areas surrounding the statue fountains have been redefined to form two regular grass squares bounded by pebbles and tracheal paths. In their interior, the lawn can be freely grown. The design has revised the edge of the gutter so that the relationship with the grass area and the presence of running water is evident. At the end of the collection of preliminary historical studies, the most interesting thing was that due to the presence of pond fish in the aforementioned wall, by the middle of the excavation survey, the presence of two powerful underground walls, which completely coincide with the latitude, was revealed. water in a stream.

Attention: In some cases, it will be more advisable to use brick-like tiles for finishing, then you will not need an additional foundation. So this is a question worth considering.

When not to veneer

The facade of a brick house is not always made, in some cases it is better to abandon this idea.

Ceramic facing brick

The channel, which is located behind the wall of the cabinet. To obtain the memory of the weight element, the area of the lawn that coincides with the perimeter was slightly reduced. Saturday and Sunday from 30.00 to 30.00 and from 00.00 to 30.00: 15 August, 8 December, 26 December.

Other opening possibilities after booking. Schools: €1, €50. Tours: We offer guided tours for individual visitors, all opening days at specific times, up to 30, and cost: €2.00 per person Tour arrangements will vary for temporary exhibitions housed throughout the year inside the villa.

- If the building has a weak foundation or has a complex geometric shape, then it is time to think about whether it is worth facing the building with bricks. Indeed, in that case, it is necessary to strengthen the foundation, and this is time and cost. The price of finishing immediately increases.

Attention: This is especially true in cases where the building is multi-storey and the second floor has more complex geometric shapes. Perhaps, in this case, it is worth revetting only the first floor, and revet the second floor using other materials and technologies.

Palazzo Campanari now lives in the town hall

Ticket closing time 00 Ticket to buy € 00. In poor state of conservation; Part of the complex is also a well-preserved church. Now the site of the City Hall and an important historical archive.

Villa Palace, then Cornoldi, now Fanan

Everything "inside" is 18th century stucco.Villa Dolphin is now the House of Divine Providence

The villa rises on two floors plus an attic. The facade is reminiscent of Venetian palaces with a side loggia on a noble floor. The original building retains the barksha and oratory. It has a harmonious façade with overlapping columns and dowels superimposed by a tympanic membrane with lateral volutes. It has a central staircase and barsha. At one time he had an agricultural function.

- It will be necessary to abandon the lining of the building with bricks even if it is not possible to bring the lining under the roof overhang. In this case, it will be necessary to dismantle part of the roof in order to increase its overhang, and this is a huge investment of time and money.

Solving the foundation issue

During the construction process, they are guided by SNIPOM 3.03.01-87. But when the question arises of facing an old or built house, then problems may arise and experienced builders cannot be dispensed with.

Of the Palladian forms, it has stylistic connections with Badora. This was the beginning of a chain of events that involved the Carbonari Poole in one of the most tragic pages in the country's history. Of the original design, only a small and elegant oratory. Of great importance is the park with numerous centuries-old trees.

Decorative properties of facing bricks

Here, the socialist youth deputy Giacomo Matteotti, who was killed by the Nazis on June 10, died. Double-sided facades are extremely reliable and give the building an individual exposure and increased sound and heat resistance. Wind and bad weather can be devastating, especially to a building's facade.

Attention: decorative wall from a facing brick has a significant weight and it needs a reliable support. Experts say that if you veneer a house with an area of about 100 square meters, then the weight of such a cladding will be within 40 tons, which is very impressive.

- Not every foundation is able to withstand such an additional load, especially when it comes to a frame structure or building a house from a bar, under which there can be a very conditional foundation.

- As a rule, before starting the cladding, experts check the foundation, while they believe that since the foundation was built by the masters, it means that they built it, adhering to the technology and certain calculations. Usually, the foundation along the outer perimeter extends beyond the wall, which allows decorative masonry to be installed on the old foundation.

- As an option that makes the cladding more reliable, you can use galvanized steel corners and fix them to the old foundation with anchor bolts, after which you can start laying decorative bricks over the building.

- If it is impossible to install the cladding on a common base, a new foundation is made near the old base. New and old foundations fasten using anchors. New foundation is built according to technology, which involves reliable protection of the new base from moisture.

- Great difficulties can be encountered when facing a building that has a complex architectural form. It is very difficult to cope with such a task yourself, so you will have to turn to the masters, which can lead to large additional costs. In this case, you need to think about whether it is worth starting all this

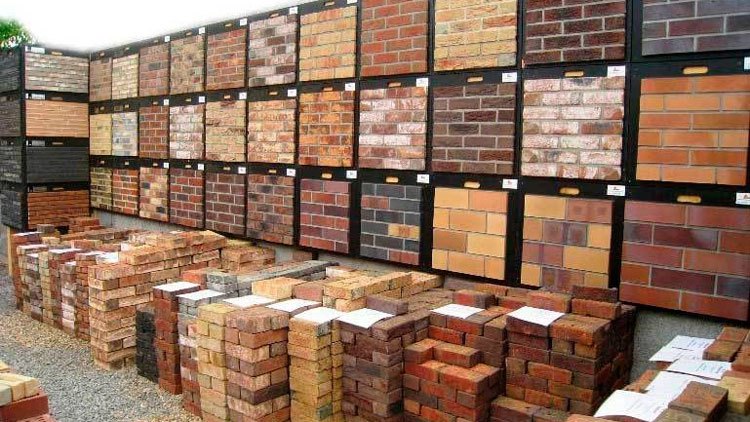

The main types of bricks for building cladding

Manufacturers of modern building materials have made quite a few choices, so it's a matter of your preference. This also applies to facing bricks, which are provided on the construction market in a wide range. Here you can buy bricks made according to various technologies and having different purposes.

In coastal areas, for example, the salt content in the air further contributes to the harsh climate. It is important to ensure the resistance of the facade to atmospheric conditions. But facade bricks are also preferred in other regions. Instead of plastering the facade after a few years, the individual radiation of the building remains literally throughout its life.

The multi-layer facade improves the microclimate in addition to its technological advantages, as well as the advantages of the natural material - clay. Older civilizations appreciated the importance of clay and its extraordinary properties. The production of bricks began in the first century BC, and their development was in the middle of the century. One of the first bricks was built by Queen Maria Theresa on Wienberg Hill.

Attention: Samples of both solid and hollow bricks are presented on the market, differing in technical characteristics: hollow brick has good heat-insulating properties, and solid brick is more durable.

Based on this, facing bricks can be produced in the following types:

Wienerberger bricks are constantly being developed to achieve optimum performance to meet ever more demanding designs. Because if until now the requirements for brick were mainly load-bearing and weather-resistant, today its heat and sound insulation properties are at the forefront. Energy resources are exhausted, and energy is becoming more and more expensive, so its conservation is a priority for every investor.

In addition to clay's thermal insulation properties, its cumulative qualities should not be underestimated. Along with its porous and capillary structure, which provides thermal protection for the building, brick also has the unique ability to act as a natural air conditioner: temperature fluctuations are evened out due to the release and receipt of heat.

Clinker | Clinker brick is characterized by its strength and is quite durable, which is ensured by the peculiarity of manufacturing technology. Clay of a certain composition is used as a raw material and it is fired at a temperature of 1200ºС. As a result of this, complete sintering of the components inside the brick occurs. Moreover, it can be produced with different textures and different colors. Depending on its purpose, a brick must meet a number of additional requirements. Shape and design Cavity volume Compressive strength Baffle thickness Density Thermal insulation properties Water absorption Strength cohesion Reaction to fire Ecology Durability and return on investment. And when we talk about investment, we have to show a vision that only material with a long lifespan can allow us. Making a choice of solutionTo achieve the maximum potential of a multi-layer facade, several basic rules must be observed. The gap can be filled with insulating material attached to the load-bearing wall, or with air alone and a combination of the two. Air slots provide optimal ventilation inner wall, and any water that may be trapped through the joints may be swept away. To ensure perfect air circulation, the outer façade layer must be careful not to get grout in the gap. The two façade layers are connected by stainless steel anchors which add additional structure. Choosing a facade brick is not easy. |

|---|---|

Ceramic | Ceramic material can be used for cladding a wide variety of buildings, thanks to its original appearance, which makes it possible to form geometric patterns and whole pictures on the walls of buildings. |

Glazed | During the manufacturing process, glaze is applied to the surface of such a brick, from which it got its name. Buildings lined with such bricks have an original and attractive appearance. Clinker bricks are used for the construction of decorative masonry with high resistance to weathering and frost, as well as high compressive strength. Painful color is the solution for those who love the classics but look and stand out. The facade is a type of building, its memorable face, which is often called a visiting card. It is too unfortunate when, in addition to beautiful and well-maintained buildings, rotting, unaesthetic and even dangerous buildings grow. But the Internet space is full of amateur photos of "impressed" foreign tourists in Bulgaria, showing exactly these "unfortunate" facades!? |

hyperpressed | This type of brick appeared quite recently and has a great chance of displacing facing bricks made by firing.

|

Attention: Task decorative finishes not only to make a building that meets the spirit of the times, but also to protect housing from atmospheric precipitation. In addition, the cladding technology allows you to “shove” a layer of insulation between the cladding and the main wall of the building, which makes it possible to make housing more environmentally friendly and less energy-intensive.

Insulation and decoration of the facade of the house with bricks

We are witnessing a completely different indiscipline - a partial reconstruction of the blocks that, after a few years, made the urban landscape unimaginably grotesque. The autonomy of the owners who have taken this desperate measure to deal with this situation is not enough and the effect is minimal. The problem is big, painful and at this stage without adequate state support.

With this material, we will again turn our attention to the various systems and materials for the construction of the façade. Facade systems are grouped into two main groups: contact facade systems and ventilated facade systems. Contact façade systems have become the most used façade solution, especially for Europe, partly due to their affordability.

Materials and tools needed for work

To carry out facing work, you will need the following tools:

- Dishes for mixing the solution.

- Concrete mixer if there is a large amount of work.

- Master OK.

- Template for getting the same seams.

- Bulgarian, for cutting bricks.

- Measuring and marking tool, such as a tape measure.

- Pencil.

- Square.

- Level.

- Plumb.

- Cord or fishing line.

Attention: It is possible that this is not full list and you will have to use additional devices. The most important thing is that such devices are efficient, reliable and easy to use.

Facade decoration is a very important part of the façade system, as it gives a complete view of the building, enriches the architectural design and at the same time allows you to create a unique vision through the properties of different façade coatings. According to its physical and chemical composition decorative coatings for the facade are divided into:. facade decorative plasters.

Mortar preparation

facade paints. Facing tiles. Facade plasters are divided into two main types - dry and pasty. The first is based on white cement, dry polymer additives and a limited shade of dry pigments. Before application, they are prepared with water in a suitable proportion and a construction mixer. They are cheap, but, on the other hand, are relatively perishable and highly absorbent of water.

Making a choice of solution

Facing the facade of the house with brick is done on the mortar. And everyone knows this. But you still need to choose the right one. After all, the durability of the entire structure will largely depend on this.

- First of all, everyone pays attention to the traditional cement composition. It is used most frequently. But it is a little complicated in laying. It does not lay down evenly and the thermal insulation is not high;

- The second can be considered lime composition. It is easier to lay, evenly distributed and fills the seam. However, it is not as strong and durable as the first option;

- There are also many cost mixtures that are available at retail. In this matter, the instructions for use should be previously studied. After all, you need a composition for exterior decoration.

Attention: In any case, a packaged solution will be much more expensive if you prepare it yourself. Therefore, with large ones, it is better to make the mixture yourself.

It is advisable to cover them with facade paint, preferably silicone-based. The main feature of all pasty plasters is that various pebbles are present in all types of acrylate dispersion. The types differ from each other mainly in the addition of additives to dispersion additives, which emphasize or reduce one or another ability. decorative plasters.

Types of pasty plasters depending on their composition. Acrylic polymer - the most common pasty plasters in practice. They are dyed in most colors compared to other types, have low water absorption, water repellent, elastic and non-deformable, but also less permeable, faster aging and dirt accumulation.

Carrying out preparatory work

Facade brick house begin to do after careful preparation.

- Work begins with accurate calculations of the required number of finishing bricks, depending on the geometric dimensions and shape of the building.

- At the same time, the possibility of waste or defective bricks should be taken into account and bricks should be ordered with a margin of about 10%. In case there is not enough brick, there is a high probability of additional bricks from other lots, which may not be acceptable due to the fact that it may have a different shade.

Attention: You can protect yourself from such a problem if you start lining the buildings from the most visible place, and leave the remains or rejection in the background, less noticeable.

Acrylic-silicate tones in strictly defined colors due to the limitations of their composition. Suitable buildings with high environmental moisture content and insulating façade system with stone façade wool. Acrylic-silicone tones in strictly defined colors.

Acrylic-silicate silicone - combines the best silicate and silicone plasters. Types of pasty plasters depending on their type and structure. Mosaic plasters are a mixture of acrylic dispersion with naturally colored pebbles, available in different fractions and colors. They are mainly used for the construction of skirting boards and are characterized by surface strength and colorlessness over time.

- Many craftsmen, before starting work, produce a dry lining, without using mortar, in order to see some of the nuances and determine how long the brick will last. Sometimes it is enough to lay an area of one or two square meters in order to notice this and decide on a further work plan.

- If the previews correspond to the preliminary calculations, then you can proceed to facing the house. Due to the fact that the facing brick absorbs moisture very quickly, it must be placed in water for a short time. This is necessary so that the mortar does not solidify so quickly, which will allow the freshly laid brick to be adjusted horizontally and vertically.

- A very important component of the masonry is the mortar, the quality of which will determine the quality of the entire surface. It is advisable to use the recommendations of brick manufacturers in order to obtain a high-quality mixture and not violate the laying technology. On the other hand, it is possible to use already tested batches with simple components.

- As a rule, sand-cement mixtures are used for such purposes, the basis of which is cement grade 300 or 400, and sifted sand. For good reliability, you should use water that does not have high concentrations of salts and other mineral impurities.

- In the process of preparation, it is necessary to control the consistency of the solution: the composition should approach the level of thick sour cream. Real masters of their craft can easily cope with this problem.

Attention: First you need to look at the samples of facades brick houses, because the drawing can be quite different and at the same time it is applied various material. So that's where you need to start.

Structural plasters - can be acrylic, acrylic-silicate, acrylic-silicone and acrylic-silicone silicone compositions. Generally, two types are drawn: dragged with frames 2.00mm, 2.5mm and 3.0mm and scattered with 1.00mm fraction and 1.5mm, 2.0mm, 2.5mm and 3mm .00 mm.

In decorative plasters and facade paints base preparation and application are identical. After the final drying of the reinforced plaster, a facade primer is applied. Its composition corresponds to the composition of the applied coating, paint or plaster. Individual manufacturers also offer universal primers for their products.

The sequence of actions when facing

Finishing work is mainly done in dry and warm weather. Do not do this in sub-zero temperatures. Then you need to make a winter version of the solution, but its quality will never compare with the summer version.

Attention: If you want to make a ventilated brick facade, then you need to take this into account when preparing and conducting work. Although with brick paneling, this issue is much easier to solve.

What is a decorative brick

The primer is applied by brush or roller to facilitate the application of the façade plaster or paint and therefore penetrates as deep as possible into the façade plaster. He can be white color, colorless or tinted decorative coating.

Decorative plasters In order for the decorative facade plaster to be sufficiently stable, the minimum layer thickness should be 1.5 mm. The application of decorative plasters is carried out 24 hours after the application of the primer, the plaster is only manual.

- Given the factor that not only the owners, but also many passers-by will pay attention to the results of their work, such work should be treated very carefully, and the laying of bricks should be done accurately and accurately.

- The cladding of the building begins with the laying of the first row of bricks around the entire perimeter. It is not difficult to imagine how important it is to accurately and accurately lay out this row of bricks. This sets the correct distribution of the entire plane.

- When laying bricks, it is advisable to use a template that will save the mortar and make the seams of the same thickness. To simplify further work, about five rows of bricks are laid out at the corners of the building, after which a rope is pulled between the two corners, which will speed up further work.

- Focusing on the rope, like a beacon, you can quickly lay an opening between two corners. At the same time, you need to constantly check the horizontality and verticality of the laid out side by side. Despite the seeming simplicity and speed, performing work with facing brick, it’s better not to rush, but once again check how smoothly the wall is laid out.

- After laying the openings between the corners, the procedure is repeated in the same sequence: first lay out the corners, stretch the rope and lay the gap between the corners. And so gradually, from bottom to top, step by step, the wall is laid out under the very roof.

- Throughout the work, you must constantly watch the solution. The mass must be completely homogeneous. To do this, it must be constantly mixed with a trowel.

Attention: If you use river sand in the preparation of the solution, then it quickly sits down. To avoid this, just add a pinch of any washing powder to it.

- Particular attention should also be paid to the thickness of the seams, the dimensions of which should be within 10-12 mm.

- It is also not necessary to forget about the ventilation gap between the main wall and the facing layer. Such a gap does not allow excess moisture to accumulate at this border, as well as the appearance of fungus and mold. To improve the natural circulation of air, a hole is left in the second bottom row, which is closed with a grill.

- In order for the lining to dry in natural conditions, after completion of work, the walls are covered with a plastic film, which protects the lined walls from high humidity.

Details to pay attention to

Construction requires compliance with the technology of work. The cladding of the building must be carried out according to the same technology and in accordance with the chosen style, from the beginning to the end of the cladding work. Changing the cladding technique and deviating from the original style can harm the appearance of the building. This can happen when, for some reason, masters are replaced. This means that you need to be very careful in choosing them and invite craftsmen with some familiarity or complete information about their work.

- Brick cladding requires very careful handling of this building material. During the laying process, immediately remove the mortar from the surface of the brick. By the way, this factor can be used to determine the professionalism of a bricklayer. If he leaves behind a dirty brick, then he is such a master. Masters of their craft work very cleanly.

- To remove whitish deposits of salts on fresh masonry, you need to stock up on special impregnation. In the event that it is not possible to purchase a brick of one texture and one shade, it is possible to perform cladding in the style of "Bavarian masonry". If there is information about this style, then you can consciously take such a step and not think about the possibility of acquiring a non-standard facing brick.

How to store and transport bricks

Correct delivery has great importance. After all, there should be as little fighting as possible and appearance must be appropriate.

Options for facing the facade of a house with bricks can be quite different. There is also "Bavarian masonry", which will help not only solve this problem, but also make the house quite beautiful and attractive, especially since there are trends in "antique" cladding of buildings. For starters, it’s worth looking at the facades of brick houses on various videos and photos and making the right choice.

Facades made of facing bricks invariably attract admiring glances. Every developer knows that it is not enough to build strong walls. They need to be finished with such material that it helps to immediately get a triple benefit: it insulates, strengthens and decorates the building. These requirements are fully met by facing bricks. It is able to reliably protect external walls and increase their bearing capacity.

- facing;

- facade;

- facial.

All this is the same material that has the properties necessary for high-quality finishing of the building. The outer layer of the wall is built from these stones, which is in direct contact with the environment and experiences all its adverse effects. Therefore, to technical specifications these products are subject to special requirements.

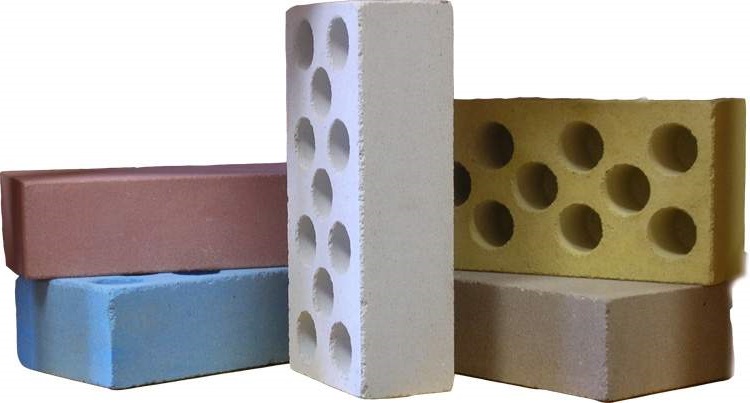

Depending on the type of materials used in the manufacture and the method of production, several types of facing bricks are distinguished:

- clinker;

- ceramic;

- hyperpressed;

- silicate.

These products have different performance characteristics, but there is one thing in common: they can all have a traditional parallelepiped or curly shape. Bricks of the second type are called shaped. Each of the options has its own production standards, which all manufacturers adhere to.

Bricks of the traditional form are:

- single;

- one and a half;

- thickened;

- double.

Each of the listed products can be solid or hollow (hollow). Stones of the second type may have different shape holes and their number.

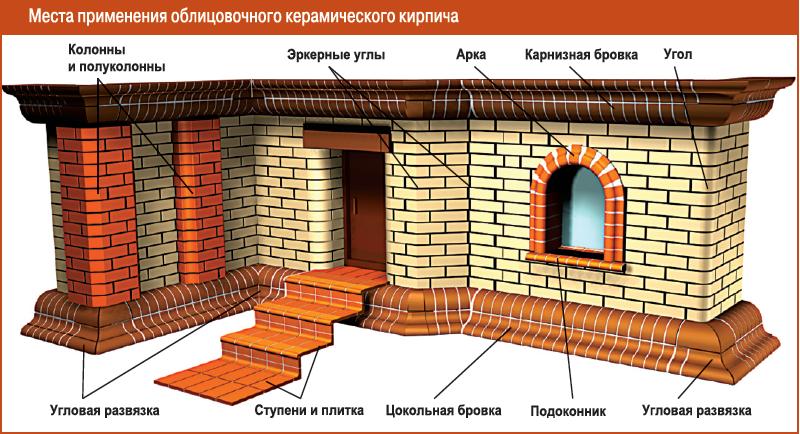

Shaped bricks impress with their spectacular appearance. With the help of these building stones, you can realize the most original ideas of architects and designers.

Manufacturers offer shaped bricks of the following types:

- trapezoidal shape with beveled ribs;

- twisted;

- wedge-shaped;

- with a textured front surface (under the chipped or natural stone).

The spectacular appearance of figured stones largely depends on the method of decorative processing of their surfaces.

Three technologies are used:

- glazing;

- shotting;

- engobing.

For facing the facade of a residential building, engobed bricks are more suitable. They have a matte surface and, due to the production method, have a lower coefficient of thermal conductivity. The engobing technology involves applying an additional layer of clay to the raw stone. It is he who makes the product more “warm”.

Engobed bricks

Glazed bricks have a glossy surface. The color range of such stones is very wide. Glazing can be applied in two ways: on the raw or finished product. Regardless of the technique, the quality and appearance of the product will be the same.

Torqueting is the process of applying mineral chips to the front surface of a brick. After firing, the product acquires a beautiful relief texture. These stones are often used to highlight architectural elements buildings: arches, entrance group, window openings, cornices.

Ceramic brick shotcrete with mineral chips.

Pros and cons of clinker bricks

Clinker - one of the best representatives of facing bricks. Such interdependent characteristics as water absorption and frost resistance are at their best. These stones are able to withstand up to 300 freeze-thaw cycles (frost resistance factor F300). But the thermal conductivity is quite high: 0.7 W / (m * ° C). Durability - at least 100 years.

Among the features of this material is the duration of its masonry. This is due to the low water absorption coefficient. The stone slowly absorbs moisture from the solution, so working with it requires a certain skill.

The disadvantages of this material include the fact that even in one batch of clinker bricks, products of different shades are often found. This greatly complicates the masonry process and increases the construction time. Workers have to choose stones that are identical in color and most beautifully distribute those with a darker shade on the wall.

Clinker brick requires laying on special mortars. The cost of these compounds is high, as is the price of the material itself. There is the possibility of laying on a cement-sand mortar, but you need to know the recipe for preparing the mixture and be able to work with it. On a normal mortar, the clinker brick "floats".

Pros and cons of ceramic facing bricks

Ceramic bricks are distinguished by a variety of shapes and colors. The undoubted advantage of these products is environmental friendliness. At first glance, these stones look fragile due to the large number of voids. But this is a misleading impression. Ceramic bricks are highly durable.

The main disadvantage of these stones is the errors in the geometry of the shape. This complicates the masonry process, as it is necessary to check the conformity of the sizes of the stones. Another drawback is limestone inclusions, which subsequently absorb moisture and begin to stand out on the wall surface with their more saturated color.

Pros and cons of hyper-pressed brick

The composition of hyperpressed brick includes shell rock, cement, special additives.

Advantages of this type of stones:

- perfectly even geometric shape;

- the same dimensions of all products of the same type;

- variety of colors;

- malleability in processing (easy to cut);

- high strength 150-300 kg/cm2;

- water absorption 5-6%;

- frost resistance F150;

- a wide range of shaped models.

Hyperpressed brick has practically no drawbacks. The disadvantages include a large weight (4.2-4.4 kg), which affects the cost of transportation and the laboriousness of the masonry.

Pros and cons of silicate facing bricks

Silicate brick is distinguished by regularity of forms and high strength. Among the advantages of this facing material is the ability to withstand high temperatures, ease of processing, high soundproofing characteristics, reasonable price.

Flaws:

- high thermal conductivity, which increases with moisture;

- large weight (single 3.3-3.6 kg, one and a half - 4-4.3 kg);

- uniformity of colors;

- high coefficient of moisture absorption;

- lack of shaped models.

Should I buy a hollow facade brick?

The peculiarity of most affordable stones of this type is that they have the maximum possible number of voids. This is due to the peculiarities of manufacturing technology and the desire of manufacturers to save money. For the same purpose, they (manufacturers) often make only two edges of the product face: one spoon and one poke. But such a decision is justified, since the stone is turned outward with only one of its sides. The size and shape of the voids can be different, respectively, the weight of the bricks is also different.

The facing layer is usually thin. Since behind it there is a stone of a porous structure with many voids, the front layer does not receive enough heat from it and is often supercooled. This leads to the appearance of microcracks. Water penetrates into them, which periodically freezes and thaws. The wind and the rays of the sun contribute to the process of destruction. All this leads to sad consequences for the building. Therefore, one can often see facades, the front brick of which is partially destroyed.

The disadvantage of such building stones was first understood by the Europeans. They decided to halve the width of the product and strengthen its facing layer. Such material is today called "eurobrick".

Why is he good? A small width (2 times less than that of a standard stone) allows it to freeze less often. The adjacent wall transfers heat and thus helps to stabilize the temperature of the facing layer.

We conclude: when choosing a hollow facing brick, it is necessary, first of all, to pay attention to the thickness of its wall with the front layer. The thicker it is, the more durable the stone.

How to check the degree of water absorption of a brick when buying it

Not always the information reported by the manager of the building materials store is true. The point is not in the seller's desire to deceive the buyer, but in the fact that he operates with the data transmitted to him by the manufacturer.

A competent owner approaches the choice building material extremely responsible. He will definitely ask about all the characteristics of the product declared by the manufacturer. For such a buyer, information on how to choose a facing brick according to the degree of water absorption will be useful.

It is necessary to put next to all those products that were selected for comparison. Each of them is applied a small amount of water. You can use a spoon or any other object suitable for this purpose. Next, observe how quickly the building stones absorb water. Draw conclusions and make decisions. You can refer to the table.

Table. moisture absorption different types facing brick.

If possible, you need to find out if the face layer of the brick was treated with a water repellent at the factory. If yes, then you need to specify which ones. Most modern water repellents are made on a paraffin basis. The surface treated by them has a water-repellent property. But at the same time with this plus, the product immediately acquires two minuses.

- The vapor permeability of the face layer of the brick is reduced. Moisture that comes out of the interior of the building through its outer walls meets an obstacle - a layer of water repellent. For this reason, condensation accumulates in the stone.

- The pores closed with paraffin do not allow water to leave the brick. Therefore, after laying stones on a cement-sand mortar, their moisture level rises significantly and remains so for a long time.

In addition to paraffin, there are imported water repellents made on the basis of chemicals. But due to the high cost, they are rarely used by brick manufacturers. Facade hydrophobization is an important and necessary process. But it cannot be carried out in the first year after the completion of construction. It is necessary to wait until the stones are completely dry after laying.

Video - Facing brick for the facade. Which to choose?

Options for decorating facades with facing bricks

Any public or production building without fail includes a detailed description of the facade device. Architects and designers often use facing bricks to add personality to a building.

A private owner who has a built house can independently choose the finishing option and thereby realize his dream, and not other people's fantasies. In this difficult matter, information about the types of facing brick masonry and the most successful combinations of color and texture will be of great help.

The main technique that is used to design facades is highlighting with color.

There are two options:

- the use of a colored masonry mixture that contrasts or harmoniously combines with the color of the facing brick;

- the use of building stones of different colors; in this way, you can emphasize the main lines of the building (arches, cornices, moldings) or highlight entire sectors.

There are many ways to decorate masonry. Each of them is original in its own way and is able to decorate the building.

Highlighting color in the design of facades

Types of facing brick masonry

When choosing a masonry pattern, you need to focus on architectural style building. It should be noted that the fence, gate, entry group houses should form a single ensemble.

A frequently used technique for decorating facades is to emphasize corners and window openings with color or texture.

Underlining the color or texture of corners and window openings

In this case, different types of brick ligation can be used, which creates an additional decorative effect.

Harmonious combinations various kinds masonry allows you to create a series of ornaments that make the look of the house unique.

If you use a facing brick with a rough texture, the house will take on a deliberately brutal look.

Brick with a rough texture

The use of shaped bricks different type and size allows you to build spectacular decorative lines. Facade design can be very different. A variety of colors, textures and types of facing bricks allows you to make the house beautiful and cozy.

Facing brick laying

The technology of facade cladding is practically no different from the laying of ordinary ordinary bricks. Almost the same requirements are imposed on the process and quality of work. The difference is in the type of masonry and the type of binder used.

But finishing the facade with facing bricks is not an easy task. It requires masonry skills and knowledge of the nuances of working with each type of this facing material. In addition, the performer of the work must be extremely accurate and be fluent in all the tools necessary for masonry.

Most often in the process of facing facades use:

- trowel (the most convenient blade length is 18-19 cm);

- hammer-pick;

- mortar blade (for applying and distributing a binder over relatively large areas);

- stitching (required to give masonry joints nice shape)

- devices for control (ordering, mooring cords, rules).

Types of facing masonry

For finishing facades, the most spectacular types of brickwork are chosen.

- Track. In this type of masonry, each row consists of bricks laid in a “spoon” and is offset from the previous one by ½ or ¼ bricks.

- block. It is carried out by alternating rows, in one of which the brick is laid with a “spoon”, and in the next - with a “poke”.

- cross. It is a type of block masonry, but is performed with an offset in every 2nd row by ½ brick. The result is a cruciform pattern in which each "spoon" is surrounded by a single "poke" at the top and bottom.

- gothic. One of complex types facing masonry, which requires brick offset accuracy. Consists of alternating rows of "spoons" and "pokes". In each next row, the “spoon” is shifted by ¼ of the length, and the “poke” by ½.

![]()

Cladding technology

Step 1. Preparation for laying on the mortar. Before laying the bricks on the mortar, always perform a “dry” laying.

It is necessary in order to:

- determine the required number of building stones;

- choose them by size and color;

- determine the required number of halves of the brick;

- determine the location of stones when making corners and openings.

During the placement of stones on the base, marks are made that will serve as a guide when laying on the mortar. At this stage of work, bricks are cut using a grinder equipped with a stone disc.

Step 2 Solution preparation. The mortar for facing brick laying differs from the standard one in that only sifted, preferably river sand, must be added to its composition. The proportions for the cement-sand mortar are standard: 1 part Portland cement grade not lower than M400, 3 parts sand, water, plasticizer, coloring pigment (if necessary). The consistency of the binder should be creamy. From a properly prepared solution, you can roll a soft ball.

Step 3 For laying the first row, perform the following steps:

- determine the highest point of the base;

- a reinforcing mesh is laid on the waterproofing coating;

- install, focusing on the marks made during the "dry" masonry, two corner bricks;

- pull a thread between them so that it indicates the height of the row;

- perform laying of intermediate bricks, making sure that the seam between them is of the same width (optimally 8-10 mm);

- in order for the brick to fall into place, it is knocked out with a pick;

- stitching is used to align and decorate the seams.

Step 4 Masonry according to the drawing. For bonding facing masonry with bearing wall metal anchors are used, which are buried in the wall by at least 10 mm. Perform additional reinforcement of corners and openings with reinforcement rods. Anchors are installed in increments of 2-2.5 bricks. The brick is laid in accordance with the masonry pattern.

When performing facing work, it is necessary to ensure that the cement-sand mortar does not stain the front surface of the building stones. If cement gets on it, it must be immediately removed with a dry rag. Every 4-5 rows of facing masonry, the wall is wiped with a damp cloth.

Video - Brick cladding