The house is clad with metal siding. Do-it-yourself siding of a wooden house with siding - the technology of work and the types of materials used. Colors of metal coatings.

Metal siding of a house today is one of the most popular ways to decorate the facade. He has an undeniable advantage over others. facade materials by cost, for example.

When purchasing it for finishing a building, consumers often do not know how to sheathe a house with metal siding with their own hands.

There are two main ways water and moisture can enter wall systems. A funnel of raw water from the outside can penetrate the wall and, if not allowed within a reasonable amount of time, can increase the moisture content of the wood to above 30% and cause decay, mildew and mildew.

Air is carried when air flows from the warm side of the wall to the cool side. Warm air will hold more moisture than cold air. As warm air passes through the wall heading towards cold side, it will begin to cool and will be forced to release moisture. This is called the dew point where condensation occurs. With a significant temperature drop across the wall, the dew point will occur somewhere inside the wall. During the winter months, the dew point is usually located on the inner surface of the outer skin.

Main material parameters

Metal siding is a cladding material made from galvanized iron sheets. These are light steel panels covered with a polymer film of various colors and shades. Used metal siding for house cladding.

Note! The sheets of material are provided with special grooves for joining when stacking the panels vertically on top of each other. Therefore, the screw heads close well from the outside and make the façade aesthetically pleasing.

Moisture carried by the air flow through the wall is deposited on the back of the shell and accumulates. In hot and humid climates where the air flow moves from the outside to the inside, warm moist air from the outside will be cooled on its way to the indoor air, releasing moisture inside the wall cavity. A home wrap is a breathable membrane with microscopic pores that allow moisture vapor to dissipate, which helps dry the wall system to avoid damage.

The rate of transfer of moisture vapor, or the rate of transfer of a material, determines the ability to diffuse or vaporize water vapor through a wall. The higher the permeability rate, the more “breathable” the material and the easier it is for water vapor to pass through. Materials with a Perm value below 1 are considered vapor retarders because the flow rate of moisture through 1 Permian material is so low there is essentially no flow. House wraps have tariffs in the Perm Territory of at least 58 perm, which are very open to let moisture vapor pass.

The material is commercially available in the following sizes:

- The strips have a total width of 211 mm and a useful width of 188 mm.

- The manufacturer offers strips with a length of 0.5-6 meters.

Calculation of the amount of material

Instructions for cladding a house with metal siding include methods for calculating the amount of material depending on the complexity of the structure:

Whatever the home wrap is, it is vapor barrier or insulation. House wrapping is pretty permeable; Any warm humid air that rises to it will pass through the bottom of the roofing steel and condense. Reflective insulation in pole buildings.

Wood siding enhances any home no matter what style of property it is installed. For many people appearance a real tree is really what makes a home home. For this reason, in addition to the improved strength with technological advances such as modified wood siding, it is very common to find homes clad in natural wood siding. These 47 ideas wood siding are designed to help you better understand what might be possible for your own home.

- Siding has certain geometric dimensions, it can be calculated with an accuracy of 1 m² (see).

- It is more convenient to make a schematic drawing of the house and apply all dimensions (height, width of walls, window, doorways) to it.

- Before sheathing the walls with metal siding, it is necessary to determine the area of the building that is planned to be sheathed with panels.

As a rule, calculations are performed according to the formula:

This property blends rustic with modern through open nails along the face of natural wood siding. The result complements the sleek, modern feel of the building while lending great interest and dimension to the siding. This Kindergarten takes a more playful approach to its facade, setting the siding in different directions. Proving the simple doesn't have to be boring.

Types of metal siding

Architect: Lund Hagem Architectter. There is no rule that you should use the same material for the entire appearance of your property; So why not mix it up? This hotel uses real wood siding as an accent on glass, metal and concrete to help break up the façade, creating a warmer, more accessible building.

- S total = S walls - S openings.

- It is good to draw up a diagram showing the exact location of the strips of material on each wall of the house.

Advice. The use of such sketches allows you to perform the calculation more accurately, as well as obtain an installation diagram.

- It is convenient to use when cladding a house with metal siding with your own hands.

According to the sketch of the house with the location of the panels, you can calculate the number of panels = H / S of one panel (H is the height of the building).

Too many houses are meticulously painted and decorated in such a way that they do not complement their surroundings and do not perform maintenance and labor intensiveness. However, for rustic appeal, the sometimes sustained appearance is the best choice... This home is allowed to age naturally, which allows it to blend in with its surroundings and does not require maintenance.

Features of metal siding: advantages, disadvantages and subtleties in operation

One of the best things about natural wood siding is the natural color variation and multi-tone color palette. Even though this home is evenly clad in wood siding, there is still variety and depth in different shades. Rustic modern houses are extremely popular almost everywhere. They combine the elegant lines of modern buildings with the rustic appeal of wood siding. This cabin makes great use of real wood siding left in its natural state to complement the style.

Calculation of the number of components

There are different options for cladding a house with metal siding, with a different number of components:

| Name | Appointment | Interchangeability | Calculation method |

| Start and finish rails. | It is used to fasten the bottom row of panels, and the finishing one - to complete the mounted surface. | A lock is cut off from the panel, which is installed as a starting strip. The remaining strip is mounted as a final one. | The length of the perimeter of the house (in running meters) is divided by the length of one plank and the quantity in pieces is obtained. |

| Outside and inside corners. | Sheathing metal walls siding provides for their use to decorate the corners of the building. | It is recommended to count the corners one by one (the places of their connection are visible, it is better to avoid this). Basically, the number of corners of the house is multiplied by their height, and the result is divided by the length of the profile. | |

| J-profile. | It is installed as the end of a plane, usually it should cover vertical ends (windows, doors) and diagonal (gables). | Can replace the finish bar. | Calculated in running meters to get the quantity, this value is divided by the length of the profile. |

| H-profile. | Used to connect siding panels. | Wall cladding with metal siding can be performed without joints (the length of the panels is selected according to the width of the wall). | Piece by piece. |

| Window profile. | Installed if door or window openings are recessed deeper than 20 mm. | J - profile, if its width is sufficient. | Piece by piece. |

| Platband. | Used for finishing openings. | The house can be sheathed with metal siding using a J - profile. | Piece by piece. |

Varieties of material

A fairly extensive assortment of colors and textures of metal siding is offered on sale:

You may not know, but natural wood siding comes in a variety of widths. This school used a thinner board to add more depth and interest to its outer walls. One of the nicest things about wood siding is that it provides an elegant, neutral color palette that can complement just about any color scheme. For example, these kids' shelters create bold, vibrant colors that really come out when installed on natural wood siding.

- There is a material that makes it possible to decorate the facade "under a tree" (see), to make an imitation under a rounded beam.

- You can consider various options for cladding houses with metal siding. For example, when finishing, use a material with a protective and decorative coating under a log.

- This siding is distinguished by a layer that imitates woody texture and color. Thus, the clad house becomes like a log house.

Note! In this case, it is important that when finishing with natural wood, it is necessary to additionally strengthen the foundation.

When you want something a little different from traditional siding, consider the beauty of planks and planks. This rustic boat house extends that same plank and stuffs siding directly onto the roof to create a seamless look that stands out from its surroundings.

Natural wood siding can be used for more than just the walls of a house or building. This hotel has wrapped entire sections in wood siding, using it on all the outer surfaces of the individual segments. Mixing this modern style installations throughout the exterior of the building, along with other contrasting building materials, creates a striking and modern facade.

Stylized wood or stone siding (see) with all the fasteners weighs so little that the load of the sheathing itself can be ignored. In addition to weight, this material has a number of other advantages.

Main advantages

Metal siding is characterized by:

- Fast and simple DIY installation technology.

- High strength and practicality (does not fade, does not burn, does not rust).

- Durability (will last at least 50 years).

- Wide operating temperature range (in the range of -50 ° C ... + 50 ° C).

- Many are attracted by the price of the material, but its use has other positive aspects. For example, it is convenient for them to decorate houses with complex geometry.

- Metal siding is used for. Insulation is laid under the material and additional heat and sound insulation is created.

Facade cladding with metal siding can be carried out on newly erected walls, and work can be carried out in any season of the year.

Homes with multiple levels can often struggle to find the right balance between diversification and unification. This property used modified wood cladding to combine the different levels and components of the house, mixing in other materials such as stone and concrete to create areas of transition from one level to the next.

Advantages and disadvantages of metal siding

While wood siding is often installed to create a solid façade, it doesn't have to be. This building separated natural wood planks far enough from each other for light to go beyond the translucent glass envelope at night. The result is a stunningly beautiful landmark in this seaside town.

Installation instructions

A frame is mounted on the outer walls - the base of the future facade. Most often they use a metal profile, sometimes a wooden bar.

So:

- The lathing is vertically level with a step of about 500 mm.

- Sheathing with metal siding of a house begins with fastening the lower horizontal row of planks and continues with the installation of subsequent rows.

- The metal siding is attached to the crate with self-tapping screws screwed into the center of a special mounting hole.

Advice. It is necessary to leave a gap of about 1 mm between the bar and the fasteners, then a change in the temperature regime will not lead to deformation of the material.

Facade cladding with metal siding

Can't decide which siding application is best for your building? Think of mixing the two, like in this school. Upright boots mounted above the spiked siding give this look a lot of size and depth. Adding the illusion of height to cottage can be a problem. If you fall into this category, try starting wood veneer a few feet off the ground by adding contrasting material along the base. The result is an enhanced appearance for the entire façade.

The whole process can be roughly divided into stages:

- Surface preparation.

- Marking.

- Installation of brackets.

- Thermal insulation.

- Installation of profiles and other elements.

- Fastening the siding.

Step by step guide

The operations must be performed in this order. To avoid any difficulties, it is recommended to watch the video in this article before starting work.

For unconventional projects like this bath house, consider creating an unconventional appearance to match. The ends of the wood planks are not trimmed, creating a more organic look that matches both the curvature of the structure and the environment in which it is embedded.

Metal siding mounting technology

The exterior of this building has an industrial, modern feel, achieved by combining wood siding with metal rails. In a very unique setup, we see that instead of a solid surface, a shell was used to create an elaborate screen.

Advice. On preparatory stage everything that can interfere with the cladding process (antennas, sinks, etc.) must be removed from the facade of the building. The old facade finish is removed and any surface defects are corrected.

- Marking is applied along the facade. It is necessary to outline the areas of the surface to be sheathed, taking into account the sequence of work. You also need to indicate the position of the fasteners with the installation of beacons.

- Next, it is necessary to mark the attachment points of the brackets with a step of 0.5 m (horizontally) and 0.8 m (vertically).

Before the house is clad with metal siding, brackets are installed according to the finished markings. For this, holes are drilled with a diameter for which dowels or anchor nails will be used.

For buildings like this beach shelter, emphasizing corners and lines helps create style out of simplicity. Using the same natural wood siding flowing in different directions throughout the interior and exterior helps complete the creative design flow.

Architect: Lincoln Miles Photo: Julian Winslow. The owner of this stunning residence wanted their home to illuminate the beauty of nature. WITH large windows with pictures, they were given an unobstructed view of their property. And their respect for nature has been further demonstrated by the use of sustainable, modified wood cladding which helped substantiate the airy design.

Working with brackets

The brackets are mounted on an isolon gasket. V different conditions different lengths of brackets and fasteners are used.

With an uneven surface of the house (in terms of level), the brackets are selected as follows:

The huge roof blends the barrier between the roof and the walls. Fully clad in modified wood siding, this restaurant's flow is seamless around the entire building. This home received a big splash in dimension during its redevelopment with varied uses of wood cladding. The cladding on the main part of the house is done vertically, while on the front it changes to a horizontal installation, which further emphasizes the space.

Typically a more rustic product, wood becomes graceful in appearance in this contemporary home design. Using simple shapes, straight lines and beautiful wood cladding to achieve a polished, modern look. This restored home uses natural wood siding to cover both its walls and roof. The clean lines of wood moving up and down the house create a frame for an open, glass façade that completes its transitional style.

- When attaching the brackets at the lowest level, they should protrude beyond the limits. For example, there is a significant depression on the surface. Then a bracket is installed, the size of which is 2-3 cm larger.

- Before sheathe the house with metal-plastic, the insulation is tightly butt-welded. When choosing the thickness of the material, the climatic conditions of the area are taken into account. For the installation of plates, disc nails are used, which ensure reliable fixation of the insulation.

They are made of 2 parts:

This mountain cabin is brought to life thanks to the unique movement that its sloping design appears to have. To facilitate this structure while allowing it to maintain its natural appearance, wood siding was used on stone, following the different planes and angles of the cockpit.

Many modern buildings use harsh materials such as concrete or metal to achieve their modern look, but not this property. These student housing buildings used real wood siding in a vertical installation to add character to the mod's design. The result helps the buildings blend in with their more organic surroundings.

- Plastic dowel with a wide head.

- Metal rod.

The number of fasteners is taken at 6-7 pcs / m² of insulation, for the protection of which a vapor-permeable membrane is used. It is fixed with an overlap of 10 cm.

Installation of guides

They are fixed to the brackets with 4.8x28 mm screws or rivets.

One of the best things about real wood siding is its ability to be used in many different ways. This building uses wood in a unique way to provide a sculptural and dimensional coverage that allows light to penetrate in a way that enhances the forms it creates.

Creating grandeur with increasing living height is made easier with vertically mounted timber siding. This home is a prime example of what can be achieved by mixing wood with contemporary design. Many homes use siding in a variety of ways to accentuate architecture. Most of these techniques involve the use of decorative elements and color changes. This tourist cabin achieves the same goals, but with only one type of wood siding and color.

Advice. After that, the finishing plane must be adjusted by changing the length of the brackets within 3 cm (the corresponding instruction is used).

The rest of the structural elements are also installed:

- Drain mountings.

- Guides and slopes.

- Corner connections.

Let's take a closer look:

- A basement drain with a guide bar is attached to the vertical profiles with 4.2x16 mm self-tapping screws. The horizontal position of the siding must be checked by the level.

- The metal siding of the house begins with the first row of planks set to the starting plank. The upper edge of the material is attached to the guide profiles with self-tapping screws.

- Subsequent rows are fixed in a similar way: they are superimposed one on top of the other.

- When working, it is regularly necessary to check the horizontal level of the strips with a level. Recommendations on how to properly sheathe a house with metal-plastic, pay attention to the fact that you cannot fasten the planks too tightly to the frame.

- Temperature fluctuations change the dimensions of the plates, which can lead to serious deformation of the entire system.

At the end, the last row is attached, adjacent to the roof, using shaped elements with special strips. You can compare the result with photos of warm and beautiful facades.

More from my site

Published byauthorFor finishing the facade of the house, metal siding is used more and more often. It consists of sheets of iron 0.5 mm thick and 0.5 to 6 meters long, different shapes polymer coated. Sheets can also be made of aluminum, but they did not find such popularity due to insufficient strength.

Siding is available in several forms: single board, shipboard or herringbone board, as well as in the form of a log (block house). The panels can have both a smooth surface and a structural (wood-like) surface. Various prints can also be applied to the metal siding, which will transform the panel into a real wood with knots or natural stone.

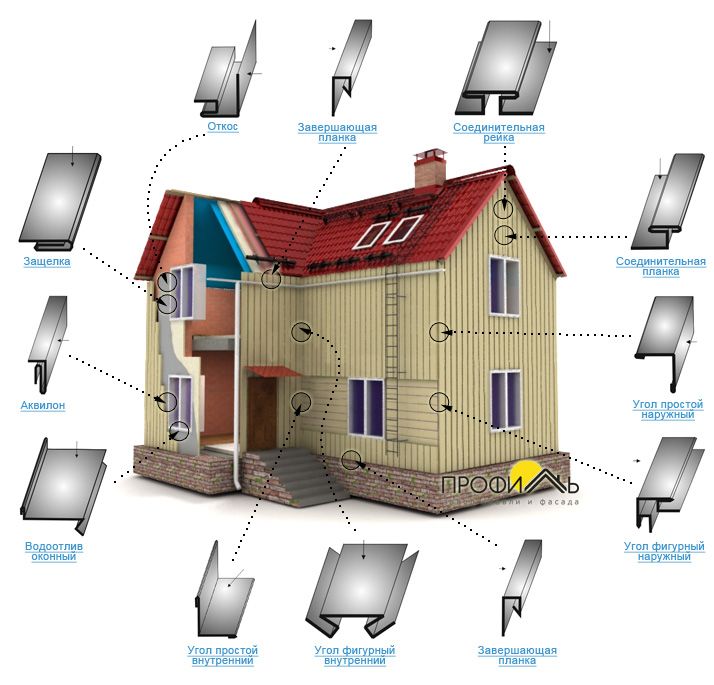

Like all types of siding, metal siding comes with various decorative elements. They, in combination with the main panels, will give the building a beautiful and finished look.

You can install a metal sidig with your own hands at any time of the year, unlike vinyl or plastic siding at low temperatures, it does not burst or break. Practically does not change color (does not fade in the sun).

Required tools

To decorate a house with metal siding with your own hands, you must have a set of the following tools:

Tape measure - for accurate measurement of panels and additional elements

Square and marker - for obtaining and marking a clear right angle

Hacksaw and scissors for metal - for cutting off siding and getting an even cut

Building level - to comply with the vertical when installing the battens and horizontal when installing the siding

Rotary hammer - in the case of concrete walls for drilling holes

Screwdriver - for attaching the siding to the crate with self-tapping screws.

Installation of the lathing

The most responsible and difficult stage in decorating a house with siding with your own hands is the installation of the sheathing. How well it will be done, the process of installing siding will be much easier and more correct.

Wall markings for brackets.

The lathing is carried out strictly vertically from wooden bars or metal profiles. In terms of durability, of course, a galvanized metal profile has an advantage. It is L-shaped and attaches to the wall with adjustable brackets. It is not recommended to use profiles intended for installation of drywall, as it is too thin and may not withstand the load from metal siding. Before attaching the brackets, markings are made on the wall, and holes of the required diameter are drilled for dowels or anchor bolts. The brackets are of different lengths and are installed based on the unevenness of the wall.

For additional insulation of the walls of the house, an insulation is placed between the crate, which is attached to the wall using plastic fungi and closed with a vapor barrier.

Siding installation

After the installation of the battens, they proceed to the installation of decorative elements: corners, ebbs and sloping strips. To accurately install these elements with your own hands, you must use the building level.

Having retreated from the low tide about a centimeter, the initial strip is mounted, to which the lower part of the panel is attached, and the top is attached with a self-tapping screw with a press washer to the crate. The self-tapping screw is not tightened tightly, but a small gap of 1 mm is left for possible thermal expansion of the metal. Do-it-yourself siding house cladding is done from the bottom up. Further, the panels are attached in the same way to each other and the crate to the very top. Every 2-3 rows the horizontal position of the panels is periodically checked. The joint of the last row of siding adjacent to the roof is closed with a special decorative element. Regardless of the shape of the panel, the siding installation process is always the same.

Do-it-yourself installation of metal siding is not at all difficult and will bring a lot of positive emotions from the work done.

After the installation of the main siding panels, the window and door openings are finished with decorative elements.

It is worth remembering !!! Metal siding should not be cut with a grinder, since when heated, the protective painted layer burns out and the siding begins to rust in this place.

Metal siding video

In order not to cut the siding panels once again, they can be ordered in the production of the required size. But decorative elements, unfortunately, are available in a certain size.

A house sheathed with metal siding with your own hands looks no worse than a house trimmed natural materials, and in terms of service life will give them a tangible head start.

The service life of metal siding according to manufacturers' data is at least 50 years.