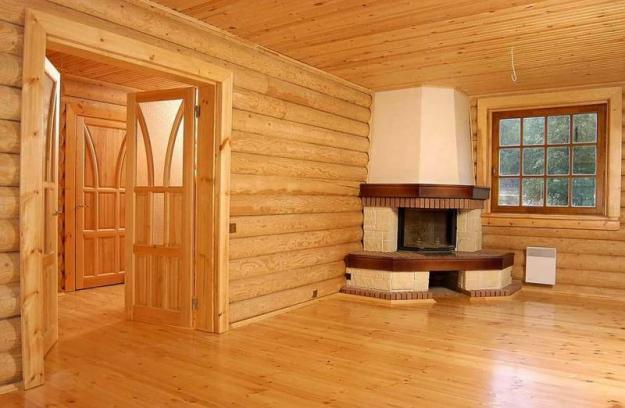

Interior decoration in a wooden house. Natural wood finishing materials

Interior and exterior design made of wood always looks beautiful, environmentally friendly and safe. Wood allows you to give uniqueness to the premises, add a zest, fill with a pleasant aroma, insulate and protect the house from excessive moisture. In this article, we will talk about the types of finishing materials made of wood, the advantages and disadvantages, and also help you choose the right material for interior and outer cladding Houses.

As in Brazil, timber houses are predominantly prefabricated and are built faster. Even if you create a completely new, customized design, it will respect the modulation, which will allow the parts to get back to work previously cut to size. The design consists of a simple assembly, which greatly speeds up the process.

Precisely because it uses less material and with much less waste, the wood is less. Not to mention the cost of labor: although it is more qualified, since the time employed is shorter, the cost does not compare to the cost of masonry.

Types of materials and scope

Wood products are widely used for both interior and exterior decoration of a home. Wood is used for cladding:

- walls;

- facades;

- floor covering;

- stairs;

- internal and load-bearing partitions;

- window, doorways;

- individual decor elements.

Finishing materials made of natural wood are able to create an excellent indoor climate, as well as perform the function of sound and noise insulation, hide defects and emphasize the individuality of the interior. The construction market offers a large selection of wood-based materials. For interior and exterior decoration, the following materials are used:

If you are one of those people who like to take out walls or walls, you might like a wood house. Depending on the system you are adopting, it is easier to make these changes quickly and with little breakage and dirt, quite different from a stone house.

Although the house is made of wood, in Brazil it has some parts of the masonry, starting with the foundations and foundations. Of course, this substructure is much more compact, as a timber house is much lighter. The ideal is to complete all the masonry first. This can include other wet areas of the home, such as the service area.

- block house;

- lining;

- decking;

- decorative wallpaper;

- wood panels;

- parquet and floor board;

- glued laminated timber;

- gusvarblok;

For internal or exterior decoration houses most often use hardwood species: ash, oak, walnut or maple. But from conifers, as a rule, they choose pine, cedar or mahogany. To make the choice easier, you can use the product evaluation criteria:

Also, if you knit a cozy feeling wooden house with a fireplace, it will also need to be built before, in the masonry. The biggest fear living in a wooden house is that they are more vulnerable to nature. Humidity and fire can cause people to discourage the idea, in addition to the risk of the house becoming a termites banquet. But many of these problems can be mitigated or even reversed with some care in the design.

In damper regions, all worries are limited. Wood is more vulnerable to biological agents such as fungi. There are three main features that will protect your home from this risk. The house should be raised relative to the ground to separate the wood from the moisture from the ground.

- material availability;

- the difficulty of caring for the product;

- what degree of material processing is required during its installation;

- conformity of the material to the requirements of wear resistance and operating conditions.

In any case, before buying a facing material, you should learn about each product in detail.

Characteristics of facing materials

Wood-based materials are ideal for finishing various structures made of concrete, metal or brick. For interior decoration the ceiling and walls are most often used coniferous trees, hard wood is used for flooring and stairs, but wood with high density and resistance to the external environment is used for outdoor decoration. Consider the characteristics of wood products.

Generous verandas and balconies protect the rainwood walls while minimizing moisture exposure during rainy seasons. Marine veneer leaves a material much more resistant to moisture. Waterproofing timber on a regular basis will also protect your home. That said, of course, timber houses can be strong and durable if applied to the right wood and treated properly.

Every builder's nightmare in the forest, termites are a real godman. But raising the house on the ground and applying appropriate cultivation techniques to the forest itself greatly mitigates the risk. There are also methods of cultivating the soil of the surroundings of the house, which guarantee several years of release from the disturbance of these insects.

Block house

House block is one of the subspecies of lining, appearance which looks like a rounded log. The product resembles a log house and is used for interior and exterior work both as the main material and as a decoration for individual elements. The main advantage of the block house is:

Other factors are related to comfort. The wooden house has almost no soundproofing: anyone who is surrounded can easily hear who is speaking in the next room. This also applies to the steps of those who go upstairs when the house is flooded. For this problem, it is best to avoid situations that might help her. As for the walls of this room, they are shared with the couple's other equally private environments, such as a wardrobe or a set. Downstairs bedrooms shouldn't be of the opposite gender to avoid sleeplessness when people on the upstairs decide to break up later.

- durability;

- high thermal insulation and sound insulation;

- high strength;

- ease of installation;

- fire-resistant, due to special treatment with fire retardants and antiseptics;

- shock resistant, not deformed.

Lining

As you can see, the solution is to prevent the problem from occurring. Solutions like this in design reduce costs with insulating coatings that only soften but don't solve the problem. Thermal insulation is another very common problem. While advertisements claim that double and insulated walls address this issue, the truth is that the technology used in Brazilian soils still leaves a lot to be desired.

Especially in summer, even with double walls, a wooden house can be very warm. The project identifies the most efficient, final and inexpensive solutions. Some of the best features. Balconies: These shade the outer walls and constitute a pocket of intermediate air temperature near the house. Large trees, mostly on the northwest façade, which receives the hottest summer sun: during the day. Prefer trees that defol in winter and fly in full foliage in summer like yellow ips, so in winter they will allow the sun to warm your home. Another way to induce ventilation is to promote the so-called "chimney effect".

- Arrangement of windows to induce ventilation at home.

- Especially in areas of damp heat, this ventilation matters.

Is economical and the best option for home decoration. The production uses tree species: pine, spruce, oak, alder, linden. The main advantages of the material include:

- long service life;

- high resistance to mechanical damage;

- ease of installation;

- high sound insulation;

- the possibility of painting or toning.

But the disadvantages include the possible appearance of insects and fungus. The photo shows the clapboard lining of the attic.

Other types are cheaper and more environmentally friendly, such as eucalyptus and pine, which are treated and still undergo thermochemical processes that make them more resistant to termites and natural degradation. If you like to change, choose colors carefully. You can change the color if the wood is wet or natural varnish, or if the previous color is white or a different light tone. But if you want to go from a dark tone to a transparent or from a stained to natural wood, this will be almost impossible.

Important! To protect the tree from the attack of rodents and insects, it is necessary to exclude the presence of gaps when laying. The resulting free space is filled with mineral wool, which is also capable of performing the function of additional sound insulation.

Decking

In double-walled systems, units can be built. On the other hand, punching through the wood to secure the jack or switches, there will be “aches” in the woods that you can never completely disguise. Articles on how to avoid movement and placement after building a house. If your style permits, it is preferable to use visible, overlapping objects. If these industrial galvanized iron pipes do not produce heads, the Brazilian market already offers obvious systems with lighter and more striking designs.

If, after reading this article, you are in awe of the charm of a wooden house, make a very important check before heading out to visit the showrooms. There are municipalities that do not allow the construction of this type of houses. Check your local building code. If you confirm that this is allowed, but your land is in a gated condominium or allotment, you still need to be sure and check if there are internal rules for this type of construction.

- loggia or balcony;

- terrace.

Using a decking will allow you to perform finishing and decorative work... The material is resistant, not afraid of open space, resistant to mechanical damage and scratches. Caring for a decking board is quite simple and consists in wet cleaning. An example of laying decking on the porch of a house

It's not that hard, is it? With a little more care of the project, you can enjoy the warmth and authenticity of wood! Write down the aspects you need to check and keep researching your suppliers in your area! Wooden frame walls are the vertical parts of the wooden frame house... This type of construction is a trend.

Wood frame wall design

Among the advantages of these houses are to build quickly, to lighten and offer interesting thermal performance by integrating the insulation into the walls. A timber frame wall is a structural panel composed of timber elements arranged vertically and horizontally to form a frame on which the claddings are fixed.

Decorative wood wallpaper

Decorative wallpaper for walls is made from valuable wood species. In addition to wood, they contain veneer, which is carefully glued onto thick paper. The advantage of the wallpaper is the possibility of pasting it on the radial sections of the room.

This frame forms the frame of the wall and is constructed using small rectangular pieces of wood arranged horizontally and vertically. These beams and these struts are assembled mechanically using twisted tenons. ... There is insulation between the posts. A bezel is attached to each side of this frame.

External and internal cladding

The external cladding consists of a wood panel. Internal cladding is usually made of plasterboard, fixed to a frame of timber spikes or metal profiles. This interior cladding panel should never be attached directly to the structure.

For information! For a long service life, wooden wallpaper must be treated with wax, varnish or oil. Wallpaper can change its color and size (swell) when hit by straight lines sun rays or water.

After completing the decor of the room with wooden wallpaper, the room will dress up a chic and original look. An example of an original living room decorated with wooden wallpaper

To complete this sandwich, a rain protective film must be installed before installing the cladding and vapor barrier membrane on the insulation fixed to the inside. Note: fixation: work that makes triangulating efforts to prevent any deformation by the side rods, for example: Saint-André cross in a frame, solid panel between two poles.

Wooden frame: what materials?

In the locations of the holes, measures are provided to ensure the stability of the panel with timber frame... Frames are made to fix doors or windows. A wooden frame wall is in contact with substrates or work of masonry or concrete.

- Thus, there is a risk of increased soil moisture in the walls.

- To combat these capillary ascents, action must be taken.

- Installing felt between stone and masonry is consistent with this problem.

Wood panels

In the production of panels, tree species such as alder, maple, cedar, oak are used. Wood wall decoration looks elegant, unusual and noble. The panel has three layers with a veneer face made of valuable wood species. To give a spectacular appearance and increase the service life, the panels are coated with a special wax or acrylic varnish.

Insulation for wood wall

These forests must be protected from weather conditions, they are treated with fungicides and insecticides.

- The wood used is usually coniferous: pine, fir, spruce.

- Their permissible moisture content is 18%, preferably about 15%.

The choice of insulation depends on the performance to be expected, and more insulation is allowed to the extent that performance is claimed and meets the technical requirements of the standards. There are no restrictions as the insulation used is subject to technical judgment. Here is a non-exhaustive list of isolators you can implement.

For information! Wooden panels treated with wax are considered the most environmentally friendly in contrast to acrylic processing. Experts recommend using waxed panels for decorating wooden walls in a nursery or bedroom.

There are also tinted panels; in the manufacture of such panels for walls, wood is used from solid pine. Such material is quite easy to install and has a lower price. It is not difficult to care for the panel; ordinary wet cleaning without the use of chemicals is enough. The photo shows the interior of the living room made using wood panels

Wooden wall: vapor barrier and raincoat

Foam insulation: expanded polystyrene boards, extruded polystyrene boards, polyurethane boards.

- Insulation from mineral wool: glass wool, mineral wool.

- Wool or wood fiber insulation.

- Wool-based insulation: like hemp.

For vapor barrier: polyethylene or polypropylene films with a thickness of 200 microns. For rain screen: bitumen felts or plastic films. ... A vapor barrier is required to insulate the wood frame panel to ensure water vapor tightness. This vapor barrier must be placed on the hot side, it must contact the insulation and not break.

Parquet and floor board

Floorboards and parquet are used for interior decoration and installation of laminate, parquet and other materials. Such material requires a thoroughly flat surface to work with. Thanks to a large selection of patterns, color palette and texture of products, floorboards are perfectly combined with various design solutions. The photo shows a living room decorated in a Scandinavian style using floorboards

Important! Plank or parquet will last longer if you choose the right underlay and take proper care of your flooring.

Glued laminated timber

Glued laminated timber is a versatile material, it is widely used for outdoor cladding of houses

Glued laminated timber is a versatile material. It is widely used for exterior cladding of houses, as well as for internal works for the construction architectural elements constructions. It is used for the device.

Wooden houses are an example of environmental friendliness and naturalness, and when cladding it is important not to negate this their main advantage, therefore it is important to involve only professionals in the implementation, to use only high-quality breathable materials. Let's try to figure out all the nuances of wall decoration in wooden house and consider what materials are suitable for their cladding, and when you can do without them.

# 1. When can you start interior decoration of wooden walls?

Alas, immediately after the construction of a wooden house, you cannot proceed to. A newly built house needs to be given time to shrink... The duration of this process depends on many factors... If the house is built of glued laminated wood, then you can proceed to finishing the walls after 3-4 weeks, and the owners of all other types wooden houses will have to wait at least 10 months, and for a guarantee - a year. The shrinkage time depends not only on the material used in construction, but also on the climatic conditions in the region and the initial moisture content of the raw materials.

Alas, immediately after the construction of a wooden house, you cannot proceed to. A newly built house needs to be given time to shrink... The duration of this process depends on many factors... If the house is built of glued laminated wood, then you can proceed to finishing the walls after 3-4 weeks, and the owners of all other types wooden houses will have to wait at least 10 months, and for a guarantee - a year. The shrinkage time depends not only on the material used in construction, but also on the climatic conditions in the region and the initial moisture content of the raw materials.

During shrinkage, the wood is actively dried, it decreases in size, and the used one is crushed under the weight of logs and timber. It is easy to imagine what will happen if you start decorating the walls during this period - the facing material will either fall off or warp. In any case, after a few months everything will have to be redone, and this is again money and effort, so it's better to wait until the main shrinkage processes take place. But you will not have to be bored without work, since it is at this time that it is necessary to ensure the tightness of all joints, which is achieved by carrying out a competent caulk.

# 2. Features of caulking the walls of a wooden house

Caulking is carried out in two steps: the first time a few months after the construction of the house, the second time - after 6-8 months. The essence of the process is to fill the gaps insulation, which is usually used as jute or tow... The thermal insulation of the house and its tightness depend on the quality of these works.

Caulking is carried out in two steps: the first time a few months after the construction of the house, the second time - after 6-8 months. The essence of the process is to fill the gaps insulation, which is usually used as jute or tow... The thermal insulation of the house and its tightness depend on the quality of these works.

Caulking is carried out immediately inside and outside, bypassing the house around the perimeter and caulking each crown from the bottom up. Each time after this, the structure will rise by 5-7 cm, and then settle, sealing the insulation, which will completely fill the cracks. TO finishing works can only be shifted when shrinkage occurs after the second caulking. To know exactly when it is already possible to perform cladding, It will be necessary to regularly measure the height of the walls: if within 2-3 months the obtained values are practically unchanged, then the main shrinkage processes have passed, and you can proceed to finishing. The next time caulking is carried out after 5 years, and then if necessary.

Caulking is performed in one of the following ways:

Caulking is performed in one of the following ways:

- "In the set". First, long thin strands are made of insulation material, and then they are wound into a ball. Slots are stuffed with such strands, and the larger the gap, the more strands will be needed;

- Stretch... This method involves the use of separate strands, which fill the cracks. A roller is formed from them, which is pushed into the gap.

To perform caulking, you need a simple one set of tools: hammer, chisels, rubber mallet and caulking shovel.

No. 3. The nuances of choosing a finishing material for wooden walls

Distinctive feature wooden walls- the ability to maintain an optimal temperature and humidity level indoors. To preserve these unique properties, the cladding requires use natural materials... The choice of a specific material is influenced by a lot of factors:

Lining, drywall, wall panels and many other finishing materials are attached to wooden walls using lathing, it is better to perform it from a wooden bar. If necessary, lay in the crate insulation, but if the house is not cold and a little money is spent, it is better to do without additional thermal insulation and vapor barrier, because wood itself does an excellent job with these tasks, and unnecessary materials can only disrupt the natural balance. Better to leave the space between the wall and the cladding free, ensuring normal air circulation which is very important to prevent wood from rotting. The resulting gap behind the finishing material can be used to organization of communications, incl. ... When it comes to wooden walls, electrical cables must be laid in non-combustible pipes, so the space will need to be decent.

Lining, drywall, wall panels and many other finishing materials are attached to wooden walls using lathing, it is better to perform it from a wooden bar. If necessary, lay in the crate insulation, but if the house is not cold and a little money is spent, it is better to do without additional thermal insulation and vapor barrier, because wood itself does an excellent job with these tasks, and unnecessary materials can only disrupt the natural balance. Better to leave the space between the wall and the cladding free, ensuring normal air circulation which is very important to prevent wood from rotting. The resulting gap behind the finishing material can be used to organization of communications, incl. ... When it comes to wooden walls, electrical cables must be laid in non-combustible pipes, so the space will need to be decent.

Regardless of what material will be chosen for installation on the crate, it is necessary to leave clearance to the ceiling 2-4 cm... If the house was recently erected, this will become insurance in case of shrinkage, and for an old wooden house - in case of a change in the geometry of the wood, because this material absorbs moisture and gives it back throughout its entire service life. The gap will allow the wood to breathe calmly without disturbing the cladding. To prevent this safety distance from being replaced, the plinth is attached only to the surface of the ceiling, and lean against the wall.

No. 4. Painting or varnishing

If possible, it is better to leave the wooden walls inside without decoration at all, because they already have an excellent look - it is better not to spoil it without special need, but only to emphasize it. For these purposes, can be used paints, antiseptics and varnishes... Only not very aesthetic can spoil the result. caulking seams, but in this case there is a way out - you can glue with a twisted cord... It turns out very original and pretty, and the cord will also serve as additional protection against drafts.

If possible, it is better to leave the wooden walls inside without decoration at all, because they already have an excellent look - it is better not to spoil it without special need, but only to emphasize it. For these purposes, can be used paints, antiseptics and varnishes... Only not very aesthetic can spoil the result. caulking seams, but in this case there is a way out - you can glue with a twisted cord... It turns out very original and pretty, and the cord will also serve as additional protection against drafts.

Before varnishing or painting, it is important to prepare the walls correctly. First stage – grinding... Many are afraid of this process, fearing to disturb the natural texture of the wood, but if you do everything correctly, the appearance of the walls will only get better. Sanding helps to remove cracks that may have resulted from shrinkage. After that, processing is carried out antiseptics that prevent the appearance of fungus and, and film-forming compounds(varnishes and oils), which create a reliable protective layer on the wood surface that protects the material from dirt, darkening and mechanical stress. It is also advisable to use fire retardants- substances that increase the resistance of wood to fire.

Before varnishing or painting, it is important to prepare the walls correctly. First stage – grinding... Many are afraid of this process, fearing to disturb the natural texture of the wood, but if you do everything correctly, the appearance of the walls will only get better. Sanding helps to remove cracks that may have resulted from shrinkage. After that, processing is carried out antiseptics that prevent the appearance of fungus and, and film-forming compounds(varnishes and oils), which create a reliable protective layer on the wood surface that protects the material from dirt, darkening and mechanical stress. It is also advisable to use fire retardants- substances that increase the resistance of wood to fire.

may be glazed or tinted... The first option is used when it is necessary to preserve the natural color of the wood, but give it a certain shade. Paints with a dense color shade completely cover the color of the wood, but before painting the entire wall or part of it, it is better to try to apply the material to an inconspicuous section of the wall. If it is necessary to hide the relief of a tree, then a primer is used for painting.

may be glazed or tinted... The first option is used when it is necessary to preserve the natural color of the wood, but give it a certain shade. Paints with a dense color shade completely cover the color of the wood, but before painting the entire wall or part of it, it is better to try to apply the material to an inconspicuous section of the wall. If it is necessary to hide the relief of a tree, then a primer is used for painting.

Most often for painting wooden walls, the following compositions are used:

The use of nitro paints and polyurethane paints is strictly not recommended - they violate the environmental friendliness of wood.

Alternative to paint - varnishes... They have a transparent structure and do not hide the natural beauty of the wood, but now there are also tinting varnishes on sale that can slightly change the shade of the wood. According to the type of surface obtained, varnishes are divided into matte and glossy- here it is as you like. If necessary, the clear varnish can be tinted. Another a good option – wax, it produces a velvety, glossy finish.

Alternative to paint - varnishes... They have a transparent structure and do not hide the natural beauty of the wood, but now there are also tinting varnishes on sale that can slightly change the shade of the wood. According to the type of surface obtained, varnishes are divided into matte and glossy- here it is as you like. If necessary, the clear varnish can be tinted. Another a good option – wax, it produces a velvety, glossy finish.

All described coating options can be used and for decorating lining... Do not forget that it is necessary to treat wood with protective agents even if lathing and facing material will be used.

No. 5. Lining for finishing wooden walls

Most often, they use a completely natural material for decorating wooden walls, a type of cladding board, which is made from different types of wood. Environmental friendliness is not the only advantage of the lining. This inexpensive and easy-to-install material with excellent decorative qualities. Lining, unlike, for example, drywall, can bear the load- it will be possible to hang something on it.

Most often, they use a completely natural material for decorating wooden walls, a type of cladding board, which is made from different types of wood. Environmental friendliness is not the only advantage of the lining. This inexpensive and easy-to-install material with excellent decorative qualities. Lining, unlike, for example, drywall, can bear the load- it will be possible to hang something on it.

For interior wall cladding, you can take lining 1.5-2 cm thick- it copes with its tasks perfectly, is inexpensive and weighs little. Thicker material will require a strong sheathing, which will take up a lot of free space. The lining slats can be mounted horizontally, vertically, at an angle, or simultaneously use different directions, creating beautiful panels.

The lining can be made from different wood species, but the tree is pre-dried well (moisture content should not exceed 12%). Hardwood(birch, ash, linden) can be used in any premises, incl. and in the bath (linden, alder), and cheaper conifers suitable only for living rooms, since when elevated temperatures emit resin. Experts advise, if possible, to select a lining from the breed from which the house was built. In this case, the walls and decoration will have approximately the same expansion coefficients.

The lining can be made from different wood species, but the tree is pre-dried well (moisture content should not exceed 12%). Hardwood(birch, ash, linden) can be used in any premises, incl. and in the bath (linden, alder), and cheaper conifers suitable only for living rooms, since when elevated temperatures emit resin. Experts advise, if possible, to select a lining from the breed from which the house was built. In this case, the walls and decoration will have approximately the same expansion coefficients.

The lining is made from edged boards - the boards from the core are less durable and do not fit in these whole. By the quality of wood, the lining is divided into the following classes:

The surface of the lining can be as follows:

Before installation on the lathing, the coniferous lining can be degummed with special means or with a 25% acetone solution. If necessary, you can lighten contrasting stripes and spots.

All modern lining has special mounts that facilitate its installation. Do not forget to leave gaps of 2-4 cm at the top and bottom to compensate for the expansion of the wood. Previously, lining to the lathing, which was driven into the front surface. In the best case, they used finishing or headless nails. Today for installation use clamps or they drive nails at an angle into a thorn or groove.

No. 6. Wall panels

Thanks to the use of wall panels, the walls can be transformed beyond recognition and embody absolutely any design idea; with their help, only separate zones are often decorated: above the bed, near the bathroom. Wall panels are made from different materials:

- wood and bamboo;

- veneered and laminated MDF;

- (transparent, matte, printed);

- leather;

Panels can be typesetting and shield... Stacked ones have a large length and small width, they are connected according to the thorn-groove principle. Wooden lining, in fact, refers to panel wall panels, but its wide distribution and unique properties made it possible to distinguish it into a separate class of finishing materials. Panel panels are already more comparable in length and width.

Wall panels are attached to the lathing, the pitch of which depends on the parameters of the finishing material. The variety of design cannot be described in words, but not all such panels meet the requirement of environmental friendliness: leather and glass will not disturb the microclimate, which cannot be said about plastic panels. However, even plastic panels, incl. and, have the right to be used to decorate a bathroom, or kitchen.

No. 7. Drywall

For cladding wooden walls rarely used for obvious reasons. Its use is justified when necessary erect a partition, hide communications or when the surface of the wood has significant defects. Installation of drywall sheets is carried out on the frame, for the construction of which you can use wooden bar or a metal profile, you cannot do without gaps near the ceiling and floor.

You can finish with plasterboard only after complete shrinkage of the house and provided that the room is heated in winter. Gypsum is a sensitive brittle material that can be severely deformed during wall shrinkage or sudden temperature changes. To prolong the life of such a finish, you can use floating frame, and glue all joints of sheets and corners reinforcing polymer mesh... To decorate the walls in the kitchen and bathroom, you must use moisture resistant drywall.

No. 8. Stone, tiles and plaster

Artificial and natural stone, as well as tiles are environmentally friendly materials that will not disturb the microclimate of a room with wooden walls, but they are rarely used as the main independent cladding. The stone, for example, is suitable for finishing the area around the fireplace, will be appropriate for bathrooms and kitchens... By the way, tiles and fake diamond can imitate wood so accurately that the appearance of the house will not be affected at all.

Wooden walls plaster also infrequently, but some that tolerate moisture and high temperature well, can be used to decorate the working area of the kitchen or in the toilet.

No. 9. Features of interior decoration of old wooden walls

Finishing work in an old house made of timber or logs is preceded by the dismantling of the cladding and assessment of the condition of wood. All light and dark spots that differ in texture and structure should be checked for strength with a chisel, screwdriver or knife. If there are no signs of destruction, then all that remains is to cover the wood with protective compounds and start finishing work.

Finishing work in an old house made of timber or logs is preceded by the dismantling of the cladding and assessment of the condition of wood. All light and dark spots that differ in texture and structure should be checked for strength with a chisel, screwdriver or knife. If there are no signs of destruction, then all that remains is to cover the wood with protective compounds and start finishing work.

When the wood has lost its strength in places, is crumbling or cracked, it is better to consult with a specialist who will help determine the cause (insects, fungus, microorganisms) and select a set of measures. Most likely, the damaged parts will have to be replaced, paying special attention to the treatment of adjacent areas with antiseptics. After carrying out the restoration work, you can proceed to finishing by choosing one of the options listed above. The main advantage in this case is that there is no need to take shrinkage into account.

Finally

Despite the fact that many materials can be used for cladding wooden walls, it is better to choose a wooden lining, or simply cover the wood with paint or varnish, preserving the original color and texture. Try to resist the temptation to start finishing before the frame shrinks - this will save money and nerves.