Decorative brick for interior use. Decorative bricks for interior decoration

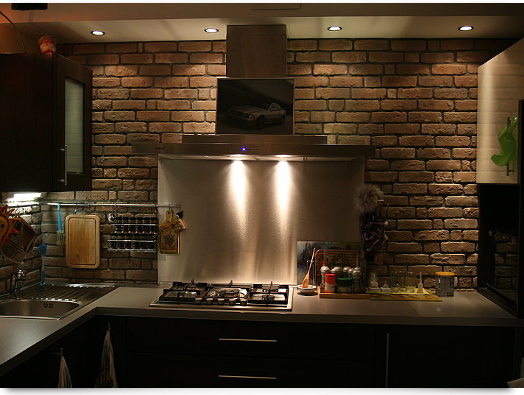

Decorative stone in the interior decoration of the premises is appropriate for any design solution and under any operating conditions. This is an original way to decorate an apartment or house, and although it is not used as often as other materials for interior decoration, decorative bricks can add a special sophistication to a room, and can also be used to protect walls from moisture in bathrooms, kitchens or swimming pools. We will talk about some of the features and applications of decorative bricks today.

Varieties of decorative bricks

Decorative bricks for interior decoration premises can be manufactured in several ways and using several special technologies. The technologies are simple, but you need to know them, because both the quality of the decorative brick and its properties depend on them.

For casting of each type of decorative bricks, special types of mold release agents are used. The composition of such spacers depends on the composition of the base material. So, for concrete artificial bricks, ordinary grease is used, for gypsum tiles - a mixture of wax and turpentine, and for acrylic materials, stearin and fiole are lubricants.

Decorative brick-like tiles for interior decoration

In terms of properties, decorative ceramic bricks are practically no different from the usual ceramic tiles, which are used to decorate kitchens and bathrooms. It is also reliable and durable, resistant to moisture and temperature extremes, and also has good frost resistance, although this hardly applies to the room. One side of ceramic bricks is made matte and slightly rough for better adhesion with adhesives, and the other side makes it an amazing material for interior decoration. The front surface of decorative ceramic bricks can be of any texture, shape and color.

The difference between ceramic and gypsum-concrete and polymer materials

Its only difference from gypsum and concrete bricks is that it cannot have a torn surface due to the specifics of manufacturing. Ceramic bricks are more expensive than other types of decorative bricks, and their price can start from 1000 r / m². When buying ceramic bricks, it is very great importance the manufacturer has, since the conditions for making the material are different for everyone. The rule of cheese and mousetrap works here - the more expensive the brick, the better it is. Worth buying good material, especially if the complete lining of the room is not performed, but fragmentary.

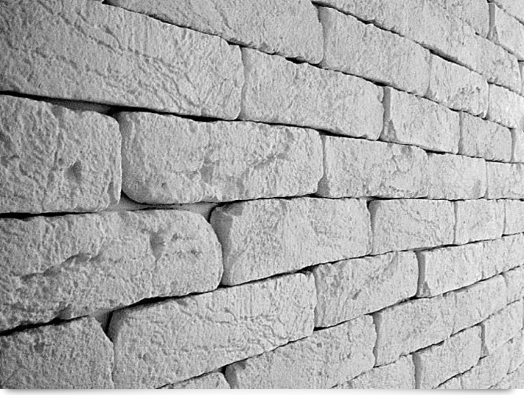

White decorative brick for interior decoration

White decorative brick - special type finishing materials that are used in the interior. In the manufacture of such a finishing brick, a certain amount of lime and dye is added in the process, which makes it almost snow-white.

This is an excellent material for decoration also because it gives the room airiness and lightness and does not require any additional processing. White brick is very specific decorative material... Despite the fact that they can decorate almost any room, since it has the same properties as the ceramic finish, the specificity white makes you reckon with. It can either become the main element in the decoration, or, if used rashly, ruin the whole work and the appearance of the room. White cladding brick can hardly be used in a kitchen if it does not have glaze, as stains may appear that will be problematic to remove.

Among the variety of decorative bricks for finishing the premises, you will definitely find your own version of the brick, which can make your interior unique.

Decorative brick for interior decoration is not some new invention of designers; it is often used for facing fireplaces, kitchens, hallways. They also decorate the walls of bedrooms and living rooms. What is the reason for such popularity? There are several of them:

- aesthetic qualities of the material, allowing you to create an original design in a room of any style;

- performance characteristics that ensure durability, wear resistance, fire safety;

- decorative elements are easy to use, they can be laid on any base.

Ordinary brick is quite heavy, therefore it creates an additional load on the floor. In addition, the masonry will "steal" part of the area. Outwardly, decorative products practically do not differ from ordinary ones, but much thinner. They are made from quality materials (most often gypsum or clay), giving the surface the desired texture.

Manufacturers offer bricks in a wide range of shapes, colors, textures. It can be traditional white or red, as well as elements of any shade. You can lay out patterns, mosaics from them. Using various methods of masonry and jointing, you can guarantee to create an exclusive interior. Cement glue is used to fix the cladding. With some experience, this process is quite simple and available for independent execution.

Material for making

The most popular are the following types of bricks: clinker, gypsum, cement. The main component of clinker is clay. This type is distinguished by its high cost due to a complex manufacturing process. The mixture is fired to give the material high density and strength. The edges are smooth and the color is uneven. It is often used for rooms with temperature extremes. These can be balconies, verandas, fireplaces.

Another type is a brick for decoration made of gypsum or its mixture with cement. It is made by hand molding. For this, the solution is poured into molds, left to gain strength. Then the finished element is removed and subjected to final drying. If the mixture consists mainly of gypsum, then the elements become white. They are quite fragile, do not tolerate high humidity. They are best used in places that are not subject to mechanical stress and do not require frequent washing.

Facing bricks made of cement are durable, resistant to moisture. They can be used for cladding inside walls and facades. It is also suitable for wet rooms.

A rather new type is porcelain stoneware brick. It is characterized by increased wear resistance, does not accumulate dust on the surface, and is easy to clean. Its disadvantage is its high cost. In addition, due to the content of granite chips in the composition, the material has a large weight, which complicates installation. It is often used in rooms with a difficult microclimate (baths, saunas).

Another interesting option is acrylic brick. It turns out to be lightweight, but durable. Will last a long time. Thanks to the rich colors and the possibility of giving any shape, acrylic products are an irreplaceable element of the cladding.

Regardless of the source material, decorative brick for interior decoration has the following advantages:

- durability - it will last for more than a dozen years without losing its color, retaining its attractiveness;

- wear resistance - even increased mechanical impact will not damage it;

- heat insulating properties - it will reduce heat loss from the premises, the walls are always pleasant to the touch;

- water resistance - the application of hydrophobic compounds will help to increase it;

- environmental safety - natural components are used in the manufacture.

Decorative bricks are made both as separate elements and in the form of panels. The surface of the panel imitates a masonry of several stones; working seams are immediately made on it. Installation of panels is much easier and faster.

What to give preference to?

The dimensions of the bricks differ depending on the manufacturer and the style of the element. Their number is calculated in the same way as the tiles. Products made from porcelain stoneware and ceramics are the heaviest, so the most mortar will be required. But then they do not need additional protection. Acrylic bricks immediately have a coating that protects from external factors. They are lightweight, so installation will take place quickly and without special costs... They have one drawback - the high price. Gypsum bricks will need to be coated with moisture protection, but less mortar will be required for the masonry. by all indicators, the most affordable option.

In order for the finish to be aesthetically pleasing, the masonry must be done carefully. Not many craftsmen are fluent in it, so it is expensive. But the result will delight you with a stylish and original look for many years.

Masonry order

Facing brick is a versatile material that is suitable for laying on concrete, drywall, wood. Preparation of the base consists in cleaning it from the old cladding, leveling, priming. Reinforcing mesh will help improve adhesion to the base.

Before laying, it is recommended to lay the bricks on the floor in order to evaluate their color, the coincidence of shade, texture, size. If the elements from different packages are slightly different, then you can alternate them. This will give the cladding heterogeneity and make it more natural. For corners, special corner elements are used.

First, markings are made on the wall, determining the position of the bottom row. It is also recommended to prime the back of the decorative brick with a primer. A thick adhesive is used for gluing so that it does not slide off the wall.

First, the adhesive mixture is applied with a spatula to a small section of the wall, rubbing it for better contact. The glue is then spread over the back of the brick with a notched trowel. The prepared element is pressed to the surface, slightly scrolling it. Squeezed out excess solution is immediately removed. To get beautiful seams, spacers from pieces of drywall or plywood are inserted between the rows. Finish finishing with grouting using a special compound or the same mortar on which the masonry was carried out.

Interior solutions

Brick is used to decorate walls in whole or in individual sections. It often becomes a frame for the head of a bed, niches, fireplaces, mirrors, and helps to zone the space. The hallway or hallway is recommended white brick... Due to the lack of lighting, dark colors will make the room gloomy and uncomfortable. If, nevertheless, a dark background is chosen, then a light grout looks good on it.

Brickwork has become an integral part of the loft style. It is used to decorate the living room, completely finishing the wall. For greater realism, the masonry should not be perfect, chips and scuffs will give it a cozy, habitable look.

The country style also goes well with brick. Using it in the decoration of walls, fireplaces, stoves, openings - all this helps to create the right atmosphere. In this case, you can use both white brick and red shades.

Even in high-tech style, brick looks modern and fashionable. Preference is given to smooth products with a glossy surface. Shades of white look appropriate. The grout is selected as much as possible to match the main cladding in order to create a monolithic coating. Aged brick looks extravagant. Its rough texture underlines the elegance of high-tech elements.

Decorating the kitchen in the English style, they use light brick. If the kitchen is large, with good lighting, then decorate the entire wall. In a small room, only the work area is often lined. Here it is appropriate to use clinker bricks, which are well washed and do not deform.

Desire to have a modern and beautiful house forces the developer to use a variety of finishing materials. At the same time, the manufacturer is not asleep. As the saying goes, demand creates supply. And today we will talk about brick. Or rather, about its imitation. So decorative bricks are especially popular today among other finishing materials.

Increased interest and love for brickwork inside the premises were formed by world-famous designers. They are the ones who dictate modern trends in interior design. And the stone in this case looks as relevant as possible. Brickwork outside is a kind of tradition for a Slavic person. But what if modern technologies and the building materials market allows you to save on building a box at home using lighter cellular materials such as foam or aerated blocks. In this case brick wall houses can be made using a facing stone in the form of a tile. Such decorative brick will successfully replace the full-fledged appearance of traditional masonry.

Decorative brick: definition

Decorative bricks are panels or tiles made in production that imitate natural stone. In this case, brick means both imitation of brick blocks and imitation of rocks of rocks, sandstone, shell rock, etc. That is decorative features such products are not limited.

Depending on the purpose, decorative bricks are divided into facade tiles and tiles for interior decoration. The first option is products made of frost-resistant and shock-resistant material capable of repelling moisture. Wherein decorative rock has sufficient weight.

The second version of the finishing material is a lighter tile made from plaster. In this case, the cladding has less weight and at the same time is afraid of cold and moisture.

Types of decorative bricks

All decorative tiles under the brick is divided not only by purpose, but also by the type of material from which it can be made. So, the building materials market offers the following types of decorative facing tiles for bricks.

Clinker bricks

Such a finishing material is made in production from refractory clay. In this case, the firing of brick blocks occurs at high temperatures. As a result of such "hardening" the resulting tile perfectly resists moisture, frost, mechanical stress, abrasion and fading in the sun. Almost an exact copy of a brick, only in a thinner version. As a rule, such stones for facing in width and height have dimensions standard brick... Only the thickness of the tiles differs. It varies from 2 to 2.5 cm. Most often, such a decorative stone in the form of a brick is used for facing the facades of a house.

Important: if the decision to veneer the house with clinker stone tiles is made at the design stage, then the bearing capacity of the foundation must be calculated based on the increase in the cladding mass. Since clinker facing bricks have a certain weight in their mass.

The advantages of decorative clinker stone are:

- Almost 100% natural appearance facade or plinth;

- Strength, increasing over time during operation;

- Simplicity of styling;

- Durability of the material;

- Favorable cost in comparison with natural brickwork.

Ceramic decorative stone in the form of a brick

In this case, low-melting clay is used for the production of decorative stone. And to give the tile structure and strength, quartz sand, carbonate additives, and dyes are used. With the help of the latter, it is possible to obtain bricks of various shades from white lime to black burnt. Such a wide range of colors of facing material allows you to bring to life a wide variety of design ideas from loft to old classics. During production, ceramic bricks are equipped with decorative chips, which enhances the aging effect of the cladding.

The advantages of ceramic decorative brick tiles are as follows:

- Strength and resistance to mechanical stress;

- Inertness to moisture, sun, frost;

- Resistance to aggressive environments;

- The durability of the material and at the same time its comparative lightness;

- Absolute environmental friendliness and aesthetics of the cladding.

Decorative ceramic stone can be used both outside the house and indoors. Such decor is especially relevant in the decoration of the fireplace portal, kitchen work apron, panels in the living room, etc.

Gypsum tile-brick

Its purpose is exclusively interior decoration of premises. Such a tile is made from a mixture of gypsum and water. Special dyes are used as a tinting agent. It is noteworthy that gypsum tiles can be made at home. It is only important to find the forms for pouring the tiles. After the final drying of the gypsum mixture in the molds, the brick can be removed and mounted on the wall using special glue. And to give it a gloss, you can cover such tiles with a special protective varnish.

Important: such tiles for interior decoration (gypsum material) are afraid of water. Therefore, it can only be used in rooms with low humidity levels.

Dimensions of decorative bricks

For those who wish to use in cladding decorative brick tiles, it should be understood that the cladding is available in various formats. So, if this is a cladding for interior decoration, then most often the tiles are the size of a standard brick. That is, the height of the tiles can vary from 6 to 15 cm, the length of the tiles varies from 16 to 24 cm, and the thickness of the facing stones is invariably 2 to 2.5 cm.

If it is planned to use facade decoration, then here, to facilitate the work, the master is offered decorative finishing bricks in the format of panels. Such fragments are easier and faster to assemble. The dimensions of such panels can vary within 320X340X25 mm; 380X200X25 mm, etc. (but strictly depending on the type of stone that the panel imitates).

Important: if the decorative brick tile imitates the rocks of a stone, then here the dimensions may look different - 210X102X48mm. That is, the thickness of the stones will be greater, and their height will be less.

Applications of decorative stone

Modern designers use a decorative coating in the form of a stone-brick in a variety of occasions and interiors. So, the most popular cladding points in the house are:

- Entrance hall and corridor;

- Kitchen work area;

- Decorative finishing of a balcony or loggia from the inside and outside;

- Fireplace portal and the area around it;

- Partial areas of rooms (corners, wall panels, panels);

- Facing the basement, corners of the house or the entire facade.

Features in the use of brick decoration

If you decide to use a finishing brick, then when working with such a decorative stone you need to remember some of the nuances:

- So, facade decoration with ceramic or clinker bricks requires strengthening the foundation, since pressure will be exerted on the walls.

- It is important to use panels in the form of decorative bricks in ventilated facade systems. And when laying bricks on the wall, it is better to provide small ventilation gaps.

- When laying the decoration on the walls, ensure that the surfaces are perfectly flat. Otherwise, the decorative stone will fall off over time.

- Gypsum tiles-bricks are glued on a gypsum-based glue, and ceramic and clinker bricks are mounted on a concrete-based glue.

- Before installing the stone, it is better to prime the walls. This will enhance the adhesion between the cladding and the wall.

- In case of interior decoration with stone, you can additionally highlight the bath or tiled area. This will add texture to the finish.

Important: any type of decorative brick looks good in combination with wood or simple plaster. Therefore, feel free to create your own interior or exterior design at home.

Completing the construction or renovation of the premises, you are approaching the last stage of this grandiose action - interior decoration, where the walls, of course, occupy a key place. There can be many finishing options: from ordinary whitewashing or painting to cladding with natural wood. However, there is a very original, accessible and effective method to give your nest a cozy and at the same time sophisticated look - use decorative bricks for interior decoration.

The material looks like brick used for masonry, only thinner and lighter. The most common sizes: width 29.0–17.0 cm, height 5.0–6.5 cm, thickness 1.0–2.5 cm. There are front and corner sizes. It should be clarified that decorative stone and brick for wall decoration are different types... Their main difference is that the stone has a relief front surface, various shapes and sizes.

The material looks like brick used for masonry, only thinner and lighter. The most common sizes: width 29.0–17.0 cm, height 5.0–6.5 cm, thickness 1.0–2.5 cm. There are front and corner sizes. It should be clarified that decorative stone and brick for wall decoration are different types... Their main difference is that the stone has a relief front surface, various shapes and sizes.

Varieties and their characteristics

Depending on the raw materials used in the manufacture, decorative bricks are distinguished:

- Ceramic (clinker) is made from clay, which is molded, dried and fired. Thanks to this technology, decorative ceramic brick has good strength, thermal conductivity, and has a smooth surface.

- From a concrete mixture, cement serves as a binding element, and sand or fine expanded clay and perlite are fillers. Such products are durable, environmentally friendly, have good water-absorbing and heat-insulating qualities.

- Gypsum - unlike the two previous types, it is quite fragile, hygroscopic, and has low water resistance. For this reason, gypsum decorative brick masonry is made in those places where the humidity is not more than 65% and the finish does not experience large mechanical stress.

The listed elements are made with dye additives, and their front side can be covered with a protective layer that protects the products from moisture and temperature fluctuations.

Technical parameters of different types:

* Aeff - specific activity of radionuclides.

Usage

Decorative brick is intended for interior decoration of houses and buildings, when planning interior decoration, you should take into account some of the nuances of its use:

If there is a fireplace in the living room, it is better to use ceramic bricks with refractory qualities to cover its contour.

2. Decorative bricks for finishing the kitchen, as a rule, are used to decorate the work wall. In such a room, a contrasting design will look good: brick in dark colors and structures made of drywall in light shades. If you want an English-style kitchen, then the ideal option would be white gypsum brick, suitable for interior decoration. Thanks to its neutral color, this stone can be used to lay out walls from ceiling to floor.

3. Wall decoration in the corridor is performed, as a rule, fragmentarily in those places where there are doorways.

4. For registration basement rooms“antique” concrete brick with a rough front surface and rounded corners is suitable.

The main thing to remember: decorative brick in the interior of your home should create coziness and comfort, and not the feeling of cold, gloomy walls.

How to make it yourself

Of the above types of finishing bricks, only ceramic can not be made at home, since it requires the use of firing equipment. Concrete and gypsum products are available for handicraft production. Making decorative facing brick do it yourself requires the following tools and materials:

- vibrating table;

- a plastic container for mixing ingredients;

- pallet;

- forms for filling;

- cement, plaster, sand;

- citric acid;

- plasticizers;

- water-based dye.

The manufacturing process consists of several stages:

1. The brick mold is made of plastic, rubber or silicone and you can make it yourself. To do this, you need a stone of a suitable size. Then, into the prepared formwork from wooden beams the sample is laid, having previously lubricated it and the container with grease, and filled with liquid silicone. The surface is smoothed with a trowel and left to harden for 2-3 weeks. After complete hardening, the formwork is disassembled, the sample is taken out and the finished form is obtained.

2. The production of bricks from a concrete mixture involves the pouring of two layers of mortar and its compaction using a vibrating table (vibratory casting method):

- Cooking. For the 1st layer, take M400 cement and river sand of fine fraction up to 2 mm in a ratio of 3: 1. Dye is diluted in warm water at the rate of 1-2% by weight of cement. The diluted pigment is added to the sand-cement mixture. For the 2nd layer, a plasticizer (about 2% of the total volume) and binding components are poured into the solution: perlite or fine expanded clay with a fineness modulus of up to 5 mm in a ratio of 1: 3 to a mixture of sand and cement.

- The first layer (1 cm thick) is laid out in a mold, previously lubricated with soapy water, and compacted for 15–30 seconds on a vibrating table. In this capacity, you can use an old washing machine by turning it on in the "Spin" mode. Vibration is necessary to remove air from the mixture.

- After the first layer is compacted, the second layer with plasticizer is poured and the mold is vibrated again for 20 seconds. Then the surface of the product is smoothed with a spatula.

- Primary drying is carried out for 12 hours. At the end, the brick is carefully removed from the mold and laid out on pallets for final drying, which lasts from 48 to 72 hours, depending on the air temperature.

3. Manufacturing from gypsum occurs in the same sequence, except that the gypsum solution dries quickly enough, therefore, a mixture is prepared per one product:

- Gypsum G8-10 is mixed with water until creamy, adding 0.5 mg of citric acid per batch to increase the setting time. If dyeing is necessary, a coloring pigment previously diluted in warm water is poured here.

- Pouring into the mold occurs in one layer, before that it must be smeared with petroleum jelly or soapy water, this will then allow you to easily and without damage to remove the dried stone from it.

- Drying of gypsum bricks occurs within 20-30 minutes.

- You can additionally paint the surface of the stone after it dries. It is necessary to remove dust with a cloth and apply paint (water-based recommended) of the color you need.

DIY styling

Before proceeding with veneering, it is necessary to prepare the tool. You will need:

- building level;

- rope;

- roulette;

- construction ruler;

- pencil;

- brush;

- Master OK;

- brush.

As well as consumables:

- tile glue or liquid nails;

- drywall strips for seams;

- hydrophobic mixture for priming the brick surface;

- grout for joints.

Finishing stages:

1. The walls are leveled by plastering or plasterboard, then primed.

2. The brick should be laid along the marked line, starting from the bottom and corner of the wall. Using a spatula with a comb, the adhesive solution is applied to the wall. The stone is laid end-to-end or with 1.5–2 cm jointing. For this, plasterboard strips of the required width are cut and placed between the rows of masonry.

3. After 48–72 hours, you can carefully remove the auxiliary strips and start grouting. The mortar that has got on the brick must be removed with a wet sponge.

4. If desired, a hydrophobic compound can be applied to the surface of the laid stone, which will facilitate further care of it and protect it from light mechanical damage.

Price

It is not difficult to buy decorative brick, since it is widely represented on the market of finishing materials. Its cost depends on the type, color, size and additional surface treatment. On average, the price of decorative bricks in Moscow is as follows:

| Name | Size, mm | Price, rub / m2 |

| Ceramic | 204x55x20 | 1 018–1 250 |

| Concrete mix | 210x60x15 | 635–854 |

| Gypsum | 235x70x15 | 805–1 000 |

| Articles |

Decorative brick for decoration inside a room today is actively used by people who regret to transform a room in a house, office or city apartment. The reason for this success is building material in that it is absolutely natural, has natural beauty and is environmentally friendly. Using this material, you can give life to even the most extraordinary and intricate ideas.

For interior cladding, today it is presented in a wide range. Each type of material has its own characteristics and scope.

Gypsum

This material can be called the most affordable at its cost. Its production process is very simple, and gypsum is used as a material. The final product is coated with a paint and varnish composition, so that it is no different from its counterparts.

In the photo - gypsum brick for interior decoration:

Gypsum brick is practical, durable and resistant to temperature extremes. But it is not worth using gypsum in those rooms where there is high humidity - a kitchen, a bathroom. It can be used when decorating a living room or corridor. Its cost is 880 rubles per m2.

Porcelain stoneware

In the photo - porcelain stonewareThis stone is distinguished by its high strength characteristics. The process of obtaining it takes place using a special technology. Crushed granite is placed in the clay mixture, then it is pressed.

Obtained from porcelain stoneware, it is distinguished by its strength and durability. It can be used when decorating an arch in a corridor, for a kitchen and a bathroom. The cost of a stone in Leroy Merlin is 2200-2800 rubles per m2.

Ceramics

Ceramic decorative bricks for interior decoration are no different from finishing bricks. The only thing that sets them apart is their thickness. The material is produced by the method of high-temperature firing, to which the clay mixture is subjected.

Various binding components are placed in it. They are used for finishing the bathroom, kitchen and toilet. Its cost is 18 rubles apiece.

Under the stone

This material allows you to give the room a noble aristocratic look. It is used when facing a hallway or living room.

Decorating with decorative bricks under a stone is no different from cladding with real stone, but it costs less, and the installation process is easier. The cost is 1800 rubles per m2.

Clinker brick

This material is classified as the most expensive. In its manufacture, a material such as clay is used. The high price indicates high quality and its properties. In the course of obtaining the material, the brick was subjected to firing, due to which it has a high density and reliability. With the help of firing, it is possible to obtain a non-uniform color spectrum.

Clinker bricks are characterized by a smooth surface. They are used mainly for decorating kitchens in the English style. In this case, the cladding can be carried out completely. For a spacious kitchen, it is advisable to use white clinker brick.

The material can be used not only for internal, but also exterior cladding... Inside the house, clinker bricks are used in those rooms where there is a temperature drop.

These are loggias, verandas, fireplaces and chimneys. To decorate the apron of the work surface in the kitchen, it is necessary to use a smooth clinker material. This part needs wet cleaning, which is associated with increased friction. It is unacceptable to use gypsum brick here. The cost is 3500 rubles per 1 m2.

And for those who want to understand, the information from the article will help to understand.

What is a lime mortar for bricklaying and how it can be done is described in this

It will also be interesting to know how and how to choose the right one.

You can glue decorative bricks if you adhere to the following action plan:

- Apply a thin layer of glue to the wall surface. Make sure that it is enough for the installation of 4-5 elements.

- On reverse side bricks also apply mortar.

- Press the material against the wall and correct its position. You can align the seams with a plastic spacer.

- Each row should be laid in a half-element.

- The glue that will come out of the seams must be removed immediately with a rubber spatula and rinsed with a brush dipped in water.

Decorative brick today has become actively used in the cladding of the interior space of the house. And this is not surprising, because this material is highly reliable and has a long service life. Thanks to the wide range of products, you can choose a specific option that is perfect for bleaching a particular room.