The cheaper it is to veneer a house with aerated concrete. Decorating the house from aerated concrete or foam blocks from the outside. Best options

Ideal for exterior wall cladding made of aerated concrete blocks. Due to the "breathing" characteristics, ventilation facades do an excellent job with their functions and allow the blocks to use their vapor-permeable properties to the fullest.

What is aerated concrete

The term aerated concrete block is considered to be a porous cellular stone, which includes cement and quartz sand with lime or gypsum additives. The average mesh size is 1-3 mm. The wall thickness is determined depending on the climatic conditions of the region of use.

The thermal conductivity of the blocks is very similar to the characteristics of natural wood, but the difference lies in the fact that the average diameter of the logs used for building houses is 26-30 cm.The thickness of the blocks is 37 or 40 cm, that is, the wall made of aerated concrete will be thicker, respectively. energy saving effects will be great.

Characteristics of a ventilated facade for aerated concrete

Unlike foam concrete, aerated concrete tends to absorb moisture, like a sponge. Thus, when mounted on a facade built from this material of a ventilated structure, protection against moisture penetration into its cells is performed.

The presence of a mandatory gap between the cladding and the thermal insulation or the wall surface (if installation is carried out without the use of insulation) guarantees that the unique vapor barrier characteristics of aerated concrete will be used, which will affect the following factors:

Thus, a wall built of aerated concrete blocks with a ventilated facade will allow heating the house and not the street.

The choice of insulation

An important nuance when performing or designing work is right choice thermal insulation. For ventilated facades made of aerated concrete, it is recommended to use only types of insulation with good vapor-permeable properties. These include mineral wool, corresponding in density and hardness for outdoor work.

An important fact during installation is the use of a vapor-permeable moisture-proof membrane. It will protect the insulation plates from the ingress of condensation that forms on the inner surface of the facing material and will allow warm vapors to escape.

It's important to know

It is not recommended to insulate such a facade with expanded polystyrene, due to the weak transmittance of steam. Thus, the main characteristics of aerated concrete blocks will be violated.

Advantages and disadvantages

If we talk about the disadvantages of technology, we can highlight what is also an advantage: the property of aerated concrete to absorb moisture. From this, the conclusion suggests itself - the use near water bodies and in areas with heavy rainfall is not recommended.

There is much more to be said about the advantages of ventilated systems for aerated concrete walls than about its disadvantages:

- Increase in heat and sound insulation of the facade;

- Dew point offset;

good to know

“Dew point” is the temperature at which the surrounding air saturated with vapors is cooled before converting into condensate droplets. In our case, the “dew point” will be brought out to the inner surface of the cladding from which it will be brought out due to the circulation of air masses inside the system.

- The ability to modify the facade of a building with any architectural or design solution (a wide range of materials used for cladding the system allows you to do this without much difficulty);

- Durability of the structure. Depending on the selected facing material, the service life of ventilated facades reaches 70 years;

- Stability and protection of the main wall from the harmful effects of atmospheric and climatic phenomena;

- A breathable facade for walls made of aerated concrete blocks can be installed in any weather (the technology excludes the presence of "wet" works).

Installation features

Installation of a ventilated facade on aerated concrete walls carried out according to the standard principle, but due to the specifics of the blocks, it is necessary to take into account some facts that can greatly affect the further characteristics of the structure.

It is necessary to start outdoor work only after all actions that cause an abundant accumulation of moisture in the air have been completed inside the room: plaster, floor screed, tile laying, and so on.

Choice of fasteners

Aerated concrete is a soft cellular material, therefore, the choice of fasteners for fixing the insulation and the details of the subsystem must be taken with due attention. Errors can lead to a gradual "peeling" of thermal insulation from the wall surface, as well as a violation of the integrity of the lathing. It is recommended to use the following fasteners for these purposes, which can provide reliable and long-term fixation:

- Universal dowel-nails made of nylon, suitable for use on all surfaces;

- spring expanding dowels;

- chemical anchors;

- mechanical anchors:

- Spacer;

- universal;

- hammer-in;

- spring.

The most effective way to attach a ventilated facade subsystem to an aerated concrete block is to use mechanical dowels. They are fixed in it, then the fastening element is screwed in, producing expansion as a result of which the teeth are pressed into the thickness of the block.

The chemical method is as follows: a resin is introduced into the hole, which, hardening, performs a reliable fixation of the anchor with the block. Such a connection has the advantage that, when solidified, the saline solution creates a tightness of the fastening.

useful in work

The choice of a specific fastening element depends on the weight of the facing material and the profile used (metal or wooden beams). When installing the system on large objects, it is necessary to require a pull test from the supplier of the fastener.

12 December 2016

The use of aerated concrete blocks has become quite popular in our country. The reasons for this boom are the affordable cost of the material and the ease of its installation. With the help of aerated concrete, the construction of cottages is carried out very quickly, since the dimensions of the material allow you to quickly erect load-bearing and internal walls.

Another indisputable advantage is the lightness of the gas block in comparison with classic brick or other types of cement-concrete structures. For a house from such blocks, it is not necessary to create a particularly solid foundation and carry out excessive reinforcement. This affects the cost of building a house and the final estimate.

Among all its advantages, aerated concrete material has one significant drawback - it is porous and quickly absorbs moisture. The creation of internal cavities with air provides high thermal protection characteristics, but contributes to high level vapor absorption. Aerated concrete house cannot be used without external cladding. This is what will be discussed in our article.

How to wall a house made of aerated concrete?

Without exception, all professionals in the field of construction will point out to you the need for high-quality exterior wall decoration of the built cottage. If someone says that it is enough to paint the surface - immediately chase such a "master", as he does not understand the essence of the issue at all. from aerated concrete initially have a separate estimate for facing work. The architects of InnovaStroy will definitely advise you on all the existing options for finishing and facing.

To get a durable and energy-efficient house from aerated concrete blocks, you need to decide at the design stage on the type of finish installed at the facility. Be sure to remember two conditions that must be met before revetting a house from aerated concrete:

- Any external finishing work should be carried out about a year after the house has shrunk and withstands spring floods and high humidity;

- Cladding outside is carried out only after all finishing work related to wet materials has passed inside the house. Aerated concrete will act as a conductor for steam and condensate, and will bring out excess moisture.

Failure to comply with these conditions will damage the new house cladding. In the first case, it will crack or change shape, and in the second, it will be saturated with moisture along with the material. In any case, the house will lose all the advantages that aerated concrete provided it.

The specialists of our company will provide the customer with complete information on each type chosen for cladding. The main requirement, which is carried out from aerated concrete blocks by the masters of InnovaStroy, is to ensure an excellent level of moisture exchange. In fact, it is necessary to ensure the unhindered penetration of moisture, condensate, steam outward - through aerated concrete and lining levels. This approach will ensure the safety of the material and the strength of your cottage.

Insufficient ventilation of facades or the use of low-quality materials will lead to saturation of aerated concrete with fumes, moisture accumulation. As a result, the house will be cold and will not be able to hold back the heat, dampness will appear and even fungus may develop.

Naturally, our designers and architects will advise you the better to tile the house from aerated concrete, but the final choice will be yours. Below we will consider all the options for exterior decoration of a cottage or a private house. Even if you plan to build a summer cottage for temporary use, cladding is definitely needed so that your summer cottage will stand for more than a decade.

How to veneer the facade of a house made of aerated concrete?

The modern market of finishing materials is able to offer customers a huge selection of varieties and types. Some are classics, while others show a modern twist in design and architecture. Whatever you choose, be sure to contact the specialists who know exactly how to properly tiling a house from aerated concrete, make an estimate of costs, and ensure quick execution of the order.

Brickwork

The most popular type of cladding, which is always in demand, as it gives the house the appearance of a building built from this particular material. Clinker or decorative brick with original shades and a smooth surface. This type of exterior decoration has several severe requirements, without which all work will be useless:

- Before revealing a house made of aerated concrete with bricks, you need to set a sufficient width of the foundation at the design stage. A wall of aerated concrete block, you need to provide a place for the width of the brick, and the recommended space for ventilation is from 10 centimeters. The outer surface of the cladding cannot extend onto the edge of the foundation by more than a third of the brick width. This will achieve greater stability and strength of the structure;

- The ventilation gap is made in two ways, which are equally suitable for gas block houses. First, the width of the space is equal to the transverse dimension of the brick. Then you can lay the cladding across and keep enough space inside for the passage of air. Second, a polystyrene plate is used, which moves along with the masonry. Thus, the uniformity of the gap along the entire height of the wall is achieved, and the ingress of cement mortar into the resulting space is prevented;

- The presence of reinforcing metal components. It can be ordinary cut wire with a thickness of 3 centimeters, mounting strips or fittings. Its installation is carried out in the seams and poured with a cement mixture. You should never bend these parts so that they are located in the seams of aerated blocks and facing bricks. This compromises the strength of the structure and does not affect stability in any way. The mounting method is of two types, which are used to the same extent. The first - the metal reinforcement fits into the seams of the cladding with one edge, and the second is driven into the goose concrete mass to a great depth. The second method is exactly the opposite, when the metal is mounted in the seams of the main wall, and is installed in the facing according to the situation. The main requirement is the presence of at least four such strips for each square meter of the wall;

- It is imperative to leave "air vents" - holes through which air from the outside will flow under the skin. Most often they are arranged under the upper eaves and at the very bottom. Appearance resembles a normal gap between bricks, only without cement mortar;

- If brick cladding is made without a ventilation gap, then it is necessary to lay internal materials with a high degree of moisture transmission - insulation, waterproofing, reinforcing nets.

Laying of decorative or natural stone is done according to exactly the same principle as brick cladding. All terms and conditions are reserved and are not subject to change.

Ready ventilated facades

This category includes several types of facing material. It can be plastic or metal siding, natural or plastic lining, ceramic tiles, metal finished panels. The advantage of this method of exterior decoration is that the house will look modern and stylish. If necessary, part of the cladding will be easy enough to replace. A unique feature of this type is that already by its technical parameters and installation rules, the material has a space for ventilation between the cladding and the wall. In the standard version, it can be only 3 centimeters, but for a house made of aerated concrete blocks, it is recommended to increase the space to 10 centimeters in order to lay the vapor barrier and insulation.

This and the region is very much in demand, as it allows you to significantly save on the construction of a cottage. The specialists of InnovaStroy quickly fulfill the assigned tasks. It should be noted that given view lining does not require additional reinforcement or expansion of the foundation. Due to its low weight, the finish has almost no effect on design features houses.

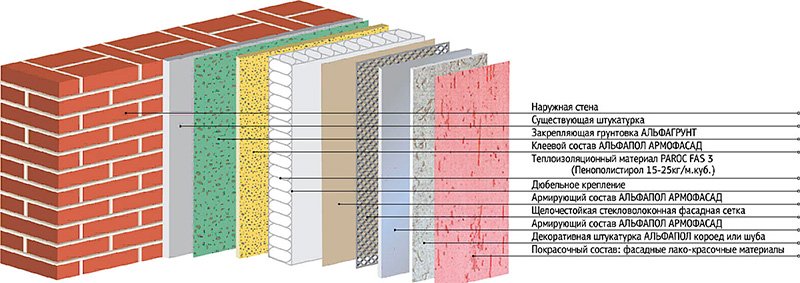

Plastering and painting

Covering aerated concrete walls with simple materials is also possible, based on the wishes of the customer and his financial capabilities. Painting or plastering can be carried out on the finished wall or on the surface of the insulation. The main requirements in the described case are:

- Leveling the surface of the wall from the influx of cement or adhesive mixture, correcting protruding segments of the masonry;

- Use a primer that does not form an impenetrable film. That is, it must be moisture and vapor permeable;

- Mandatory reinforcement with a special mesh. This requirement especially applies to the corners of the building, window and door openings;

- Using breathable textured plaster and paint to wick moisture away from walls and insulation;

- With complete insulation, you should also select a material that can let steam out. Fastening of the layers is carried out using dowels and self-tapping screws with external linings.

Who can you find out how to veneer the facade of a house from aerated concrete?

The specialists of our company will always help the customer to decide on the appearance of the cottage or house. At the stage of individual design or purchase of a finished development, this issue is necessarily discussed. Professionals of InnovaStroy will provide complete information about the advantages and disadvantages of each type of cladding, make a comparative estimate and develop copies of a cottage with different external cladding. You just need to contact us for advice. Even if you have already built your house from aerated concrete blocks, our masters will help you to revet it with modern and reliable materials at an affordable price.

At the end of the construction of a private house or cottage, the question arises of how and how to decorate the facade and other external walls, what finishing material to choose based on its artistic, design and operational qualities. After all, the external decoration of the walls of the house is not only beauty, it is also protection from moisture, temperature, wind and sun rays... If we are talking about a house made of aerated concrete, then its decoration is noticeably different from the decoration of the facades of houses made of concrete, wood or brick.

Exterior decoration of a house made of aerated concrete is desirable, and in most cases it is mandatory, since over time the blocks become covered with dust, dirt, microcracks from exposure to the sun, frost and wind, which makes the facade and side walls unattractive, and moreover, reduces the period of their maintenance-free operation ... And if the exterior decoration can be postponed due to lack of funds, then for a very short time - for a year or two, if you want to extend the life of your home.

Aerated concrete is a type of cellular lightweight concrete, the surface of which has open pores and a porous internal structure. This material was developed as insulation, but the properties obtained made it possible to use it as the main material for construction load-bearing walls and partitions in low-rise construction. The porosity is achieved by involving aluminum powder and lime in the foaming reaction. Cured foam provides high vapor permeability - higher than the rest building materials traditional and innovative direction.

| Parameter | Aerated concrete | Foam concrete |

| Thermal conductivity coefficient, W / (m ° C) | 0.10-0.14 | 0.09-0.38 |

| Volume weight (density), kg / m³ | 400-800 | 400-1200 |

| Density grade | D350, D400 ... 700 | D400 ... 800, D1000 ... 1200 |

| Concrete compressive strength class | class B2.5 at D500 | class B2.5 at D750 |

| Vapor permeability, mg / mchPa | 0.2 | 0.2 |

| Water absorption,% by weight | 20-25 | 10-16 |

| Frost resistance not less | 50 cycles | 25 cycles |

| Masonry ... / thickness masonry joint, mm | glue only / 2-3 mm | for glue, solution / 10 mm |

| Average shrinkage of finished masonry, mm / m | 0.3 mm / m | 2-3 mm / m |

| Possibility of masonry reinforcement | there is | No |

| Average thickness of a single-layer wall, m | 0.4 | 0.63 |

| Soundproofing | worse | better |

| Pore structure | closed | open |

| Appearance | better | worse |

| Average cost, (self-pickup), rubles / m³ | 3 100.00 | 2 500.00 |

Therefore, the outside finishing of aerated concrete house is carried out without deviating from the developed technology in order to prevent the appearance and accumulation of condensate, "cold bridges" and microcracks in the wall panel. So, it is imperative that inter-row reinforcement is carried out when laying walls, and instead of special glue, it is categorically not recommended to use cement mortar. And if you choose the correct wall thickness in a specific climatic region, then you can do without thermal insulation, having carried out only decorative cladding or finishing the facade of the house made of aerated concrete.

But there are materials that combine the properties of insulation and the quality of decorative material. For example, finishing a wall of aerated concrete with clinker tiles or facing brick- this is saving on the size of gas blocks, additional insulation, as well as a beautiful facade of the house. But the use of these materials will require strengthening the foundation - bricks or tiles will greatly increase the weight of the building.

Another must for outdoor finishing works- first you need to complete all internal operations on wet finish and decorating wall, floor and ceiling surfaces. This is a screed, plaster, laying tiles on aerated concrete walls, gluing wallpaper, etc. Dry interiors will prevent moisture from entering the aerated concrete.

Decorating with curtain facades

When finishing with hinged materials, it is best to sheathe the facade with siding or clapboard. These structures are mounted on a pre-prepared frame made of a metal profile - it is not recommended to use wood. A gap of 5-7 cm should remain between the frame and the wall, which is called ventilation - it serves to circulate air and remove excess moisture that accumulates during the operation of the house.

When decorating a house from gas silicate blocks with a ventilated space at the top and bottom of the sheathing, air gaps should be left so that air can move not only along the walls, but also up and down. When fastening metal frame to the wall made of aerated concrete blocks, dowels "quick installation" are used, which do not contribute to the appearance of "cold bridges". It is better not to use self-tapping screws, since they contribute to the formation of condensation when temperatures change, and under wind loads, the vibration of the screws destroys the wall material. Standard size dowels - 6 x 40 mm.

But siding or lining is attached to the profile frame with self-tapping screws, and this is a separate and complex process. The space between the siding and the wall can be additionally insulated with rolls of mineral wool, placing them in a checkerboard pattern so that air continues to circulate between the insulation.

How to plaster an aerated concrete facade

You cannot use ordinary cement-sand mortar for plastering a facade made of gas silicate - only gypsum or alabaster plaster will firmly adhere to the surface interspersed with aluminum, but only after preliminary priming in 2-3 layers. Gypsum sets very quickly, and aerated concrete does not have time to draw out all the moisture from it, so the gypsum plaster will be solid. The cement sets slowly, and there will be enough time for dehydration, therefore, after the plaster layer has hardened, the entire surface will be covered with microcracks.

Before finishing a house made of aerated concrete with plaster, the surface of the wall should be prepared - cleaned of excess mortar and dirt, primed several times and let the walls dry. Then, a metal or fiberglass reinforcing mesh is attached to the surface of aerated concrete walls with short (10 mm) self-tapping screws, which increases the adhesion of gypsum to aerated concrete.

The solution can be applied to the mesh almost immediately, and it can also be applied in several steps. Complete drying of the plaster layer depends on the ventilation of the premises, and lasts from 3 to 7 days, after which the house is clad with a suitable material. Choose what to decorate Vacation home, it is recommended based not on the cost of materials, but on their performance characteristics.

The cheapest, but not the highest quality exterior decoration is painting or whitewashing the facade and side walls. Such decorative trim it is advisable to open it from above with a special water repellent so that moisture does not linger on the walls and is not absorbed into them. However, it is recommended to open both facing bricks and clinker tiles with hydrophobic compounds.

The water-repellent compound must be applied once in a thin layer so that the clinker or ceramic tiled, tiled or painted house continues to "breathe". If you work with decorative plaster, then you can add various coloring segments or marble chips to it.

Often homeowners use a combination of finishing options: for example, painting is combined with plaster, siding with clapboard, or wood paneling, polyurethane panels - with facing bricks, etc. Also, the basement of the house, corners and window (door) openings, the porch and the pediment of the roof are subjected to decoration.

For a house made of aerated concrete, the finishing of external surfaces will visually be well combined if, together with a layer of decorative plaster, special finishing panels made of polyurethane, plastic or fiberglass are used. Such panels can be used to decorate balconies, piers, window slopes, basement.

Plaster as the main type of exterior decoration is used if the house is located in a warm climatic area, and the walls need not be additionally insulated. This option is designed so that the walls will be insulated from the inside.

Facing aerated concrete with tiles and bricks - advantages and disadvantages

Facing brick - optimal material for finishing the house from the outside, as it is also a heater at the same time. And its hollow structure helps to maintain a comfortable microclimate in the house with optimal humidity. The cladding can withstand any adverse weather conditions and is resistant to cracks from temperature extremes.

Of the minuses, the obvious is the high cost of work and the material itself, as well as the high labor intensity of the masonry, which is expressed in the duration of the process and in the presence of professional skill. The many options for laying in order to beautifully clad the facade with facing bricks is the result of professional developments. Single architectural ensemble using bricks can be created by continuing the cladding of the fence or plinths of neighboring outbuildings.

But brick as a facing material can only be used for low-rise construction... When decorating high-rise buildings cover panels made of metal or fiber cement should be used.

Facing with clinker or ceramic tiles looks financially more profitable with the same operational parameters as those of bricks. But an additional advantage of tiles is their low weight compared to bricks, so the load on the foundation is noticeably reduced. Among the disadvantages are the small size of the products, which slows down the laying of tiles, therefore, most often they are laid on a plinth or facade details in combination with decorative plaster.

Before decorating a house with such expensive materials, think about an option with thermal panels that decorate and insulate the facade at the same time.

Porcelain stoneware tiles are produced in larger sizes than clinker and bricks, so sheathing the facade with it will turn out to be much faster in time. Such tiles can be attached not only to glue, but also to a wooden or aluminum frame, which will cost the developer less and create conditions for ventilating the walls (ventilated facade).

Preparatory work before decorating walls with bricks or tiles is reduced to cleaning the surface from mortar, dust and dirt, sealing deep seams, voids and irregularities with foam or mortar, as well as gluing narrow microcracks with special tape and their putty.

Tiles, bricks, ventilated facades, plastering - this is a small part of the list of materials and methods of finishing the exterior walls of a house from aerated concrete blocks. Subject to certain operating conditions, you can use wood and plastic panels, mosaics, glass blocks, and much more. Therefore, the choice of finishes and materials depends only on the capabilities and desire of the homeowner to decorate and protect their home.

How to decorate the outside of a house made of aerated concrete updated: January 14, 2017 by the author: Artyom

A well-built and well-designed house will not only delight the eye for many years, but will also significantly reduce unforeseen expenses for various minor imperfections and miscalculations in the project. Therefore, when thinking over what to make the exterior of a house made of aerated concrete from, be sure to take into account the peculiarities of the structure of the blocks and use the appropriate finishing materials.

Why “dress” the house?

Finishing the facade of a house made of aerated concrete blocks has two main goals: to protect from the adverse effects of the external environment and to decorate visually. Protection is required due to the technical features of production and structural composition. The fact is that blocks are cut during the production process after the formation of a porous structure. This means that some of the pores become open and, in fact, represent holes in which moisture can easily accumulate. As you know, when water freezes, it expands, and molecular forces can easily break fragile internal partitions, which will lead to the formation of microcracks. The building, of course, will not collapse, but the first line of defense will already be violated.

Feature of porous materials

One of the essential advantages of aerated concrete is its vapor permeability. It is an order of magnitude higher than even in buildings built entirely of wood. This advantage can easily be turned into a disadvantage, using materials for external work that do not have vapor permeability or paints that create a continuous film on the surface.

Therefore, outside aerated concrete walls are decorated with special lightweight plastering systems that do not prevent water vapor from infiltrating. If you block this exit, then the moisture that could not get out will remain in the wall and will gradually destroy it from the inside.

The better to finish the outside of the house

The modern market provides a wide variety of specialized finishing elements, both in terms of material and in a wide gap in the price range. Here are just a few of them:

- Siding.

- Lining.

- Hinged decorative panels.

- Clinker tiles.

- Natural stone cladding (air gap required).

- Decorating for joining (provided that textured paint is used).

- Decorative plaster.

Panel technology

Finishing with siding, clapboard or decorative panels requires the installation of lathing. It is made of 6x4 cm wooden slats. To facilitate the work process, it is better to make all the calculations in advance. For example, let's take a working surface area of 15 m 2.

- Remember to subtract door and window openings when doing your calculations.

- The slats are installed in 30 cm increments. Thus, for this area, we need 51 m running strips.

- Every 40 cm, they must be fixed with a screw on the dowel. Total - 128 pieces.

- We use nails (preferably aluminum) to mount the panels. At the rate of 1 nail per 300 mm - 170 pieces.

- Be sure to add 10% to 15 m 2 of facing material. They will be used to make the fit. Total - 16.5 m 2.

Siding price ranges from 180-320 rubles per m2.

Lining costs from 140 to 220 rubles per m2.

Big choice decorative panels determines a wide range of prices for them. The cost of panels ranges on average from 200 to 1000 rubles per square meter. If you carefully carry out the preparatory work, carefully installing the lathing from the slats on the dowels, the installation of the panels themselves is quite easy and quick.

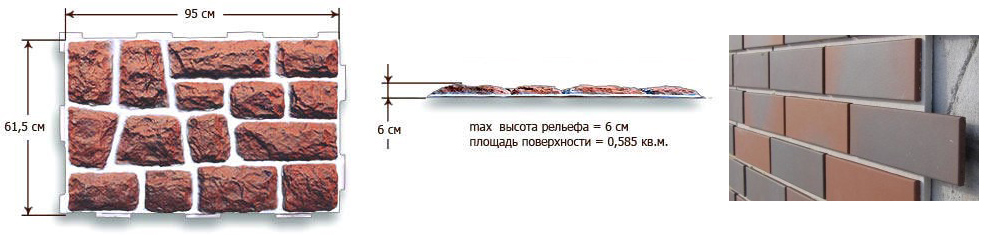

Working with clinker tiles

Clinker tiles on the exterior walls should be planned for another initial stage construction, since the foundation must be calculated taking into account the width of the tile itself and the air gap, which is necessary for the ventilation of the walls. The material should not be allowed to overhang even a few centimeters beyond the foundation.

In order to prevent the solution from entering the provided air gap, during the installation process, you can place a sheet of foam plastic there and move it as the work progresses. To ensure ventilation, small air vents are left in the joints between the tiles. There should not be too many of them - only about 1% of the total area. The air is best done in vertical joints under the eaves and not far from the foundation. Thus, the outer finish of aerated concrete will not impede the necessary steam circulation.

Stone use

In this case, it is necessary to resort to the hinged ventilated facade technique. It is attached to the structural layer on the wall of the building. The frame is made of aluminum or stainless steel. An additional layer of mineral wool insulation can be placed between it and the wall. Finishing aerated concrete house natural stone occurs in the following order:

- Mark on the wall below the level of the attachment point.

- Drill holes.

- Reinforce the metal frame with dowels.

- Install a layer of insulation (if planned).

- Install the facing stone.

Approximate calculation of consumption per 1m 2:

One of the most economical design methods is finishing the outside of the gas block for joining. It involves highlighting the seams between the blocks. This selection is carried out by deepening the grooves of the seams or applying paint to them. It is also advisable to consider this option even during the initial planning of construction. Because, in this case, it will be possible to first remove the chamfer from the blocks and subsequently the jointing will turn out to be original and beautiful.

Embroidery

It is better to use acrylic paint. It has excellent water-repellent properties and sufficient vapor permeability. It is preferable to highlight the seams with a contrasting color or a darker shade.

The average price of 10 liters of acrylic paint is 400 rubles. This amount is enough to process 100 m2 of walls. For greater reliability, it is recommended to apply two coats of paint.

The exterior of your home is a necessary step to protect your building. The possibilities of varying materials will allow you to do both a budget option and create your own unique style. It can protect your investment by preventing external factors from ruining what has already been done, and it can be beneficial to highlight the originality expressed in the individual design of the façade.

| Articles |

Aerated concrete building can stand without external finishing without any damage to the integrity of the blocks (we are talking about autoclaved gas silicate). But, over time, dust settles on the surface of the blocks, and the previously white outer surface becomes an untidy gray with drips. So it doesn't matter, sooner or later, but the question arises about the facing or finishing of aerated concrete outside. Inside, aerated concrete is finished almost immediately after construction: the blocks in the interior do not look very attractive.

Since aerated concrete has a very high vapor permeability, there are certain nuances when carrying out finishing work. The fact is that practically all materials conduct vapors worse than gas silicate. This causes difficulties, since in order to ensure the normal removal of water vapor from the room, the vapor permeability of the walls - from the room - to the outside, must increase. Only special plaster mixes for foam concrete meet this requirement. But subject to certain rules, the finish can be any.

Exterior finishing of aerated concrete

First, about how you can not trim. Do not insulate with polystyrene or expanded polystyrene, plaster the outside with ordinary sand-concrete plaster, paint with covering film-forming paints. As a heater, if necessary, you can use mineral wool, paint with paints that do not block the pores for moisture to escape from the wall. Now about how you can decorate the facade of foam concrete.

Curtain facades: lining, siding, panels, etc.

When finishing with any materials that are mounted on the lathing or guides, a gap remains between the finishing material and the wall. It is called ventilation, since in this interval, with the correct device, there is an active movement of air from bottom to top. Correct device- this is the presence of holes in the finishing material at the bottom and top. This ensures the movement of the air flow from the bottom to the top. This stream carries with it moisture, which is removed from the room. Such a device solves the problem of condensation, and also maintains normal wall humidity. Since at high humidity, aerated concrete has lower strength characteristics, maintaining its normal humidity contributes to a longer "life". The dependence of the strength of aerated concrete on the percentage of moisture is shown in the graph.

At exterior decoration aerated concrete with a ventilated gap, most of the time it has a moisture content in the range of 10-15%, i.e. is in the optimal zone. To create such a gap, a crate is stuffed over the entire area of the wall, providing a distance from the wall to the outer finish of 3-5 cm.

For lathing use wooden bar(treated with antiseptics), metal guides - galvanized profiles for drywall or special for ventilation facades. The frequency of the lathing is 40 cm. According to this principle, the aerated concrete facade is sheathed with clapboard, facade panels.

When attaching the lathing to the wall, the question arises: what or, rather, "what for" to fasten the lathing to the gas silicate. You can just use self-tapping screws (black, they are stronger), but in order to hold the crate well, you will need a large length. This means that metal penetrates deep into the body of the block. In winter, it is an excellent cold bridge. But this is not the worst. Under wind loads, the frame vibrates, vibration, of course, is transmitted to the fasteners. Under the influence of vibrations, foam concrete is crushed. As a result, the screw may fall out.

And that is not all. Due to the temperature difference - the relatively warm aerated concrete and the rapidly cooling metal of the screw - condensation forms on the screw. When the temperature drops, it freezes, destroying the body of the block. In general, do not use just self-tapping screws for attaching the battens to aerated concrete from the outside.

To avoid such a situation, plastic plugs are inserted into the wall and dowel-nails are used. The usual ones are of little use, although they are better than just self-tapping screws. If you use regular plugs, the length of the plastic plug should be at least 30 mm.

In general, it is better to fix it on special ones, which are called “for aerated concrete”. They are available in specialized stores selling hardware. They may not be found in the regular construction market. From the usual ones, they are poured with large plastic parts, as well as more developed screw plates.

The installation method is standard. A hole is drilled under the dowel plug (plastic part). Depending on the shape of the screw surface, the upper dowel is driven into it (in the photo) or a (lower) plastic insert is screwed into it. Then the screw is screwed in.

When using wooden blocks or galvanized profiles, they are attached to such dowels. The pitch of installing the battens is less than usual - it is about 40 cm. This is for a more even distribution of shock loads that occur in strong winds. An example of aerated concrete siding can be seen in the video. There are many useful nuances.

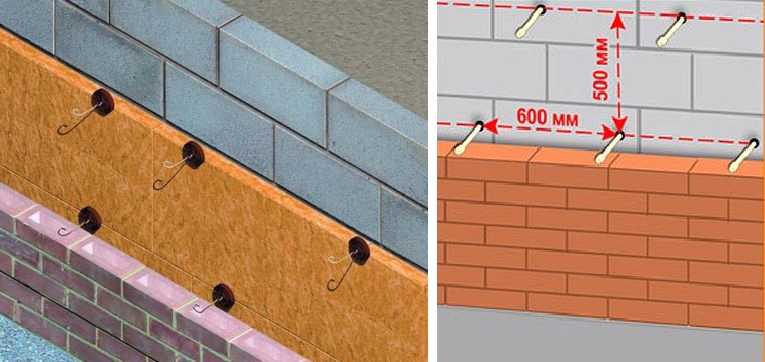

Brick finishing

If you lay a facade made of aerated concrete with bricks correctly, it will stand without problems for decades. A prerequisite is between the wall finishing material and a wall of aerated concrete must be a ventilation gap. Its width is not less than 30 mm. In order for it to work, when laying the finishing brick, air vents are left in the lower part - small holes into which air will enter. To prevent animals from getting into them, they are covered with ventilation grilles.

![]()

The principle of "operation" of the system with a wall of finishing bricks spaced 3-5 cm

Only this type of finish, in contrast to ventilated facades, should be taken into account when calculating the foundation. Firstly, the mass of brick finishing, even in half a brick, is considerable, and it must be taken into account when calculating the bearing capacity of the foundation. Secondly, the width of the finish is taken into account when determining the width of the foundation: the overhang of the brick cannot be more than 3 cm, and a ventilation gap of 3 to 5 cm between the wall and the finish is also needed.

But, if you just put a brick wall at the required distance from the wall of the house, it is very likely that it will simply fall. Therefore, it is necessary to tie the walls of foam concrete and brick. To do this, even at the stage of laying the foam concrete, thin plates are installed between the blocks, which are called "flexible bonds". Best of all - if they are made of stainless steel. The medium in the solution in which these strips are immersed has an alkaline reaction, and in an alkaline medium, metal, even galvanized metal, is rapidly destroyed.

Mounting plates inserted into the seams for connection with aerated concrete brick finish, but they are galvanized and after a few years the brick finish may fall off

Plates on the wall surface are placed about 60 cm in every second row, the maximum distance in height between two rows is 50 cm. Plates are staggered. In the area of corners, window and doorways it is worth placing them more often.

Sometimes, when laying, the plates are forgotten. In this case, a dowel is screwed into the wall, to which a perforated metal plate or also a special stainless hairpin is already attached. Another option: during bricklaying, strictly opposite the seam, a hole is made in the wall into which a hairpin is driven. The hairpin should go 10 cm into the concrete body and almost the entire width of the brick. But the hairpin is not flexible and can break both aerated concrete and brick trim (for sure). Therefore, it is better not to suffer from such "economy". How is the finishing of aerated concrete with the help of finishing bricks with a ventilator - in the video.

How to plaster aerated concrete facade

As already mentioned, plasters for aerated concrete can only be used with high vapor permeability. These plasters are expensive, but they are applied in a thin layer. Therefore, to obtain an even surface, a number of preparatory measures are required.

Plastering can be started when the humidity of the aerated concrete blocks is not higher than 27%. Before starting work, the surface is processed:

- dust-free with a brush;

- the surface is leveled with a float;

- dents and chips are sealed with glue mixed with aerated concrete dust, which was obtained when cutting blocks.

The minimum layer - up to 10 mm, can be left unreinforced. Due to the adhesive additives in the composition, it will adhere tightly to the surface. If the layer is 10-15 mm, reinforcement with a fiberglass mesh is necessary, with a thickness of 15-20 mm, a metal painting mesh is required. Exterior finishing of aerated concrete with plaster of greater thickness is impractical.

The mesh for outdoor use should have a mesh of about 3 mm. It must be resistant to alkaline environments (written on the package), otherwise, after a couple of months, it will lose strength and stop holding the plaster. As a result, the finishing layer will fall off.

Reinforcement is carried out over the applied layer of the primer mixture. It is also used special, has excellent adhesion to foam concrete, creates a basis for applying decorative plaster. The composition is applied to the wall in a strip. While it is not frozen, a net is rolled onto it. Using a notched trowel or float, the mesh is pressed into the mortar. After it is completely submerged, take an ordinary wide spatula and level the surface, adding mortar if necessary. The leveled surface is left to dry. The term depends on the material used and is indicated by the manufacturer. The average period is 7 days.

A primer is applied to the dried surface of the reinforcing layer. It performs several functions:

- evens out the absorbency of the base (reduces it);

- paints over gray (it is white);

- reduces porosity.

On the dried primer (is in the description) it is already applied finishing — decorative plaster... The technique of its application depends on the type of composition.

Thermal insulation of walls made of aerated concrete

With normal calculation and adherence to technology (laying on glue with a seam thickness of 1-2 mm), gas silicate walls do not need insulation. In central Russia, there is a sufficient block thickness of 325 mm. If, nevertheless, the need arose, the insulation must be vapor-permeable. And this is mineral wool and foam glass. Foam glass has excellent characteristics, but a high price. Mineral wool- cheaper. The thickness of the insulation depends on how cold it is in the house, but usually the minimum is 50 mm.

When finishing with a crate, it is made from a wider board or profile, taking into account the fact that the thickness of the insulation is also added to the thickness of the ventilation gap. Sometimes a counter grill may be needed. These are additional planks, which, depending on the circumstances, are stuffed along or across the first lathing. Thermal insulation is attached to the wall with special plastic dowels with a wide head in the form of a fungus.

Interior finishing of aerated concrete

Indoor aerated concrete finishing has its own characteristics. Most often, such walls are still plastered. It is possible to use the same expensive mixtures as for outdoor decoration, but it is very expensive. There are ways to make walls normally using conventional cement or gypsum plaster. But this requires additional measures: a preliminary relief is created using cheap tile adhesive. It has good adhesion (adhesion) even with a relatively flat surface of aerated concrete, it creates an excellent basis for applying subsequent layers. plaster. The procedure is as follows:

On the dried glue, you can apply plaster, or you can lay tiles. She will definitely not go anywhere: she will hold on well. In wet visits - bathroom, kitchen - you can choose a film-forming primer, which reduces the vapor permeability of paints.

For information on how to properly prepare a gas silicate wall for plaster, see the video. With its help, plastering of aerated concrete walls with your own hands is understandable: everything is painted in steps and chewed up.

Interior finishing options

For the decoration of walls made of aerated concrete inside, almost all options are acceptable:

- Drywall or gypsum plasterboard on bars or profiles. There are already no difficulties with fastening: no wind loads, no frost. But, this is only when it comes to home permanent residence... At the seasonal unheated summer cottage and inside, the installation of dowels is required.

- Lining in all its forms.

- Plastic panels.

- Painting, but on a prepared and leveled surface. And paints, after all, are better at least with some vapor permeability. Unless in the bathroom or in the kitchen, you can use film-forming compounds.

Of all these processes, only painting requires some explanation. For this type of decoration, a wall made of aerated concrete does not have to be plastered. In general, the walls should be almost flat. If there are chips, dents or protrusions, the solution is very simple. They are sealed with the same glue on which the blocks were placed. If the dents are large, you can add sawdust to the glue, which is formed when the block is cut. The seams are rubbed with the same composition.

If there are protrusions, they are cut off with a special float, but you can also use sandpaper fixed to the bar. With these means, they achieve a flat surface that can be painted. The wall is cleaned with a brush attached to the holder - dust is swept away. The dust-free wall is primed. A primer is selected that is compatible with the selected paint. They must be compatible. It is desirable to apply the primer two times. Then paint is applied on a completely dry primed surface.