Calculation of aerated concrete blocks on the wall. Online calculator for calculating the house of gas-silicate blocks with plaster, strip block foundation, timber-beam floors, ondulin roofing. Which load-bearing walls are cheaper

Modern materials used in the construction of houses have similar properties.

Today there are several types.

The most common of them are aerated concrete and aerated concrete.

Both building materials belong to the cellular class.

With an equal density and a similar composition, the second material is more environmentally friendly and durable.

If a factory building is regular, it becomes the "enemy" of an earthquake

However, for masonry, a distinction should be made between new buildings and existing buildings. In addition, the masonry panel will break very soon in case of deformation outside of it. On the other hand, in historic centers or in confined buildings, stone or masonry panels are characterized by high thickness and good regularity. Such features allow the cluster structure, once consolidated, to withstand an earthquake. But earthquake resistance also contributes to other elements: for example, the regularity of the building plant, which is certainly one of the goals that must be met in structural design, as it affects the quality of the structure's behavior under an earthquake, minimizing torsional effects.

Its service life is almost twice as long.

Building a house from aerated concrete is a fairly quick process.

The main advantages of the material

Aerated concrete is obtained by autoclaving at a high temperature and humidity. It has a number of significant advantages:

Consequently, the necessary costs for a structure consistent with the safety requirements required by the standard will decrease in accordance with the level of regularity in the height and height of the building. But how can you predict the horizontal thrust typical of seismic waves, and how much a house can swing without falling in the event of severe shocks? As for the possibility of determining the maximum displacement of a building without destruction, it is impossible to answer in absolute terms. However, if the relative displacement between the foot and the head of the post between the two floors is less than one and a half centimeters, you can feel that the earthquake does not cause significant damage.

- has a low weight;

- consists of high quality and environmentally friendly components: water, sand, cement and lime with the addition of aluminum powder as a blowing agent;

- is non-flammable and does not support combustion;

- easy to process;

- strong and durable;

- moisture resistant.

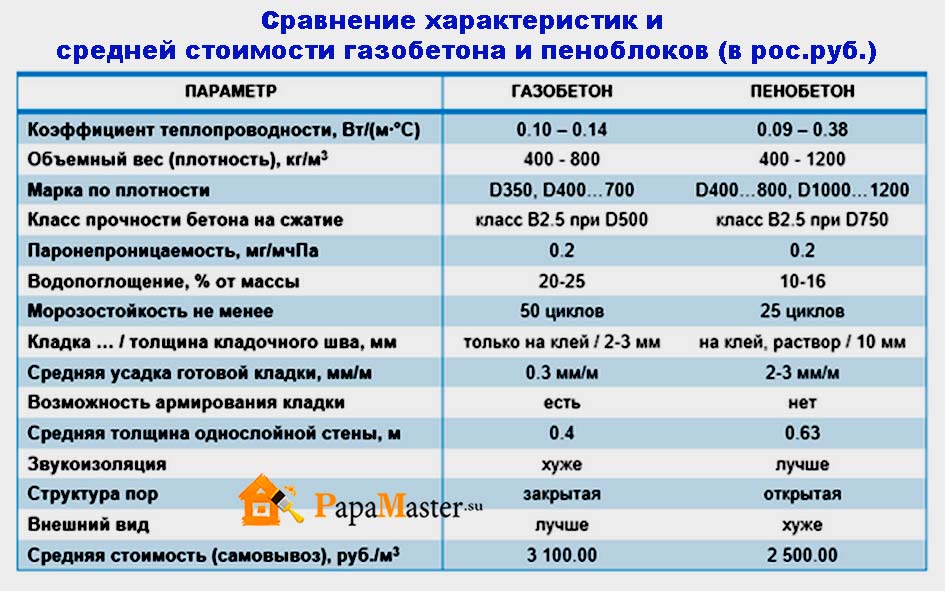

Comparative characteristics of GB and PB

Despite the fact that the raw materials for both materials are similar main components, they differ in production technology and different properties of the final product.

Here, the houses have reached a virtual shock

From theory to practice: several designers "exposed" their designs to virtual implants, or renovation work they have developed, highlighting their implications and risks. Starting with the same engineer Saverio Valicenti, responsible for several anti-seismic projects. Like a building subjected to a theoretical seismic equivalent, roughly to an earthquake with an intensity equal to the eighth grade of the Mercalli scale or magnitude 4, 7 of the Richter scale. The simulation tested the effectiveness of the operation, the designer said. The combined soles were able to transfer seismic forces to different planes and murals, which, armed with a new concrete elevator block, can absorb earthquake stresses, transferring them to the bottom.

The main components of GB and PB:

- water;

- lime;

- cement.

In its construction competitor, porization is achieved by a chemical method - during its production in an autoclave, where high temperatures and pressures are maintained, with the addition of a gas-forming substance.

How is the amount of aerated concrete calculated using a calculator?

Even the former industrial zone was subjected to a theoretical earthquake of similar intensity. Even so, the kindness of the interventions was shown. The new reinforced concrete block and consolidated soles have fulfilled their functions, as well as the reinforced concrete reinforcement on the stone and the existing reinforced concrete structures reinforced by the use of high-strength microcalcuricules with fibrin reinforcement and reinforcement of existing reinforced concrete beams through new beams. The new 12 cm thick loft tops were made using high-strength self-locking concrete.

In this case, hardening occurs naturally. The material shrinks, which leads to cracks.

Finally, it is more difficult to handle than GB. The production technology is more complicated, since the autoclave method is used. This improves the performance properties of the material.

Many people prefer to entrust the construction of aerated concrete house to professionals who do not make mistakes.

Which load-bearing walls are cheaper

As for the Aqua condominium, due to the presence of some false pillars, a vertical seismic action was also required. The theoretical earthquake was always intense, equal to the eighth grade of the Mercalli scale, and the building was shown to support the action of telluric forces due to the absorbing function of the two blocks of elevator stairs. The new floors were able to transfer horizontal seismic forces to various planes and seismic resistive structures, and the pillars and beams confirmed their ductility.

In the process of manufacturing, the GB acquires its main characteristics: durability, strength, reliability.

According to these indicators, the material is in the lead. Its endurance and rigidity is higher than many other building blocks.

GB is able to maintain its shape and volume during operation.

The cost of building a house from aerated concrete is about 20% higher than that of its counterpart.

Features of aerated concrete houses

When would it be advisable to update with anti-seismic criteria from historic centers with especially dated or constructed buildings with special design features? This rule requires that seismic seismic surveys are only necessary strategically and appropriately. public buildings such as hospitals, barracks, guards, school buildings. Everything residential buildings... And who spends most of their time in offices, sheds?

“Employers need to adapt their existing structures, whether prefabricated or otherwise, from their seismic point of view, as well as the landing of their production sites,” Saverio Valicenti said, recalling that seismic adaptation of their production facilities, as well as protecting people's lives, is a good investment. : on the one hand, the value of real estate increases, and on the other hand, production facilities and warehouses of goods are provided.

Calculation of the average cost of aerated concrete house

If the house is being built from blocks with standard sizes: 400x250x600, then the construction of walls may require materials for a total of 195,156 rubles.

It should be borne in mind that the glue will help accelerate the construction of a residential building from GB and provide the walls with additional thermal insulation, only if it is of the correct consistency.

Mr. Milanov, in his previous interview, talked about how the market defines and obliges manufacturers to offer high quality materials. Why do you think people choose Porotherm Walls? The history of ceramics is as old as humanity itself. Over the years, bricks have constantly striven for development in order to achieve optimal performance that adequately responds to constantly changing requirements in construction industry... For example, if the requirements for bricks were mostly strong and durable, today it is necessary to add high thermal and acoustic properties.

If a private owner plans to build a house from aerated concrete, then it is important to know how much is needed.

To do this, you can carry out simple calculations. Suppose the walls are 6x9x3m.

- First, calculate the perimeter... Add up the length and width of the walls and multiply by 2.

- To calculate the area, the resulting value is multiplied by the height: 30x3 = 90 m2.

- Now it is necessary to calculate the area of windows and doors... Subtract the final figure from 90m2. Suppose the house has 2 doors and 10 windows. Their area is 22 m2.

- This means that after subtracting the total is 68 m2.

- After that the final area must be divided by the length and height of the blocks: 68:0,400:0,600=283.

The cost of the work of the team for laying

The trend towards increased size, which makes it easier for builders and speeds up the process, is on the rise. When we want to minimize the cost of thermal insulation, we often forget one important fact, namely that cooling a building sometimes also requires more energy, especially in our climatic conditions, than the cost of heating. We must not forget about the unique properties of ceramics - its high capacity, and we must not confuse thermal insulation capacity with the possibility of heating. The relationship between the noise insulation index and the bulk density of single-layer structures is simple - the heavier one material, the higher the airborne noise is reduced due to the barrier structure created by such a material.

The average cost of laying one m3 by a team of professional workers will cost the customer about 1,512 rubles.

The full scope of work will cost the private owner 84,084 rubles. In many ways, the final estimate will be influenced by the selected building materials and the construction option.

At the same time, the cost of a box of aerated concrete house is about 14,584 rubles per square meter. As an example, a suburban one-story Vacation home with an attic.

Correct tightness and filling of horizontal joints, as well as subsequent plastering of the walls, significantly contribute to their even better sound insulation. Thus, in just 25 cm we achieve an enviable 56 dB at an extremely attractive price. A very important quality of Porotherm bricks is that they do not burn - they once "went through fire".

Massive brick structures have the highest degree of fire protection compared to other building materials and, most importantly, in brickwork, brick factories maintain their integrity and do not cause collapses and do not emit hazardous gases. This increases the likelihood that residents in such a building will avoid suffocation and subsequent injury to people in the evacuation. High water absorption of Porotherm ceramic blocks, especially those with low density due to the porous structure of the brick skull.

All calculations presented in the article are approximate.

Obtained by mixing sand, water and blowing agents. Round and oval pores with different diameters are evenly distributed on its plane and inside. The quality of the starting material depends on their quantity and distribution uniformity. Due to the presence of pores along the entire plane, this material has excellent heat-shielding characteristics. The initial purpose of gas silicate was reduced to its use as a heater. Further developments led to the conclusion that it is possible to completely build houses from such blocks. Aerated concrete is a lightweight material that allows you to raise it to a height without much effort. An important factor in the popularity of aerated concrete is its low cost and excellent construction qualities.

However, thanks to their capillary structure, the bricks also very quickly and completely abandon the moisture that they have taken, i.e. they "breathe" actively. Their permeability to water vapor is one of the highest compared to others. wall materials... In practice, the walls are completely dry and their thermal insulation properties are not adversely affected by the increased moisture content. Moisture content in brick walls ranges from 0.05 to 2.86%, on average 0.45% by weight. Practical humidity ≤ 0.5% does not affect thermal conductivity, and the computational values are almost identical to work.

The dimensions of aerated concrete allow you to quickly build the walls of the dwelling

The dimensions of aerated concrete allow you to quickly build the main, load-bearing walls and interior partitions. There are many types of aerated concrete blocks with different thicknesses from 50 to 400 mm. Most gas blocks are 600 mm long and 200 mm high. However, in direct constructions this does not matter, you can put this block in any way, achieving required thickness... Some manufacturers make aerated concrete blocks with a convenient groove-comb design, which ensures the construction of a house like a children's designer, only with the use of block glue. The dimensions of aerated concrete can be 600x300x (100 or 200,250,300, 400) or 400x300x (100 or 150,200,250,300). Different manufacturers have their own size ranges.

Often various materials for wall or thermal insulation are going to declare incredible values of thermal conductivity, but remember that these materials only have this ability when they are completely dry, which is difficult to achieve outside the laboratory!

Baked ceramics are extremely durable and time-resistant materials. The comfort of life is not only good protection against external influences but also how well residents feel inside the building. The definition of this is largely subjective, but a number of studies of this sensation have surfaced interior walls ok must be dry and hot to the touch, the surrounding structures and their coatings do not cause allergic reactions and do not have sensations that are unpleasant to the perception.

Wall thickness

Most specialists and owners of houses made of foam materials believe that the most favorable will be a house whose load-bearing walls are at least 60 cm thick (in this case, aerated concrete block, a layer of insulation, etc. are taken into account). Many are inclined to believe that 40 cm is sufficient for modern home from aerated concrete. Interior partitions can be of different thicknesses. If a large space is desired, thin walls are installed, with the dimensions of aerated concrete 600x200x50. If you need to achieve good sound absorption, and there are no restrictions on the area - the interior walls can be 10-40 cm.

Because of natural materials used in its production, ceramics are neutral neutral mineral products and do not contain substances that cause allergic reactions. The technically achieved capillary structure allows ceramic bricks to act as a natural regulator of air humidity, absorbing excess water vapor in the air and, thus, minimizing both the sensation of splashing air and the risk of mold formation, provide a high biological tolerance for passengers.

Maintaining optimal indoor air humidity and a healthy microclimate are key factors in a comfortable life. And so on, and so on. ecological balance building materials- as their ecological products; how much and without harmful effects on the environment - this is the period of their operation and how safe they are for nature as waste. When treated in accordance with the Building Waste Management Strategy, bricks are among the safest and can be used with minimal treatment in infrastructure projects.

Aerated concrete blocks  building a house from aerated concrete

building a house from aerated concrete ![]()

comparison of characteristics and average cost of aerated concrete and foam blocks

comparison of characteristics and average cost of aerated concrete and foam blocks

Choosing a foundation for the future building

Cedarwood roofs made in the past are usually homes with uninhabited roof space, with energy efficiency in the background. More and more people are turning to us, using the free consultations and training for the masters that we offer, because they understand the need to use a systematic expert approach. Unfortunately, in addition to the renovation of old roofs in new construction of single-family houses, there has been a trend towards flat roof and cubic buildings in the last 4-5 years.

An approximate estimate - the cost of a house made of aerated concrete

To calculate the cost of a house made of aerated concrete, they are determined with the size and number of storeys of such a structure. Then they calculate how many blocks will fit along the length and height of the walls. V one-story house with dimensions of 12x12 m, the walls will be 48 m long. The height is taken as 3 meters. Having chosen the size of aerated concrete 600x200x400, we determine the required number of blocks with a thickness of 400 mm. The erection of 48 meters of walls with a height of 3 meters will take 1000 pieces of blocks. This amount is determined based on calculations: 48x3 = 144 m2 - the area that the walls will occupy. From this indicator, subtract the quadrature that falls on windows and doors, for example, 24 square meters. m. If the area of one aerated concrete block is 0.12 square meters (0.6x0.2), then the required number of blocks will be equal to (144-24): 0.12 = 1000 pieces. When choosing a different size of aerated concrete 600x300x300, the need will be 667 pieces, which is calculated in a similar way. (144-24): 0.18 = 667. The surface area of one aerated concrete block is 0.6x0.3 = 0.18 sq.m.

This applies not only to our traditions and design requirements for roofing due to the geographic latitudes in which we live, but in my opinion it is personally mistakenly perceived as “modern architecture”. We live in Bulgaria, where it is reasonable to observe not only traditions, but also climatic requirements. Of course, sloped roofs can be trendy and there are many examples.

Roof racks are extremely lightweight and drain the roof quickly, and this usually happens outside the building. In flat roofs, especially when the rain is heavier, when drains cannot drain, water is trapped on the roof. Even more drainage is done in the building plan, and if pipe repairs are needed, the walls collapse.

The industry offers the cost of blocks based on the cost per unit or per square meter. One gas block 600x200x400 is 0.6x0.2x0.4 (0.048 cubic meters). 1000 of these blocks will be 48 cubes. With the cost of a cubic meter of such material 3,500 rubles (98 dollars), for the construction of the main walls of the house you will need 48x3500 = 168,000 rubles (4,667 dollars). Based on the calculations, one block costs 168 rubles or $ 4.67. These metrics can come in handy when purchasing multiple missing blocks. Although usually, the amount is calculated with a small margin, because there are cases of unintentional breakdown of the material. Wholesale construction bases release aerated concrete in packs with a certain amount. If desired, they can break the package and release several blocks to the customer, but more often than not they do not trifle in such cases. When blocks with a length of 60 cm, a height of 30 cm and a thickness of 30 cm are taken as a basis, then 117,300 rubles ($ 3258) will be required for the construction of load-bearing walls. Here are the calculations: one such block is 0.6x0.3x0.3 = 0.054 cubic meters. The total need for blocks with a thickness of 30 cm is 0.054x 667 = 36 cubic meters. The price of such blocks is slightly lower, 3450 rubles per cubic meter ($ 96). 34x3450 = 117,300 rubles ($ 3258). In this case, the walls will be 10 cm thinner, which plays a significant role in further operation.

stages of construction affecting the cost of houses made of aerated concrete blocks 1

stages of construction affecting the cost of houses made of aerated concrete blocks 1  stages of construction that affect the cost of houses made of aerated concrete blocks part 2

stages of construction that affect the cost of houses made of aerated concrete blocks part 2  it is important to know when building a house from aerated concrete part 1

it is important to know when building a house from aerated concrete part 1  important to know when building a house from aerated concrete part 2

important to know when building a house from aerated concrete part 2

Internal partitions

For the construction of internal partitions, you can take thin blocks. , 10-15 cm thick, will suffice. The price of such blocks is less - 3150 rubles per cubic meter ($ 88). If the partitions occupy a total of 50m, then we need to build 50x3 = 150 square meters of partitions. This will require 1250 pieces of gas silicate, with a length of 60 cm and a height of 20 cm. If in one such gas block with a thickness of 10 cm - 0.012 cubic meters, then 1250x0.012 = 15 cubic meters of gas blocks are required for the construction of partitions. They will cost 15x3150 = 47250 rubles ($ 1313).

Glue costs

For laying gas blocks, special glue is required, the consumption of which is determined based on the need for 1.5 kg of glue per square meter. For the construction of the main walls and partitions, you will need 405 kg of glue, which is calculated based on an area of 120 + 150 = 270 sq.m. We multiply the consumption rate by an area of 1.5x270 = 405. Sixteen 25 kg bags of glue should be enough. If a bag of glue costs about 250 rubles ($ 7), then 4000 rubles ($ 111) will be needed for the whole construction.

The cost of erecting load-bearing walls and internal partitions

Based on our calculations, to determine the value of a house made of aerated concrete, we need a capital of 219,250 rubles. ($ 6090) (only for the construction of load-bearing and internal walls made of aerated concrete). This figure consists of the construction of load-bearing walls 168,000 rubles ($ 4,667), the construction of partitions 47,250 rubles ($ 1,313), the cost of glue 4,000 rubles ($ 111). This does not yet include the costs of masonry, fare related to delivery and unloading, cladding, insulation (if desired). In addition, a reinforcing belt of the entire perimeter of the house is required. It costs more than a block layer.

Full calculation of the cost of aerated concrete houses

- floor slabs;

- windows and doors, accessories;

- the cost of plaster;

- installation of screeds and floors;

- laying of communications.

The cost of a house made of aerated concrete should include the costs associated with the development design and estimate documentation... If, in monetary terms, we conditionally break the house under construction into parts, then we get the following result:

- 1st place - foundation equipment;

- ІІ place - the construction of walls and their outer cladding;

- ІІІ place - roof arrangement;

- 4th place - interior wall cladding and floor installation.

These indicators are debatable. Each customer has its own requirements, especially those related to interior decoration... Often a huge amount of money is spent on it, exceeding the entire construction. Therefore, the final cost of a house made of aerated concrete is very difficult to predict. The price of a rough house made of gas silicate can be determined more accurately.

Different opinions on the effectiveness of aerated concrete houses

There are many opinions about the effectiveness of the construction and operation of aerated concrete houses. Many owners were satisfied with the built house and do not experience any inconvenience. Some people do not like the fact that such a house cools down quickly, although it quickly gains warmth. The owners are not satisfied that it is scary to hang heavy objects on the walls without reinsurance.