Do-it-yourself sheathing of a wooden house with siding - the technology of work and the types of materials used. Sheathing a house with metal siding is reliable and practical.

Recently, finishing the house with siding has become very popular. This material perfectly copes with the protection of the outer surface of the walls from external negative influences. siding with insulation will make your home not only beautiful, but also more comfortable. With the help of these panels, it is possible to hide the imperfections of the lining, ensuring the removal of condensate along the internal surfaces of the products.

When visiting the store, you can choose from a wide range of colors and designs. As practice shows, siding today is the most durable facing material that is ready to serve for about 30 years or longer with proper installation and operation. However, before starting work, it is important to decide which siding is best for cladding a house. Reviews may help you understand this.

Vinyl Siding Reviews

This material is made from high-quality polyvinyl chloride using extrusion technology. The panels have a special structure, which provides for the presence of two layers, the inner one is characterized by impact resistance, while the outer one is resistant to pigment fading. When manufacturers compare vinyl siding to stucco and natural finishes, which are quite expensive, they highlight certain benefits. Among them - ease of installation, no need for periodic repainting, as well as resistance to fading. Among other things, vinyl siding is characterized by unpretentiousness in operation.

Home craftsmen note that this cladding can be installed on any frame buildings by one person. This is also due to the fact that each panel has a small specific gravity. It will be quite difficult to install facade panels incorrectly, as the manufacturer puts instructions in the kit, and fasteners are supplied with the products, so you do not have to choose it additionally. Buyers note that vinyl siding is so popular also for the reason that it does not provide for the need to apply paint during operation, this is the advantage of PVC sheets over wood ones. The manufacturer guarantees that for ten years the finish will keep the original appearance. But the replacement of panels may be required only after 25 years. However, this period will depend on the correct installation and operating conditions.

Reviews of the main characteristics of vinyl siding

If you want to choose a good siding for house cladding, then you can pay attention to its vinyl variety, which almost does not fade during the entire period of operation. You can install such a finish even in areas with a difficult climate, it remains resistant to destruction up to -50 degrees. High temperatures are also not terrible for the panels, like precipitation and wind. Buyers claim that these products are completely unaffected by mold and fungi. The finish is not afraid of the effects of insects, it does not rot or rust.

If you want to choose a good siding for house cladding, then you can pay attention to its vinyl variety, which almost does not fade during the entire period of operation. You can install such a finish even in areas with a difficult climate, it remains resistant to destruction up to -50 degrees. High temperatures are also not terrible for the panels, like precipitation and wind. Buyers claim that these products are completely unaffected by mold and fungi. The finish is not afraid of the effects of insects, it does not rot or rust.

According to the owners of detached houses, a very important feature of PVC is that it does not conduct electricity. If you want to save money, then you should choose vinyl siding, the installation costs of which will be less compared to lining, which requires repainting every year.

Acrylic siding reviews

When choosing facade panels, you should consider their acrylic variety, which is made using polymers of the same name. This finish is very similar in characteristics to the one described above, but acrylic is made using a different technology. Among other things, he absorbed all the advantages of a vinyl counterpart, which allowed him to acquire many other advantages. Consumers claim that the main one is less susceptibility to ultraviolet radiation.

When choosing facade panels, you should consider their acrylic variety, which is made using polymers of the same name. This finish is very similar in characteristics to the one described above, but acrylic is made using a different technology. Among other things, he absorbed all the advantages of a vinyl counterpart, which allowed him to acquire many other advantages. Consumers claim that the main one is less susceptibility to ultraviolet radiation.

If you decide for yourself the question of which siding is best for cladding a house, it is recommended that you read the reviews. From them you can find out that acrylic does not lose strength during the entire period of operation. Attachment points cannot become points of weakness. You can use such a lining at higher temperatures, which sometimes rise to the mark of 85 degrees. The front part can be exposed to chemical solvents that can adversely affect products. This indicates the possibility of cleaning with synthetic detergents.

According to users, this material almost does not burn, and with direct exposure to fire, it will release the smallest amount of harmful substances for the human respiratory system. If the issue of price is significant for you, then it is worth remembering that acrylic siding will cost more to finish than vinyl paneling. At the same time, however, it should be borne in mind that the service life of acrylic is much longer and is 50 years. Owners of private houses argue that the ultimate benefit is obvious.

Metal siding reviews

If you are faced with the question of which siding is best for cladding a house, it is recommended to read reviews of each type. This will allow you to understand that the leader in fire safety is a metallic finish that is able to cope with exposure to extremely high temperatures. According to buyers, the price of this lining is slightly higher compared to the above-mentioned materials. Having visited the store, you will be able to understand that the cost depends on the thickness of the steel and the polymer coating, the latter of which protects the material from the effects of precipitation. Sheathing a house with metal siding allows you to get a facade that will become durable, because such a finish can be used for several decades.

If you are faced with the question of which siding is best for cladding a house, it is recommended to read reviews of each type. This will allow you to understand that the leader in fire safety is a metallic finish that is able to cope with exposure to extremely high temperatures. According to buyers, the price of this lining is slightly higher compared to the above-mentioned materials. Having visited the store, you will be able to understand that the cost depends on the thickness of the steel and the polymer coating, the latter of which protects the material from the effects of precipitation. Sheathing a house with metal siding allows you to get a facade that will become durable, because such a finish can be used for several decades.

This coating consists of individual elements that are not subject to deformation. The thick basis excellently resists mechanical influences. Owners of private houses claim that they choose metal products for the reason that they are environmentally friendly, since no chemicals are used in the manufacturing process. The metal is distinguished by the fact that it can be used to produce finishes with a maximum service life, as well as to be used in aggressive environments. Such characteristics are not able to boast of vinyl and acrylic siding.

For reference

Installation of siding, the price of which is not so high, is carried out simply because you can not be afraid to damage it. The structure of products and manufacturing technology are in many ways similar to metal tiles. The difference is only in the profiling of sheets and dimensions.

The choice of finishes taking into account aesthetic considerations

Despite the totality of all positive characteristics, the modern market is dominated by vinyl siding in pastel shades. For the manufacture of these panels is used, which is characterized by color fastness. But sometimes bright colors on such coatings turn pale. In order to achieve saturation of tone, very expensive stabilizers are added to the products, which negatively affects the cost. Despite the fact that special pigments are among the ingredients, bright shades are at risk of fading from exposure to the sun. Given this circumstance, it is recommended to buy pastel-colored vinyl products.

Despite the totality of all positive characteristics, the modern market is dominated by vinyl siding in pastel shades. For the manufacture of these panels is used, which is characterized by color fastness. But sometimes bright colors on such coatings turn pale. In order to achieve saturation of tone, very expensive stabilizers are added to the products, which negatively affects the cost. Despite the fact that special pigments are among the ingredients, bright shades are at risk of fading from exposure to the sun. Given this circumstance, it is recommended to buy pastel-colored vinyl products.

The color range of metal coatings

If you are still thinking about which siding is best for cladding your home, it is definitely recommended that you read the reviews before visiting the store. After reviewing them, you can understand that the metal finish is better than the rest in terms of color. If we compare vinyl products with others, we can highlight the advantage in a variety of colors.

If you are still thinking about which siding is best for cladding your home, it is definitely recommended that you read the reviews before visiting the store. After reviewing them, you can understand that the metal finish is better than the rest in terms of color. If we compare vinyl products with others, we can highlight the advantage in a variety of colors.

The range of metal cladding is so diverse that you can choose absolutely any color - from dark to light. In this case, the brightness will not affect the final cost of the constituent elements. That is why you can create a truly original facade. Before purchasing, you need to pay attention to the color schemes of the buildings in the neighborhood. If they were created taking into account a certain trend, then you should decide what is more priority for you - general harmony or your own originality.

Material calculation

The calculation of siding for house cladding is very important, because by doing it, you can determine how much material is needed in order not to visit the store again and not overpay for unclaimed finishes. Here everything will depend on how the panels are supposed to be oriented - horizontally or vertically. In the first case, it is necessary to measure the height of the walls, and then pay attention to the width of one panel. At the next stage, the first value is divided by the second, and then multiplied by 4. This is true if the house has a simple architectural solution, otherwise it is necessary to multiply the result of the division by the number of walls that are supposed to be faced. It is important to take the material with a margin of 10-15%, as it will have to be cut during the installation process.

Siding installation

Exterior cladding of the house with siding can be carried out only after the master familiarizes himself with the technology. It provides for initial preparation, during which old finishing materials are removed from the surface. Cracks can be repaired with plaster. In order to exclude the occurrence and spread of harmful mold and fungus, the walls must be treated with special solutions. Items that are loose or rotted must be removed or replaced.

Lathing installation

Installation of siding, the price of which is 300 rubles. per piece, can be produced by you yourself. The mentioned cost is relevant for metal products. When installing them, you will need to install a frame, which is also called a crate. This system can be made of wood or metal. The first option is cheaper and does not require special skills from the master. But such a frame will not last so long, as it undergoes decay.

If the mentioned price of siding for house sheathing does not suit you, then you can choose the vinyl version of this finish. For one product you will have to pay an average of 200 rubles. Whatever material the lining is chosen from, the technology remains the same. The next step is to install the panels. The first is inserted into the grooves of the vertical profiles, while you need to bend the middle. After the panel is lowered to the starting profile, and the locking connection snaps into place. As soon as the lower part is fixed, the top of the panel can be pressed and fasteners can be installed in the center of the technological holes.

Conclusion

The price of siding for house cladding is not in all cases a fundamental factor for the buyer that influences the choice. Each consumer is guided by certain principles. Among them - quality, environmental friendliness and aesthetic appearance.

In order to give it a finished look, material such as siding is often used. Moreover, preference is most often given to plastic or metal material. Wooden siding, although attractive, is still more susceptible to the negative effects of atmospheric phenomena (rain, snow, sun, etc.). And if everything is clear with plastic panels during finishing, then the question of how to sheathe a house with metal siding worries many private developers.

By its structure, siding, including metal, is a long panel with a special groove in one of its parts. Accordingly, the second part of the panel has a protruding edge that covers the groove during installation. As a result, the skin takes on a single area, uniform over the entire surface.

Features of metal siding: advantages, disadvantages and subtleties in operation

Metal panels for house cladding are made from various kinds metals: steel, aluminum, zinc. Moreover, all of them can be produced with a width of 120-300 mm. Occasionally panels have a width of 500 mm. The length of the panels is 5-6 meters. In any case, the thickness of the metal siding is 5 mm, which allows you to take the metal sheathing as a light finishing material. However, this is not quite true. Metal plates for finishing the house in a complete structure are of sufficient weight, which requires a reinforced foundation. Therefore, when choosing finishing material this factor should be taken into account.

Tip: the simpler and less embossed the surface of the metal siding, the cleaner the facade of the building will be and the easier it will be to care for the sheathing.

Metal siding plates are supplied with special perforation along the upper edge, which simplifies the installation of panels on the frame. In addition, it is this perforation that provides for a reduction in the stress of the plates during their thermal expansion. In addition, metal siding plates are equipped with special holes for high-quality removal of condensate from the skin.

The benefits of metal siding include:

- Metal plates for house cladding can be operated with various temperatures. Their range is -50-+50 degrees Celsius, which is ideal for all climatic regions of Russia.

- Metal siding belongs to the category of ventilated facades, which means that with a competent finishing device, the walls of your house will breathe freely without forming unnecessary condensate, followed by fungus on its surface.

- Metal siding does not fade in the sun and, of course, is not afraid of moisture.

Important: if the panels are not installed correctly, slight corrosion may form at the joints and corners.

- Under the influence of temperature changes, metal panels do not crack. The thermal expansion of the material does not affect the structure of the skin in any way. That is, cracks and other deformation do not appear.

- The service life of the material, declared by the manufacturer, is 50 years, but subject to proper conditions of use for the panels.

- The combustibility of metal siding is reduced to zero, which is an important factor when choosing a sheathing for a house.

- The assembly of panels into a single skin is quite simple. Therefore, even a novice master without vast experience can sheathe a house with metal siding with his own hands.

- Metal panels are easy to maintain and do not require periodic painting.

- When installing the panels, it is possible to hide all the fasteners, as a result of which the coating takes on an even and uniform structure without disturbing the appearance of the facade of the building.

However, metal cladding For houses, there are some disadvantages. These include:

- The possibility of deformation of the plates under mechanical action. A blow with a heavy object can bend the panel and it will be difficult to return it to its previous state. You will either have to completely disassemble the skin in order to replace the bar, or be content with what you have.

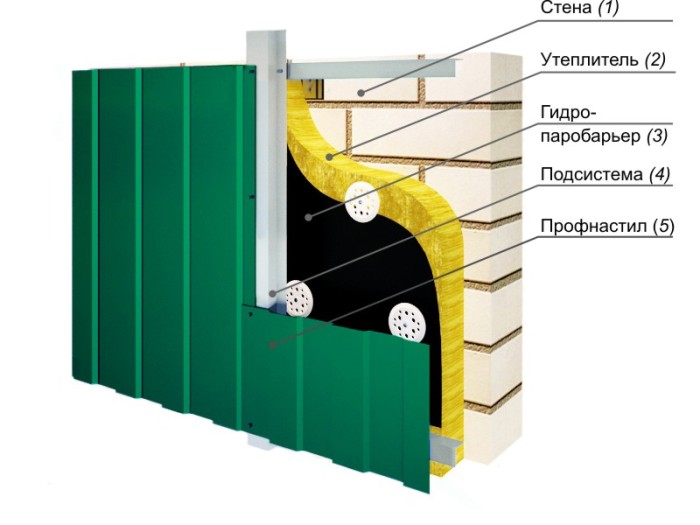

- As for the thermal insulation properties of the metal, there is an absolute minus. Metal plates do not heat up, unlike PVC siding. Therefore, under them it is necessary to arrange a heat-insulating cake.

- In addition, metal panels have a reduced level of sound insulation. Namely, during the rain, households can periodically listen to a light drum roll, albeit softened by a heater laid under the panels.

The price of metal material for home decoration

As for the cost of metal siding, everything is simple here. On the Russian market metal panels will cost you within 8-10 USD/m2. Further, the price will increase depending on the texture of the panels and the individuality of their dimensions in length and width. Thus, we can assume that metal panels for house cladding belong to the class of an average material in terms of cost (that is, between budget and elite).

Metal siding installation technology

Installation of house cladding from siding plates is carried out in several stages. Moreover, you need to approach each one carefully, otherwise the result will surprise you with distortions of the facade of the house and troubles in the form of rainwater pouring over the cladding. Work is performed in the following order:

- Waterproofing the walls of your house. To do this, use bituminous mastic or other coating materials. At the same time, you need to grab the basement of the house, otherwise moisture risks seeping in there.

- Marking the surface of the walls and mounting the frame for cladding.

Important: it is better to use a metal profile for the frame, since the timber, even if it is treated with high-quality antiseptics, threatens to rot over time at the junction of metal fasteners and wood.

- Thermal insulation device.

- Installation of the panels themselves in a single coating.

Let us analyze in detail the structure of the frame, thermal insulation and cladding.

Frame installation

In order to perfectly evenly fix the vertical racks of the frame, markup should be applied to the walls of the house. You need to do this with the help of a building level and a construction pencil. So, in increments of 50-60 cm, vertical lines are applied along the perimeter of the walls. Or you can make a step in the location of the racks, a multiple of the length of the metal siding panels. Also, the step width can be calculated based on the width of the insulating material.

Tip, in order to perfectly fix all vertical racks in the same plane, you should fix two extreme profile strips along the parallel sides of the wall and pull a fishing line between them. On it, then the device of the brackets and the level of the protrusion of the profile from the wall are leveled.

All vertical profiles are attached to the applied marking lines using U-shaped fasteners. First, they are fixed with a self-tapping screw in the center, and then the edges of the fastener are bent towards the future profile. The vertical spacing of P-eshes can be 40-50 cm. The markings for them should also be applied in advance using a level.

It remains to connect all the metal profiles with the installed fasteners. It is better to do this with a screwdriver to speed up the workflow. The frame is ready.

Insulation installation

Now it is worth additionally insulating the walls of the house. And in addition to the warming effect, in this way we will also create a soundproof layer between the siding and the walls of the house. As a heater, you can choose polystyrene plates or mineral wool. mineral wool it is better to choose a roll. It is easier and faster to install.

So, we lay the heater in this order:

- First, we cut strips of material of the required length and insert them between the mounted profiles. You can fix the insulation with dowels-mushrooms. They securely fix the insulation to the walls. It is worth paying attention to the gaps between the insulation segments if you use polystyrene. Joints and cracks are filled with mounting foam.

- It is worth laying a membrane on top of the arranged thermal insulation, which will ensure the outflow of condensate to the outside and ensure ventilation of the facade. Therefore, the membrane is laid on top of the insulating material, with overlaps at the joints. The joints are glued with construction tape.

- On top of the membrane, it is recommended to additionally arrange a counter-lattice to ensure ventilation of the entire “pie”. And for the counter-lattice it is better to use thin wooden slats.

Siding installation

The final stage of work is the installation of metal panels. First you need to screw the guides to the vertical racks of the frame, into which the panels will be inserted in the future. Start installing the siding from the bottom plate. It is inserted into the guide and fastened with self-tapping screws through perforated holes to the frame posts.

Important: the screws should be placed strictly in the center of the perforation and at the same time do not clamp the fastener head all the way. This will minimize possible deformations of the skin under the influence of thermal expansion of the panels.

The corners of the house along the sheathing are covered with decorative metal corners. The finished coating can be lightly wiped with a dry cloth to remove possible contamination. A house sheathed with metal siding looks modern and colorful, in accordance with the chosen style. As you can see, cladding a house with metal siding panels is simple and easy.

Video:

You can extend the life of the building by protecting its walls with decorative cladding. The increasing popularity in our country is gaining such material as siding, in particular metal. Today, many companies offer their services for cladding buildings, however, sheathing a country cottage with metal siding is an absolutely not complicated and quite exciting process.

The result of your labors will be a homestead that has a modern appearance and is protected from the effects of harmful environmental factors.

So, let's get acquainted with the process of sheathing a house with metal siding with our own hands, taking into account the advice of professionals.

Basic concepts

Types of siding

Today, sheathing houses with metal siding - a panel that is used to decorate the exterior walls of buildings - is one of the most popular types of decoration.

This is due to the fact that the material has a number of advantages over its competitors:

- Strength;

- incombustibility;

- Resistance to mechanical damage;

- Resistance to temperature extremes;

- Low coefficient of thermal expansion;

- Minor operating costs;

- Ease of installation.

The panel has the following parameters (in millimeters):

- The thickness of the metal is 0.5. (Building codes govern limit deviation from standard thickness at normal rolling accuracy +/- 0.05 - SNiP III-V.5-62)

- Lamella length up to 6,000 (usually made according to the customer's size with a resolution of 50);

- Length of decorative elements – 2000;

- Lamella width - 200;

- The width of the working surface of the lamella depends on the configuration of the board.

The canvas can be made in several versions - a single board, a Christmas tree board, a ship board.

Useful advice 1: When calculating the required amount of material, do not take into account the quadrature of the wall, but the parameters of it and the sheet of the product. Thus, you will insure yourself against shortages and avoid interruptions in work.

Helpful Tip 2: Be aware that when ordering sheets, you can specify the dimensions you need, because. products of this kind are rarely kept in stock, more often they are made to order.

The number of planks in one length is a multiple of five sheets (this is due to the width of the standard sheet).

Helpful Tip 3: When choosing a board configuration, be guided by the useful width of the product. Thus, you can accurately calculate the required number of sheets.

Siding is available with a roll - the structure of the tree is visible, and without a roll - the surface is smooth.

Helpful Hint 4: A more embossed panel structure will make the surface dirty more quickly.

A wide range of color solutions will allow you to choose the most preferred solution for a monophonic or combinatorial finish. For the most demanding customers, solutions are offered for wood, stone or brick (shown in the photo).

Helpful Tip 5: When choosing a pattern, ask a specialist to show how the finished product strip will look (in a catalog or on a sample).

This will allow you to avoid disappointment when it turns out that the drawing does not meet your expectations (for example, the drawing of a brick on a sheet will not be horizontal, but vertical).

decorative elements

In order for the facade sheathed with metal siding to have a finished look, a variety of functional components are used in the process of its finishing.

Despite the large number of various components of the process of decorating walls, do-it-yourself wall cladding with metal siding is quite within the power of any person.

Required tool:

- Construction level;

- Perforator;

- Screwdriver;

- Roulette;

- Square.

- Hacksaw;

- Scissors.

How to sheathe a house with metal siding? How can a beginner take into account all the nuances of finishing? How to make your home beautiful and maintenance-free? You will learn about this by studying the step-by-step instructions presented here.

Helpful Tip 6: When cutting lamellas, do not use a “grinder” with an abrasive wheel, because. sparks can burn through the outer coating, and exposed to air, the unprotected steel core can quickly rust. .

Mounting order

By itself, the installation of the components of the process is quite fast and does not require significant qualifications.

However, all of the steps below require attention, as the cost of a mistake can be very high.

- Surface preparation (checking walls, corners for verticality using a level and plumb line, as well as for crumbling masonry and plaster);

- Assessment of the need to use heat-insulating raw materials;

- Installation ;

- Fastening waterproofing films, insulation and wind barrier;

- Fixing lamellas and decorative components.

We will dwell on some stages and nuances that give a complete picture of how to sheathe a house with metal siding.

Lathing installation

The lathing serves not only as a supporting structure, but also contributes to the ventilation of the facade, because. does not interfere with air movement. A bar with a thickness of at least 25 mm can be chosen as the basis. or metallic.

The latter is preferable because has stable characteristics, does not deform over time and does not spoil the appearance of the structure.

The step of the crate is determined by the width of the insulation. The structure is fastened using dowels, every half meter.

Warming

The best option to save heat at home is to apply thermal insulation. Any are suitable for this - cotton wool, polystyrene foam or polystyrene foam is placed between the crate and fastened with dowels with a large cap, which should be buried in the material. The preservation of the properties of the insulation is ensured by the use of a hydro and wind barrier.

Installation of metal siding sheets

Before proceeding with the fastening of the sheets, it is necessary to fix the guide strips:

- The initial bar, which will ensure the fixation of the first panel;

- Corners, platbands, slopes;

- Joint planks.

When fastening, temperature differences should be foreseen, which are compensated by incompletely screwing the self-tapping screws into the center of the perforated mounting holes. The allowance is 6 mm. (SNiP III-18-75).

Making openings

Any design looks complete when all its elements are logically completed. An external slope strip is used to frame window and door openings. It is fastened before installation, with self-tapping screws in increments of 200-300 mm. At the corner joint of the decor elements, it is necessary to cut out “ears” in them, which are then bent down.

The design of the docking strips

The location of the docking strips must be determined before installing the slats. In order to make sure that the docking bar is vertical, it is better to fix it only at the top point, and only then fix it completely.

Helpful Tip 7: In order to protect the facade from snow getting between the canvas and the planks, it is better to use a self-adhesive universal sealant.

The process and features of installation.

Conclusion

We figured out how to properly sheathe a house with metal siding. We hope that this manual will provide you with comprehensive information about the material, technology, fixtures, and fastening features. And also, will provide all possible assistance in translating into reality the dream of an ideal home.

Metal siding is a very popular and sought-after cladding material today for cladding private cottages and houses. Despite the fact that this material has an undeniable advantage in terms of merits among other types of facade cladding, its cost remains affordable for the general population. Which only adds to his collection of "pluses". Choosing it as a house cladding, not everyone knows how to sheathe a house with metal siding. That's why this moment We will try to cover it in as much detail as possible in the subsequent presentation of the material. But first, let's find out everything about this type of finishing material.

The advantages of metal siding include its reasonable price, ease of installation, as well as the durability and reliability of facades sheathed with this material.

The main parameters of metal siding

Metal siding dimensions:

- Useful width - 188 mm (at 211 mm full).

- The recommended length is 3 meters.

- Length from the manufacturer - 0.5-6 meters.

Varieties of metal siding

Metal siding under a log is distinguished by an upper protective and decorative layer that imitates wood texture and color and thereby makes a house sheathed with such material look like a log house.

Metal siding is called light steel panels, which are galvanized and coated with a polymer film. In most cases, this kind of material is made outer skin at home, although in some cases they sheathe the walls with them from the inside.

The choice of the range of colors and textures of metal siding is very extensive. Prefer to sheathe your house under a tree? Siding satisfies this need to the fullest: it is possible to simply finish the facade “under the tree”, or you can imitate the exterior of the house under the rounded timber.

It is worth noting one important point in this regard. Unlike natural wood, siding does not require additional strengthening of the foundation to finish the house with siding. Together with fasteners, such a stylized different types wood or stone facade weighs very little. So much so that the load from the skin can not be taken into account at all. For example, one meter weighs about a kilogram and a half.

In addition to low weight, metal siding has a number of other advantages. Let's consider them.

Advantages of metal siding for house cladding

- Durability and strength. This property metal siding is explained by the fact that the steel sheet at its base is sprayed with zinc and polymers, and this gives it the strength of steel. At the same time, the material is resistant to atmospheric adversity, mechanical damage, bio-pests.

- High execution speed repair work from this type of lining. Metal siding is allowed to be installed on newly erected walls, and this can be done in any season of the year.

- It is possible to finish houses with complex geometry. If budget funds for repairs are limited, then there is simply no other way to finish the facade with complex shapes.

- Installation of metal siding is a good opportunity to make the facade of the house ventilated. Mounting gaps from the inside can be easily insulated, creating additional heat and sound insulation.

- The material does not fade when exposed sun rays while maintaining the brightness of the colors.

- Its service life is over 50 years.

There are some other differences between metal siding and vinyl siding - this is its heat resistance and increased fire safety.

How to sheathe a house yourself with metal siding?

Preparatory moments for cladding with metal siding

An obligatory stage of preparatory work before facing with metal siding is the installation of the crate.

Finishing with metal siding will require some preparatory work from the owner of the house. It is necessary to prepare the material for the crate on which the siding will be hung, and the appropriate tool for this.

List of siding tools:

- electric saw portable;

- cross saw;

- hacksaw for metal;

- hammer;

- screws of the required size.

First you need to prepare a crate that will eliminate all errors and distortions on the old facade. It is equipped exactly on the level. And only when the crate is fully installed, they proceed to the preparation of the panels themselves.

Acquaintance with the description on the packaging will help to avoid many problems in operation.

Sheets of metal siding have special grooves for joining with each other. Based on this feature of the panels, the heads of screws and nails can be hidden from external observation, making the facade aesthetically more attractive. To sheathe the house yourself using metal siding, follow the instructions issued by the manufacturer. This way you can avoid mistakes. In the instructions you can read about how to install sheets in complex structural nodes.

Next, you need to remove the existing defects on the surface. They inspect the exterior of the house and remove or remove all elements that interfere with the non-stop repair of the house. For example, climbing stems of plants, branches of shrubs growing close to the house, devices for draining water, window sills outside the house, lanterns, pipes and other special items or decorative elements can become such obstacles. If the basis of the facade is wooden material, then you need to examine it for the detection of rotten or outgoing boards.

When mounting the crate, they immediately provide for laying the cells with an antiseptic or insulating material. View the facing plane for curvature. If there are any, then this drawback is eliminated so that there is no curvature on the already finished facade.

The installation of the crate is made from narrow wooden slats. Filling the internal voids with an antiseptic is necessary so that mold and rust, rotting do not form, and also for safety purposes from deforming the siding sheets.

The panels begin to arrange from the bottom row. Starting panels are attached around the entire perimeter of the house. They are fastened by driving in nails or screwing screws in the center of an oblong hole made specifically for this purpose. If there are not enough of them, then new ones are drilled with a puncher. Having reached the end of the entire bottom row, they begin the second, and so on.

During the fastening of metal siding sheets, it is worth considering the possibility of panels moving during acclimatization and hammering nails in the center of the hole.

Before attaching the panel, each sheet is first inserted into the panel of the previously laid out row. To fix the sheets together there is a special design with a locking mechanism. After sounding a characteristic click, the strips are considered to be securely connected, after which they are fastened. The principle of installation of metal siding is the absence of fasteners on visible surfaces. This becomes possible due to the fact that the screws are not screwed into the sheet itself, but onto the lower strip (with horizontal laying) or on the side (vertical panels). When screwing in screws, the panel is not pulled hard and does not press too hard against the wall. Otherwise, its form will be lost. But its loosening is also not allowed. This moment is considered the most important when mounting.

The moment of hammering nails is given special attention.

The oval shape of the nail holes provides for the possibility of strip movement during their acclimatization. For which they also make a small gap (1-2 millimeters) between the head of the nails and the surface of the wall. If the installation is carried out in the winter, then the gap is further increased.

Some subtleties of working with metal panels

For competent and accurate siding of the house with siding, in addition to the main material, additional elements are used: various trims, corners, platbands, chamfers, spotlights.

The panels are cut using a saw with fine teeth or a metal knife.

Returning previously removed objects to the metal finish, holes are drilled on the panels with a slightly larger diameter (3-5 mm more) than it should be.

There are some nuances of installing metal siding in the corners of the house. In the corners, the ends of the strips are connected using external corners. Doorways, window frames, the top row of panels are finished using a J-bar. Such details got their name like a capital letter of the Latin alphabet due to their shape, which allows for a neat edging.

You can also sheathe the facade of an old house with metal siding. This is the most the best choice, therefore, time should not be spent on the selection of some other material for cladding the house.

In conclusion, we note that the issue of self-plating the facade of the house with metal siding was considered above.

We hope that after getting acquainted with the topic, there are no incomprehensible moments on the sheathing of the house with metal siding. Therefore, you can safely get to work.

Siding is a very well-known cladding material. This is due to the favorable ratio of its price and quality. In addition, it is not difficult to veneer an object with metal siding yourself. It is only necessary to clearly calculate the dimensions and the total V- of the desired panels, and also do everything exactly according to the instructions. The house can be sheathed and vinyl siding, which was discussed in .

Contents of the article about sheathing and finishing the house with metal siding

Manufacturers and price of metal siding

Before proceeding with the installation of siding with our own hands - let's get acquainted with the manufacturers and the price of the material in cities such as Moscow, Novosibirsk, Yekaterinburg, Ufa, Krasnoyarsk, Omsk, Perm, etc.

Metal siding under a log, Block House

Log (block house) is modern material for exterior decoration of buildings. The material is made of cold rolled galvanized steel, thanks to which metal siding on a log imitates the construction of a house from wooden logs. The thickness of the metal used is 0.40-0.45 mm, the mounting width is 335 mm, the overall width is 361 mm, the length is 0.50-6 m.

The price of metal siding "ship board" and "block house"

| Type of metal siding | Supplier company | City | Price, rub./m2 |

|---|---|---|---|

| Siding "Ship Board" | AVER | Barnaul | 260 |

| SeverSnab | Ekaterinburg | 250 | |

| Siberian Roof Plant | Novosibirsk | 245 | |

| Alfacom | Barnaul | 260 | |

| Mitlex | Lipetsk | 320 | |

| Special installation | Ufa | 230 | |

| SOCROFF | Ivanovo | 300 | |

| TD Uralsky Supplier | Ekaterinburg | 240 | |

| Avento | Ufa | 215 | |

| metal siding under the log Block House | Siberian Roof Plant | Novosibirsk | 370 |

| Special installation | Ufa | 250 | |

| Constructive decisions | Ufa | 340 | |

| thymal | Ufa | 330 | |

| Roof-PROF | Chelyabinsk | 430 | |

| TD Uralsky Supplier | Ekaterinburg | 390 | |

| TSK ARCHITEK | Kazan | 380 |

Sheathing a house with metal siding: preparing tools

You will need:

Staircase or scaffolding.

- level;

Nails or screws;

- scissors for cutting metal;

Perforator;

- pliers;

Roulette;

- hammer;

Do-it-yourself metal siding installation

Preparatory work

1. Choose a material. Facing with siding helps to make the house a well-groomed and aesthetic appearance. Still, the material itself does not need careful maintenance. This is one of its great virtues. Metal siding has a long service life, as well as sudden temperature changes, protects the facade from mechanical damage and bad weather conditions. It is also very important that thanks to the installation of panels, you can insulate the house and improve sound insulation without much loss of internal volume.

2. We get acquainted with the instructions on the package. Sheets of metal siding have special fasteners for attaching to each other. As a result, the heads of screws and nails are hidden from the outside observer, giving aesthetics to the facade. In order to veneer the object with metal siding yourself, follow the instructions given by the manufacturer. So you will save yourself from mistakes, moreover, the sheets of this book often give ways to lay sheets in heavy structural units.

3. Remove surface defects. Inspect the exterior of the home and remove or remove any items that may be preventing full operation. This is a fauna with a climbing stem, branches of bushes growing too close to the walls, etc. In addition, water drains, pipes, external window sills, skylights, and other special or decorative protruding items must be removed. If the facade is wooden, look for loose or rotten boards. If yes, then these shortcomings need to be removed.

4. We mount the crate, lay the cells with an antiseptic. Look at the cladding plane for curvature. If it is, fix it, otherwise the same irregularities will be on the finished facade. Mount the crate of narrow wooden slats. Lay the space inside the cells with an antiseptic to prevent mold and rust, rotting, and also to secure the deformation of the siding sheets. Instead of an antiseptic composition, it is possible to lay insulating material, this will improve.

Installation of metal siding

Consider the classic version of laying siding, but it is more popular.

5. We proceed to the installation of the bottom row.

First you need to mount the metal siding from the bottom edge. Attach launch pads around the entire circumference of the house. Attach them by screwing in screws or driving nails into the center of the oblong hole that is made for this. If there are not enough of them, then drill new ones with a puncher. Having completed the entire bottom row, go to the second, and so on.

6. Attach the panel. To begin with, insert each sheet into the panel of the row laid before. For this, a special lock design was made. As soon as you hear a characteristic click, the panels are firmly connected, you can connect. The principle of mounting metal siding panels is made in such a way that there are no fasteners on the visible surface. This is due to the fact that the nails are not driven into the panel itself, but into the lower (horizontal siding) or side (vertical siding) strip. When driving in nails, do not pull the panel and do not press it against the wall too hard, otherwise it will lose its own shape. But she shouldn't be shaky either. This is the hardest part of the installation.

7. We drive in nails. Not round form The holes allow the panels to move during the acclimatization of temperatures, when the material contracts or expands. For the same purpose, leave a small space between the nail head and the plane, about 1-2 millimeters. If for some reason you are doing the installation in the frozen season, then make the gap even larger.

8. We work with panels correctly. Cut the panels with a fine-toothed saw or a metal cutter. In the future, when returning to the metal lining of previously removed objects, drill holes in the panels of a significant diameter by 3-5 millimeters than necessary.

9. We mount metal siding at the corners. At the corners of the house, attach the ends of the panels using special outer corners. around the perimeter doorways, window frames and use J-Strips for the top edge. They got their name from this large letter of the Latin alphabet because of their shape, which allows you to make a neat edging.

If you decide, do not waste time choosing a material, use metal siding.