Calculation of laminated wood beams. Wooden floor beam span: types, dimensions and calculations. Advantages of wooden I-beams

The floors of the first floor between the basement or subfloor are usually made either from special floor slabs or on beams supported by fairly frequently standing support columns. This solves many problems regarding their calculation, design and further operation. But the beams interfloor slabs rest only with their edges on the walls of the premises and do not have any additional supports. Therefore, their design requires a more careful approach.

The following figure shows the process. Forces obtained for each of the tested combinations. Release the axial force in the pressed diagonal. - Determine the pressure value in the stretched diagonal. The axial force is eliminated in the pressed diagonal and added to the stretched diagonal.

Wooden floor beams - GOSTs and SNPs

Distribution of axial force increases in a stretched diagonal. The increase in axial force in the diagonal is decomposed in the direction of the rods that receive the nodes. Restore equilibrium at the end nodes of the diagonals. In each core and external carrier of the reinforced panel, the vector sum of the tensile strength components increases.

For the construction of floor beams, only dry wood should be used, at least 1 year of air drying, preferably 2-3 years. Those who lay beams from freshly cut timber from “this year” run the risk of getting large sagging beams even with their short length. As a rule, coniferous wood is used for beams, and its butt part contains a minimum number of knots.

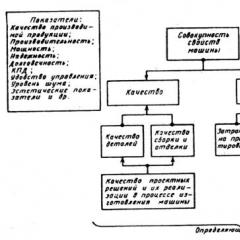

Determining the section and pitch of a beam

The final state of effort and response is evident in the following figure. These values can be viewed at each member or node for combinations and load combinations. Each load combination is treated as a separate combination. Fire resistance control.

This module carries out fire resistance examination and measures the laying of elements and measures fire incidents in accordance with selected standards. As a result, the user receives all the checks carried out in accordance with the selected standards, a three-dimensional image of the completed connection, as well as a drawing suitable for export or printing.

Depending on the planned load on the floor, the frequency of laying floor beams is selected. As a rule, this is at least 1 meter, and usually more often.

The most bending section of a wooden beam is 5:7. That is. Beam 7 measures high, 5 measures wide. This beam is strong both in bending and torsion. If the beam is wider than tall, they will have excessive deflection. And if it’s the other way around, it will tend to bend to the side under load. Thus, from the available “standard” sizes of lumber, it is very convenient to use either timber with a section of 10 x 15 cm, or a pair of “fifty” boards sewn together (50 x 150 mm).

Locking parts are anchor devices. Structural details can be designed and calculated using various software modules. One of the modules is "Connections" and the other is "Base Tiles". The possibilities for calibrating spare parts through two modules are as follows.

Plate type - dimensions of welded support parts with hot-rolled profiles. Welding - includes the calculation and calibration of welds between the plate, tongs, column and bolts. Automatic merging - the program aligns the strips in one design.

The beam bends under its own weight under the weight of the load from a higher floor (furniture, floor... etc.). In this case, one should not fight deflection as a phenomenon, but one should take it into account and calculate it in advance. To do this, proceed as follows.

The permissible deflection of the beam is considered to be 1/200 - 1/300 of its length. Those. a beam 6 meters long will bend by about 2-3 cm. So that the ceiling of the lower floor does not fall down in a “bubble”, the beam is trimmed from the side facing downwards with a plane by this amount so that 2-3 cm of wood is removed. Those. give the beam the appearance of an arch. The ends of the beam remain the same, but in the middle it becomes 2-3 cm thinner. After laying, such a beam will be slightly curved upward, but quite quickly under load it will become almost horizontal.

Differentiated three-dimensional view of elements and welds. The program can display a three-dimensional image of a workpiece or structure, displaying in different colors welds, which she recommends being done in the factory, and those that should be done on site.

Details. You can see a drawing with all the elements contained in the spare parts, as well as the welds between them. This drawing may be included in all design documents. Documentation - the program can prepare complete documentation for the project, which will contain all checks and quantitative records.

Usually, when calculating wooden beams, it is believed that its cross-section should be no worse than 1/25 of its length. For example, a 6-meter floor should be at least 24-25 cm thick. With a beam width of 15 – 18 cm, respectively. Since it is difficult to maintain such parameters (due to the lack of lumber of such sizes), a set of them is produced from smaller-sized (cross-section) materials. The following rules usually apply.

The bases can be concrete and reinforced concrete, with a standard or variable section. It must not be used without prior approval. In the case of an irregular grounding plan, they are installed in a fan-shaped manner. With large spans and deformations, it is possible to connect two or more cross sections in height using bolts and dowels. Nowadays, however, glued laminated wood profiles are also predominantly used.

Length ceiling mount on the load-bearing wall, select from 150 to 200 mm. To protect against moisture and subsequent biological damage, the beams of the beam are placed on washers with a biocidal coating. There must be at least 50 mm of air gap between the masonry and the beams for good ventilation of its head.

1) Beams of the same height laid next to each other add up their “loads”. Those. if one beam can withstand 400 kg, then 2 beams - 800 kg.

2) Beams laid one on top of the other (vertically) and fastened together can withstand a load 4 times greater than each of them. Therefore, it is more profitable to increase the beams in height than in thickness. Those. the same 2 beams, but placed not side by side, but on top of each other, will support 1600 kg, and not 800.

If there is no requirement for thermal insulation, it is also possible to provide more intensive ventilation through slots in the perimeter wall. On the contrary, additional thermal insulation placed in front of the beam can prevent water vapor from condensing. The connection of the ceiling structure with the load-bearing wall is solved by connecting the ceiling of the ceiling with clamps.

The most typical design one-story houses for farms is a ceiling with adjacent ceilings, a stacked 25mm thick solid roof and a pile or clay screed. Ceiling floors in multi-storey buildings usually consisting of boards placed on a tongue, groove or semi-circle. The interlocking boards are covered with cardboard sealing strips, and the hopper itself increases the fire resistance of the structure.

Of course, the possibility of bending a beam that is too high and narrow should also be taken into account. Therefore, with an optimal height to width ratio of 1.4, its value should not be exceeded to more than 2.0 - 2.5, provided that the beam is securely fastened along its entire length.

Particular mention should be made of the need to carefully fasten the beams to each other when connecting them vertically. Known, so-called Derevyagina beam. In it, two beams were connected to each other using dowels and dowels (in much the same way as when laying walls made of timber). The meaning of this is to eliminate the longitudinal displacement of the beams relative to each other during bending. Those. the beams become like a monolithic element, which gives them additional rigidity. Such rigidity can be achieved even more modern methods, for example, using glue, dowels, pins and special metal plates.

Floating floors for beam ceilings on thermal and sound insulating mineral fiber boards are currently being developed. Beam ceiling with exposed beams. For classic flat top beam ceilings, the underside ceilings are 25mm thick boards and applied to a reed mat or timber cladding.

Beam beam ceilings have a double load-bearing structure. Possible ceiling deviations are not transferred to the ceiling. The ceiling design is also better in terms of fire resistance and sound insulation. Recessed ceiling with straight ceiling. This ceiling is suitable for large spans. Fixed expansion is ensured by a steel rod with a straightening element. Thus, there is a spatial arrangement that allows the load to be evenly distributed across the individual beams.

However, increasing the height of beams is subject to serious restrictions by the requirements for rational use spaces of the house. Therefore, beams are not made more than 20-30 cm (who needs floors half a meter thick...). Consequently, to increase the load-bearing capacity of beams and floors, they are laid more frequently. In this case, it is important to take into account the load-bearing capacity of the beams per 1 m2 of flooring. And at the same time it turns out to be more profitable to use narrower but tall beams. Judge for yourself:

Beam ceiling with cross braces. At that time, Karl Lindner introduced his layer of the middle class. He was awarded the status of a high-ranking official, and because of his social prestige, he chose the so-called good address for the construction of his house - Humboldt Street, now Tchaikovsky. His neighbor was, for example, the then general manager of the chemist Usti and bearer of the noble title of Alexander Wölfel. However, Lindner could not match his neighbors in terms of property.

What kind of wooden floor beams should be

The only thing that can be said is that the house is located on a narrow and inaccessible site. There must be a long staircase to the main entrance, the access road does not exist at all. The fact that a family with three children and a maid lived in not even a large house. However, without a huge amount of money, a beautiful building worthy of its owner was built. The project was commissioned by the architect Anton Kunner, who designed a unique and attractive house. We find elements of Art Nouveau, historicism and rustic architecture.

For example, to cover a 5-meter span with a load of 1200 kg, you will need 2 beams with a cross-section of 200 x 150 mm laid every 1 meter. They can be replaced with 3 beams 200 x 70 mm, after half a meter (gain in the volume of lumber 30%!) or 4 beams 200 x 50. (gain 34%)

Since lumber is sold “by volume”, correct calculation of beams can significantly reduce the cost of their installation without loss of quality and load-bearing properties of the floor.

Karl Lindner was pleased with the proposal, except for minor changes, the project was implemented as it was drawn up on paper. The basement, which extends above ground level, is characterized by combinations of stone and matching bricks. Its unusual and modern surface finish is found on the ground floor - the plaster forms a system of horizontal waves. Wood predominates on the ground floor. Carved and reddish painted beams form railings, balcony posts and also imitate half-timbered brickwork.

Below I provide an approximate table that will help you choose the right beam sections when installing interfloor and attic floors.

Of course, adjustments should be made for changes in load, quality of material, changes in the frequency of laying beams and their deviations from standard dimensions.

Konstantin Timoshenko

To make the ceiling as reliable as possible, you should select the exact dimensions of the beams used for work. So, for example, the calculation of wooden beams is an invariable part of the work before their manufacture; the length of the beams and their cross-section are taken into account. The length of both wooden and metal beam structures depends on the width of the planned floor, and the cross-section must be calculated depending on the pitch, load and span length.

Shards of broken roofs cover a colorful mosaic of eternity, as happens in the cottages of the Ore Mountains or in the Lusat Mountains, in a rustic spirit the window sills are decorated with hearts and six-legged stairs and brick stairs with ornamental heads.

In the middle of the stairs that go up to the main entrance, a tree grows today. Entrance door gone, and only part of the gap with green glass remains from the door in the corridor. There is trash and leftovers in the central hall wood paneling walls The main salon features a neo-Renaissance stucco ceiling. The plaster is shaped like boards and beams and covered with a wood-like finish, so it acts as a cassette ceiling. The room is accented by a niche with two windows. All of them were equipped with wooden shutters, the remains of which rolled across the floor.

You can find special ones on the Internet online calculators, helping to perform calculations online, but not everyone trusts the calculator, so we will tell you what formulas are used and how exactly floor beams are calculated.

How to calculate a wooden floor beam

A wooden floor beam is a structural element with load-bearing functions. When calculating and selecting material, you need to consider the following:

There are only two complete ones in the house. The next room also has a stucco ceiling, this time in an Art Nouveau style with floral stripes. The wood floor is eaten by the wood floor. The room opens onto a loggia with large semicircular windows that have unusual partitions - the partitions are not flat, but wavy, so the glass tables have an irregular shape. The main decoration of the loggia consists of decorative forged bars in the form of bars surrounded by a flower. There are remains of colored ceramic tiles on the floor.

And when you turn the view from the floor up, you can see through the sunken ceiling to the attic. The staircase has long since lost its decorative handrails, but it shows an image of the destruction to the first floor. Leaking through the roof, water flows into the house and destroys everything in its path. The massive rays rot with rot, like gingerbread.

Therefore, when using the calculator to make calculations, do not forget to take into account the above tips, this will help you install the floors more reliably.

Determining the approximate floor load

It is quite natural that the ceiling will give the beams a load, which will consist of its direct weight and the weight of the objects that will be on the ceiling. A detailed calculation of the load can only be done using a special calculator in the design organization. But you can more easily calculate the load on the floor using the following tips:

The house still has a small apartment with a separate entrance to the basement. It consists only of a kitchen and a room, which is formed by a representative salon on the ground floor. It's just that instead of a stucco ceiling there are simple vaults. The remaining basements became slopes that served as storage and laundry. An important part of the building is the system of high supporting walls. They share the parcel and a smaller garden with a steep slope. The garden is located next to the forest. The original owners were apparently afraid of thieves attacking this side, so all the windows on the first floor were equipped with bars.

How to determine the pitch and cross-section of floor beams

Now that we know their length and design load, we should calculate the pitch of the floor beams and their cross-section. To do this, we are guided by the following rules:

They ended up in the collection, leaving only the heavy metal door side entrance, which resembled a prison cell door with its small locked eyelid. Of Karel Lindner's children, only the daughter of Juliana, the pharmacist Usti, remained in the house. After studying, the sons went to work in Germany. The owner, meanwhile, left the republic as part of his expulsion. The house, with its location, size and articulation of the interior, was not as profitable as the other villas on the street, which mostly became business or government buildings.

The villa was divided into two apartments, rented out and later transferred to the ownership of tenants. By the beginning of the year, the house was occupied and witnesses described it as intact. The rooms also have the original tiled stoves, which are now just broken pieces scattered throughout the cellar. After some time, the villa was sold for only 400 thousand crowns. Why she remained deserted and became a homeless homeless person and a metal construction worker is not obvious. Perhaps, like other villas, it was put on hold by the bank as security for a speculative loan.

What kind of wooden floor beams should be

Features of metal floor beams

For floors, metal beams are not used as often as wooden beams, but their advantages include such factors as a longer service life compared to wood, fire resistance and safe spanning of 5 meters.

The salvage will most likely not be able to survive because it will require disproportionately high costs to repair. Laminated timber poles are high-level straight, curved, single-sided, double-sided timber elements used as building support structures. Can be standard sizes or manufactured according to individual orders and special projects. Laminated wood planks are 80% stronger and 40% more rigid than conventional solid wood structures of the same size.

Wood - spruce, pine, larch. The surface is calibrated and planed. Wooden structures are environmentally friendly and hygienic, do not emit harmful substances and are made from renewable materials. natural resources. The course project takes into account and designs wooden enclosing structures for a heated building. Building without shelter, frame with retaining walls. The columns are rigidly connected to the foundation. The protective support structure is multi-layer cross-section beams.

Angles, channels and I-beams are used as metal beams.

The distance between metal beams should be twice as large as between wooden beams. It depends on the size of the flooring slabs that exert a certain load. Also, they cannot be used as floor joists, and it will not be easy to attach a ceiling to them.

However, the unpopularity of using metal structures associated with such disadvantages as:

- with high humidity, rust forms;

- During installation, a forklift should be used;

- the need to eliminate sound conduction by wrapping the ends with felt.

To prevent corrosion on load-bearing structures You can use reinforced concrete; they should be laid at a distance of about a meter from each other, and the resulting space between them is filled with lightweight concrete slabs or blocks. On top, the ceiling is equipped with a screed under the floor, and the ceiling is plastered.

To prevent corrosion on load-bearing structures You can use reinforced concrete; they should be laid at a distance of about a meter from each other, and the resulting space between them is filled with lightweight concrete slabs or blocks. On top, the ceiling is equipped with a screed under the floor, and the ceiling is plastered.

As you can see, it is very difficult to make the necessary calculations when using floor beams, but you can do it yourself without using special computers or calculators.