Frame material. Frame technology materials. How does the pitch of the frame posts affect the consumption of materials?

In Russia, many craftsmen can boast of a house they built on their own. And there are even more people who want to do this. Home craftsmen especially became bolder after a new direction in construction appeared - the construction frame houses. Indeed, houses of this type are built quickly and inexpensively. If, of course, the work is done correctly preparatory stage. This part of the work, in addition to the project (or at least a sketch if you are building a small dacha), includes calculating the needs building materials. It is more convenient to carry out this calculation in accordance with the stages of construction. The amount of materials required for the construction of the foundation and roof frame house calculated using the same methods as for other types of buildings. How to calculate the need for materials for wall construction? The complexity of this task lies in the many options for combining materials. It is important to choose the right frame scheme here.

Calculation of the cross-section of materials for a frame house

Frame trick: the building is supported by a steel frame that does not require thick walls inside load-bearing walls. This creates space, nothing narrows the point of view, says Wolfgang Hugo. It's a different feeling of living, with open passages that dissolve boundaries between spaces, but functional and more intimate spaces can also be separated and protected from each other.

The design of a steel beam is a matter of taste. Some people find this independent aesthetic too cool, admits the architect. "Because the steel remains visible in the interior." This is why oak turned out to be the most beautiful additional wood for this model, explains Christian Hugo. “It matches the metal, gradually turning into a honey color, giving a steely glow, and the combination of steel, wood and stone can be very comfortable,” she says.

How does the pitch of the frame posts affect the consumption of materials?

- 600 mm;

- 575 mm.

In this case, the pitch of the racks must be consistent with standard sizes drywall or OSB. You can ignore the insulation in this combination. It will be more economical to choose a frame scheme with a rack pitch of 600 mm (since the width of a standard sheet of plasterboard is the same 600 mm). The OSB sheet is adjusted in width taking into account the expansion joint.Option 2: the wall will be sheathed: - on the outside - with OSB sheet (2500 x 1250 x 12 mm); - on the inside - with clapboard. For insulation, we will take basalt insulation (slabs), the width of which is 600 mm. The deformation strip of the slab is 50 mm. In this combination, the determining factor will be the size OSB boards: we get the permissible pitch range of the racks from 595 to 560 mm. At the same time, the geometric dimensions of the board from which the racks are made impose significant restrictions on the choice of pitch. The maximum permissible distance between the posts depends on their cross-section and is:

- 650 mm – for boards with a cross section of 50 x 150 mm;

- 400 mm – for a board with a section of 50 x 100 mm.

Dimensions of rack sections

| Wall type | Load presence | Minimum permissible rack section |

| internal | From the attic (not in use) | 38 x 64 (with a rack height of 3 m) 38 x 89 (with a rack height of 3.6 m) |

| Outdoor | From the roof with the attic | 38 x 64 (with a stand height of 2.4 m) 38 x 89 (with a stand height of 3 m) |

| Roof + attic + one floor | 38 x 89 (with a rack height of 3 m and a pitch of 400 mm) 38 x 140 (with a rack height of 3 m and a pitch of 600 mm) | |

| Roof + attic + two floors | 64 x 89 (with a stand height of 3 m and a pitch of 400 mm) |

Based on the above, the following rule emerges: the width of the rack should be equal to maximum thickness insulation and should not be less than the minimum permissible value. The optimal cross-section will allow you to hide the insulation, withstand loads and will not result in excess consumption of material.

Calculation of the quantity of basic materials

Once you have decided on the name of the main materials, the cross-section of the racks and their pitch, you can begin to calculate the required quantity.Lumber calculation

So, before you is a house plan with the installation locations of racks, windows and windows marked on it. doorways. First, calculate how much lumber you will need to build the frame. The frame of the house is assembled from the following types of lumber:- timber;

- bar;

- boards.

Bottom harness

total length bottom trim corresponds to the perimeter of the building: add the length and width of the house and multiply by 2. Typically, to make this part of the frame, take a beam with a cross-section of 150 x 150 mm. To calculate cubic capacity, you need:- calculate the cross-sectional area of the beam: for this, the length and width of the beam are converted into meters and multiplied (150 mm = 0.150 m);

- the resulting area is multiplied by the total length of the harness. As a result, you will get the volume expressed in cubic meters.

Upper harness

The calculation of the timber from which the upper strap is made is carried out in the same way as in the case of the lower chord. Typically, a beam with a cross-section of 100 x 150 millimeters is used to construct this element.Vertical racks

You already know how to choose the cross-section of the racks. But this applies to intermediate supports. Corner posts are made of timber with a cross-section of 150 x 150. Therefore, calculate the volume for each section separately. Do the following:- count the number of racks of the same section according to the markings on the house plan;

- multiply the resulting number by the height of one rack (you will receive the required number of linear meters of this material);

- calculate the cross-sectional area of the rack (in meters);

- multiply the resulting area by the number of linear meters.

Calculation of the quantity of other materials

The amount of insulation, internal and external cladding, vapor barrier film and other materials included in the construction of the walls, is calculated as follows:- the perimeter of the building is multiplied by the height of the wall;

- the total area of door and window openings is determined: the width of one opening is multiplied by its height and the resulting value is multiplied by their number;

- The area of the openings is subtracted from the total area of the walls.

This is how you can calculate the amount of basic materials needed to build the walls of a frame house.

The quality of building materials plays an important role in the strength of the future home. For example, if you purchase a tree that is infected with a fungus, then part of the structure will soon become infected, which will lead to the need to replace elements. If you don’t have the slightest desire to monitor processes and also go shopping, entrust this matter to PROEKTSTROY-P LLC. We carefully select building materials for a frame house, and some are manufactured using our own equipment in the factory and using the latest technologies.

With the help of builders, the company creates new buildings with pitched roofs or pitched roofs, conventional or futuristic, but always with steel frames. However, the great opportunity of the model lies in the development of gaps, vapors and connections in metropolitan areas, emphasizes Wolfgang Hugo.

“The infrastructure can be easily extended, even in applications, and all loads are carried through the supporting structure, while still offering a good thermal insulation cover,” says Hugo. “A framed house can also be created as a penthouse on an existing building such as office building" Finally, there are a million left in Berlin square meters roof space. “They can be grown and designed in attic style,” asks the architect enthusiastically.

What materials are needed to build a frame house?

Most important element– the frame itself, which must comply with all norms and standards. In the company PROEKTSTROY-P LLC you can order its production. The main thing is that you have a project for which our specialists will produce all the elements, from the floor to the roof. If you don’t have a project, no problem, our architects and designers can complete it in a short time.

As an extension to a prefabricated house or as part of a renovation or reorganization of buildings: with wood, interior design is not only fast and flexible. You also get a piece of nature into the interior of your home. Wood and classic carpentry skills bring flexibility and aesthetics. Innovative technologies and modern materials provide individuality and comfort.

The most important advantages at a glance

Wood is bio-hygienic and healthy. Bacterial density is lower on the surface of wood than many other materials. In addition, wood has been shown to reduce some allergies and skin conditions. Some types of wood even directly affect our health.

You will also need insulation, for example, mineral wool, polyurethane foam, sawdust or another. Their delivery can be provided by the contractor, subject to drawing up an agreement with him. What exactly to choose depends on you and the project itself, but it is better to focus on high-quality and modern materials.

Gypsum and wood, symbiosis at a high level

Contact us already at the planning stage. Our technical capabilities open up many solutions. Moisture causes shrinkage, especially in wood structures through drying, which can cause cracks. It follows that caulking can only be carried out after the construction site has dried, and according to experts, the screed plays a decisive role. According to experts, it is important to ensure decoupling of the wall sections. “With the help of dividing strips or blunt turned rentals of sparkling reinforcing strips, expansion joints are prohibited exactly in the corner where they cause the least disturbance, when it is straight and” is explained.

A ventilated facade is a good option for improving frame housing, as well as for providing additional heat in the room. The façade, made using a special technology, allows the walls to breathe, thereby increasing the life of the home.

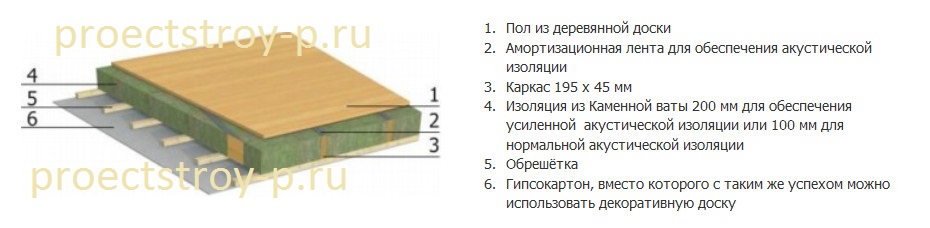

Steam, hydro and sound insulation will be required. For this purpose they use various materials, starting from ordinary film and ending mineral wool. If you are far from construction and have never even held a hammer in your hands, contact our specialists for a consultation, who will explain in detail a number of nuances and advise what materials to use for a frame house. It is unlikely that you will be able to buy everything yourself without missing out on anything. Yes, and correctly calculating the amount needed is also unrealistic.

Reinforcing the paper at the corner can also help in this case. Silicone or acrylic triangular joints are not allowed as standard. Filling must be performed in several operations. Naturally, not all of these residences were of the same type. The poorest lived in small rooms installed at the back of a workshop or business, or in an attic that did not exceed 50 square meters.

Then there were the stately houses occupied by the local aristocracy, wealthy merchants and the highly respectable Pompeii, by far the most famous and most attractive to visitors and scholars. One of the best preserved is Marco Lucrecio Fronton. Although it was not one of the most extensive - it was 460 square meters - it is known for possessing some of the most exquisite paintings in the city.

If you order a project from us, no matter whether it is turnkey or not, you will never regret your choice. Plus, you don't have to worry about building materials - we'll do everything for you. The LLC PROEKTSTROY-P company is an excellent choice made by responsible people who want to get the ideal housing at the most reasonable price.

From this point on, traditional Italic dwellings included an implium in the center of an open atrium and a ported garden at the rear of the house. In addition, it had rooms for receiving guests, food and recreation. When the dining room was moved to the peristyle area, the kitchen was also placed at the rear of the house. Thus, the tablinus, a luxurious room in which the owner of the house received freedmen and clients, was in the middle of the house between the atrium and the peristyle. Thus, it became the center of the visual architectural perspective that was created from the front door.

Go to: