Projects of houses from facing bricks. How to impose a brick on a foam block house and decorate the facade

In order to use facing bricks, the foam blocks from which the walls are folded must be prepared. This problem stems from the fact that both materials that form the wall are breathable. For this reason, when facing foam blocks with bricks, it is very difficult, and sometimes impossible, to bring both materials into full contact. However, it is necessary to solve this problem, since foam blocks are afraid of moisture. If you want your house to be not only beautiful, but also durable, it urgently needs to be faced with brick.

Facing foam blocks with bricks helps to solve the issue of waterproofing walls.

Features of facing of foam blocks

Foam concrete houses are built quickly, in just a few weeks. This process can be carried out independently, without the involvement of outside labor. However, if the process of erecting walls is delayed, you should not follow the usual tactics in these cases of sequential work on the principle of "walls first, and then facing." While you are building the main elements of the house, the foam blocks will be saturated with moisture, covered with dirt and take on an unpleasant appearance.

It is necessary to cover the house from foam blocks immediately as the walls are being erected, without waiting for the end of their construction. Tiles, facade panels, stone, brick are used as facing material.

The most popular material is usually facing brick.

It is beautiful, reliable and prestigious. In addition, decorating a house with bricks can combine maximum protection and the basis for a flight of design imagination.

Usually, facing is carried out in two ways - in parallel and after the fact. In the first case, it is carried out along the way of construction. However, few do this. Most often, they refuse to carry out facing work in parallel with the construction of walls due to a lack of labor.

The cladding is carried out after the fact immediately after the laying of the walls is completed. However, it is very important to complete the work before the rains. This linking of the timing of work to weather conditions negates all the benefits of consistent work. The weather does not take into account your needs and the established rhythm of actions. If cyclones come and your walls are defenseless, there will be a lot of extra work to do.

Wall forming structure with facing masonry

The main thing in the technology of wall cladding is the binding of the inner and outer layers to each other. At the same time, you should not arrange a brick bundle, as this will reduce the heat-insulating functions of the brick. Typically, metal structures, such as reinforcement, are used as a bond.

The best option for forming a wall is the following scheme:

- facing layer;

- air gap between brick and foam block layers;

- reinforcing layer;

- vapor barrier layer;

- anchors for fixing the insulation;

- insulation coating;

- foam blocks;

- plaster.

Such a sandwich will perform well as an insulating function. Moreover, the insulation will be not only air (retention of heat or coolness), but also water (protection of foam blocks from moisture).

Cladding technology

In order to carry out a full-fledged cladding, you need a foundation stock of at least 20 cm. Usually, this gap is provided for by house projects. However, in reality, it happens in different ways. If the time has come for cladding, and there is no necessary gap, then you will have to spend time to build up the foundation.

To do this, you need to dig a trench for the entire length of the masonry, but so that there is a free space of 20 cm in front of the house.The depth of the trench should fully correspond to the depth of the foundation, and its width should be 40 cm.

A sand pillow should be covered at the bottom of the trench. The sand must be settled within two days. It is not necessary to water and tamp it specially, so as not to accidentally damage the main foundation.

Holes must be made in the main foundation under the house with a hammer drill and a diamond drill. In this case, special care should be taken, as you can provoke the appearance of a crack.

- rods are laid out parallel to each other every 8 cm;

- they need to put more iron rods perpendicularly, but at a distance of 20 cm from each other, in the places of these intersections, welding is performed;

- a rod 25 cm long is welded to each point of the fixed intersection, which is necessary for the joint with the main structure.

- the whole structure is installed in the right place and welded to the main structure.

The surface of the foundation is cleaned of dirt, after which a primer is laid on it.

The formwork must be installed at a distance of 25 cm from the main structure. The solution is poured into it to the height of the foundation. After that, the work will need to take a break for 3 weeks to completely dry the new foundation.

At this time, the walls and foundation will have to be completely covered with polyethylene. If this is not done, then the rains will saturate the walls with moisture. They will have to dry for two months.

After three weeks, the formwork is removed and the finishing of the house continues.

Before starting finishing, you need to prepare a cement mortar. To do this, 1 part of cement and 1.5 parts of clean sifted sand are poured into the container. Everything needs to be mixed well, preferably with a drill with a nozzle. After that, 0.3 parts of slaked lime is added, and everything is mixed again. Now you need to pour 0.6 parts of water and stir until homogeneous. In the process of mixing, it is advisable to add a little plasticizer. The mortar is ready, it's time to start facing.

How to tax a house? Very simple. First you need to make a 35 mm measurement between foam blocks and bricks, then pull the thread along this mark. Next, the usual masonry algorithm begins. A cement mortar is laid, a brick is laid on it, then it breaks through from all sides with a rubber hammer. The space for the mortar to be squeezed should be about 6-9 mm.

On each next brick, the mortar is laid first on the side, then on the previous brick. The grinding of bricks is done by moving first horizontally to the adjacent one, then vertically to the underlying one. Each time, with a trowel, you need to remove excess mortar, transferring them to an adjacent surface.

The difference between this facing masonry from the usual construction of a brick wall is the need to provide points of contact with the foam block wall.

The main thing is not the correct laying of bricks, but preventing the blocks from being saturated with water. If all the conditions are met, you will have a beautiful and comfortable home.

One of the common finishes of all types country houses- facing the house with bricks. This type of finish is attractive because it looks beautiful and stylish; externally brick houses look solid and solid, even if inside, under the brickwork, is hidden wooden blockhouse or foam blocks; and it is, moreover, very durable: built and forgotten.

It must, however, be borne in mind that bricks are different. A good, high-quality brick really lasts a very long time. The quality of a brick is determined mainly by its frost resistance, which is measured in the number of freeze / thaw cycles. A good facing brick has 50 freeze / thaw cycles or more.

Brick cladding options

There are many varieties facing brick, differing in color, texture, surface shape and production technology. Accordingly, you can choose options for cladding in different architectural styles.

In particular, the facing of the facade of the house with a dark brick with a pronounced relief texture gives the building the appearance of an ancient castle. Decorative elements of facades of complex shapes can be overlaid with figured (shaped) bricks. Clinker brick, which looks extremely decorative, also has the lowest water absorption and increased frost resistance. Glazed bricks of various shades are often used in the design of facades, for example, in the Art Nouveau style.

For example, the company "Terca", part of the concern "Wienerberger", offers four basic colors: traditional terracotta, black, coffee and yellow (variegated colors are obtained through the use of a special firing technology), plus seven options for the texture of the front surfaces: smooth, rough, grooved, antique, antique chipped, chipped and St. John's from the Holy Family series, which is produced by hand molding. (By the way, hand molding not only raises the price and gives an unusual appearance, but also doubles the durability.) Such a variety allows you to choose an adequate solution for almost any architectural style.

For example, the company "Terca", part of the concern "Wienerberger", offers four basic colors: traditional terracotta, black, coffee and yellow (variegated colors are obtained through the use of a special firing technology), plus seven options for the texture of the front surfaces: smooth, rough, grooved, antique, antique chipped, chipped and St. John's from the Holy Family series, which is produced by hand molding. (By the way, hand molding not only raises the price and gives an unusual appearance, but also doubles the durability.) Such a variety allows you to choose an adequate solution for almost any architectural style.

Decorative masonry with facing bricks can be carried out not with ordinary mortar, but with ready-made masonry mixtures of various colors - it turns out very beautifully. An example of such mixtures is Vetonit. Beauty masonry seams emphasizes the chamfer on the edges of the bricks, a style also characteristic of Terca.

Technology features

Regardless of what the house box is made of, a ventilation gap is left between the facing brick and the main wall.

If cladding is performed wooden house, then the ventilation gap protects the wooden, folded from a bar, walls from mold and rot, and the insulation, if the house is insulated, from moisture.

The same can be said about: according to the current thermal engineering standards, they need to be insulated, which means that a ventilation gap is necessary.

With the subsequent lining with brick, it is also carried out with leaving a ventilation gap: although such houses do not need additional insulation, but due to the high vapor permeability of foam concrete and gas silicate at the border with brickwork in the absence of a ventilation gap, moisture would condense, moistening the walls and causing dampness.

The air in the lower part of the brick cladding, necessary for the street air to circulate freely in the ventilation gap, is left not in the first, but in the second row of bricks so that they are not flooded with mortar during construction. These vents look either as windows covered with a grill or mesh, or as vertical seams not filled with mortar, into which plastic segmented liners are inserted.

The facing masonry must be tied to the main walls of the house. The classic way is to use galvanized steel mesh. The disadvantage of this method is that, despite galvanizing, the mesh still rusts and collapses over time.

Ties made of composite materials - carbon fiber or basalt - are not destroyed, but in this case, the masonry joints in the main wall and cladding must match in height.

Flexible stainless steel ties are used, in the form of strips - such ties can be used if the masonry seams do not match.

Stainless steel ties are also used, which are attached with dowels, if the main wall is made of foam blocks, or screwed into a wooden wall like self-tapping screws. In the case of facing insulated wooden houses such ties, equipped with special "umbrellas", press the insulation against the wall. When facing a house made of foam blocks with bricks, these connections can be installed anywhere and do not depend on the location of the masonry joints. Therefore, they can be used even if no connections were laid at the stage of laying walls from foam blocks.

Stainless steel ties are also used, which are attached with dowels, if the main wall is made of foam blocks, or screwed into a wooden wall like self-tapping screws. In the case of facing insulated wooden houses such ties, equipped with special "umbrellas", press the insulation against the wall. When facing a house made of foam blocks with bricks, these connections can be installed anywhere and do not depend on the location of the masonry joints. Therefore, they can be used even if no connections were laid at the stage of laying walls from foam blocks.

At the design stage, it is important not to forget to take into account the thickness of the brick cladding with a ventilation gap, which will be added to the thickness of the main walls, so that an area of the corresponding width is provided on the basement strip.

Cost issues

Facing a house with bricks is a relatively expensive type exterior decoration... Facing a wooden structure with a brick will, in fact, cost more than finishing with a decorative board or, even more so, vinyl siding.

However, compared to plaster, brick cladding of a stone house does not always cost significantly more. Of course, when compared with ordinary plaster, the difference will be quite significant. However, ordinary plaster, in principle, can only be used on non-insulated brick walls that do not meet modern requirements for heat conservation.

On walls made of gas silicate or foam concrete, as well as on insulated brick walls (" wet facade”), It is necessary to use relatively expensive compositions with high vapor permeability, and the numbers turn out to be quite comparable. In this case, brick cladding will not be much more expensive than other methods of exterior decoration.

Even at the design stage of the future house, it is worth thinking about how its facade will look like. And if an unattractive material is used to make the walls, then the facade is most often covered with facing bricks. In some cases, such cladding has not only decorative functions, but also protects the walls of the house from moisture saturation. This, for example, happens in the case of building a house from foam blocks or aerated concrete. In our article, we will tell you how to overlay a house with facing bricks, as well as how to choose the right material for these purposes, because there are many varieties of it, differing not only in color and texture, but also in important technical characteristics.

Material selection

When deciding how to decorate the facade, many owners of country houses choose exactly facing brick. And this is not surprising, because this material has excellent specifications... However, the house can be faced with several types of this material:

- ceramic bricks;

- clinker products;

- silicate elements;

- finishing material made using hyper-pressing technology.

Each of them has its own unique technical characteristics. When choosing elements, you should pay attention to the correctness of the shape, the evenness and clarity of the edges, and uniform color. There should be no defects on the surface of the material. It is also important to take into account water absorption (the smaller it is, the better), frost resistance (optimally within 25-50 freeze-thaw cycles), as well as compressive strength.

Ceramic brick

Clay is used as a filler in this product. After molding, the material is fired in an oven at temperatures up to 1000 ° C. A house lined with this material becomes warmer, its soundproofing qualities increase, the structure will last a longer period. Therefore, it is much more profitable to build a brick-lined house from foam blocks than to build a wooden or frame structure.

Among the advantages of ceramic wall products, the following should be listed:

- Typically, the water absorption is 6-14 percent, which makes it possible to use the material for facade cladding. In some varieties of such products, this figure may be higher, since a different clay is used for the production.

- Frost resistance - the material can withstand 25-50 cycles.

- The thermal conductivity of ceramic products is low - 0.3-0.5.

- The impressive strength (1300-1460 kg / m³) allows the use of such material for construction load-bearing structures at home.

Among the disadvantages of ceramic products are the following:

- A small selection of colors and textures. On sale you can find different shades of red-brown and red brick, since the material contains red clay.

- If we compare ceramic elements with silicate ones, then their price is higher.

Clinker products for wall cladding

The clinker brick contains refractory clay additives. The material is fired at very high temperatures, up to 1200-1300 ° C. Due to this, the structure of the product is very dense, which reduces its water absorption. Also for this reason, the frost resistance of the material increases. If you decide to brick a building made of foam blocks, then it is best to use clinker.

This material has a lot of advantages:

- Products have increased frost resistance, which can be up to 100 cycles.

- Low water absorption allows it to withstand any weather influences, which is especially important for a house made of material such as foam concrete.

- An impressive service life of over 100 years.

- A wide range of colors, textures and shapes allows you to embody any ideas of architects.

- Clinker can be used to make columns, decorative details of facades, fences, gazebos, cover fireplaces and stoves with it, and use it to decorate interiors.

- Due to its high density (up to 2100 kg / m³), the solid material can be used for the construction of load-bearing structures of a building, for example, foundations.

There are few disadvantages of clinker, but they are:

- These products cost a lot of money. The costs should also be added to the costs of styling, because to lay well face brick only a specialist can.

- Due to the high density of the material, it has a high thermal conductivity, so a house lined with such a brick needs additional insulation.

Important: only solid clinker has high thermal conductivity. As for hollow clinker bricks, its thermal insulation characteristics are higher.

Silicate wall materials

Quartz sand acts as a filler here. Compared to ceramic bricks, silicate material is not so expensive, which makes it more acceptable for most citizens. However, the thermal conductivity of the material, its strength and frost resistance are lower than those of its ceramic counterpart.

Among the few advantages it is worth mentioning:

- Water absorption within 6-8%.

- High soundproofing characteristics.

The disadvantages include:

- Thermal conductivity in the range of 0.39-0.8.

- Density from 1500 to 1950 kg / m³.

- Low frost resistance within 15-50 cycles.

- A small selection of colors, textures and shapes, which significantly reduces the decorative possibilities of the material.

Products made by hyper pressing

The use of the semi-dry hyper pressing method allows obtaining a fairly wide range of wall cladding products. A house made of foam blocks can be safely overlaid with such a brick, because in terms of characteristics it is not inferior to ceramic products. Depending on the filler used, hyper-pressed products can differ significantly in their technical characteristics:

- Water absorption is 3-7%.

- Frost resistance can be within 30-300 cycles.

- Strength can also vary significantly and is in the region of 1000-4000 kg / m³.

Among the disadvantages of elements obtained by the method of hyper pressing, the following can be mentioned:

- High thermal conductivity - from 0.43 to 0.9.

- In comparison with ceramic bricks, the price of hyper-pressed products is higher.

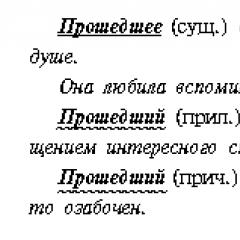

Facial masonry methods

![]()

If you do not know which masonry option to choose in order to brick the house, photos from the Internet will help you choose the appropriate option. can be performed using one of the popular methods of laying wall material:

- Spooning and treading are the most commonly used options. In this case, the material is laid with the long spoon side. In the next row, the vertical seam between the elements is shifted by half or a third of the element. This ensures a permanent overlap of the vertical seam.

- Block lining at home implies the alternation of spoon and butt rows.

- Cross masonry it is performed in the same way as a block one, only you need to make sure that the vertical seam falls exactly on the middle part of the end part of the brick in the upper row.

- Gothic styling- this is an alternation in one row of products laid with a spoon and a poke. In the next row, the vertical seam of the spoon must be shifted by 1/3 of the length, and the poke - by 1/2.

- Chain or Brandenburg masonry performed with alternation in one row of two spoons and one poke. In the next row, the jab should fit exactly over the vertical seam of the two spoons.

- Chaotic masonry most suitable for independent execution, since it does not require compliance with any alternations.

House cladding technology

If the cladding of a house made of foam blocks or other material will be done by hand, then it is very important to correctly calculate the number of bricks in order to purchase products from one batch. Material from different batches may differ in color or tone. To calculate the amount of material, the area of the facades without taking into account the openings is multiplied by 51 - this is the number of bricks that are required for cladding 1 m² of the surface.

Wooden elements of the walls must undergo antiseptic treatment before covering. If the expansion under the front brick was not provided in advance in the construction of the foundation, it is worth pouring an additional tape next to it, which is connected with the old base with the help of reinforcing pins.

When performing masonry, the following technology is adhered to:

- Work can be carried out on a not rainy day at an air temperature of at least 5 degrees so that the properties of the solution do not change.

- First, a trial laying of the material without mortar is carried out in order to adjust the stones to size, select elements for decorating doors and windows.

- Before proceeding with the laying of the first row, the horizontality of the base is checked.

- It is forbidden to chop stones with a hammer. They can be cut with a grinder.

- For laying, a mortar is prepared from Portland cement, sand and water in a ratio of 1: 3: 1. The mixture must be thick enough so that the brick does not move.

- First, masonry is laid in the corners of the house to a height of 4-6 rows. After that, the cord is pulled and the intermediate stones are laid.

- Before laying, the elements must be moistened with water so that they do not draw moisture from the solution.

Attention: all horizontal seams are made with a height of 1.2 cm, and vertical ones - 1 cm.

- The cladding is installed at a distance of 3-4 cm from the walls of the house. This space is needed for ventilation. Also for this purpose, in the bottom row, every three vertical seams, a seam without mortar is made, filled with insulating material, and on top of the masonry one row does not reach the cornice.

- Anchors, wire dowels, clamps or long nails are used to bond the cladding layer to the walls. The step of installing the fasteners is at least 0.5 m.

- After completing the masonry, the seams are embroidered with a wooden rod, simply by pressing the solution into the depths.

No matter how high-quality the wood used for, over time it begins to deteriorate under the influence of moisture and the sun. This is especially noticeable on old houses that were built before the appearance of special protective impregnations. Save wooden house cladding of facades with bricks helps. This gives the house a new aesthetic look and makes it possible to insulate a wooden house by laying a layer of, for example, mineral wool between the walls and the new cladding.

Any cladding increases the total weight of the building, and brick cladding - especially. Some experts estimate that a 100 m2 brick-clad house increases in weight by 40 tons.

Therefore, before starting cladding work, it is important to analyze the foundation of the house and its roof. Brick finishing will not violate the geometry of the house if a foundation of concrete blocks or reinforced concrete is built under it (taking into account the bearing capacity of the soil and the height of groundwater). The old base will be sufficient if it protrudes beyond the wall of the house to the outside for a distance sufficient to install finishing bricks on it. The maximum part to which the cladding can extend beyond the edge of the foundation is a third of its width.

If old foundation according to calculations, it will not withstand the weight of a house with brick cladding, then an additional one is poured, with a small gap in relation to the old one. This base should be twice as thick as the cladding (about 30 cm), lie on the soil freezing line (and not less than 70 cm), be covered with waterproofing materials and fastened to the main foundation with anchors.

The second important point is the roof, or rather, its eaves. The thickness of the walls with brick cladding will be greater than the original, and the roof may not cover the new masonry.

When determining the number of bricks for decoration, it is considered that 1 sq. m wooden wall 50-55 bricks are required, plus 10% - a margin for defects.

Cladding begins with laying the first row of bricks on the ground along the wall. This will help to take into account all the openings on it and to minimize the number of incomplete bricks as much as possible. Then all this is transferred to the finished base. After the first and then every 13 rows (with a horizontal step of 1 m), using a special strip made of galvanized steel, the cladding is fastened to the main wall. One end of the plank is nailed to the wood, and the other is laid in the mortar between the bricks.

Solution for brickwork comprises:

- water. The batch starts with it, and the required rate is added in the process;

- lime - 2 parts;

- cement - 1 part;

- sand - 9 parts.

The thickness of the seam between the bricks should be no more than 13 mm, which is checked every 5 rows with a special device. If the dimensions of the masonry are not maintained, then the seams are thickened or narrowed to the calculated height.

They begin the construction of brickwork from the corners of the house. Then a string is pulled along the level between them, along which the correctness of further laying is checked. For ventilation, special holes are made in the two lower rows through which moisture generated between wooden wall and cladding.

Let's say a few more words about the types of bricks used for cladding a wooden house.

Silicate brick (a mixture of lime and sand) hardly absorbs water, insulates sounds well and is affordable.

Ceramic (fired clay) absorbs moisture more, is more expensive to manufacture, but is lighter in weight and has high heat-saving characteristics.

Clinker bricks are the most expensive and high quality, frost-resistant and durable.

The lowest cost will be required by a special facing brick, produced in various colors.