How apples are processed for longer storage. Chemicals in vegetables and fruits - how to protect yourself? How to process fruits

Long-term storage of apples in storage is the easiest way to increase the value of the crop, since selling fruits outside the harvest season allows you to count on maximum profits. At the same time, the modern buyer does not want to purchase frankly waste goods, forcing agricultural companies to use modern technologies storage that preserves not only the presentation, but also the nutritional value of the product.

One of these technologies is the practice of crop conservation in a controlled gas environment (CGA).

Classic apple storage technology

Traditional storage technologies are based on the high keeping quality of apples. These fruits are able to ripen during storage, simultaneously improving both the presentation and nutritional quality of the product.

The classical scheme assumes placing containers with fruit in an area with low temperatures - from 0 to 7 degrees Celsius. Certain varieties can be placed in refrigeration chambers with temperatures ranging from -2 to 0 °C. In this case, the humidity of the storage environment should be maintained at 85-95 percent.

The following options are used as storage locations:

- Above ground warehouses and underground bunkers, in which a constant storage temperature for apples is maintained: 4 °C. This mode is ensured due to the heat resistance of the walls and 30-fold air exchange.

- Calders– storage facilities with cooled ventilation, which involves the movement of inflow air through the fruit. The air in such a room is cooled due to the low temperature outside. The microclimate is monitored by a differentiating thermostat, which determines the volume of cold air intake. Thermal equipment is not used in this case.

- Refrigerators– thermally insulated storage facilities, the atmosphere of which is cooled using special thermal equipment. (review and cost of equipment for cold supply of fruit and vegetable storage facilities)

You can get acquainted with a typical storage project for fruits and vegetables (for 1500-1600 tons of products) with several storage zones at the link

The stated storage conditions for apples provide preservation of fruits for 4-6 months. Then the unsold harvest residues are sent for processing or disposed of. At the same time, some apples retain their marketable appearance for a very short period, and only special varieties of fruit can survive a 6-month period.

This practice leads to a reduction in assortment on the market; for example, even in Italy and France, two or three varieties account for about 70-80 percent of the turnover. However, even the most persistent and shelf-stable varieties cannot survive a six-month storage period without treating the body of the fruit with chemical reagents, which protects the apple from bacteria and fungi.

As a result, classical storage technologies are associated not only with a reduction in the species diversity of varieties, but also with the risk of losing consumer interest in the product. Common long-storage varieties quickly become boring, after which the buyer switches his attention to imported, exotic fruits with a pronounced variety of flavors.

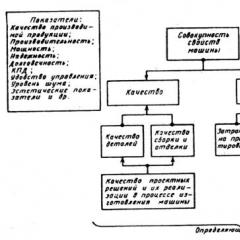

Industrial storage of apples in a controlled gas environment

Modern storage technologies are based on classic conditions, seasoned with an innovative solution - controlled atmosphere(read more about the technology here). The warehouse is maintained at 90 percent humidity and controlled temperature (maintained between -2 and 7 degrees Celsius), while simultaneously changing the proportions of the components of the storage atmosphere.

The classic composition is replaced with an environment with a depleted oxygen content and a high content of carbon dioxide and nitrogen. oxygen does not exceed 5%, and the proportion of carbon dioxide can range from 1 to 10%. The rest of the air mass is formed from cheap nitrogen.

OA - normal atmosphere, RA controlled atmosphere, 1MCP - 1-Methylcyclopropene (base preparation of the group of pesticides in SmartFresh and Fitomag), Bi-On - ultra-adsorbent ethylene absorber; - Not recommended; * - if the storage period is exceeded, there is a possibility of fruit damage by tanning

Deprived of a natural oxidizing agent, apples remain in the same condition as at the time of harvest. Nitrogenous and pectic substances, carbohydrates and organic acids, phenolic compounds and vitamins, pigments and lipids - they all lose the chance for natural transformation after interaction with oxygen, and excess carbon dioxide perpetuates this effect.

As a result, any warehouse with a CGS allows you to count on the following advantages:

- Long shelf life of apples - some varieties can be sold even in June.

- Minimal losses - the volume of defects can be reduced by half, even compared to refrigerators.

- Possibility of storing varieties with a phobia to low temperatures - in the RGS chamber it can be increased to 3-4 degrees Celsius, without any consequences.

- Easy tolerability of the process of unloading and unloading - the apple tissue retains its natural elasticity.

- The absence of “tan” on the surface of the skin, spots of rot inside the apple tissue and other traditional defects that reduce the commercial value of the crop.

In a controlled atmosphere (gas environment), even the most delicate varieties of apples can be preserved until the next harvest, increasing the assortment offered to customers or retailers.

Equipment for RGS warehouse

Such a storage facility can be based on an ordinary refrigerated warehouse, retrofitting it with the following elements:

- Sealed gates, which will ensure the stability of the atmosphere created inside the warehouse.

- Nitrogen generators, which will increase the content of this gas in the warehouse.

- Equipment for fast and ultra-fast removal of oxygen from the warehouse atmosphere, since from the moment the fruits are collected from the apple tree, it is better to reduce the time for loading fruits into the CGS storage to 24 hours. Each subsequent day reduces the storage time by 2-3 weeks.

- Adsorbers excess carbon dioxide and gaseous products released by the apples themselves (ethylene, etc.).

- Humidifiers and dehumidifiers that maintain the recommended level of environmental humidity.

The walls and ceilings of the storage facility must ensure zero (or close to it) gas permeability, so they will have to be treated with special compounds or protected with special materials.

RCA or ILOS units are usually used as oxygen removal equipment. To remove excess ethylene, catalytic converters (LECA technology) are used.

Besseling PSA Nitrogen Generator

The nitrogen generator is connected to the pressure channels, and the catalysts and adsorbers are connected to the exhaust lines of the ventilation system, cycling the air exchange of the warehouse.

The creation and maintenance of a controlled atmosphere is controlled by automation (often DANFOSS automation is used), reading signals from internal gas analyzers and transmitting commands to air dampers and fans. The circulating medium passes through generators and adsorbers until the desired concentration of the components of the controlled atmosphere is achieved.

The temperature in the storage room is maintained using the thermal equipment of the refrigerated warehouse. The fruits are stored in containers placed in a special way.

Methods for placing containers

Apple storage boxes usually hold from 20-30 to 250-300 kilograms of fruit. When sorting, preference is given to hand-picked fruits with intact skin.

Typical wooden container for long-term storage of apples

The walls of the box should not be solid - this interferes with air exchange, and containers cannot occupy more than 80% of the total volume of the warehouse. When placing containers inside a warehouse, it is customary to adhere to the following schemes:

- Forming a continuous stack with ventilation gaps separating every two or four boxes. The minimum dimensions of the gaps are 10 centimeters.

- Laying in stacks on a grated floor, up to three meters high. At the same time, meter-long passages are made in the stacks, placed in increments of 3-5 meters. They are necessary for visual control of the quality of stored products.

- Formation of a package, 4-5 tiers high. This scheme involves the use of a forklift moving the stack on a pallet. Moreover, in 50-ton warehouses, stacks are placed without gaps, and in rooms with large storage volumes, a central 1.5-meter passage is left. With this scheme, the distance from the wall to the nearest package (pallet) should not be less than 50 centimeters.

- Packing the box in a film that retains water vapor, but is permeable to carbon dioxide and oxygen. In this case, you can operate both kg boxes and 300 kg containers.

When loading a warehouse with a controlled atmosphere, it is customary to use a scheme with a continuous stack, leaving control boxes in front of the inspection window of the sealed gate for visual control of the safety of the fruit.

Before stacking, it is customary to treat the warehouse premises with special compounds that destroy the beginnings of colonies of fungi and mold. You can do the same with stored fruits, using additional protective measures.

How are apples processed for storage?

Varieties with a structure that is problematic for storage - thin skin and juicy pulp - are usually treated with wax, covering the fruits with a thin layer protector mixed with fungicides. Thanks to this, you can preserve both the density of the apple and its color.

An alternative to wax is a special composition prepared on the basis baking soda, iodine, starch and potassium iodide, which are dissolved in water. An iodine-polymer film appears on the surface of an apple immersed in this solution, which is washed off with ordinary water.

Any wax analogue can be considered edible fat, mixed with an antiseptic approved by sanitary standards. For example, apples can be stored in paper treated with petroleum jelly.

The mentioned compositions increase the shelf life of fruits even when using classical technologies, reducing losses from physiological diseases.

The AgroHranStroy company carries out the construction of fruit and vegetable warehouses for storage in the RGS, as well as the supply and installation of equipment to existing warehouses. All details regarding equipment configuration and its cost can be clarified by phone - 8 - 800 -234-03-44 or by leaving a request using the feedback form below.

Source: http://skladovoy.ru/xranenie-yablok-na-sklade.html

How apples are processed for long-term storage. How are apples processed?

If you have ever held an imported apple in your hands or, for example, washed it, you may have probably noticed a kind of oily film covering the surface of the fruit.

What is this? Is it really some kind of harmful substance? Most likely, your fears are in vain, because before transportation they are simply covered with a thin layer of ordinary wax or paraffin. And it’s not even about the attractiveness of the product, although, of course, shiny, glossy apples are very beautiful.

It's all about preserving the fruit and extending its shelf life, because apples have to travel huge distances before getting to your table.

For young children, it is always better to peel apples, and the point here is not that the peel is harmful. It’s just that the baby is not always able to chew and digest the peel. It can damage her delicate mucous membranes or even choke.

When apples are placed tightly together in large quantities, they can begin to spoil very quickly. It turns out that ripe fruits are capable of secreting special substances - plant hormones, which can affect the condition of neighboring fruits.

If one apple was spoiled during transportation, then there is a high probability that the rest of the fruits will also suffer. It is for this reason that apples are treated with paraffin. The resulting film prevents the spread of plant matter, which means it helps preserve these fruits much longer. You should not worry too much about paraffin, because it is good for the body, especially in such small quantities. Of course, you should not intentionally eat it.

That is why apples brought from should be thoroughly washed under running, preferably warm, water using a small amount of soap and a special soft brush. This way you can be sure that you have completely gotten rid of the paraffin film. After the apples are washed, they should be wiped with a soft towel, and then eaten. You see, peeling apples is not at all necessary.

Remember that after removing the film, apples can quickly begin to deteriorate, so it is recommended to wash imported fruits only immediately before.

How are fruits and vegetables sold in stores processed? How are oranges, dried fruits and grapes processed and how to buy safe

If the fruit is washed before consumption, is the harm from protective chemicals very conditional?

Not always. For example, one of the most dangerous substances is biphenyl (included in the category food additives under the symbol E-230, prohibited in many countries); suppresses the action of all types of fungi, but it is difficult to wash off from the surface of the fruit even hot water with soap. It has been proven that biphenyl is able to penetrate into the fruit and remain there. Citrus fruits are often used with it.

Then appearance the fruit does not change, but they become sticky to the touch. Of course, citrus fruits have thick peels, and before you eat an orange, you peel it. So the risk of harmful effects is reduced. But it is not excluded! Do all of us wash our hands with soap after peeling an orange?

And if an apple is treated with biphenyl, it may be completely saturated with this substance. And, by and large, you eat the antifungal along with the fruit.

Treatment with sulfur oxide is relatively dangerous.

This is a powerful allergen; when bound with other elements, it forms sulfides, which cause a hypersensitivity reaction, including asthma attacks. In addition, sulfur oxide can destroy vitamin B1. But if an empty fruit storage facility is fumigated for disinfection, with strict adherence to concentration, and then thoroughly ventilated, harmful effects on the fruit are practically eliminated.

If the fruit itself is processed, it will have a sulfuric odor. It is safer to peel it - if possible.

Dried fruits are also treated with sulfur oxide. They then have a glossy, very presentable appearance and are stored for a long time. They just need to be washed in running water, and then be sure to soak for an hour or two in water at room temperature.

Plums and grapes can be treated with chlorine gas. It can be recognized by its characteristic “hospital” smell and a whitish coating in the area of the stalk. Such fruits must be washed thoroughly and for a long time in running water, preferably each berry. If whitish stains remain after washing, it means that the salts of the substances used have managed to penetrate deep inside the fruit. It's better not to eat at all.

Imported berries - raspberries, strawberries and cherries - can also be fumigated with chlorine and other antifungal agents. It is difficult to recognize the chemical treatment method in raspberries by their appearance: a bluish coating, which is often mistakenly mistaken for a sign of chlorine, is completely natural for this berry. But the smell is your true guide.

What about waxing? Wax doesn’t smell, how can you tell?

Compared to antifungals, waxing does not pose a major safety concern. But it matters what kind of wax is used and whether something else was used in addition to it.

All-natural beeswax or palm wax is completely harmless, but it is expensive. More often, artificial wax is used, which is produced from oil refining waste.

The substance does not penetrate into the pulp, but to remove it from the surface of the fruit, you need to wash the fruit with hot water and then wipe it well with a towel.

There is one caveat here. Some fruits produce their own natural wax. Some varieties of apples grown in northern and temperate latitudes, including Belarusian ones, have this property. And southern apples have a rough surface. Therefore, if you see an apple from Italy with a characteristic “mastic” coating on the counter, it has been treated with wax. But if Polish looks the same, it may not have been processed in any way.

What fruits are not treated with chemicals? Apples

Untreated in the cellar, they can last until February at most, and they are sold in stores all year round. It turns out that certain varieties of apples are rubbed with a thin layer of wax before storage - this is a mixture of paraffin, wax and sorbic acid. This coating gives the fruit a glossy shine and allows it to be stored for almost two years.

To get rid of wax, you should purchase special detergents for fruits and vegetables, or brush it with a brush under hot water for a few minutes or cut off the peel. Apples are also sprayed with biphenyl. Diphenyl is a hydrocarbon product of petroleum refining, slows down the rotting processes of fruits and vegetables, is a strong allergen, prohibited in the USA and EU countries due to carcinogenicity.

Biphenyl is colorless, odorless and tasteless, and therefore people do not see or hear it and quite often do not wash fruits. Biphenyl remains on the hands and enters the body along with fruit. Processed fruits look fresh, but they may have already begun to rot inside, which means they contain a toxin that is dangerous to humans - patulin.

Patulin is a mycotoxin produced various types mold fungi, has mutagenic properties, and can cause acute toxicosis in animals and humans. If the apple skin feels sticky and slippery to the touch, it means the fruit has been treated with biphenyl. Biphenyl is not washed off with water; such fruits must be washed with soap and the peels must be cut off. Citrus fruits are also treated with it.

But even if the fruits and vegetables have not been rubbed or sprayed with anything, then special smoke bombs are lit at the vegetable bases. The emitted smoke contains a fungicide that protects fruits and vegetables from pathogens of rot, scab and mold. In a ventilated room, the fungicide quickly evaporates, and the residues are washed off with water, so it is not at all dangerous to human health.

Subsequently, vegetables and fruits that have not been treated with chemicals can cause more significant harm to the body if rot and mold begin to develop in them. If fresh fruits and vegetables are stored in warehouses that are not protected from rats (the main carriers of infections), then they can become a source of yersiniosis. To protect yourself, place the vegetables in a weak solution of vinegar or salt for 10 minutes, then rinse with water. After this treatment, the yersiniosis bacteria will die.

How to treat apple trees so that the apples are not wormy. Folk remedies and chemicals against caterpillars

How to get rid of worms on an apple tree? There are many ways to control worms and caterpillars. There are also traditional methods, and medications that will help get rid of these pests. The very first and the very the easy way insect control is water. If you direct a strong pressure on the branches and foliage, the caterpillars will simply be washed away by the flow of water. This method is good for those pests that are visible on the surface of flowers and leaves, since those that are not washed away by water must be collected manually.

On a note. How to spray apple trees against worms? An environmentally friendly method of fighting insects is to spray the tree with infusions of various herbs. For this, infusions of dry leaves and decoctions of them are used. To combat the codling moth, celandine is used. From the fresh leaves of this medicinal plant a belt is woven, which is secured in a spiral around the entire trunk. Such a belt is woven twice a year: in spring and autumn.

Worms that feed on foliage are combated with a decoction of tomato leaves. Another infusion is made with wormwood. The effective result of spraying trees with these infusions and decoctions will be if you repeat the procedure 3-4 times. Typically the interval between spraying is a week.

If worms have already appeared in apple flowers, what should you do in this case? Chemicals that have a faster and stronger effect will come to the rescue. So how to treat apple trees to prevent wormy apples?

Chemicals used to control worms on apple trees are not uncommon these days. They can be purchased freely at any specialized store. The most common drug is the insecticide Intavir. One tablet is enough for one tree. It must be dissolved in a bucket of water and sprayed completely over the apple tree. It effectively fights various categories insects, but has some disadvantages.

Apple tree processing

Important! Inravir should not be used during the flowering period; it is also very toxic to bees. If you use it for a long time, it will become addictive.

Another insecticide is a drug called Tonrek. You only need 3 ml per bucket of water. To treat one tree you need 3 liters of water with Tonrek dissolved in it. It is also a toxic drug and can be addictive.

Fufanon causes mass poisoning of the pest. It dies within 20 hours after spraying. The duration of action of this drug is 10 days. In one season, this drug can only be used twice. Also toxic.

Karbofos causes instant death of worms. Its validity period is 10 days. Effective only upon direct contact. That is, those caterpillars that were not exposed to the solution during spraying continue to live and harm the future harvest. But it is not toxic to bees. Has a strong unpleasant odor.

How do corporations process apples for long-term storage? Principles for long-term storage of apples

There are a number of principles for storing apples that are recommended to be followed:

- Before placing fruit in the basement, the walls are treated with slaked lime. The proportions are 1.5 kg of product per 10 liters. water. The floor is wiped with iron sulfate (5%). The containers where the fruits will be stored are washed with soda ash. Experts also advise treating the room from mice.

- When selecting apples, you should remember that unripe or, conversely, overripe, as well as not fully fertilized fruits are not recommended to be stored in winter. Effective preservation is ensured by selecting medium-sized apples.

- Fruit picking should preferably be done with hands protected by cotton gloves. Each apple is slightly lifted, then scrolled and only then torn off.

- The collected apples are placed in wooden containers or cardboard boxes. In this case, it all depends on the variety. If the stalk is too long, it is cut off. Otherwise, there is a risk of damage to other fruits.

Attention! When placing fruit in a container, the stalk is placed upward.

Source: https://zdorovaya-eda.com/produkty/chem-obrabatyvayut-yabloki

How and how apples are processed for long-term storage

With the onset of autumn, many gardeners and farmers begin to worry about the question of how to properly store and how to process the apple harvest so that they are suitable for long-term storage, but do not cause harm to health. Doing this is not as difficult as it might seem at first glance.

In order for a rich harvest to last throughout the winter and spring, you need not only to prepare a basement and special solutions for processing fruit, but also to pay attention to the varieties being harvested and the quality of the material itself. Then there is a high probability that the harvested crop will not spoil during storage and will retain its taste and nutritional properties.

How to treat apples before storage

Fruits arriving on store shelves are coated with wax or biphenyl for storage. While the first can be washed off with a special product, the second has neither color nor odor, so buyers often do not know that they bought a product treated with a dangerous carcinogen.

To harvest homemade apples and process them, natural compounds are used that will increase the shelf life of the product and will not cause negative reactions. The following tools are best suited for this:

- Glycerol. A small piece of cloth is soaked in this substance and the fruit intended for long-term storage is carefully wiped.

- Paraffin. There is no need to cover the entire apple with it; it is enough to treat the place where the stalk attaches to the fruit itself.

- Calcium chloride. A large container is filled with a 2% solution, after which the fruits are dipped into it one by one. The processed apples are allowed to dry and only then stored for long-term storage.

- Alcohol solution of propolis. The beekeeping product is first kept in the refrigerator so that it hardens and is easier to grate. Propolis and alcohol are taken in a ratio of 1:5 and mixed thoroughly. The resulting solution is used to treat apples and the fruits are stored much longer.

- Natural antibiotics and biofungicides. Containers with already laid out apples are sprayed with one of the preparations - Fitoflavin or Golden Autumn. It is important to choose only 1 solution, since the compositions cannot be layered on top of each other. The method of preparing the solution and the required amount depends on the size of the crop.

All the methods described above help preserve the crop and avoid its rapid spoilage. Before eating processed apples, you need to wash them thoroughly in warm water using a soft brush and a special detergent for vegetables and fruits.

How to store apples

But simply processing apples for long-term storage is not enough. It is important to properly prepare the room itself where the harvest will be stored, as well as take care of the correct collection of apples and their subsequent packaging.

First, you should take care of preparing the basement:

- Activities to put the harvest storage room in order begin in the summer. At this time, the basement is regularly ventilated. If there is a sharp temperature difference between day and night, this can cause condensation to form on the walls of the room. Then you need to install and equip the exhaust pipe with a fan and turn it on at night.

- No later than 2 weeks before the start of storing apples, the walls and ceiling of the basement are treated with biological products to prevent the development of pathogenic microorganisms in the room.

- After it gets colder at night, the basement is left to air. It is important that the temperature in the basement does not rise above 10 degrees; this is important for the preservation of the fruit.

- It is necessary to protect the exhaust pipe from rodents. To do this, it is filled mineral wool, this material will allow air exchange in the room, but mice and rats will not get to the apples.

The next stage is the selection of varieties suitable for long-term storage and their collection:

- Their beneficial features Only winter varieties are preserved for a long time. These are Welsey, Zhigulevskoye, Melba, Antonovka or Bogatyr. Apples are removed from the tree slightly unripe; they ripen for the first month in storage, after which they can be eaten.

- Carrion is not suitable for storing in the basement. It is best to pick fruit by hand. They need to be removed from the tree in such a way as not to accidentally tear off the stem - it is its presence that guarantees better preservation of the product. The collection is carried out only in dry weather, and the fruits begin to be picked from the lower branches of the tree. It is important to carefully place the apples in pre-prepared boxes so that there are no dents or cracks on the sides - such specimens are not suitable for long-term storage. You cannot crush or throw apples - all this reduces the shelf life of the fruit.

- Before processing and storing in the basement, the harvested crop is carefully sorted, specimens with even the slightest signs of spoilage are put aside - it is better to squeeze juice from them, make jam, dry them or use them in baking. The same applies to wormy specimens. If there are a lot of such fruits, then they are given a separate storage box and placed away from whole apples to avoid spoilage.

- Medium-sized fruits are best stored. Small apples will quickly wither, and large ones will spoil, since a large fruit releases a lot of ethanol, a gas responsible for the rapid withering of the product.

After the harvest has been sorted and the best specimens have been separated for storage, they are treated with homemade solutions, dipped in wax or rubbed with fat. It is important not to destroy the existing thin waxy layer covering the apples. This is a natural protection, thanks to which the tree protects the fruits from the effects of pathogenic microorganisms.

The next stage is placing the fruits in the basement. You can do this in several ways:

- Wooden containers. They are used when the harvest is very large. Inside such a container there should be dividing boards for better air ventilation. Apples can also be arranged with straw. The disadvantage of this storage method is that it is labor intensive and has a high risk of fruit spoilage. If at least one apple becomes unusable, then the rest of the fruits will not last long.

- Folding in a slide. Hay and dry leaves, mint, lemon balm or thyme are placed on the floor - these herbs will protect the crop from insects and rodents. Each subsequent layer must also be sandwiched with a mixture of hay and medicinal herbs so that the apples are better preserved.

- Wooden and cardboard boxes. Fruits are carefully placed in them in several layers, and it is important not to accidentally scratch them with the stalks. The boxes are not filled to the top to make it easier to stack them one on one.

- Packing in paper. The method is suitable for small harvests. Each fruit is wrapped in a piece of paper before being placed in a box or basket. Such protection will allow the harvest to be stored longer: even if one of the fruits disappears, the others will not suffer.

- Sand. It is pre-calcined and allowed to cool. Plywood boxes are lined with paper, after which a layer of sand of at least 20 cm is poured onto the bottom. Apples are laid on the resulting pillow. When the bottom is filled, the fruit is covered with sand again and a new layer of fruit is laid out. The procedure is repeated until the container is almost completely filled. After this, the boxes are stacked on top of each other so that there is a little space between them for better ventilation.

- Shelves with drawers. The fruits are laid out in them in one layer. Since the air temperature near the ceiling is always a little higher, fruits that need to be consumed the fastest are placed on the upper shelves.

- Plastic bags. Apples are packaged in 3 kg bags and taken to storage, but the packaging is not tied. The next day, when there is no risk of condensation, the bags are tied, but they must have small holes for air ventilation.

- A piece of polyethylene film. Place 2 pieces of film on the bottom of the box so that when folded they form an envelope. Before rolling the film in this way, apples are placed at the bottom of the box.

Each method has both advantages and disadvantages; their choice will depend on the number of apples collected and the size of the room.

After the harvest is planted, it is important to monitor its safety and the condition of the basement. If condensation appears on the walls, it must be removed promptly with a soft cloth. It is recommended to spray the basement walls with special bioprotection, but not more than once a month. It is important to check the safety of fruits and throw away rotten ones, and promptly respond to the appearance of rodents.

How can fruits and vegetables be processed? What to do if you don’t have your own garden and have to buy fruit in a store or market?

Wax

Apples are treated with a thin layer of paraffin or wax. This not only gives the fruit an appetizing glossy shine, but also allows it to be stored for almost two years. It is impossible to wash off the waxy coating by simply rinsing the apple with tap water. It is necessary to brush it with a brush under hot water for at least a few minutes.

Oranges and peppers are also treated with wax.

Diphenyl

It is used to treat citrus fruits, in particular oranges, to prevent them from rotting. Biphenyl is colorless, odorless and tasteless, and therefore people do not see or hear it and quite often do not wash the fruit before peeling it. The biphenyl remains on the fingers, and we safely eat it along with dessert.

And the worst thing is that children eat it too.

For those who don't know, pesticides are chemicals that can fight many harmful microorganisms. Many gardeners love to use them, and they begin to do this even in the process of fruit ripening, in order to prevent the attack of all kinds of insects, fungi, etc. Unfortunately, pesticides are harmful not only to insects, they have an adverse effect on the human body.

To avoid accidentally eating the wax and paraffins that coat imported vegetables and fruits, you need to thoroughly wash the fruits with a brush, preferably in soapy water.

For children, especially those with allergies, experts advise pre-soaking imported fruits and vegetables for an hour in cold water. It is believed that it will remove some of the harmful substances. And, most importantly, you must not forget to peel off the upper layers of the fruit from overseas wonders. The glossy red peel of an apple without the slightest blemish just plays the role of a beautiful wrapper for a gift. For both children and adults, wrapping paper eating is contraindicated!

To reduce the loss of precious vitamins, you need to peel and wash vegetables quickly. Immediately after washing, the fruits significantly lose their ability to be preserved for a long time, since their skin is partially damaged. Therefore, washed fruits and vegetables must be immediately cleaned, chopped and put into further processing. To avoid losing nutrients, you should use a stainless steel knife when cleaning.

If the housewife discovers yellow spots under the skin on cucumbers, zucchini or potatoes, it is better not to eat them - they contain too many nitrates.

You always want to crunch on fruit from your own garden during the cold season. And how nice it is to hear from your grandchildren that they need pears or apples for school during breaks! Therefore, storing apples and pears for the winter is a pressing topic for all owners. personal plot. Let's look at how to prepare the cellar and how apples and pears are processed for long-term storage so as not to harm your health.

Preparing the cellar

In the summer, when the stored supplies have already run out and only a few jars of pickles and wine remain, you need to ventilate the room. If the differences in night and day temperatures are too sharp, condensation may appear on the walls and ceiling, then it is better to put a small fan in the exhaust pipe and turn it on at night.

In September, approximately 2-3 weeks before storing apples, it is necessary to treat the walls, floor and ceiling with biological products. Good for processing EM-drugs ( Baikal, East, Radiance, Revival), Fitosporin-M and its derivatives ( Golden autumn).

When the temperature drops at night, we open the basement or cellar for the night. It is necessary to lower the temperature to at least 10 degrees. In late autumn, when stable frosts set in, we cover the hood with mineral wool - the basement will breathe through the cotton wool, but mice and rats will not get in there. We do not treat the cellar for storing apples and pears for the winter with sulfur or other carcinogens - so there is a lot of toxic substances all around.

How apples and pears are processed for long-term storage

In supermarkets, you may have seen great-looking fruits and vegetables coated with something sticky. Most likely, it is biphenyl (preservative E230), which accumulates in the body and can cause cancer. Sometimes apples are imported in wrappers that are saturated with this carcinogen. And, if we remove the banana skin and throw it away, protecting ourselves from chemicals, then it is unlikely that we will be able to wash the apples even under hot water. Well, okay, everyone knows about the passion for chemicalizing purchased products. And we need to increase the shelf life of our own harvest, so let's use natural antioxidants.

How apples and pears are coated and sandwiched for storage in private households

The development of fungi on fruits is well protected by ferns and sphagnum moss. But we can’t always get moss, so we actively use ferns. Before harvesting, we place several layers of overlapping fern fronds in boxes - you can take fronds of shield frond, ostrich frond and other large species.

It is better to lay apples in two, maximum three layers, sandwiching each layer with fronds. We put elderberry leaves on the top layer; they repel rats and mice. It is also better to sort fruits by size. You should eat the larger fruits first, then the medium ones. Medium-sized fruits of apples and pears are more suitable for long-term storage.

When harvesting, be extremely careful - it is unacceptable to shake the fruits from the trees; you need to carefully pick the fruits with the stalk. If you reach the fruit with your hand, try to take it in such a way as to damage the wax coating less, it protects the fruit from drying out (sluggishness).

It is better to put apples and pears with accidentally torn stems in a separate box, since it is better to store them for a short time. Place the harvest heavily damaged by the codling moth there - these couple of boxes will need to be eaten first. And don’t even think about placing these boxes in the general rows of the main storage; let them stand separately at the entrance to the basement or cellar. Otherwise, the moths will move to a healthier crop.

Processing apples and pears for storage

So, we have layered the fruit boxes, what else are apples and pears processed for storage? This is a difficult question, because you don’t want to pick up carcinogens from your own garden. Nevertheless, processing is necessary, because it is impossible to select fruits for storage without signs of damage - both the codling moth is present in the garden, and monilla, and black rot makes itself felt.

Therefore, small concentrations of natural antibiotics and biofungicides will help us. We carry out the treatment before we put the boxes in the basement (in October), spraying each box Fitolavin(see manufacturer’s instructions for dilution rate) or Golden autumn (Fitosporin-M). You cannot mix or layer preparations; if you choose one of them, use it all season.

Storing apples and pears in a cellar or basement

When storing apples and pears in the cellar in winter, it is necessary to periodically carry out an inspection - in each box you need to select rotten and blackened fruits. If significant condensation has accumulated on the surfaces of the walls of the room, it is better to remove it with a well-absorbing cloth (for example, a gauze rag). Floors and walls can be sprayed Fitolavin \ Fitosporin-M ( or Golden autumn), but not more often than every three weeks.

In winter, look into your storage often, since storing apples and pears in a cellar or basement still needs to be under supervision: mice may visit, and excess condensation may accumulate. When storing winter apples and pears, beware of using chemicals; it is better to use natural repellents and bioprotection. Good luck storing your own fruit and bon appetit this winter! May there always be a bountiful harvest for storing apples and pears in the cellar for the winter.

Every buyer now knows that all fruits and most vegetables are processed in some way. And, of course, concerns and questions arise about how safe the substances used to process fruits are. So let's find out!

One of the common substances used to treat imported fruit is methyl bromide.

METHYL BROMIDE (METHYLBROMIDE) is an organic fumigant used to treat fruits and vegetables exported to protect them from harmful insects. Fruits treated with methyl bromide last longer than those not treated. Meanwhile, methyl bromide poisoning severely affects the lungs, kidneys and nervous system, and changes the composition of the blood, which often occurs in people working with methyl bromide when processing fruits, vegetables and grains in warehouses. It is believed that when the fruit reaches store shelves, there is practically no methyl bromide left and particles of this substance are washed off the fruit with water. But in fact... any substances that fall on the surface of fruits and grains, one way or another, penetrate inside the plant cell. Next, these substances interact with cellular inclusions, changing chemical composition intracellular juice. Naturally, the organoleptic characteristics of the fruit (taste and aroma) also change. Nobody is studying how deeply these substances penetrate, and whether the peel of, for example, a banana or an apple protects against such penetration. The goal is one - to increase shelf life and get more profit.

The use of methyl bromide is prohibited in the Scandinavian countries, Germany, Italy, and the Netherlands. The UN recognized methyl bromide as a substance that thins the earth's ozone layer, and by 2010 all industrialized countries were supposed to phase out the use of it as a fungicide, but they still do.

In 2005, it was banned for use in the Russian Federation. And in 2011 it was again included in the list of permitted ones, only under a different name - “Metabrom-RFO”. In addition to fruits and vegetables, grains are also processed with this substance.

Fruits that were picked unripe receive another dose of chemistry. Therefore, to bring them to marketable condition, they are “fumigated” with ethylene.

ETHYLENE (ETHEN) is an organic compound, a flammable gas, colorless, with a faint odor, the most produced substance in the world. Ethylene is used in the production of polyethylene.

Ethylene gas is synthesized in small quantities by plants; it is a phytohormone involved in the ripening process of fruits, berries and vegetables, causes the aging of leaves and flowers, and the falling off of faded inflorescences and ripened fruits.

Industrial ethylene is widely used as an accelerator for the ripening of fruits in warehouses (tangerines, lemons, oranges, bananas, melons, tomatoes). The amount of ethylene that can remain on fruit is considered harmless to humans. However, it is worth remembering that unripe fruits are treated with ethylene and are used to achieve only decorative, external ripeness.

But inside such fruits will never again have that bouquet of tastes and aromas, as well as useful substances, who could purchase fruits fully ripened in the sun.

But what happens to fruits in the sun that cannot happen when treated with ethylene? First of all, this is the transformation of starches into sugars and their accumulation in cell sap. The amount of tannins and acids decreases, the content of vitamins, aromatic and pigment (coloring) substances increases.

As it matures in natural conditions the content of soluble pectin increases. It is soluble pectin, when harvested correctly, that preserves them and prevents cell sap from quickly evaporating. Vegetable pectin is very necessary for our body. It helps reduce cholesterol and normalize metabolism in the human body.

And another important point occurs when fruits ripen under natural conditions - this is the ripening of seeds, from which new fruit plants can be obtained.

The most dangerous of all the chemicals used to increase the shelf life of fruit is biphenyl.

BIPHENYL (BIPHENYL), food preservative E230. Has a strong antibacterial effect. Biphenyl is used to treat the surface of fruits and vegetables to increase shelf life. Preservative E230 prevents the development of bacteria, mold and yeast. Biphenyl is a carcinogen (cancer-causing substance) that accumulates in the body. Negatively affects the respiratory system and eyes, causing allergic reactions.

If the fruit is sticky, it means it has been treated with biphenyl. Have you probably noticed that imported fruits are carefully wrapped in a separate beautiful wrapper? So, this wrapper acts as a preservative, since it is usually treated with biphenyl or other fungicides.

Biphenyl is washed off from fruits using special products, soap and hot water. If the peel is removed from bananas and citrus fruits and it is quite dense, then on apples it is too thin, and therefore is not able to protect the fruit from the penetration of diphenyl into the pulp. Therefore, it is better not to buy sticky apples at all.

SULFUR OXIDE SO2 (E220) is a sulfur dioxide gas, it is colorless, has a strong pungent odor, and is highly soluble in water. Vegetables, fruits, dried fruits and fresh grapes are treated with sulfur dioxide to increase shelf life. Changes in grapes and dried fruits occur already during treatment with sulfur oxide - just as during treatment with any other chemicals, namely, the chemical composition of cell sap changes, some vitamins and microelements are destroyed. But, since E220 is a gas, after processing is completed, it may remain on the surface of dried fruits. a small amount of sulfites (salts of sulfurous acid), while the gas itself evaporates. However, sulfites can cause severe allergies in asthmatics. And when sulfites enter the body, they destroy vitamin B1, which can cause nervous disorders with prolonged exposure.

Dried fruits treated with sulfur oxide have a brighter glossy surface. Sometimes you can smell the smell of a lit match from such fruits and dried fruits. Unprocessed fruits, on the contrary, have a matte surface, dried fruits are strongly wrinkled and have an aroma characteristic of this fruit.

In order to protect yourself and “neutralize the enemy,” it is recommended to soak grapes and dried fruits in water at room temperature for at least 1 hour before consumption. This will cause the sulfites to pass into the water. Then the fruits should be rinsed well with running water. In this case, it is recommended to wash and peel vegetables and fruits well.

PARAFFIN, WAX AND SORBIC ACID. This mixture is used to treat apples, pears, citrus fruits, and peppers. Sorbic acid (E 200) - preservative, antibacterial agent. Scientists have found that sorbic acid destroys vitamin B12, which is so necessary for our nervous system. Sorbic acid may cause gastrointestinal problems. However, E200 is widely used in the food and pharmaceutical industries. Paraffin and wax prevent moisture from evaporating from fruits and make them “long-lived” and more attractive in appearance.

Therefore, “glossy” fruits and vegetables must be washed with hot water and a brush and, best of all, with soap or special products; this is the only way to wash off the mixture of paraffin, wax and sorbic acid from the peel. Or you can peel off the skin...

1-METHYL CYCLOPROPENE (patented name SmartFresh - “smart freshness”) is a gas that suppresses the processes of overripening of fruits and vegetables. The inventors of this gas believe that treating fruits and vegetables with SmartFresh in tiny doses no later than 3 days after harvest preserves all nutritional properties for a longer period. Scientists also claim that this substance is harmless to humans. 1-methylcyclopropene is an inhibitor (suppresses the effect) of ethylene. And, as we wrote earlier, ethylene is released in small quantities when fruits ripen.

But here’s an interesting point: SmartFresh was previously positioned as a processing tool for preserving cut flowers, and now they are trying to process fruits and vegetables with this “freshness”.

1-methylcyclopropene can be obtained in different ways, and all methods are a combination of various chemical reagents. Well, for example, 3-chloro-2-methylpropene and lithium amide are combined in a boiling dioxane environment, or obtained by combining finilithium with alichlorides...

Moreover, this gas, as it turned out, cannot be preserved. But chemists (that’s why they are chemists) have come up with a way to preserve this gas using special sorbents. And, since “smart freshness” is patented and is know-how, we probably won’t know how we got this gas? Although I would really like...)

But there is a safe method of storing vegetables and fruits in a controlled gas environment using CO2 (carbon dioxide). This is a much more natural and healthier component. And since children buy fruit most of all, the issue of the safety of agricultural products is a matter of the future of the country. Therefore, if it uses incompletely studied substances that can enter the body of an adult or child (!), then this is not just negligence, but an intentional crime. Then you can guess why you should “fence such a garden” around SmartFresh...

RGS - controlled gas environment. These are special refrigeration units used in storage for vegetables and fruits. Carbon dioxide CO2 is used as a preservative to suppress ripening (overripening) processes during storage. Fruits and vegetables preserved in this way are no different from freshly picked ones and retain all the beneficial substances and vitamins.

Good advice: Turkey, China, Holland, Israel, more than others, process fruits and vegetables with all kinds of chemicals, especially those products that “go” to Russia. Of course, nothing can replace your own freshly picked fruits and vegetables, but if such are inaccessible to many, then it is best to buy domestic fruits and vegetables from the countries of the former CIS. Choose products according to the season, because, for example, cucumbers and tomatoes from Uzbekistan in January can only be grown in greenhouses and also not without the use of growth accelerators and fertilizers. Therefore, you should expect more nitrates and minimal benefits from their content. Pay attention to the appearance of the products, do not chase after external attractiveness and gloss, you can focus on the aroma (many “chemicalized” fruits and vegetables do not have their characteristic aroma).

And it happens that strangers hide under the name of “our own”, using the names of farms that have long been closed or never existed. And if you doubt that the sellers are telling the truth about “where the fruit comes from”, you have the right to demand a certificate of conformity or a quality certificate.

If we all become more demanding of the quality of products, and do not allow ourselves to be deceived, then there will be less deception. Be healthy and vigilant!

Sometimes fruits are treated with chemicals to make them last longer. You look at grapes or apples, and indeed: sometimes the fruits are sticky to the touch, sometimes they shine unnaturally. Concern is also fueled by the fact that special detergents have appeared on sale - they are designed to clean the surface of the fruit from harmful substances. Deputy Director for scientific work Institute of Fruit Growing National Academy Sciences of Belarus Anatoly Krivorot.

Anatoly Krivorot, Candidate of Agricultural Sciences. Photo: Elena Kleshchenok, TUT.BY

Are all fruits treated with chemicals?

No. We have this risk when we buy imported fruits. The farther from us the country where the fruit grew, the more processing it probably went through. After all, the fruits must be guaranteed to be protected: from drying and withering, from fungal diseases, and from damage by insects. The manufacturer is armed with all possible means to preserve the presentation of the fruit as much as possible.

- Are Belarusian apples treated with chemicals?

I am 99.9% sure: no, they are not processed. For a simple reason: our manufacturer does not have enough funds to implement such technologies. Our apples are sold out before the New Year. As a rule, those stored in modern refrigerators with a controlled gas environment (we have few of them) survive until spring sales.

The controlled gas environment is the same gases as in ordinary atmospheric air. But their concentration makes it possible to reduce oxidation processes in fruits: there is more nitrogen and carbon dioxide, and less oxygen.

How are oranges, dried fruits and grapes processed and how to buy safe

- If the fruit is washed before consumption, is the harm from protective chemicals very conditional?

Not always. For example, one of the most dangerous substances is biphenyl(included in the category of food additives under the index E-230, prohibited in many countries); suppresses the action of all types of fungi, but it is difficult to wash off from the surface of the fruit even with hot water and soap. It has been proven that biphenyl is able to penetrate into the fruit and remain there. Citrus fruits are often used with it.

Photo: pixabay.com

Photo: pixabay.com

Then the appearance of the fruit does not change, but they become sticky to the touch. Of course, citrus fruits have thick peels, and before you eat an orange, you peel it. So the risk of harmful effects is reduced. But it is not excluded! Do all of us wash our hands with soap after peeling an orange?

And if an apple is treated with biphenyl, it may be completely saturated with this substance. And, by and large, you eat the antifungal along with the fruit.

Relatively dangerous processing sulfur oxide.

This is a powerful allergen; when bound with other elements, it forms sulfides, which cause a hypersensitivity reaction, including asthma attacks. In addition, sulfur oxide can destroy vitamin B1. But if an empty fruit storage facility is fumigated for disinfection, with strict adherence to concentration, and then thoroughly ventilated, harmful effects on the fruit are practically eliminated.

If the fruit itself is processed, it will have a sulfuric odor. It is safer to peel it - if possible.

Dried fruits are also treated with sulfur oxide. They then have a glossy, very presentable appearance and are stored for a long time. They just need to be washed in running water, and then be sure to soak for an hour or two in water at room temperature.

Photo: Igor Matveev

Photo: Igor Matveev

Plums and grapes can be processed chlorine gas. It can be recognized by its characteristic “hospital” smell and a whitish coating in the area of the stalk. Such fruits must be washed thoroughly and for a long time in running water, preferably each berry. If whitish stains remain after washing, it means that the salts of the substances used have managed to penetrate deep inside the fruit. It's better not to eat at all.

Imported berries - raspberries, strawberries and cherries - can also be fumigated with chlorine and other antifungal agents. It is difficult to recognize the chemical treatment method in raspberries by their appearance: a bluish coating, which is often mistakenly mistaken for a sign of chlorine, is completely natural for this berry. But the smell is your true guide.

- What about waxing? Wax doesn’t smell, how can you tell?

Compared to antifungal agents, waxing does not pose a major security problem. But it matters what kind of wax is used and whether something else was used in addition to it. All-natural beeswax or palm wax is completely harmless, but it is expensive. More often, artificial wax is used, which is produced from oil refining waste. The substance does not penetrate into the pulp, but to remove it from the surface of the fruit, you need to wash the fruit with hot water and then wipe it well with a towel.

There is one caveat here. Some fruits produce their own natural wax. Some varieties of apples grown in northern and temperate latitudes, including Belarusian ones, have this property. And southern apples have a rough surface. Therefore, if you see an apple from Italy with a characteristic “mastic” coating on the counter, it has been treated with wax. But if Polish looks the same, it may not have been processed in any way.

Why can apples ripen, but bananas cannot?

- Could science really not find non-toxic and effective substances to process berries and fruits?

They are. For example, 1-methylcyclopropene. This substance is synthesized, but does not affect the chemical composition of the fetus, it only controls its “physiology”. It is used for fruits and vegetables that ripen after picking: apples, plums, tomatoes, melons, peaches, apricots - thanks to the ethylene they produce. It is ethylene that “starts” all ripening processes after the fruit is removed from the branch. And 1-methylcyclopropene allows you to “turn off” this mechanism during transportation and storage. The fruits seem to be sleeping. When the time comes to sell the products, the fruits are removed from the chambers and the ripening process is resumed, with no substance remaining in the fruits. Our institute confirmed the safety of this substance during testing.

There are American and Russian analogues of this technology. Russian is the only technology that extends shelf life, which is allowed in our country. Unfortunately, our manufacturers use it poorly for economic reasons.

- Green imported bananas also ripen thanks to 1-methylcyclopropene and are equivalent to ripened ones?

No, these are two opposing technologies. Bananas do not produce ethylene themselves. They are picked unripe, when they have not had time to gain vitamins, healthy sugars and minerals, and these processes stop. Ripening in artificial conditions allows you to achieve a “ripe” appearance, but inside there will not be as many vitamins and other nutrients as a ripe fruit. That's why we often buy yellow bananas, but they taste like soap.

Photo: pixabay.com. Photo is for illustrative purposes only.

Photo: pixabay.com. Photo is for illustrative purposes only.

For comparison: apples late varieties, which produce their own natural ethylene, not only ripen without loss of nutritional value, but become tastier over time.

“A very large fruit is inferior in usefulness to a medium-sized fruit”

It is difficult for an ordinary person to understand all these intricacies. The maximum he can do is ask the seller how the fruit was stored.

And he won’t even know it! It is difficult to check how the fruits were stored and what they were treated with before transportation - information about all storage technologies is usually not indicated in the accompanying documents.

A simple consumer needs to adhere to simple rules. First: if the fruit looks suspicious in appearance (sticky, covered with plaque), then it is safer to refuse the purchase. If you have already bought it, cut off the peel. Second: wash your fruit thoroughly.

By the way, do not chase large fruits: large ones have less vitamins and other nutrients per unit volume. Simply put, when we purchase large fruits, we pay for water. The best apples- no more than eight cm in diameter.

And most importantly, thirdly, give preference to seasonal domestically produced products or fruits brought from neighboring countries. Better yet, grow it yourself in your own garden plots.

- What about special products for washing fruits and vegetables? Will they help remove all questionable substances?

Not always. The fact is that such products are produced on the basis of alcohols or alkalis, and this too chemical agent. Artificial wax, for example, it will successfully help remove. And if you use alkali on natural wax, what’s the point? It is still unknown which is more harmful.

- Do you buy imported fruits yourself?

Of those that grow in Belarus - very rarely, only when ours are not there. I eat what I grow in my dacha. Now I am faced with a gardening dilemma: treat apple trees with chemicals against aphids, which are very active due to the hot and dry weather this year, or wait for sanitary pruning of the branches.

How are apples processed for longer storage?

An unprecedented harvest can be harvested from an apple orchard, but it sometimes takes weeks to process it. It is much easier to send some of the apples for storage. These fruits are distinguished by the fact that over time the amount of vitamins and microelements in them remains unchanged. It is important not only to study how apples are processed on agricultural farms for long-term storage, but also to learn how to properly prepare the fruits. Let us sort out these issues so that you can preserve your harvest without processing for as long as possible.

An unprecedented harvest can be harvested from an apple orchard, but it sometimes takes weeks to process it. It is much easier to send some of the apples for storage. These fruits are distinguished by the fact that over time the amount of vitamins and microelements in them remains unchanged. It is important not only to study how apples are processed on agricultural farms for long-term storage, but also to learn how to properly prepare the fruits. Let us sort out these issues so that you can preserve your harvest without processing for as long as possible.

Which apples will be stored for a long time?

Even at the time of planting apple trees, you need to take into account your needs. All fruit trees This type is divided into groups:

- summer - suitable for immediate consumption and canning;

- autumn - stored for no more than 2 months;

- winter - at the right approach can be saved until spring.

If you want to enjoy juicy fruits throughout the second half of winter, then it is best to plant apple trees of the following varieties:

- Antonovka;

- Bogatyr;

- Zhigulevskie;

- Welsey;

- Melba.

At the time of harvest, the fruits seem unripe - they are very hard and sour. After several months of storage, the fruits become softer and a sweet tint appears in the taste.

Features of harvesting

- do not pick fruits on rainy days;

- do not shake the apple tree;

- start collecting from the lower branches;

- pick the fruits together with the stalk;

- do not throw the fruits, fold them carefully;

- line the drawers with burlap;

- do not crush the fruits or scratch them.

These tips will help you preserve your harvest longer. Please note that apples have a bluish coating on them; it is not recommended to wash it off. It protects the fetus from exposure to pathogenic microorganisms. It is best to wear soft cloth gloves when picking fruit.

Fallen fruits are not suitable for storage, since their surface already contains microorganisms from the soil. It is best to process such fruits or eat them straight away. Place them in a separate container to avoid confusion during sorting.

It is also worth setting aside separately the fruits located on the eastern side of the crown of old apple trees. They receive more light and are stored longer. Young trees are more likely to get sick, so the shelf life of fruits is significantly reduced.

When sorting, you need to select medium-sized fruits that do not have damage or traces of worm activity. Large fruits emit a lot of ethylene, which contributes to the ripening of fruits and their rapid spoilage. Small apples will become lethargic and tasteless within 1-2 months. It is best to process fruits that are not the right size.

How to treat fruits

All preparations used to process apples can be divided into 2 groups: industrial and folk. The former are used to send fruits en masse for storage, while more affordable means are used by amateur gardeners. All chemicals are aimed at suppressing ethylene synthesis. Fruits in agricultural storage facilities are treated with different preparations:

All preparations used to process apples can be divided into 2 groups: industrial and folk. The former are used to send fruits en masse for storage, while more affordable means are used by amateur gardeners. All chemicals are aimed at suppressing ethylene synthesis. Fruits in agricultural storage facilities are treated with different preparations:

- DPA antioxidants;

- ethotoxin;

- diphenylamine;

- 1-methylcyclopene.

The latter drug has become the most common in agricultural storage facilities, since it does not penetrate into the fruit. The only condition after treatment with chemicals is that you need to thoroughly ventilate the warehouse during the day, and then maintain the temperature in it no more than 5 degrees. Chemicals eliminate the likelihood of fruit rot by 95%.

However, farmers prefer to use more available methods apple processing:

- To process fruits, you can melt 100 grams of purified propolis, mix it with 96% ethyl alcohol and keep in a water bath until a homogeneous consistency is obtained. Then you need to dip the fruits into this mixture one by one and store them.

- An easier way is to treat each apple with a cotton napkin soaked in glycerin.

- You can also dip apples in melted wax or paraffin.

- The most common processing method is to prepare a solution of calcium chloride (4%) or potassium permanganate. You need to keep the apples in it for 1 minute, and then, without wiping, dry them and place them in sawdust.

Fruits processed by any of these methods must be thoroughly washed before consumption. It is recommended to cut off the peel after applying chemical solutions.

Methods for storing apples

Long before harvesting, you need to prepare the room in which you will store the processed fruits. The temperature in it should be -1...+5 °C, and the humidity should be within 85-95%. To prevent mold, it is necessary to whitewash the walls and treat the floor with copper sulfate. It is important to reliably isolate the room from groundwater(if it is located on ground floor), and also insulate. It is important to provide a ventilation system that will prevent air from stagnating and will remove gases.

The apples themselves can be placed in one of the following ways:

- wrap each in paper and place in boxes or baskets;

- lay in a heap on hay or straw (it is best to cover each row with dried mint, thyme, lemon balm);

- place in boxes with disinfected sand;

- wrap in plastic;

- place in polyethylene bags (3 kg per container) and, without tying them, place in storage;

- place on shelves with drawers, the fruits should not touch;

- carefully place in wooden boxes, without sprinkling with anything;

- place in sawdust.

Treated fruits are best preserved in disinfected sand. To do this, you must first warm up the clean sand and then fill it with fruit.

How apples and other fruits and vegetables are processed

Since we live in a country where the climate does not allow growing fruits and vegetables all year round, our ancestors have long prepared them for the winter in the form of preservation (salted and soaked in wooden barrels). But modern trade relations today make it possible to see fresh fruits and vegetables on store shelves throughout the year. But are they as useful as we think? Fresh cucumbers, tomatoes, Bell pepper, apples, pears, bananas, kiwis, oranges, grapes - all this is brought from abroad unripe. Often the ripening process takes place in special gas chambers. For example, bananas, which we see yellow, could have been green just yesterday and would have ripened for several months under natural conditions. And with the help of a gas chamber, they ripen from 4 to 9 days. The gas chamber is heated to a temperature of 18 ° C, the humidity in the chamber is maintained at 90%, and “banana gas” is launched - a mixture of nitrogen and ethylene. Ethylene is a chemical compound that is a phytohormone that causes fruits to grow and ripen. There is nothing harmful in fruits that ripen in a gas chamber, but there is also little useful, because vitamins in vegetables and fruits are formed when interacting with sunlight, but the sun does not shine in a gas chamber. But sometimes bananas on the market are bland and tasteless - this is the first sign that the technology has been violated in order to speed up the ripening process to 10-12 hours with an increase in the dose of gas.

Apples

Untreated in the cellar, they can last until February at most, and they are sold in stores all year round. It turns out that certain varieties of apples are rubbed with a thin layer of wax before storage - this is a mixture of paraffin, wax and sorbic acid. This coating gives the fruit a glossy shine and allows it to be stored for almost two years. To get rid of wax, you should purchase special detergents for fruits and vegetables, or brush it with a brush under hot water for a few minutes or cut off the peel. Apples are also sprayed with biphenyl. Diphenyl is a hydrocarbon product of petroleum refining, slows down the rotting processes of fruits and vegetables, is a strong allergen, prohibited in the USA and EU countries due to carcinogenicity. Biphenyl is colorless, odorless and tasteless, and therefore people do not see or hear it and quite often do not wash fruits. Biphenyl remains on the hands and enters the body along with fruit. Processed fruits look fresh, but they may have already begun to rot inside, which means they contain a toxin that is dangerous to humans - patulin. Patulin is a mycotoxin, produced by various types of mold fungi, has mutagenic properties, and can cause acute toxicosis in animals and humans. If the apple skin feels sticky and slippery to the touch, it means the fruit has been treated with biphenyl. Biphenyl is not washed off with water; such fruits must be washed with soap and the peels must be cut off. Citrus fruits are also treated with it. But even if the fruits and vegetables have not been rubbed or sprayed with anything, then special smoke bombs are lit at the vegetable bases. The emitted smoke contains a fungicide that protects fruits and vegetables from pathogens of rot, scab and mold. In a ventilated room, the fungicide quickly evaporates, and the residues are washed off with water, so it is not at all dangerous to human health. Subsequently, vegetables and fruits that have not been treated with chemicals can cause more significant harm to the body if rot and mold begin to develop in them. If fresh fruits and vegetables are stored in warehouses that are not protected from rats (the main carriers of infections), then they can become a source of yersiniosis. To protect yourself, place the vegetables in a weak solution of vinegar or salt for 10 minutes, then rinse with water. After this treatment, the yersiniosis bacteria will die.

Grape

during transportation, they are preserved using potassium metabisulfite in tablets; they are evenly laid out on the bottom of boxes under paper. When exposed to air, the tablets react with oxygen and release sulfur dioxide, an antiseptic and antioxidant, which “fumigates” the grapes. Also, paper packaging can be treated with fungicides, which reduces losses by five times.

Berries

Black and red currants, gooseberries, raspberries, blueberries, blackberries are cooled to freezing point immediately after picking, then placed in a controlled atmosphere, where they can be stored from two weeks to two months. Without artificial refrigeration and special means, the berries are stored for no more than 12 hours. However, in some countries, berries are irradiated with microdoses of radiation, which allows the shelf life to be extended by another week. These technologies have been known for a hundred years and are widely used in China and the United States, but have not been proven to be safe for humans in the long term. Lingonberries and cranberries can be stored in the refrigerator for 10 months to a year.

cucumbers

They are not stored for a long time, their lifespan is 2-3 weeks, in a controlled atmosphere - no more than 40 days. To extend their shelf life, they are treated with mixtures of mineral substances, covered with a layer of starch and wrapped in plastic film. They are also treated with paraffin. It creates an invisible film on cucumbers that does not allow moisture to pass through. Cucumbers treated with paraffin can remain juicy and fresh for a long time, but the paraffins themselves, which remain on the peel, can be dangerous. Six months is a critical period for a cucumber; even a paraffin-treated vegetable begins to deteriorate by this time. Before you buy a cucumber, feel it near the stalk; if it is soft, it means it is old and no longer contains any vitamins, taste or smell. Run your hand over the cucumber; if the spines are soft, thin and can be wiped off with your palm, then the cucumber is ready to buy and eat. If the spines are rough and the skin is dark green, it may have been grown with chemicals.

Potato

one of the most popular root vegetables in Russia, which is prepared for storage in the garden beds. To combat late blight, it is sprayed with copper oxychloride, Bordeaux mixture, zineb, captan and other preparations. Then they are collected, dried, cooled and sent for storage. In the spring, when the potatoes become flabby and are preparing to germinate, they are treated with chemicals: M-1 (methyl ester of a-naphthylacetic acid), which is considered low-toxic for humans, low-toxic hydrel, the breakdown of which produces ethylene, HMA (maleic acid hydrozide) and TB (tetrachloronitrobenzene), which are considered non-toxic. However, most effective means from germination is exposure to low doses of radiation. Potatoes grown without chemicals will be dense and elastic, and the tuber, which contains a lot of nitrates and pesticides, will be smooth, even and soft. If you hear a crunch when you press a fingernail on a potato, it means there are no pesticides in it. If the nail silently enters the tuber, like cotton wool, it means that the potatoes were grown on nitrogen and mineral fertilizers. Do not buy green potatoes; they contain solanine, which is very toxic even in small quantities. It appears in tubers if the potatoes have been in the sun for a long time.

Carrot

Carrots are poorly preserved, so mechanical and chemical methods protection. Mechanical:

- chalking (soaking in a chalk solution and drying);

- claying (carrots are dipped into a clay mash and dried).

Chemical methods include treatment with mixtures based on glycerin, paraffin with the addition of antiseptics (benzoic acid, sulfur dioxide). Carrots can also be stored in sand mixed with sawdust and a solution of indole (a colorless substance obtained from coal tars with the smell of naphthalene) or other antiseptics.

Tomatoes

Tomatoes are harvested from the branches when they are still greenish-white in color for ease of transportation and to increase shelf life. To combat late blight, after collection they are heated for several hours at a temperature of about 40 ° C. They ripen under the influence of ethylene immediately before sale. In containers with a special gas that penetrates vegetables, tomatoes turn red, but do not ripen - they simply change color due to a chemical reaction at the pigment level, while remaining unripe. This reaction adds substances to the tomato that corrode the soft tissues of the body, causing a burning sensation. The catch is that you experience a similar burning sensation from the juice of a tomato that is grown according to all the rules - from ordinary fruit acids. Typically, the thicker the skin of a tomato, the more nitrates it contains. And also if the tomato has light flesh and white veins, it means there is a lot of nitrates, and if the tomato is bright red both inside and outside, then the nitrate content in it is normal.

Application chemical substances- the only way to preserve plants and harvest a healthy harvest. If nitrates are used normally, they will not cause any harm to the human body. But many unscrupulous farms use fertilizers in quantities many times higher than all norms. This is beneficial, vegetables grow quickly and are not affected by pests. The fungus most quickly attacks nitrate vegetables in the form of dark spots, so if you see dark spots on vegetables, this is the first sign that the vegetables were grown with nitrates. To buy cabbage without nitrates, first feel the head of cabbage; healthy cabbage leaves should be dense, and the base of the leaf at the stalk should not be thick. Nitrates are not the worst thing that can be found in vegetables and fruits. It is much worse if pesticides remain in the fruits (vegetables with pesticides almost do not spoil or rot).

Pesticides

chemicals that destroy weeds, insects, pathogenic fungi and other pests. In people in large dosages they provoke allergic reactions and cause poisoning. Over the course of a year, we eat about a handful of chemical fertilizers along with vegetables and fruits. As a rule, all fertilizers and pesticides must be completely decomposed and evaporate from the surface of fruits and vegetables before the fruits ripen. But as experience and practice prove, not everyone follows the rules and regulations for the use of chemicals and, as a result, we are exposed to danger, so we need to carefully select and buy vegetables and fruits on store shelves. In order to protect yourself from purchasing low-quality products, remember simple rules: Ask the seller for a certificate and declaration in order to find out where the fruits and vegetables were grown. Feel the apple; if the peel is sticky and slippery, it means the fruit has been treated with biphenyl. It is better to wash such an apple with soap and remove the peel. If the tomato is bright red both inside and outside, it means that the amount of nitrates in it does not exceed the norm and the thinner the peel, the safer the vegetable. When buying cucumbers, pay attention to the thorns; if they are soft, thin and can be easily rubbed off with your palm, then there are no nitrates in it. If the cucumber is soft and odorless, it means that there are most likely no vitamins and nutrients left in it. If white cabbage has a dense head and the stem of the leaf is not thick, then it contains almost no nitrates. Do not buy potatoes with green spots, they contain solanine and are toxic to the body. Before buying, press the potato with your fingernail; if you hear a crunch, it means there are no pesticides in it.

Processing apples for long-term storage: a review of methods