Fasteners for wooden stairs. For the home handyman: how to fasten the steps of a wooden staircase. Fastening balusters and railings

Wooden stairs in the house are a very attractive element that can decorate or, conversely, spoil the appearance of any room. Beautiful carved stairs, like the one shown in the title photo, are the prerogative of professional assemblers and carvers, but this does not mean that simple structures assembled with your own hands cannot look impressive.

In today's article we will look at the installation of wooden stairs step by step. This material will allow you to assemble a high-quality structure with your own hands, without spending a lot of money on hiring specialists and materials.

The first thing any builder faces is the design of future work. In the case of building a staircase, you will need to create an actual drawing to scale.

It is a drawing, not sketches on a piece of cardboard or a pack of cigarettes. This approach will allow you to avoid common errors in the manufacture and assembly of parts.

Terminological dictionary

Before starting the story about installing a wooden staircase with your own hands, let's plunge a little into the world of terms and concepts.

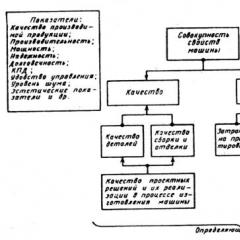

Our task is to study the main parts that make up a wooden staircase:

- Bowstring– a support beam that stands at a slope and holds the steps. A special feature of the bowstrings is that the steps are inserted into grooves sawn into the body of the board. In the diagram, this detail is shown on the left side of the viewer.

- Kosour– the purpose is similar to a bowstring, but there is a difference in the structure of the part. If in the first case the steps were installed in grooves, then here the support is cut right on the top edge of the board, and the steps are laid on top. In the diagram it is located on the right.

- Tread or step- This is the part of the structure that a moving person steps on. You can also hear the name – step cover.

- Riser– this is the side decorative part of the step, installed vertically. It is not a load-bearing element, so some designs do not provide for its presence at all.

- Support pillars– there are starting, finishing and turning posts. They are the main load-bearing element for stair railings. Rotary ones are installed if the structure has more than one flight.

- Handrails- This is a holder on which a person leans when ascending or descending.

- Balusters– vertical elements that form the filling of the railing. Unlike pillars, they are not supports; however, when firmly fixed, they significantly enhance the strength of the entire fence structure.

- Ordinary stage– a standard flight step with fixed dimensions.

- Frieze steps– the first and last stages of the flight. They may differ from ordinary ones in size and shape, compensating for the remaining distance when dividing the span height by the number of steps.

Explanation! This means that the distance between the floors of the first and second floors is rarely a multiple of the height of the steps. Because of this, the lower step has different dimensions. And the upper frieze step extends into the same plane as the upper platform, and depending on the fastening of the stringer, it can be completely retracted or protruding, with a larger tread.

The designs that we will look at today are called marching ones. They are characterized by the presence of straight, level sections of ascent. Depending on the height of the span, the space for the stairs and the number of floors, single-flight and multi-flight structures are arranged.

Multi-flight stairs must have a rotation: 90, 180 or 270 degrees. The degree of rotation, again, depends on the space in which the staircase is located. In the first two options the number of marches is two, and in the last - three.

The more turns, the more compact the staircase can be made. To connect the marches, intermediate platforms and winder steps are used.

The turntable is a horizontal plane. It is usually located in the middle of the span, dividing the climb into two equal sections.

Winder steps, as if part spiral staircase, provide a smooth rise during a turn. They can be located either in the middle of the span or closer to the level of the first floor, reducing the first flight, down to several steps. In this case, the spread is most often placed in the corner of the room.

The step itself is an irregularly shaped trapezoid and is mounted around a rotating support column in compliance total height risers and a certain degree of displacement.

Drawing up a drawing

So, we have become aware of the main elements that make up a wooden flight of stairs. As you already understand, this is what we will be collecting in this article. Now you can safely move on to creating a drawing.

First of all, we advise you to turn to a professional designer for help, who will competently calculate the amount of material, dimensions of the structure, optimal shape, etc. design features. Naturally, you will have to spend money, but sometimes saving can become even more expensive.

If you don’t have the opportunity to spend additional money, you can use free online staircase designers.

To work with these tools, you do not need any specific computer knowledge. Everything is extremely simple and intuitive. All you need to do is accurately take all measurements on site and indicate them on the calculation page.

The assembly of the staircase railings is completed by installing the handrail. Not everyone knows how to fasten a handrail, how to do it correctly, reliably and discreetly. We will describe some common methods for wooden and metal stairs here.

Attaching a handrail to the balusters of a wooden staircase

It turns out that wooden railings the hardest thing to do. That's because there are a lot different ways and techniques for working with wood and there are almost no ready-made solutions, since each staircase is individual and has its own characteristics. For example, attaching a handrail to balusters can be done using dowels, self-tapping screws, nails, bolts, special ties (zipbolts), and glue. In addition, you can “mount” the railing directly on the balusters and posts, but there are options with an additional strip, which is sometimes called a “rail rail.” And all of these are the “correct” ways to connect the posts to the handrail. We will talk about how to do this in this section.

First of all, cut a piece of the handrail to the required length. This can be a fragment from one support pillar to another, a piece for the entire span - from the upper/lower pillar until the moment of turning. It all depends on the design of the staircase. If there are joints between two fragments, they must be processed well, achieving a perfect match. Then the handrails for the street must be coated with protective impregnations, and then painted/varnished. Afterwards you can deal with the issues of attaching the handrail to the stairs.

How to trim balusters for installing handrails

After installing the balusters on the steps, their tops are at different levels, and without trimming the handrail cannot be installed on them - it does not fit like that. To install a support handrail on a staircase, you must top part cut the posts at a certain angle. This angle is determined by the steepness of the flight of stairs and does not need to be calculated. It is determined “on the spot”.

To find the cutting angle of the balusters, you can use a thread stretched between the support posts. We tie it at the same distance from the tops of the pillars, which are installed at the top and bottom of the span. Where, according to the plan, the lower border of the handrail will pass. Using this stretched thread, we draw a line with a pencil onto the tops of the posts. You can use a thread instead of a thread, or you can also temporarily secure a guide (any flat strip).

This is how it should turn out - the staircase railings are ready for installing handrails

We got the line, now we saw off the tops of the columns on the stairs strictly along it. Next, you can continue attaching the handrail to balusters or posts.

Allow me one piece of advice: if for the subsequent installation of the railing you need to drill holes for dowels or studs, it is better to do this before trimming. This makes it easier to find the center, easier to hold the drill perpendicular. After the holes are made, you can take a saw/jigsaw and file along the intended markings of the rack.

Connecting balusters and railings with dowels and threaded rods

Let's consider one of the traditional methods: attaching the handrail using dowels or pins. For this type of connection, it is necessary to make matching holes in the handrail and staircase railing posts. If you install studs, you can screw them into the holes made in the center of the balusters and install the handrail in the position in which it should stand. After checking that everything is in place correctly, walk along the handrail, tapping each baluster with your fist. The protruding ends of the metal pins will be left on back side handrail trace Remove the handrail and mark the resulting marks with a marker/pencil for reliability. Now you can drill the holes. With this method of marking the handrail, there are almost no problems with its “fitting” into place.

The second option for marking the handrail for installing pins and dowels is carried out before they are installed in the balusters. First of all, we put the cut piece of the handrail in place. Then, with a pencil, mark on both sides where the balusters are installed. Before making marks, check the distance between adjacent posts below and near the handrail. If they match, everything is fine, we put marks; if not, we adjust the position of the rack and only then make marks. Adjustments are needed to ensure that all the staircase supports are vertical. This will make the railing more secure.

After all the balusters are marked, remove the handrail. WITH reverse side The marks we made are worth it. We draw diagonals between the pairs of lines that outline the baluster. We put a mark at the place where they intersect. Here you will need to drill a hole for a dowel or pin. We find the centers on the balusters in the same way (if there are no holes in them yet). As you understand, with this method of marking the handrail for the railing, problems can arise - the slightest inaccuracy and the handrail does not fit into the post. The good news is that the baluster can be moved within certain limits. As long as it is not fixed, there is a certain freedom, and this can be used when installing the railing. Just move it so that the tenon fits into the groove. In general, you know how to attach handrails to dowels.

To make the installation of the railing more reliable, in addition to dowels or studs, you can coat the connection with glue. This will make the structure more rigid and extend its service life without backlash.

With an auxiliary bar - support rail

Agree that the easiest way to install handrails on balusters is to use self-tapping screws or nails through them. What stops you from making such a decision? An overly unsightly result in the form of fastener caps that spoil the whole look. But there is a very similar method that guarantees a good appearance of the stair railings. An auxiliary bar is used, which is also called a bolster.

The auxiliary strip is cut with a tenon, which in mirror image repeats the shape of the groove in the lower part of the handrail. The flat side is placed on sawn balusters and fastened through (screws or nails - your choice). Don't forget to check the distances between adjacent posts.

Then the upper part of the support is coated with glue and the handrail is “planted”. All. There are no traces of fasteners on the front of the handrail, everything is holding together. The only thing that needs to be taken into account is that the height of the handrail turns out to be slightly larger, since the thickness of the auxiliary plank is added (if the plank is wooden, this is at least 2-3 cm).

There is another way to attach the handrail to the support rail - with small nails or self-tapping screws from below, at an angle. But with this fastening, the caps are visible. They can be disguised using one of the known methods, but it will take a long time...

The easiest way is to screw it with self-tapping screws

As you know, over time, wooden railings become “loose” due to the fact that under load they wobble, the wood fibers become crushed, and play appears. To reduce the possibility of play, when fastening through a plank, two or more screws/nails can be used for each baluster. This will make the handrail mount more rigid.

Also, for greater reliability, the bar can be made of metal. Any thin metal will do. Be it steel or aluminum. But then it will be necessary to either cut the bar to fit the size of the recess in the handrail, or modify the groove so that the handrail fits well on the structure. And one more thing: if the plank is metal, you need to find a universal glue that glues wood and metal well. This handrail mount for stairs is simple, beautiful, and reliable. Suitable for those who decided to make a stair railing with their own hands for the first time.

For spikes of different shapes

It is possible to install a wooden handrail without metal fasteners: with spikes and glue. Spikes are cut at the top of the balusters. Under them, recesses of the same shape are formed in the handrail. Tenon/groove shape - any. It can be a rhombus, a rectangle, a circle, an oval. The main thing is that the tenon and groove match perfectly. This can be achieved by making a template and repeating it exactly on each fragment. The minimum tenon height is 2.5 cm, so the height of the handrail cannot be less than 4.5 cm.

After a tenon is formed on each baluster and a groove is cut in the corresponding place on the handrail, they are glued. When installing the handrail on the balusters, they can be shifted slightly to align the holes. You can use the installed handrail after the glue has dried (the time is on the package).

Connection between handrail and support post

Often the handrail does not go on top of the post, but is connected to its side edge. How to connect the handrail and the post in this case? The easiest way is to, after cutting the handrail at the desired angle, secure it with screws or nails driven in at an angle. The disadvantages are obvious - the fastener heads are visible.

There is another way - to use a zip bolt, which consists of two movably connected studs and a gearbox. For its installation, a technological hole is required, which is made in the lower part of the handrail. It is then covered with a plug to match the wood and it becomes almost invisible. The second advantage of such a connection: it can be tightened (to a certain extent) if suddenly a backlash appears.

You also need to drill holes for the studs under the zipbolt - one in the post and one in the handrail. The technological hole is usually made in the handrail. It is positioned so that it is possible to tighten the thread under the gearbox (the length of this thread is usually 10 mm). The depth of the holes is the size of the studs (from the joint to the edge), the diameter is 1-2 mm less than the diameter of the stud.

Studs are installed in the drilled holes. It is screwed into the post and simply inserted into the handrail. A gearbox is installed in the prepared technological hole, in which there is a hole for a hex key (6 mm). We rotate the gearbox so that it is convenient to use the key. Turn the key and tighten the thread, pulling the handrail to the post. This must be done after the balusters are connected to the handrail. By attaching the handrail to the post, you can assume that the railing is installed.

Installing handrails on prefabricated metal fencing

In general, assembling handrails from metal (stainless, nickel-plated, chrome-plated) pipes is similar to a construction set. There are pipes of different diameters, decorative elements for them, and a whole set of different fasteners. The railings are assembled from all these parts. That’s why they are called “prefabricated”. When deciding how to attach handrails to metal balusters/posts/racks, your task is to choose those elements that suit your task better than others or that you like more than others.

To connect metal posts/balusters to the handrail, there are special ends that are attached to a round/square/rectangular pipe on one side and to the handrail on the other. There are models different types. You just need to find the most suitable one, choose the one you need: according to the size of the racks and the type of handrail.

In metal prefabricated fences, handrails can be different:

- round metal pipe;

- profile (rectangular, square) metal pipe;

- plastic handrail (round, oval or original shape);

- wooden of any profile.

Under each of these handrails there is a fastening, and usually more than one. Choose what you like. They are easy to fasten with clamping bolts. But, for reliability, and if the thickness of the metal allows, you can weld all the connections of the two metal parts. - it’s not an easy thing, but if you know how to handle a welding machine, nothing is impossible. Welding takes more time, but such fastening of the handrail will be very reliable.

When connecting elements metal stairs with plastic or wood, you must use the fasteners recommended by the manufacturers. Additionally, you can glue the joints with universal glue. True, in the case of stainless steel, there is no particular point in this: the adhesion will be very low. But still…

Attaching a handrail to a welded or forged stair railing

A wooden handrail is usually placed on a forged or welded fence. In its lower part, a cut is made according to the dimensions of the upper lintel of the finished fence. The seating depth of the handrail is about 2 cm. More or less is possible - it depends on your desire. The railings are connected to the handrail with self-tapping screws, which are screwed through the holes in the upper lintel. It is important to choose the length of the fastener: it should be slightly (at least 5 mm) less than the height of the handrail so that the screw does not stick out on the surface.

In this case, installing a handrail on the stairs is simple:

There is also the possibility of gluing a wooden handrail to welded or forged metal railings. When choosing a glue, you need to make sure that it can connect wood and metal. For external stairs (on, for example), you must also pay attention to the range of operating temperatures. Otherwise there are no difficulties:

- apply glue according to instructions;

- press the parts, secure with clamps;

- leave until the glue dries;

- remove the clamps.

To securely attach a handrail to a steel staircase, you can use both of these methods. One does not interfere with the other.

Methods for attaching a stair handrail to a wall

A handrail is attached to the wall if the width of the steps on the stairs exceeds 120 cm. The second handrail is made of the same material and the same shape as on the balusters, but it is attached to the wall.

To install a handrail on a wall, there is a whole range of fastenings - brackets - for different profiles (round, oval, shaped). On one side of the fastener there is a round or square fragment with a flat surface and holes made in it. We install this part on the wall. We select fasteners depending on the material from which the wall is made. We use self-tapping screws if the walls are wooden, dowels for walls made of concrete and brick, and special dowels for fastening to lightweight concrete.

The number and size of fasteners for installing a stair handrail on a wall are selected based on reliability considerations. Manufacturers make at least four holes on each bracket. Here are four self-tapping screws/dowels/nails for each and we install them. When choosing a length, it is better to proceed from the considerations “the longer, the better.” Still, the wall handrail can bear a significant load, so it’s better to be safe than to fly down...

The second part for wall mounting of stair railings - where the handrail itself is attached - can be different. There may be a ring of a certain diameter for round pipes; there is usually a flat platform for rectangular or square handrails. This part of the stair handrail bracket also has holes so that the railing can be secured. And in this case, the number of fasteners should be equal to the number of holes (for the same reasons).

There are brackets for wall mounting of handrails with different angles tilt They are chosen based on their own ideas about convenience and the planned height of the support. There are also telescopic models that allow you to set the distance to the wall and/or the angle of inclination. There are also end wall brackets, which, while fixing the edges of the handrail, also decorate them.

The number of brackets depends on the length of the handrail. Usually one element is placed at the edges, and a calculated number between them, with a distance of 40-60 cm. The lower the load-bearing capacity of the wall, the more often we install wall holders for railings.

Many private houses have a staircase leading to the second floor. As a rule, it is designed at the stage of developing the layout of the entire building. In principle, during construction there are various works that can be done independently, for example, installing the same steps if they are made of wood. However, many craftsmen cannot understand how to attach the steps wooden stairs. From this article you will learn about the main method of assembling such a structure and make sure that such a procedure can be easily carried out with your own hands.

Ladder on bowstrings

The vast majority of indoor stairs are assembled using bowstrings. This is the name given to the supporting structure of the flight of stairs itself. It looks like a beam with cutouts, which, in turn, are made on its inside - it is in these cutouts that the steps are placed. This method of fastening the master is called classic.

Materials

Most often, bowstrings are made from:

- Wood. Only coniferous and deciduous species are used. Conifers are considered very good, but they have one drawback - they are capable of releasing resin. For this reason, it is better to choose hardwood.

- Metal.

- Reinforced concrete.

Options

The dimensions of the finished bowstring directly depend on the length of the flight of stairs. Before attaching the steps of a wooden staircase, it is worth considering the following parameters:

- For a staircase whose width is 90 cm, it is better to make a string from a board whose thickness is approximately 0.5 cm and width 30 cm.

- Nesting cuts are made at a depth of 2 cm.

- The minimum width of the bowstring itself is 27.5 cm.

In order to correctly mark the bowstring, two main methods are used:

- Using a ruler and square.

- Using a special template.

Important! For each method you need to draw a support line. It must be marked 4-5 cm from the edge of the workpiece. Before you begin to perform all operations for making a bowstring, you must mandatory saturate the wood blank with a primer composition.

When marking the bowstring, you need to consider the following points:

- It is necessary that the marching inclination is 30-40 degrees.

- The depth of the steps must be at least 30 cm.

- The height of each of them is approximately 20 cm.

Tools

In order to make steps and a bowstring, you need to stock up on the following items:

- Tape measure, square and ruler.

- Jigsaw.

- Level.

- Drill.

- Manual milling machine.

- Hammer.

- Screwdriver Set.

- Bit.

- Wood slats (can be replaced with metal corners).

Installation

Before you start attaching the steps of a wooden staircase, you need to cut the grooves using manual frezer ny machine. After this, the structure must be attached to the location of the wooden staircase. This procedure can be carried out in two ways:

- By installing the racks in the designated holes in the floor.

- Attach these posts using anchor bolts.

The next step is to attach the steps to the string. The steps, which you have already cut to suitable sizes and processed, and the risers are attached to grooves or screwed to wooden blocks or metal corners.

Important! It is very important to do these parts with extreme precision, otherwise the entire structure will wobble more and more over time and make an unpleasant creaking sound.

The strings should be fastened to each other using ties every 3-4 steps.

We attach the steps with stringers

You can attach the steps on a wooden staircase to a stringer made of metal or wood. This is the name of the support beam, which has a sawtooth shape. Wooden parts are attached to its protrusions. You can install either one stringer or several. The steps are attached to them with screws, and their top caps must be closed with small wooden plugs.

Important! The best option There will be cutting out steps from oak or pine wood. As a rule, craftsmen do not install risers - this gives the structure a lighter and softer look. It is also worth noting that even to assemble a wooden staircase you simply need to have welding skills.

Final finishing

After you have secured the steps of the wooden staircase, you need to make a good fence for it, consisting of railings with balusters. For this purpose, you need to follow several rules:

- It is necessary that the gap between them be at least 15 cm and no more than 20 cm.

- They are attached to the outside of the bowstring using screws, dowels, pins or spikes.

- For the studs, you need to drill a hole with a diameter of 12 mm to a depth of 80 mm. They are planted on glue, leaving 5-7 mm outside.

Further work is as follows:

- It is necessary to drill a hole in the bowstring, the depth of which is 10 cm.

- Next, the outermost columns are installed. Between them you need to pull the twine and place the remaining balusters.

- Attach the railings, which are made of a block, 80-100 mm wide.

- Cover the entire structure with varnish or paint to provide a protective layer.

Safety

Finally, materials that resist slipping can be laid on the steps.

Wood is one of the most popular materials for making stairs. Among its advantages, we note its affordable cost and high strength, environmental safety and aesthetic appeal. However, in order for the staircase to serve you for a long time, it should be designed and installed correctly. We will consider the features of installing wooden stairs below.

Advantages, production and installation of wooden stairs

Wood products surround us everywhere. This is explained primarily by the availability of this material and its low cost. When choosing a staircase that is installed inside the house, its wooden version is one of the most successful.

Also, wood is easy to process, so the staircase can be made in any shape or design idea. In addition, wood has a special texture, smell and textured elements. Therefore, its use in the interior enriches it with comfort and creates an atmosphere of coziness.

Among the main advantages of wooden stairs we note:

1. Strength and reliability - this ladder is quite durable and can withstand heavy operating loads. However, the duration of use of the ladder also determines the type of wood from which it is made.

2. Environmental safety is another important advantage of a wooden staircase. Wood is a natural material that is not prone to negative effects on human health. Wooden products add comfort to the room, since when the humidity is too high, the tree absorbs moisture, and when it is low, it releases it. If the staircase is made of pine, then it also has antiseptic properties, improving indoor air.

3. Affordable cost - the cost of constructing a wooden staircase is much less than manufacturing a metal or concrete staircase. In addition, there is always a choice: to choose cheaper options, such as larch or pine, or to give preference to more expensive, but at the same time powerful oak.

4. Light weight - thanks to this advantage, transporting the material to the site is much cheaper. In addition, the staircase does not load the overall weight of the building, and its construction and installation does not require specialized equipment.

5. The ease of changing the appearance is achieved by painting or transforming a wooden staircase.

6. Attractive appearance allows you to install such a staircase in any interior. Since wood, being a natural material, goes with almost everything.

Types and installation of stairs in a wooden house

The staircase is not only an element of connection between two floors, but an aesthetic part of the room. It is wooden stairs that are distinguished by their attractive appearance and decorate the room in which they are installed. Threaded elements, beautiful railings, balusters, wood texture - add beauty, chic and decoration to the staircase.

In order to independently make such a structure, you will first need experience with carpentry tools, as well as effort in wood processing. Before starting work, special calculations should be made to determine the optimal angle of inclination of the stairs, the number of steps, their sizes, etc.

In addition, stairs can be made entirely of wood or of combined materials such as glass, metal, concrete, forging, etc. However, any staircase contains its main components, in the form of steps, stringers, bowstrings, supports. To decorate this structure, elements in the form of fittings, handrails, balusters, and risers are used.

If you plan to install wooden stairs with a complex configuration, then you should think about certain difficulties that arise during its operation. First of all, it is difficult to carry large furniture on a turning staircase. Balusters should be spaced at least 15 cm apart from each other.

Depending on the manufacturing method, wooden stairs are:

- marching;

- console;

- spinal;

- screw;

- combined.

The simplest staircase design is a marching staircase. It consists of one or more flights that perform the function of connecting floors together. This version of the staircase can be straight or rotary. The most common option is the lower part of the staircase, made of a monolith, and the balusters, steps and railings are made of wood. This staircase is very durable, can withstand heavy operating loads and at the same time is very convenient, as it is found everywhere: in schools, hospitals and other public institutions.

A cantilever-type staircase is airy and light, but less safe than a marching staircase. Such a staircase seems to hang in the air, since there is empty space between the steps. However, in fact, the steps are fixed to the wall surface using anchors, which make the structure quite strong. Among the advantages of the ladder, we note the absence of the need to install it.

The spiral staircase is small in size, so it can be easily installed in the smallest room. It contains both straight and curved marching sections.

The spine-type wooden staircase is distinguished by its similarity to a real spine. Since this design includes individual elements, for connecting which only their sequential order is used. This design combines various rotary, spiral, and winder flights. However, the process of its construction is quite long and labor-intensive. After installing the steps, a fence is built, making the structure more holistic. In this case, it is appropriate to use flexible handrails. This version of the staircase has a high price, which is several times higher than the price of standard stairs.

In the process of manufacturing and assembling a wooden staircase, you should carefully read the available information on how to complete this process. The selection of materials must be made with special care and seriousness, because the life of the staircase directly depends on the quality of the wood.

The composition for tinting must meet all quality norms and standards. If the staircase is installed inside the house, then care should be taken to ensure the environmental safety of the substances used to treat the wood. Since some of them can cause allergies. Also, you need to decide on the type of varnish and tinting for the stairs.

All parts of the stairs must be painted in clean conditions using a spray gun. In this way, it will be possible to achieve a perfectly even structure and color. The wooden staircase is assembled after painting and completely drying each of the parts.

Wood is a material that is unstable to moisture and temperature changes, so the room should always have moderate humidity and optimal temperature. Otherwise, the tree begins to become moldy, rot, or simply become deformed.

When choosing hardwood for making wood, you should be guided by the fact that it is quite durable, but at the same time labor-intensive to process. Beech, oak, ash, maple are woods that can withstand high operating loads, mechanical damage, and strength. When choosing coniferous wood for making stairs, you should take into account that they contain resin that purifies the air and has an antiseptic effect. The cost of such wood is an order of magnitude lower, however, the aesthetic appeal is at a lower level than that of oak.

When choosing the design of a wooden staircase, try to ensure that it fits into general style interior design. Railings, handrails, balusters should be in harmony with the overall style. You should also pay attention to such subtleties as choosing the color of the wood, calculating the stairs that are optimally convenient for movement and determining the shape of the stairs.

Installing steps on a wooden staircase

The type of fastening of steps to a staircase depends primarily on its shape and configuration. There are two main options for staircase execution: on a bowstring and on a stringer. Stringer is a place for installing steps from above, and a stringer means installing it on the side of the staircase and installing steps between it and the wall or between two stringers.

The stringer is an element that takes up the total load, so installing steps on its surface implies fixing it and protecting it from vibration and displacement.

The easiest option for installing a step in this case is to fix it on the surface of the stringer using a drill. Self-tapping screws must have decorative heads that screw into the inside of the steps. It is also possible to install decorative plugs made of polymer materials. This fastening is appropriate if the staircase was built independently, without the involvement of specialists.

Please note that only a feather drill and a high-speed drill are used to fix the steps, in this way it will be possible to avoid the appearance of bevels. If the staircase is open and does not require additional cladding, then a hidden method is used to install the steps, that is, cotter pins. In this case, these elements are installed on the surface of the stringer and fixed with glue. However, for a staircase with high operational load and mobility, this option is inappropriate, since the steps will quickly begin to fail.

Installing wooden stairs with your own hands is a rather labor-intensive process that requires special skills. Among the main ways of fixing a step on a bowstring, we note:

1. Fixing the support bar under the step on the string.

2. Steel brackets installed under the steps and secured with screws and bolts.

3. Overlays and notches installed on the inside of the bowstring in a zigzag stringer.

4. Manufacturing of groove elements for steps on a bowstring.

The most popular and simplest are the first two methods of fixing steps. If the ladder will withstand heavy loads, then it is better to give preference to the last two options.

The use of bars and overlays is appropriate if the stairs will be covered in the future. If the staircase is not sheathed, then the places where the screws are fixed should be hidden.

Installation of wooden stairs video:

Another option for installing steps is to fix them in the wall. Steel studs or bushings are used to tighten one side of the ladder, and the other is fixed to the wall surface.

Wooden steps are installed in the wall by mounting them on supporting elements, which are bars, corners, and decorative turned elements. To fix the steps, anchor elements are also used. In addition, the steps should be milled in relation to the width and depth of their installation in the wall.

Installing balusters on a wooden staircase

When installing balusters, you should follow certain rules:

- the minimum height of the stair railing is 90 cm;

- The minimum installation interval for racks is 15 cm.

If there are small children in the house, the latter figure is reduced to 10 cm. Among the main elements of the baluster, we note the presence of:

- main part;

- central part;

- handrails

The main decorative element is precisely the center of the baluster. There are several ways to install railings on a wooden staircase, as well as install balusters:

1. Holes for balusters are drilled. Their lower and upper parts are cut off. Use a miter saw to make cuts.

2. Install the pins inside the holes, drill holes inside the bowstring.

3. Install balusters made of wood with studs already built into them.

4. The top installation of the baluster is done in the same way. Next, the entire structure should be glued to the handrail.

The second option for installing balusters involves the use of dowels. Since the racks are not subject to heavy loads, this method is quite appropriate. Holes are drilled for dowels, just like for studs, but their diameter is slightly larger.

The dowels must be coated with glue, installed inside the balusters and fixed in them with glue. Next, the base is placed on the surface of the bowstring. For additional fixation of the baluster, anchors are used, which are installed from below.

Also, to fix the balusters, self-tapping screws installed on the steps are used. This method quite simple, but less reliable than fixation with pins.

Installing balusters on a wooden staircase video:

Stairs with bowstrings are often installed in multi-level apartments and private houses. This traditional staircase design is different from other options high level reliability, and, in some cases, attractive appearance. For experienced craftsmen installing a ladder on bowstrings does not pose any problem.

But, if you do the work yourself, you will need photo or video installation instructions to minimize the number of questions that arise during installation. In addition, you should study in advance all the features of fastening and marking, as well as the basic rules for their arrangement. Consider not only the essence of the concept, but also existing species structures, as well as possible technologies for their independent production.

Types of stairs

Bowstrings are the side elements of a staircase structure that hold the steps and act as limiters. It is worth noting that in in different forms bowstrings are present in almost all designs.

What is a bowstring and how is it different from a stringer?

What is a bowstring and how is it different from a stringer? Variety of models:

- Attached. The simplest option of all. Most often used on summer cottages. It includes only a few elements: crossbars (steps) and side strings. Anyone can make such a staircase with their own hands. Video instructions recorded by experienced craftsmen can help with this.

- Folding attic. This model consists of two sections. In this case, the bowstring is folded. Hinges, carriages and other fasteners are used as connecting elements.

- Screw. One of the most complex designs. The bowstring is located on the outside. Such models made of wood look very impressive.

- Marching. The most common design. The string in this case forms the march and holds the steps.

Step mounting options

From the outside it may seem that ladders on bowstrings look monotonous and uncomplicated. But this is far from true. There are a huge number of options for their design.

In order to pick up best option installation, you should study possible ways to install steps:

- Sliding steps are not simply inserted into pre-made grooves, but are carefully pushed into them. The cut-out recess should not only have an entrance for the steps, but also an exit to the outside. In these structures, the treads can be dismantled without dismantling the entire staircase structure.

- Mortise steps are a standard method of connecting treads and risers. A hole is pre-cut in the bowstring, into which a step is then hammered. To make the grooves, you should use a hand router. If you don’t have a router, you can take a chisel and a hammer. But this method takes a lot of time. After the steps are secured to one string, you should fill the second element from the other edge.

- Application of corners. This method involves the use of additional elements. In order not to waste time cutting out corners, you can attach metal corners to the sides. It is on these additional elements that the treads will be attached in the future.

Bowstring for stairs: features of fastening and marking

If you plan to build a staircase with mortise steps, then the grooves are made from the inside. Their depth should be between 1.5 and 2 centimeters. After this, risers and treads are carefully inserted into the grooves. When working on your own, remember that the bowstring must have cutouts with smooth edges and the same depth.

Be careful about marking the relative position of the grooves on the two support beams. If it is uneven, then unexpected distortion of the staircase structure may occur in the future.

In such cases, experts recommend making special templates cut from a thin sheet of plywood. To prevent the string from turning into a stringer, the guides should be attached at a distance of 50 millimeters from a pre-marked line.

The markings for the grooves are as follows. Longitudinal lines are drawn on the inside of the beam. They should retreat 50 millimeters from the edges of the beam. If such a need arises, this distance can be reduced to 30 millimeters. Next, the finished template is carefully moved along the edge using guides. The location of the steps is marked with a pencil.

Remember that when applying markings to the string of one ladder structure, the location of the grooves must be completely mirror-like.

The lower and upper parts of the support beams must completely coincide with the floor levels. But whether this coincidence will be vertical or horizontal depends directly on the type of structure.

Experts who know all the features of fastening and marking do not advise quickly sawing off the excess ends. It is quite possible that they will be needed for insertion into a special support beam during final installation.

In order to get a reliable and very durable ladder on bowstrings, fastening the side elements is best done using rods. This can be a wooden tie on bolts or wedges, or a metal tie on nuts. Strands are installed at both edges of the staircase and in its central part. These elements allow you to avoid unwanted spreading of the sidewalls, which occurs when walking on steps and with a high load on them.

DIY installation instructions

Determine the height of the structure, its dimensions and the number of steps. To make a bowstring, take a wooden stick of the required thickness. As noted above, cutting grooves should be done using templates.

When cutting grooves yourself, you should copy the marks from the template onto the workpiece. The wood is processed with a special milling cutter with a nozzle of the required diameter.

After this, fix the internal string at the construction site and connect all the elements of the steps. When the work is finished, press the elements of the steps on the other side with another string and carefully tamp them down. With the help of glue and nails you can make the structure more durable and reliable in use.

By installing tie rods, you can prevent unwanted loosening of the staircase structure. The rods are installed at the rate of one per 5 steps.

In conclusion, it is worth noting that constructing a string for a ladder with your own hands is not as difficult as it might seem at first glance. Before you use staircase structure intended for use, you should ensure that the fastenings are secure.

If necessary, additional vertical support elements can be installed. Metal tubes or wooden beams are suitable for this purpose. The models of stairs that are mounted to the ceilings with the help of hangers look interesting.

As for the fences, they can be installed both on the string and on the steps themselves. It all depends on your aesthetic preferences. If you are not sure that you can handle the work yourself, even with the help of video instructions, then it is better to contact a specialist. The Ladder Master company employs craftsmen who will complete all tasks assigned to them not only quickly, but also efficiently. Such a string for stairs is guaranteed to be reliable, durable and aesthetically attractive.