Mount the lock in the iron door. How to embed a lock in a metal door. The order of installation work for the overhead lock

In many apartments, owners install metal front doors. They better protect the home from the intrusion of unauthorized persons. But the constipation in them is weak, so there is a need to install a new locking mechanism on a different type of door. The need to put a lock on a metal door may arise for other reasons.

When buying metal doors, losing keys or having a desire to install a new lock on a door of a better model, you have to look for it in stores. It is not recommended to buy a cheap Chinese-made mechanism and door leaf. Experienced experts advise you to opt for products of Spanish, Israeli and Italian manufacturers. They are of high quality, reliability and long service life.

Products are divided depending on the type of mechanism, the level of secrecy and the degree of reliability into:

- level;

- cylinder;

- disk;

- crossbar;

- magnetic;

- electronic.

Most often, locks are installed on the door with lever and cylindrical mechanisms.

Good locks are produced by the Russian companies Polivector, Gerion and Elbor. Products must be with an additional handle. It fixes the door leaf in the closed position. It is better to purchase models with lever and cylinder mechanisms. When installing locks in metal doors, it is necessary to take into account the thickness of the leaf. For reliability, you should choose products of the third, and even better - the second class.

There are several categories of door locks. They are usually divided into 4 classes. The highest quality ones belong to the 3-4 safety class. And they cost more. First class products are the easiest to hack. The second and third classes are of average degree of reliability. They can be used at home. Installing a lock in a metal structure is better than the fourth or third security class.

Locks are mortise and overhead. Mortise structures are inserted into metal doors with their own hands. Lever mechanisms provide reliable protection of the apartment from the penetration of uninvited guests into it. The principle of operation is based on the presence of iron plates in the mechanism. Each plate has special curly cutouts. The degree of reliability of the device depends on the number of cutouts.

Cylinder models of products are very popular. They include pins equipped with springs. A lock of this type is most often inserted into an iron door. A failed core can be replaced. The most secure and reliable door locks are code locks. They are installed in office doors. The code set and the magnetic reader provide high reliability and quality of the lock.

Required Tools

To install the lock yourself quickly and correctly, you need to prepare for work in advance. To do the job you will need tools:

- chisel;

- bit;

- screwdriver;

- metalwork hammer;

- drills for metal;

- Bulgarian;

- electric drill;

- chisel;

- square;

- pencil;

- fixing screws;

- self-tapping screws for metal;

- file;

- roulette;

- cutters;

- screwdriver;

- tap.

When working, you need to follow safety rules, so you need to prepare protective equipment. These include goggles and dielectric gloves. They come in handy when working with power tools. Goggles protect your eyes from sparks and metal chips.

How to embed a lock in a metal door?

Inserting locks into a metal door is a difficult and responsible task. It can be handled by a person who knows how to handle measuring and electrical tools, who has experience working with metal. All operations are carried out with great care and accuracy. The work consists of separate stages.

The first step involves preparing the right tools. The next step is to choose the location of the mechanism: it is located 1 m from the floor level. You can raise it to a level of 1.5 m. At this distance, the body of the mechanism leans against the end of the canvas and tie-in points are outlined. Now you need to take a drill, the diameter of which is equal to the thickness of the lock, drill holes on the upper and lower boundaries of the device. The grinder cuts a hole exactly according to the markup. The edges are processed with a file.

The main stage involves inserting the body into the resulting groove. To do this, you need to mark the places for the mounting screws. They are drilled with a drill of the appropriate diameter and a thread is cut with a tap. With the help of a grinder and a drill, large holes are made for the keyhole and the handle on 2 sides of the door leaf. After that, the mechanism is finally inserted into the groove and fixed with screws. The lock and all its parts are set in motion with the keys several times to check the quality of the work done.

After the main steps, you need to mark and install the overlays. The crossbars are rubbed with chalk and tightly close the door leaf. With the help of a key, the crossbars are moved so that traces of chalk remain. They will show where to drill holes for the crossbars. A counter plate is installed on top. After each operation performed, you need to check the operation of the mechanism.

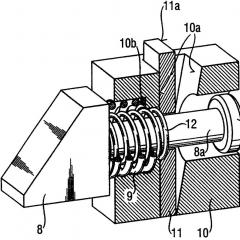

The overhead lock is installed less often. This is done a little differently. The mechanism of the device is located above the door leaf. It must be well fixed on the surface of the canvas. All work is carried out in the following order:

- The lock is applied to the canvas for marking.

- Mounting pins are installed.

- Through holes are drilled for the well.

- The mechanism is fixed on the installed pins, its operation is checked.

- The lock is finally fixed on the canvas.

- An overlay is attached to the back.

- The crossbar fixation block is screwed to the opposite side of the door frame.

If you are not afraid of the listed conditions for installing constipation, you can get to work. With a lack of skills and knowledge, the best way out is to entrust the work to the masters.

In conclusion, it is worth giving advice from experienced people and craftsmen involved in installing locking devices in doors professionally.

- High-quality constipation is an excellent protection of the apartment from uninvited guests. But along with it, you should not abandon other methods of protection: video surveillance, alarms, etc.

- When installing the mechanism, it is necessary to check its operation at each stage of marking and installation. Any violation in the marking and drilling of holes can completely disrupt the operation of an expensive locking device.

- The installed mechanism must be constantly monitored. It must be periodically lubricated, as the old coating gradually loses its properties.

- The crossbars are processed with liquid formulations in the most extended state. After that, you need to push them to their original position for 30-45 seconds. The procedure is repeated 3-4 times.

Before buying a product, you must follow the selection rules:

- expensive, but high-quality lock is better than 2 cheap ones;

- 1 constipation - not enough, 3 - bust;

- it is better to install 2 different types of devices on the door;

- a cheap model is an extra headache.

Embedding a lock in the door leaf is a simple task. But only a knowledgeable person with experience can install a lock on a metal door. When installing, you need to take into account the thickness of the metal sheet on the canvas. Otherwise, you can ruin both the lock and the door itself. And this will lead to higher cash costs. It is better to entrust this work to professional workers.

When buying a metal front door, the product comes with a lock already installed. In the case when the manufacture is done by one's own hands or it becomes necessary to increase the safety of the home by installing another locking mechanism, all work can be carried out without the involvement of specialists. To do this, it is enough to study the intricacies of the installation process, prepare the necessary tools and select the appropriate lock model.

Inserting a lock into a metal door, with a tool, is a real task for an amateur

To achieve a positive result, it is not enough to know how to properly install a lock of one modification or another, you will need a tool suitable for working with metal:

- The main thing that will be used for tie-in is an electric drill with 12-18 mm metal drills and a nozzle for screwing fasteners.

- To cut rectangular segments into which volumetric internal parts of the lock will be installed, you must have an angle grinder or a simple grinder with metal discs.

- You can not do without a measuring tape or construction tape measure. You can use a simple ruler.

- A pencil or marker will be needed for marking, which should be done before installing the structure itself. The accuracy of the location of the lines can be controlled with a square and a caliper.

- Additionally, to process the edges of the cut, you may need a coarse-grained grinding stone in the form of a nozzle for a drill or a simple file.

- Installing a door lock in a metal door is impossible without auxiliary tools such as pliers, a screwdriver, a hammer.

Inserting a lock into a metal door does not require a particularly expensive tool.

When it comes to consumable components, it is better to purchase them with a margin. A disk or a drill for metal in the singular will be able to cope with all the processes when installing a locking mechanism on a door made of thin metal. A thick steel plate will require a lot of effort and consumables.

Once everything you need is prepared, you can begin to deal with suitable devices and installation methods for each of them.

Castle selection

When choosing a lock for an entrance metal door, you should pay attention to the indicators of safety, reliability and protection of the mechanism from breaking. Only after that you can choose the model you like according to external characteristics.

First of all, when choosing a lock for the front door, you need to pay attention to the security class, i.e. the complexity of the hacking mechanism. According to these criteria, products are divided into 4 categories:

- - 1st class - the weakest models that even a novice cracker can handle;

- - Grade 2 has a more complex mechanism, but for an experienced burglar, 10 minutes will be enough to open it;

- - 3rd class is quite reliable, requiring some effort and time, if there is a desire to open it without a key;

- - Grade 4 is the safest, skills and a simple master key will not be enough for hacking, here you will have to use special equipment and spend a lot of time.

In fact, you can pick any lock, it's all about how long it can take

Another characteristic of security is secrecy, i.e. the number of possible combinations required to open the locking mechanism. There are 3 levels of security:

- Small, including 5 thousand combinations. Such locking structures are equipped with additional means of protection.

- The average can support up to a million combinations. It is difficult to pick such locks.

- Products with a high degree are almost unique. They can have up to 4 million combinations and are equipped with additional protective mechanisms.

Key and combination locks of the same class do not differ much in the number of possible combinations, but code systems are an order of magnitude more expensive

For an apartment, it will be enough to purchase a lock with 2 or 3 security class and with an average level of secrecy. For the door of a private house, it is better to give preference to more complex structures, while installing 2 or more locks.

Types of castles

There are many types of locking mechanisms designed to be installed on front doors. From a wide range, only a few are inserted, inserted, such locks are inserted into metal sheets, taking into account the design features of the products.

Cylinder English locks

If there is a choice of which lock to install in a metal front door, designs with cylinder cores take the lead. The weak point of such a mechanism is the larva, which, if desired, can be knocked out or drilled out, therefore, an armored plate is almost always installed inside the door leaf.

The opening key has the usual flat appearance. It is equipped with notches and notches that act on the cylinder rings. Even if one notch does not match the secret combination, the mechanism will not open.

Overhead installation or tie-in of this type of lock is simple. The product package includes a diagram of the location of fasteners for drilling holes and installation instructions.

A distinctive feature of the English castle is a removable cylinder-type larva

Lever plate locks

Another popular locking mechanism is the lever lock, the key to which is in the form of a rod with small plates along the edges. When using such a key, the impact is made on the levers inside the product, which set in motion powerful crossbars. The number of these elements may vary.

Lever locks of different types differ in installation - the installation of a patch lock on a metal sheet is carried out from the inside together with a counter plate, and armored trim is placed on the outside to protect against cutting the crossbars. Mortise models are inserted into the hole from the end of the web. On the outside, there may be one hole for the key and an additional one for the handle.

Lever models are considered the most protected in terms of resistance to mechanical stress, in other words, to knocking out

Electronic locks

Constipation with the presence of an electronic component is gaining more and more popularity. Two types of such devices are suitable for entrance doors:

- Electromechanical locking mechanisms are a variation of crossbar protection systems. Instead of a key, they use remote controls, magnetic cards, programmed codes, etc. Some modern models are equipped with fingerprint scanners. To open such a mechanism, you will not be able to use the master key. You will need special equipment and time.

- Electromagnetic devices are similar to intercoms. The holding of the door plate is carried out by means of an electromagnet, which is turned off by the controller. To open it, you need to have a magnetic key or code.

Electromechanical locks can have different coding systems and keys, but the locking mechanism is always mechanical, while there is no mechanics in the electromagnetic system

The disadvantage of designs with electronic mechanisms is the dependence on the power supply, so it is recommended to additionally supply a simple model for protection during a power outage.

Mortise model installation

Do-it-yourself mortise installation of a lock in a metal door involves not only drilling holes for a handle and a well, but also cutting a piece of metal from the end of the leaf to install the mechanism. The process is time-consuming, requires attention to detail and patience.

The main steps on how to embed a lock in a metal door:

- At the desired height, mark the location of the lock with a pencil or marker.

- Using a pattern or measuring the dimensions of the inner part of the product at the end of the canvas, the boundaries of the groove are indicated.

- 4 holes are drilled at the corners of the rectangle. To ensure accuracy, the marks are first punched. Then, with a grinder, an unnecessary piece of metal is cut out.

- The lock is inserted into the groove and the location of the fasteners is marked. Holes are drilled under them and threaded.

- Determine the location of the well and handle. Drill holes of the desired diameter under them.

- With the help of a file or nozzle for a drill, metal is ground in the places of the holes formed.

It doesn't really matter which type of mortise lock is used, the technology is always the same

- The lock is installed in the specified sequence in its place. Check its functionality.

- Inserting locks into metal doors implies the presence of a counter plate, for which recesses for crossbars and fasteners are drilled on the box.

Rim lock installation

Overhead installation of locks in a metal door is much easier than a mortise one, since all structural elements are located on top of the canvas. To implement the process, you need:

- Apply markings that will show the location of the holes for the fasteners and the well.

- Drill all the necessary holes from the inside of the canvas and one through for the keyhole.

- Fix the position of the locking mechanism with pins. Check its functionality and screw the housing.

- On the outside of the door on the well, install the overlay.

- Mark the location of the counter plate and mount it.

Overhead locks are easier to install than mortise locks, but their level of security is lower

In order to properly install the lock on an iron door, you need to carefully monitor the mirror location of the device with a counter plate, otherwise the crossbars will not be able to enter the holes intended for them.

The best door security is achieved by using a mortise lock. Overhead locking mechanisms are used much less frequently.

Experts recommend locks with a cylinder or lever mechanism for use. Cylinder mechanisms are quite easy to use, and lever mechanisms are more resistant to breaking. You can install locks with various types of mechanisms on one door, this will be the best option.

When buying a domestic product, you need to pay attention to its certificate. It should be remembered that a cheap lock is by no means always reliable. The poor quality of the lock can make it difficult to insert and further use.

Required Tools

If you need to insert a lock into an iron door, you should not rush to call a locksmith, you can do this work yourself. To install the locking mechanism, you will need the usual set of tools, which every prudent owner probably has at home:

Before starting work, it is necessary to understand that inserting locks into metal doors requires certain training and knowledge from the home master. Otherwise, this process is best left to a specialist. If you are confident in your skills, you can safely get to work.

Sequencing

The correct insertion of the lock into the metal door is carried out in several stages:

- Marking for determining the location of the lock in the door. To do this, you need to measure 800-1000mm from the bottom of the door leaf and make a notch on its side. Then you should attach a lock to the door, mark and drill in two places the extreme holes for the entrance of its body. This operation is performed with a hammer, punch and drill. Thanks to the traces of the center punch in the metal of the door, the drill bit will not slip from the intended points. The diameter of the drill is selected a couple of millimeters larger than the thickness of the lock.

- Cutting out the mounting hole. To do this, using a pencil or a sharp object, the edges of the holes obtained must be connected with lines, indicating the cut mark. Then, using the "grinder", it is necessary to make two slots according to the markup to obtain the mounting hole of the lock. As a result of this operation, the middle usually falls out with the formation of an oblong hole. In the case of making a door frame from a profile pipe, the hole will have to be cut from both sides.

- Cutting a hole for the lock cylinder. This work begins with markup. Using a tape measure, you need to determine the distance between the keyhole and the edge of the lock, and then transfer it to the plane of the door. At the same time, you can mark the hole for the door handle. Before drilling a hole for the cylinder mechanism, you need to outline its outline, and then drill many small holes along it with a thin drill at the closest distance from each other. When the process is ready, using a drill as a cutter, the holes must be combined into a slot. The released piece of metal should be removed and a lock equipped with a cylinder should be tried on. If necessary, the hole can be slightly bored until the cylinder freely enters the lock body.

- Cutting a hole for a doorknob. This is not difficult: if precise markings were made for its location, it remains just to drill a hole of the appropriate diameter for the handle with your own hands.

- Lock installation. This stage of work is carried out when all the mounting holes of the door leaf are ready. To install the lock, you need to insert it into the seat cut out at the end of the door leaf and fix it with self-tapping screws or screws from the lock kit. Then you need to insert the cylinder mechanism and connect it to the lock body with a screw from the side of the long end of the door leaf. The operability of the lock and the soft movement of its crossbars are checked using the door key. With the correct installation of the mechanism, the door should unlock without interference.

- Installation of handles and pads. When the installation of the main mechanism is completed, you need to fasten the handles and linings. It is made using the screws included in the lock kit. In their absence, the linings are attached to the door with self-tapping screws.

- Cutting holes for lock bolts. These holes are made in the door frame and are intended for the bolt and latch of the lock to enter it when the door is locked. The process requires precise markup. To do this, you need to put a striker on the lock bolts and, with the door almost closed, mark its position on the door frame. Then the bar again needs to be attached to the box, mark the location of the reciprocal holes and drill them with a drill. The width of the slot should exceed the size of the bolt by 1-2mm. After obtaining the desired hole, it should be closed with an overlay, which is fixed in place with self-tapping screws.

That's all science. In this way, you can equip the door with a reliable locking mechanism with your own hands, which will last for years and protect your home from uninvited guests for a long time.

Often there are situations when you need to install a lock on a metal front door. This is necessary if it is made by hand, it is required to embed a second locking mechanism for greater protection. The easiest way to do this is to call a special service, but in most cases, installing a lock in a metal door is not so complicated, so installation can be done on your own. This will save you some money.

Selecting and buying a locking mechanism, one or two, is the first step in installing it. Locks differ among themselves in the class of resistance to burglary, the higher the category, the more protection the mechanism guarantees and the longer the attackers will have to tinker with it.

For an apartment or a country house, it is worth getting locks of 3 or 4 stability classes, products of lower categories (1 or 2) are only suitable for utility rooms.

If the product is not marked with a burglary resistance class, you should not buy it.

It is possible to install locks on the entrance iron doortwo types:

- Cylinder. They are widespread. Their design provides pins of a specific shape, as well as a key with reciprocal recesses for them. This type of lock has a disk code mechanism. Despite its complexity, the larva of such a device can be quite easily damaged - knocked out. Therefore, it is worth purchasing premium-class products that include an armor plate. It protects the mask from being knocked out.

- Level. They got their name because of the plates (suvald). At the time of opening the castle, they line up in a clear order. The more levers, the more reliable the lock (its protection class is higher). Armored plates are also installed in such locks.

Since each type has its own specifics and disadvantages, the best option is to mount two locks with different mechanisms in a metal door. This will provide the maximum degree of property protection. But the whole process takes a lot of time. In this case, a specialist will help to solve the problem. The master will install locks on a metal door quickly and efficiently.

In addition to mechanical locking mechanisms, electronic locks are installed in the iron door. They open with a remote control, a magnetic card, the most modern models respond to a fingerprint.

According to the method of installation, locks on an iron door are divided into the following categories:

- Overhead. Almost the entire castle is located outside the sash. Installing it is quite easy on your own.

- Mortise. The most common option. To install a lock in an iron door, a hole is cut out in the canvas. Outwardly, this is the best option, since the lock is not visible.

- Embedded. The insertion of locks into the iron door is carried out in the sash at the stage of product assembly at the factory. It is quite problematic to replace or install such a lock on your own; you will have to completely disassemble the sash.

- Mounted. This type is not used for residential premises; it will fit only for change houses or outbuildings. For its installation on a metal sheet, lugs are welded.

You should not buy cheap products, otherwise you will have to spend money later on repairing or replacing them. It is better to purchase one high-quality and expensive high-class security lock than two cheap and easy-to-open ones. In addition, cheap mechanisms begin to seize after a short period of operation. That is, again you will need to put a lock on the front metal door.

But you should not rush to the other extreme and mount as many locking mechanisms as possible in the canvas. The insertion of each of the elements gradually weakens the sash. Therefore, experts do not advise mounting more than 2 locks. For maximum protection, it is better to install two doors to the apartment (entrance and vestibule).

Instrument preparation

To insert a new lock on a metal door or replace an old one if it breaks, complex tools are not needed. You will need a grinder and a drill, a screwdriver. To drill, you should purchase drills of 12-18 mm in diameter. It is also good to have a coarse-grained grinding stone, so that, if necessary, you can easily expand the technological holes, polish them, removing roughness.

You also need a file, screwdrivers, a tap for threading. For marking, it is worth preparing a tape measure and a pencil. From the fasteners, it is necessary to make a stock of self-tapping screws and screws. That's the whole set, it can be found in the house of every owner.

The difficulty of installing a door lock on a metal door is only that you will have to work with metal of considerable thickness and strength. For overhead and mortise locks, the installation method is slightly different.

When carrying out any repair work, you must not forget about your safety. Therefore, it is better to work with protective gloves, and wear goggles when cutting metal.

Scheme of mounting a mortise type lock

To insert a lock into an iron door, you will need to drill several holes: they are needed for the handles, the mechanism itself, and also for the well.

Insertion of the lock in the entrance iron dooris performed in the following sequence:

- Mark the location of the castle. The most convenient height for its installation is from 1 to 1.5 m. You can also place the lock, retreating from the floor 80 or 90 cm.

- In the end area of the sash, mark the edges of the groove. From each end of the markup made, make small indentations with a drill, then between them you will need to make a notch with a grinder. To prevent the drill from “driving” through the metal, you can first make light dents with a core and a hammer. For drilling, it is important to choose a drill of the appropriate diameter, it should be taken 2 mm larger than the thickness of the lock.

- Cut a hole for the lock. Connect the drilled edges with lines. Now you have to work as a grinder, it is better to use a small tool. If the door is made of a profile, then a hole will need to be cut on both sides. For such work, a small grinder is the best fit. After making the hole, be sure to file the edges so that they are even.

- Make a hole for the lock cylinder. At the next stage of inserting the lock into the entrance metal door, it is necessary to calculate the distance from the well to the edge of the device, transfer the marking to the sash. Also at this stage, you need to make markings in order to install door handles later. On the canvas, it is best to draw the outline of the castle, and make small holes with a small step along its perimeter, which are then connected into a single whole. After the slot is made, remove the metal, insert the lock (try it on), if necessary, bore the hole to the desired dimensions. This can be done with a drill equipped with a small abrasive wheel. The cylinder should fit well into the lock.

- Make holes for fixing the handles. It's simple: just drill holes of the required diameter.

- Place the mechanism in the door leaf body, mark the points for its fastening. For fixing screws, make holes, then form a thread in them with taps.

- Mount the lock. Insert the iron door lock (into the prepared slot), fasten it with screws or self-tapping screws. Often fasteners are included with the device. Then install the cylinder, connect it to the lock. This will require a long screw that is inserted from the end.

- After tightening the screws, check if the lock works properly. If everything is in order, mount the door handles, lining. Lubricate the core with machine oil or other lubricant, check how the crossbars work.

- Now you need to make a reciprocal hole in the box, which will include a latch and a deadbolt. First, mark up, you need to do this as accurately as possible. You can hang a reciprocal plan on the bolts of the lock, cover (close) the sash as much as possible and mark the edges of the answer in this position. Drill appropriate recesses for the crossbars in the door frame. Fix the answer.

To avoid any shifts, it is necessary to regularly check the functionality of the mechanism as the lock is installed.

After inserting the lock into a metal door, for the normal operation of the mechanism, it is important to periodically clean it from dust, dirt, and lubricate the mechanism. Lubrication is already present in new products, but those that have worked for several months require maintenance. To lubricate the crossbars, you need to push them to the maximum, distribute the lubricant over them, push them back. After 40 seconds, repeat this procedure again. Do this 3 or 4 times. Also, for the normal operation of the locks, do not allow the sash to sag. To do this, you need to adjust the loops and adjust their work, select canopies that are suitable for the mass of the canvas.

The order of installation work for the overhead lock

This version of the lock is easier to install, since the main part is on the sash, and not in the middle.

To install a lock on an entrance metal door, you will need to perform the following steps:

- Attach the lock to the sash, make marks for its fastening, wells and all other elements. Locking devices of this type are usually installed higher than mortise ones. This is done in order to make it more convenient to use the latch.

- Mount pins for fastening on a metal sheet.

- According to the marking, make a hole for the well to exit to the outer side of the leaf. Fix the overhead lock with pins from inside the room.

- Check how accurately the mechanism works. If there are no problems, finally fix its body on the sash. Mount the trim on the outside of the door.

- Make a reciprocal recess in the box, thread, install the patch block. It is necessary to fix the crossbars. It is important to do everything correctly, otherwise the crossbars will not fall into the corresponding recesses.

You can put a lock on a metal overhead door on your own without any special skills. It is much easier to do this than to embed it. The process itself takes a little time.

Replacing a cylinder lock

Installing locks on an entrance metal door equipped with a cylinder mechanism is very common, since in the event of a breakdown there is no need to insert a new lock. It is enough to replace only its damaged larva.

The core is made in the form of a cylinder; updating such a device is not at all difficult.

- First you need to remove the spent larva.

- After that, using a special key, you need to open the mechanism. No other elements of the lock need to be removed.

- From the side of the end, unscrew the screws with which the lock plate is fixed.

- Use the key to close the device. Unscrew the screw in the center of the tongue.

- Turn the key 40 degrees and pull the larva up.

If the core of the lock is damaged, then you will have to drill it out and then knock it out of the mechanism.

Replacing a lever type lock

There are a lot of manufacturers of lever locks, but when choosing them, European brands should be preferred, since they are much easier to repair. If such a device fails, then you need to change its spent core.

To install a lock of this type in a metal door, it is necessary to dismantle the existing housing. To do this, open the door so that the crossbar elements are visible. After dismantling the lock core. It is necessary to remove the armor plate, deadbolt, handle and key. Decorative elements do not need to be removed.

After that, unscrew the fixing screws, remove the old part. Then install a new core, fix it. In some cases, it is not necessary to replace the lock element, and for its better operation, it is enough to simply recode the mechanism using a special key and instructions that come with the product.

Features of the electromagnetic lock

These types of devices differ significantly from level and cylinder. They include two parts - main and counter plates.

Inserting a lock into a metal doorconsists of several stages:

- The first step, as in the case of any similar work, is to mark the installation site. First you need to attach the case to the door leaf. Glue the stencil in the place where the response plate will be located. After that, mark the points where the fasteners will be installed.

- The next step is to drill a suitable size hole for them. Fix the plate on the metal sheet with special washers. To ensure sufficient strength, you need to install a pair of washers on each screw. The steel washer is screwed on first, then the rubber washer. This ensures a tight fit of the core.

- Choose a place where the corner of the device will be located. Combine the main part with the anchor element. Use a hexagon to fix.

- Loosen the fixing screw slightly to check the correct installation. So it will turn out to release the response plate.

After that, you can connect the power supply and check how well the lock works. The main condition is the correspondence of the plate and the base. With any displacement of parts, the mechanism will not work. To make it easier to install the lock on the front iron door, you should first study the instructions for it, watch the training video.

If there are no skills in the installation of electrical mechanisms, then in order to insert a lock into an iron door, it is better to call the master. He will do everything quickly and accurately.

A metal door is the best defender of an apartment, country cottage or industrial premises. But it will begin to fulfill its security functions only when the locks in it are of a high class of resistance to opening. It is quite possible to put a lock on an iron door on your own, it is enough to have a set of ordinary building tools and do everything accurately and accurately. It is better to install two different locks, then you can be sure of your safety.

Installing a lock on a metal front door is not the easiest thing to do, requiring a competent approach. Therefore, those who are not confident in their abilities or have never encountered such work at all, it is better to call a professional. For those who want to do everything themselves, we recommend that you read our article.

Choosing a castle

Be patient before starting the installation and choose the lock itself, which will serve faithfully for years. Finding a good castle is not so difficult these days. It is important to know what exactly you want to buy. In turn, we will help you make the right choice and tell you about the main types of locks installed on the front doors.

Now, taking into account technological progress, all locks that can be inserted into a metal door are divided into three groups - cylinder, lever and electronic.

All locks differ in class - locks of 3 and 4 security classes are considered the best, but locks of a smaller class should be purchased for less significant doors. The same locks, on the packaging of which there is no indication of the security class, it is better not to purchase.

The most common are cylinder locks, the design of which involves the presence of pins of a special shape, and a key with reciprocal holes for them. Locks of this type, designed for entrance doors, have a disc coded mechanism. These discs and the key have comparable notches and grooves.

No matter how difficult such a lock may be in terms of secrecy, it will not cause problems for burglars, since the lock cylinder can be easily knocked out with a strong blow. However, high-end locks usually have an armored tab that protects the mechanism from this method of breaking.

Lever locks are named so because of the levers - steel plates that, when the lock is opened with a key, line up in the order specified by it. The more such plates in the mechanism and the better the material from which they are made, the higher the class of the lock. These locks are also equipped with an armored tab, so you can't handle them with a kick from the foot. However, a master key can be picked up for this type of locks.

Locksmiths are advised to purchase and install two locks of different types on the front door for greater reliability.

Electronic locks due to their ingenuity and relative novelty in the market are more expensive than the previous two types. Some locks can be opened with a magnetic card, some are opened with a remote control, and some with a code on the keyboard.

Particularly wealthy residents can afford the luxury of locks that recognize the owner by a pattern on a finger or retina.

Installing a lock on a metal door

If you need to install or reinstall a lock on a metal front door, you will need a screwdriver, an electric drill, a grinder, drills, metal screws, taps and files. In addition to them, you will need a carrying case corresponding to the power of the power tool, as well as safety glasses and dielectric gloves.

When choosing a lock, pay attention to the thickness of the metal sheet on your door. A lock that is too strong can damage the door if the material thickness is less than 3-4mm.

It is best to embed a lock in a metal door. So you will hide and protect the lock mechanism from harmful external influences. If the lock bar is installed on the end of the door, then you can install such a lock yourself. If the lock has increased reliability and will be hidden in the door so that you can only see the crossbars at the end, it is better to trust the professionals. Believe me, such a lock is worth the additional cost of the work of the master.

In this case, we will not consider overhead locks - the inside of the door is too unreliable to secure such locks, and the appearance of the door and the hallway will suffer.

Instructions for inserting a door lock (video)

First, outline the place where the castle will be located. The best height for him from the floor level is 90-110cm. The marking should be carried out according to the dimensions of the castle.

Using two drilled small holes, mark the upper and lower borders of the mortise area of the lock.

Next, a grinder with a cutting disc comes into play - two cuts are made from top to bottom along the vertical marking lines. If the resulting hole is slightly smaller than necessary, cut off the excess and clean out the burrs with a file.

Now you need to insert the lock and outline the location of the mounting screws. Holes are drilled for them, and threads are cut with a tap.

The diameter for the screws is made a little smaller than necessary - usually this difference is 0.2 mm.

Now you need to attach the lock to the door on both sides and outline a place for the keyhole. This place is drilled and cut through with a grinder.

Now the lock itself can be inserted into the door, fixed with screws and checked for readiness for operation.

We attach the lining to the door, insert the key into the lock and mark the places where we will make holes for their fastening with self-tapping screws.

The tabs on the door are fixed on both sides, and the lock itself is again checked for smooth operation. The wrench should turn easily and not wedge overlays.

Holes for crossbars must be marked with special attention. If the ends of the crossbars are smeared with something coloring (paint, chalk), the door can be closed and the key turned all the way. The necessary contours and marks will remain on the counterpart of the door.

The holes for the crossbars are drilled with a drill and cut out by a grinder. The same applies to the installation of overlays.

Are there other lock options?

When buying doors with an already installed electronic lock, you will be spared the opportunity to tinker with installing the lock. It remains only to come up with an electronic digital key.

Once you come up with a code, save it in your head. Now no one can open the lock except you, even the master who installs the door and connects the lock.

True, if you are well versed in electronics and electromechanics, it will be even easier for you to install such a door yourself than a conventional mortise lock.