Traditional and new mason's construction tools - overview and description. Brickwork Equipment and Tools

Construction tool - Trowel

The main tool mason, is considered a trowel, as well as a level. This is the main instrument symbolizing construction and repair. It looks like a small, steel spatula, polished on all sides, with a comfortable wooden handle. Its main purpose is to level the mortar on the masonry, clean the seams from excess mortar and fill vertical joints with it.

Construction Tool - Hammer Pick

The second essential attribute is a hammer-pick, which is necessary for a mason to cut solid bricks into half or three-quarter pieces, as well as for trimming them.

Construction Tools - Jointing

Joining serves to clean the seams and give them an aesthetic shape. The size of the jointing, as well as the profile of its cross section, must have the required shape and thickness of the mortar joint.

Mopping

Construction and renovation of large residential and industrial buildings involves work on arranging ventilation ducts. A mason's tool such as a mop is used to clean ventilation shafts from mortar protruding from the seams into the interior, and to fill the seams more densely with mortar. To do this, a rubber plate is attached to the mop handle, which is used to clean and fill the seams.

Quality control

Plumb

The remaining tools are used by the mason to control the quality brickwork, and they belong to control and measuring instruments. The most common of them is the plumb line. Using a plumb line, the mason controls the verticality of walls, piers and corners. Plumb lines with a mass of 200-400 grams are used to control the vertical within a floor or tier. Plumb lines with a mass of 600-1000 grams are used to control the verticality of the outer corners of several floors.

Construction Tool Level

Also, to control the vertical and horizontal, the mason uses a level. Construction tool levels are available in different lengths - from 300 mm and more. To do this, the corresponding “flasks” are fixed in the level body, slightly curved in a circle of large radius and filled with non-freezing liquid with a small air bubble. In a strictly horizontal and vertical position, the air bubble, tending upward, is installed in the center between the divisions on the “flask”. The displacement of an air bubble in any direction indicates that the surface being tested is not ideal. And the greater the displacement of the bubble from the center, the greater the error of the surface from the horizon or from the vertical.

Construction Tool - Rule

Often the mason needs to use a rule. The rule is a perfectly straight and smooth wooden strip, with a cross-section of 30x80 mm and a length of 1.5-3 m. Nowadays, it is produced in the form of a metal strip made of aluminum alloy. This tool is used to check the straightness of the facing masonry. Often, in conjunction with the rule, the mason uses a square, which checks the correctness of the laid angles. The square has different side lengths with dimensions of 500x700 mm.

Construction tools - Cord-mooring

For versts of masonry, between beacons or lines, the mason uses a mooring cord. It is an ordinary cord with a diameter of up to 3 mm. The mason uses this cord as a guide to check the evenness and horizontality of the rows in the masonry, as well as to check the thickness of the horizontal joints. The cord helps you find your brick location in a row.

Construction tools - Arrangement

For correct marking of rows in masonry and fixing the upper and lower marks of window and doorways, as well as lintels, etc., the mason applies the order. This is a flat wooden strip with a cross-section of 50x50 mm and a length of about 2 meters, which has serifs on itself corresponding to the thickness of the row and located every 77 mm. This size consists of a brick height of 65 mm and a mortar joint thickness of 12 mm. The order is fixed to the surface of the wall opposite from the mason, so that the side on which the serifs are located is visible to the mason. Most often, this outer part walls of the building, as the master works from the inside.

For many generations, mason builders continue to use all of the above traditional tools. But modern construction buildings, as well as modern renovation, of course, cannot do without the introduction modern technologies and tools, but along with traditional equipment, modern masons use various power tools. For example, for cutting bricks, angular grinding machines with diamond cutting wheel. To check the horizontal and vertical, a construction tool increasingly comes to the rescue - a laser level and much more.

Everyone knows that brick has been used for over a thousand years. Even in ancient Babylon, real masterpieces were made from it. Therefore, brick has received a lot of attention in history. And here masonry tool attracted attention much later, and it was connected with mysterious events.

The tradition of honoring bricklaying tools goes back to the times of the Masonic lodges, and even then the “free masons” honored the tools - Master OK, compass, square, plumb line, hammer and cutter. As you know, a mason in medieval England was considered a privileged citizen and his tool was the main means of subsistence, as well as the guarantor of his freedom. After all, only construction workers were allowed to move around the country freely. At first, free masons formed a kind of artel, and then it grew into Masonic fraternity, which became secret and then swept the whole world. Since then, the tool for a mason has acquired a certain hidden meaning and true professionals treat it with special respect. This is where the special attitude towards these seemingly simple devices came from.

Today trowelsfor brickwork And picks they no longer carry mystical meanings; they help the builder to build walls faster and with better quality. Do not deny yourself the pleasure of purchasing high-quality tools so that the work is easy and proceeds at a rapid pace. In order for your instrument to begin to work miracles, you need to take it seriously, perhaps then you too will receive an invitation to visit the mysterious order.

If brick or blocks If you have already chosen, and all that remains is to buy them, then it’s worth taking a closer look at the tools. The basic dogmas of brickwork can only be observed with the use of high-quality assistant devices. We will tell you about the necessary masonry details so that you can raise brick walls with your own hands. The Masons believed that the world was ruled by the great architect of the world and the builder of man, and today you can become the author of the whole world of your new home. To do this, you need to study the brickwork algorithm and understand its essence, then your wall will be strong and reliable, because everything that is done with an understanding of the essence becomes a masterpiece.

Brickwork algorithm

According to building codes and regulations, after the foundation is laid out, the construction of the “box” of your house begins. Those builders who start it without proper preparation quickly hit the first bumps and begin remodeling. But you and I approached the process responsibly and creatively, so correct masonry interior and exterior walls are just around the corner. Before we begin practical manipulations, let’s break down the brickwork algorithm. First, let's look at the sequence of operations. The entire masonry process consists of a number of work processes:

- Setting up orders;

- Tensioning mooring cords to ensure correct laying of bricks and rows;

- Feeding and laying out bricks on the wall;

- Mixing the solution in the box with a shovel;

- Supplying the mortar to the wall and spreading it outwards;

- Laying the outer mile;

- Spreading the mortar under the backfill;

- Laying the backfill;

- Checking the correctness of the laid out row of masonry with a level.

Orders and mooring lines

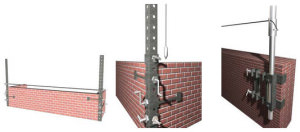

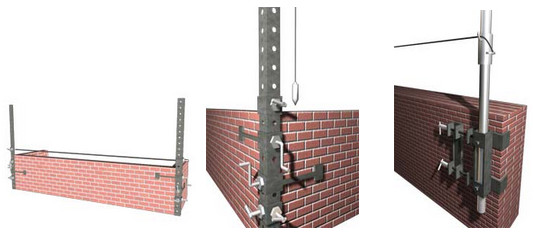

Let us pay attention to the terms; they are named by domestic builders; Masonic lodges are unlikely to have any idea about them. Orders are devices made from corners, pipes, slats and corner profiles with divisions corresponding to the thickness of the horizontal rows of masonry (77 mm for single and 100 mm for thickened bricks). They are designed to secure mooring line(berths) and ensuring the verticality and horizontality of the rows of laid out walls.

Builders mark the bottom and top of window and door openings, lintels, purlins, floor slabs and other building elements in order. Orders are used for marking rows of masonry, fixing marks of the bottom and top of window and door openings, lintels, purlins, floor slabs and other building elements.

Orders installed before the start of masonry on the corners of the building, at the junction of walls, and on extended sections every 12 meters. The correct installation of the rows must be controlled by a plumb line, and only after you are sure that they are level can you tighten the moorings.

Various order designs are distinguished according to several characteristics. Corner metal orders play the role of a template, which, with correct installation and rigid coupling, ensures the verticality of the masonry. Such orders are secured with staples with a screw clamp or hooks. The mooring cord is attached to a mobile clamp or to holes in the rows. After completion of the masonry process, the orders are removed. Intermediate orders made of wood are also used; they are healed with U-shaped staples, which are inserted after 6-8 rows of masonry. Therefore, laying ordinary brick, aerated concrete blocks , and of course, façade decorative brick , without using orders is highly undesirable.

Mooring line, as a rule, is a twisted cord 3-5 mm thick, which is pulled when laying versts between rows and beacons. It is used as a guide for the horizontal consistency of the masonry and its straightness. It also helps to create horizontal seams of uniform thickness. Using a cord, the mason determines the position of each brick laid in a mile. So it doesn’t matter if you bought expensive facing brick ideal geometry or if you are building an extension from rough bricks, you cannot do without a mooring. Smooth walls are necessary in both cases, as the basis of your object, but if the recommended techniques and rules are neglected, no quality brick won't save you. You can purchase working and facing bricks on our website; specialists will quickly create an order and deliver it to any address in Russia and the CIS.

Brickwork Tools

For a Mason, a trowel, compass and plumb line meant building a temple in his own soul. But the builder will only think about the spiritual when he creates his own house. To do this, we will need measuring materials, such as a tape measure 10-20 meters long, a ruler with millimeters, a building level, a plumb line, a folding meter and mooring cords. We talked about the order and mooring cords above - they are the standard form and guideline for raising the walls of your house.

Then basic brick masonry tools:

Trowel- she is also a “trowel” - you need this good friend throughout the entire process of laying block and brick walls. This is a triangular-shaped spatula with a curved handle, which serves to distribute the solution and lay it out. The trowel should fit well in the hand, the handle should not slip; a wooden or rubberized handle is better. The stainless steel spatula itself has a working surface of 17-19 cm. When choosing a trowel, base it only on your own convenience, because only this will make the masonry more comfortable. You can familiarize yourself with the requirements of professionals in GOST 9533-81.

Construction scoop– a spatula for portion feeding of the solution. A mortar shovel (GOST 3620-76) is necessary for spreading a batch of mortar. The solution is also mixed with a shovel and leveled under the rubbish.

Combination hammer- aka pick hammer for chopping, splitting, hewing bricks. On one side he has a mini-pick, on the other there is a striking surface. A hammer of standard length 30 cm. You can use these tools separately.

Masonry jointing- a spatula equipped with a narrow spatula (triangular or semi-oval), which is used for decorative jointing of brick wall joints. Without jointing it will be difficult for you to lay facing brick. Pay attention to the progressive patterns of jointing, which are designed for internal seams. Joints are quite inexpensive, so stock up on them to form convex and concave seams. A chisel and hammer are useful for punching small holes.

Mopping will be useful for cleaning ventilation ducts and openings from dried solution. The squeegee is a square-shaped rubber plate on a steel handle.

Plumb– checking the verticality of walls, piers, columns and masonry corners is carried out using plumb lines. A plumb line weighing 200-400 grams is used to check the masonry in tiers within the floor. A heavy plumb line of up to 1 kg is used to check the outer corners of a building within several floors. To pair it, buy a building level to check the horizontalness of the masonry. When laying facing bricks, do not forget about Rule- This is a wooden or duralumin ruler for checking the front surface of the masonry. They work with the rule as follows: after distributing the solution onto the outer surface, take the rule moistened with water and move it very smoothly, smoothing out unevenness. Clean surfaces with a steel brush, light facing brick It is recommended to clean with a synthetic brush.

Masonry nets

To strengthen brickwork, use masonry mesh. This is a flat, sparsely woven product made of wire with a diameter of 3 to 12 mm. Masonry meshes are reinforcing elements that allow you to strengthen your wall. When using meshes, you can be sure of the reliability of the masonry. Don't be confused reinforcing mesh with polymer meshes to maintain efficiency.

Pay special attention to masonry mesh for hollow bricks. Only such a stack can preserve the effectiveness of hollow bricks during masonry. Now we mean its thermal conductivity. After all, technological voids in the block during laying are often clogged with mortar. And special meshes for bricklaying do not allow the mortar to penetrate into the voids, but also do not interfere with the adhesion of the wall. Masonry mesh is sold in rolls and is unrolled onto each row of bricks or blocks before applying the mortar. In this case, the solution is applied directly to the mesh, in which the smallest cells of the material do not allow the solution to go into the voids. The result is 100% preservation of the thermal properties of hollow bricks, ceramic blocks, and gas blocks. You can buy masonry nets for slotted bricks on the construction market.

After checking all the tools, you can safely begin laying. If you haven't purchased yet wall material, take a look at our catalogues. Even experienced masons will appreciate our range and will notice the many traditional materials and new products in the construction industry. The advantage of our cooperation is that you do not have to waste time ordering and delivering bricks and blocks. Our specialists will do everything themselves, you just receive the building bricks at your site. Delivery advantages work throughout Russia and the CIS. At the same time, we supply bricks in any configuration, and our experienced drivers deliver them quickly and carefully.

When constructing brick structures, masons use hand tools and a variety of devices allowing:

- increase accuracy when laying masonry, maintain the evenness of the seams and the overall flatness of the wall surface;

- make work easier;

- increase work productivity.

Hand tool

The main tool of a mason, used directly in laying masonry:

- Trowel (trowel)- a device in the form of a triangular metal flat blade attached to a wooden or plastic handle. Required:

- applying and leveling masonry mortar;

- removal of excess plastic mass;

- leveling bricks by tamping back side pens;

- filling and grouting joints between adjacent blocks.

- Pick hammer, - the difference from the classical instrument consists in a different form of metal mutual strikers. On one side there is a pointed part, reminiscent of a chisel or chisel, on the other there is a striker in the form of a rectangular block. The sharp end is used to break off small parts from the brick, while the blunt end is used to level the brick on the surface or split the block into two pieces.

- Joining,- used at the final stage of work. Necessary for creating a continuous seam between adjacent rows and giving a decorative look.

Another group of tools belongs to the marking and measuring group:

- plumb line, - used to control the verticality of external and internal walls;

- mooring line, - with its help, the horizontality of the rows of masonry is monitored;

- water level, - is necessary to determine the level of the axes of various corners of the building and check the horizontalness of the seams along the entire perimeter of the building;

- building level, - used for current monitoring of vertical and horizontal surfaces;

- square, - this tool is used to check the squareness of the corners; one of the rulers must be at least 500 mm long (the size of two bricks);

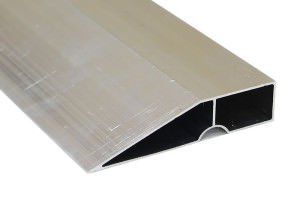

- aluminum rail 2–3 meters long, used for general measurement of the horizon or vertical; can be equipped with water eye controllers.

This entire set of tools was and is used directly in the construction of brick structures. With sufficient experience, such a special set will be enough for a professional mason when working on a garage, one-, two- or three-story houses, or any outbuildings.

The construction of a building, which is subject to increased requirements for the condition of the front surface, will require the use of special devices that increase the accuracy of the work. They will also be useful for a beginner and inexperienced master.

Adaptations

Control of horizontal seams, vertical wall surface and corners is carried out using orders . This device is metal corner or a wooden strip with marked marking lines. The divisions determine the vertical size of the block along with the thickness of the seam. At these points, a mooring cord is attached, along which the horizontalness of the seam is monitored.

The order is mounted on the finished wall, when at least 5–6 rows are completed and the solution has set. Before this, a standard mason's tool and a device for performing smooth masonry are used.

Arrangement on your own

The easiest way to make a tool is from wooden slats, but the strength will not be sufficient. Therefore, it is advisable to use such a device when constructing a garage, outbuildings or a small garden house.

Using a metal corner with verified edges and a shelf of 40–50 mm, you can get a more serious tool. The length of the slats is 1.5–2 meters. The markings are applied based on the height of the block (from 65 mm) and the thickness of the seam (10–15 mm). Under the mooring cord, at the locations of the control points, holes Ø 4–8 mm are drilled.

In the lower part, symmetrically, side supports are attached, through which fixation is carried out with the side walls of the building. The distance between the lower and upper plates must be at least 40–50 cm. The device is aligned using a building level and a plumb line.

Cleaning internal cavities

New chimneys or ventilation ducts are freed from excess solution flows using mopping. This tool is a 14 cm square plate attached to a steel handle 1–2 meters long. In addition to the cleaning function, with a rubber plate, the seams are completely filled and the surface is smoothed with a solution.

Performing smooth masonry

Horizontal and vertical seam, and, accordingly, the accuracy of the entire building structure made of brick, in addition to the skill of the performer of the work, depend on the correct application of the masonry mortar.

An excess or deficiency of the latter leads to curvature of the walls, decrease in strength, disruption of sound and heat insulation. In addition, the moisture resistance of the seams is impaired.

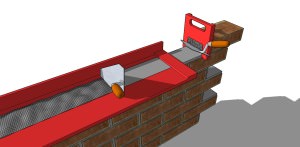

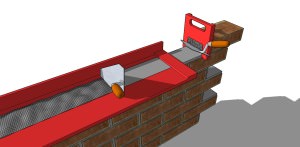

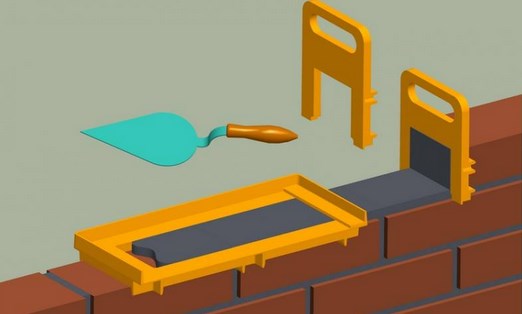

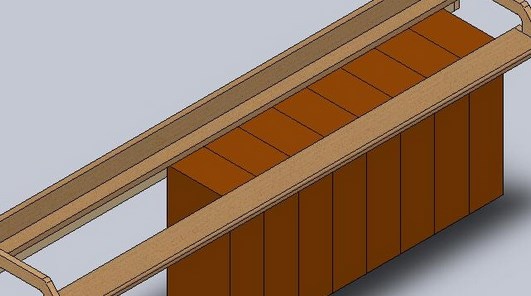

To improve accuracy it is used solution dispenser. It is a rectangular tray having the width of the wall being made. In the center there is a through hole through which the solution is applied.

The length of the device is selected to fit the size of one to three bricks at once. The device is designed in such a way that when installed on a wall, a free space is formed between the row of bricks and the upper cut of the product - this is the thickness of the applied mortar.

Together with horizontal design, a device is used for end application of the mixture. Thus, a constant thickness of the seam is ensured, the solution is dosed and saved.

Application

The dispenser is installed on the finished row of masonry. Thanks to the lower and side stops, the product ensures, subject to the exact previous layer, the horizontalness of the mixture and its uniform thickness. Filling is carried out using a shovel, ladle or trowel. The latter, among other things, is used to level the solution and remove its excess.

The principle of using an end dispenser is similar to a horizontal device. The only difference is that due to the small amount of solution, all operations are performed with a hand trowel.

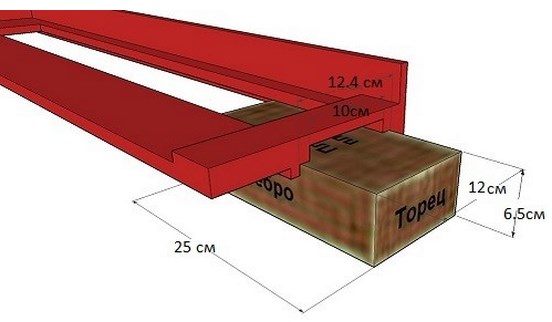

DIY dispenser

You can make a device for level masonry yourself. The material used is wood, plastic or metal. The difference between them is the service life and the method of fastening the elements to each other.

The geometric parameters of the future device depend on the type of blocks used - brick, gas or foam concrete, etc. For each type of product, the thickness of the seam and, accordingly, the amount of mixture will be different.

The width is selected to match the size of the future wall and is fixed with side stops. The height of the lower stops is determined by the thickness of the seam. The simplest design is a plywood product with a thickness of 16–24 mm.

A wooden box is made from it in accordance with the selected parameters. Wooden blocks or scraps from the same plywood can be used as lower limiters and side stops. A steel corner or furniture corners will do.

Cost of factory products

For large volumes of work, it is advisable to consider the possibility of purchasing a finished product. It is most often sold as a kit. For example, the “Brick Set” consists of:

- “Brick” template - used for laying the mixture on a horizontal row (bed);

- “Brick” template - used for a single block measuring 65 mm;

- template “Brick” - for one-and-a-half bricks measuring 88 mm;

- Corner "Mason" - mounted on the outer corners of the building; in addition to controlling angular parameters, it is used to fix the mooring cord;

- mason's trowel;

- video material with lessons on the use of the device and the basics of masonry.

The main elements of the dispenser are made of high-strength plastic. The average market price is 1500–1900 rubles per set.

Tip 1. When making devices for level masonry, it is advisable to lay a seam thickness of 10 mm, which is the most popular for single and one-and-a-half bricks.

Tip 2. To extend the life of a dispenser made of wood or plastic, several layers of highly wear-resistant varnish, for example, a parquet composition, can be periodically applied to the most worn areas.

Tip 3. All tools, without exception, must be cleaned of any remaining mixture and thoroughly washed upon completion of work, otherwise they will quickly fail.

Tip 4. The time or money spent on the manufacture or purchase of the necessary devices will be more than repaid by the quality of the masonry, the speed of completion of the work and the economy of the masonry mixture.

Bricklaying– this is quite a complex job and a painstaking process that requires a lot of time, effort and equipment. To start such work, you should definitely get acquainted with all the nuances regarding this work.

If you do not do the work yourself, then you should initially make sure that you entrust the work to specialists, and they will really do what you need.

It is also necessary to monitor during each stage so as not to doubt the effectiveness of the result obtained. In order for the work to be truly effective, it is worth taking care of the availability of appropriate devices, including the availability of devices for laying bricks.

Types of masonry devices

The types of fixtures are selected depending on the size and type of brick. After all, all dimensions must be proportional to the size of the wall or brick. Based on this, we can conclude that the devices can be adjusted to fit one, one and a half or two bricks.

Their selection will also be based on the availability of their sizes. Thanks to this tool, you can even make your own adjustments and nuances to the work process. For example, it will not be difficult to adjust the thickness of the seam, as well as the width of the opening, with the help of which further mortar tape will be formed.

Also, it won’t be difficult to make your own masonry tool. To do this, you just need to select required material, which will have durable characteristics, as well as light weight, which will allow you to freely hold it in your hands and manipulate it during work.

With such devices, work will move much faster, and as a result you will get high-quality and practical work that will delight you for many years to come.

Basic tools:

Trowel (trowel)

It is considered the most common tool that is widely used in the field of construction work. It really performs the main function, and is a smooth steel spatula, which is indispensable for a professional. Designed for particularly important functions, it is responsible for leveling the concrete mortar, grouting joints, and also for removing excess mortar from the resulting structure.

Plumb

This is a measuring tool with which the master can measure the angle that is formed during laying. This is a very important point, since all angles must correspond as closely as possible to all calculations included in the drawings.

Cord

This is also an important device, without which it will be impossible to check the height and distance which must be observed during preparation for the main job. Responsible for the correct execution of the work, he checks the height and width of the bricks being laid.

This is a device of different sizes, without which not a single construction process can be completed. It is used during brick laying. It plays a special role when working with large quantities cement mortar, which is why it comes in different sizes.

Level

This is a measuring instrument that consists of a durable body. Inside there is a container filled with non-freezing liquid. In addition, inside you can also mark balls of air, with the help of which you can determine as accurately as possible how accurately and correctly the masonry is being carried out, and whether there are any shifts in the horizontal or vertical position.

Joining

This is a tool widely used in, especially during those works that require the formation of decor. The joints can be of different sizes, and accordingly, the designs turn out completely different.

Rule

This is a smooth smooth strip, thanks to which you can check the surface and measure it, determining how smoothly the installation is taking place. This tool is very widely used when checking external masonry.

This is a tool that is used in critical situations when something went wrong at work.

Order

This is a device with which you can measure the location of bricks, as well as maximum compliance with each other.

In order for all the work to proceed correctly and the structures to be durable, you should definitely learn how to work with devices for laying bricks and use them only for their intended purpose.

The article above already provided a list of available devices and what they are needed for. For example, to smooth out uneven seams on the resulting structure, you need to use only a trowel or mallet, because these are the tools that are suitable for this work.

To create the correct level and avoid unevenness on the surface, a tool called “Level” is used, because it contains all those edges that will indicate evenness or bends on the surface.

How to do it yourself?

Before starting such work, you should definitely determine for yourself what dimensions should be present on certain devices. Because there are certain standard sizes that are worth sticking to.

To make this or that tool, you initially need to select appropriate materials that will be light in weight, but at the same time be as durable as possible.

In order to prepare this or that instrument, you may need the following materials:

- screws;

- screwdriver and hammer;

- roulette;

- pencil;

- steel squares;

- chipboard sheets;

- electric drill, etc.;

At each stage of bricklaying, you may need tools that will allow you to monitor the accuracy and quality of the work as much as possible. Each of the tools has its own functions and is useful; you just need to decide what you need to use them for.

Among the devices that are used to control the process are:

- level;

- furnace hammer;

- square;

- jointing and others.;

Additional accessories

As a rule, any work can be accompanied by difficulties. It is at such moments that the need arises to use new additional tools and devices that will be useful in this situation. Let's look at one such situation. It involves securing a mooring cord to the corner bricks.

To properly secure the cord, you will need to make such a simple device yourself as a metal crab. It is created from a T-shaped plate, the ends of which are completely bent. It needs to be placed on top of the brickwork, and a mooring cord tied to it to provide a slight stretch.

At the moment when you have already built several rows of bricks, inconvenience arises in subsequent work, since the level is already quite high. For this you will need scaffolding. They don't take a lot of time or effort to make, but it will save you a lot more time in the process. The forest is built along the entire perimeter of the construction site, which can be easily moved by making two wooden trestles in advance.

To save on the purchase of devices for laying bricks, you need to use a function such as buying in bulk. Indeed, when working you will need absolutely everything Building tools, and buying in bulk will save you a decent amount.

On average, everything necessary equipment for this work it will cost you 1500 rubles.

Date: 2016-05-15

When constructing a building or other structures, brick is often used. Working with it requires some skills and knowledge. If you don’t have enough of them, then it is better to use various additional designs that will simplify your work. We’ll talk about one such device for laying bricks with your own hands.

Common devices

Building houses using bricks has been practiced for a long time. Therefore, specialists in this field have long been using various devices and systems that make the work as simple as possible and increase the quality of the result.

Most frequently used tools:

- - Level. With its help, the evenness of the masonry in the horizontal plane is achieved;

- - Rule. Used to control the outside of the rows;

- - Joining. This device is necessary for decorative seams;

- - Trowel. A device for working with a solution, using it cement mixture smoothes out and excess is removed;

- - Plumb line. A simple device for monitoring the verticality of walls and corners. Moreover, this can be done within several floors;

- — Mooring line. It is used to control the straightness and horizontality of masonry.

There are other tools with which you can control the correctness of geometric dimensions, make decorative special designs and much more. You can buy all these additional devices at any hardware store. And you can even make some yourself.

There are other tools with which you can control the correctness of geometric dimensions, make decorative special designs and much more. You can buy all these additional devices at any hardware store. And you can even make some yourself.

For example, a plumb line and a mooring cord are made from an ordinary strong cord and iron or wood pins.

Device for smooth brick laying

To improve the quality of the work performed, you can use a special device for laying bricks with your own hands. Its appearance is similar to a container without a bottom. This device helps to apply an even layer of mortar and simplifies the laying itself.

It is quite difficult to apply the required and even layer of cement-sand mixture. Not even every professional master copes with this task properly, let alone beginners in this matter. But a lot depends on this layer.

If not used enough, the bricks may not hold together well. And if you take it in excess, then you will increase the consumption without that expensive material. And appearance home may be damaged. There will be different amounts of mortar between the rows of bricks and it will look bad.

To avoid such inaccuracies, you need to use a special tool. It is used by all masters, even the most high level. This way you increase the quality and speed of work, while reducing costs.

What is the device and how to use it

As mentioned earlier, a device for laying bricks with your own hands looks like a container without a bottom. It has restrictions on the sides and is held rigidly in place. The dimensions of the structure depend on the type of bricks and masonry used.

Tool is installed on a row of bricks and forms a niche into which the sand-cement mortar is placed. As a result, the mixture layer turns out to be almost flawless.

After filling the niche, the device is removed and moved to the next row. This way you can quickly and accurately complete the laying.

We make the device ourselves

If you buy a device in a store, you will receive a professional tool with the ability to adjust all sizes. But if suddenly you don’t want to spend money, then do everything yourself. First you need to decide on the geometric dimensions.

Here everything will depend on the materials used to build the walls. This device can be used when laying not only bricks, but also other building blocks (aerated concrete, slag concrete, etc.). Depending on this, the required layer of cement-sand mortar will be different.

If you have sorted out the volumes, then stock up on suitable materials and tools.

You will need:

- — A plastic box or (if it is not available) a sheet of chipboard;

- — Measuring devices (ruler, level, pencil);

- — Electric or hand drill;

- — Steel angles, screws, screws and nuts;

- - Hammer, screwdriver or screwdriver.

So, you have found a plastic box, from which we will make the device. The plastic is quite durable and doesn’t weigh much, which is very important for us. But you can construct a system made of chipboard sheets, but then the weight will be a little more. Buy them in the store and select a drawer without a top or bottom that is the right size.

So, you have found a plastic box, from which we will make the device. The plastic is quite durable and doesn’t weigh much, which is very important for us. But you can construct a system made of chipboard sheets, but then the weight will be a little more. Buy them in the store and select a drawer without a top or bottom that is the right size.

Iron corners will serve as limiters and stops. Drill holes in a suitable location and secure the corners using screws and nuts. To make the device comfortable to carry, you can attach a handle.

Summarize

As you can see, making bricklaying devices with your own hands is very simple and inexpensive. Although it will serve you for a very long time.

Brickwork is a job that should be done with at least some experience. If you do it haphazardly, then the strength of the walls will not be sufficient, and this is risky, as you yourself understand. In addition, the quality of the masonry will determine how the house will look from the outside.

It is imperative to use various devices and tools to control the work being carried out. It is not reasonable to think that if you can do without them, then you are a professional. Mechanical devices are designed to make our lives easier.