Selecting a quarter using a plane. Sampling a quarter using an electric planer. Video: jointer from a conventional electric planer

A quarter or fold is a notch made along the wooden edge along the entire length. With the help of a fold, the parts are connected to each other by placing them on top of each other. In this way we collect:

- Doorways;

- Window frames;

- Furniture.

Choosing a tool

From the huge number of electric planers, we will find a tool with the “select a quarter” function . This means that the plane must be equipped with a special stop that determines the planing width and a depth regulator, which is attached to the side opposite the stop.

When performing work with a good tool:

- The quarter line is straight;

- There is no staircase defect;

- A perfectly right angle is created.

Checking the operation of the electric planer

Before starting work, the selected power tool must be checked. Carefully inspect the body, cord, drum where the knives are attached. The rotation of this part must be free.

Important! We check the rotation of the drum manually with the instrument turned off. If the electric planer vibrates and when working, unevenness and burrs appear on the surface of the board, you need to check the sharpening and installation of the knives. If necessary, adjust the gap between the plates. The knife should protrude beyond the slabs by 0.5-1.0 mm; without this condition, the plane will not select a quarter. You also need to check the fastening of all knives.

We work according to the rules

First you need to carry out trial work on any board of a similar shape. Then, the block on which we will cut the quarter with a plane must be carefully secured to a workbench or a strong, stable work surface. An uneven angle results from the fact that the workpiece is not securely fastened.

You need to turn on the plane and give it the opportunity to gain momentum. You should start the action by holding the tool strictly parallel to the working surface. It is necessary to move the plane along its length smoothly, without jerking. There is no need to increase speed or stop, we work evenly.

Choosing lumber

All the lumber we need must be well dried. You need to carefully check that the block for cutting out a quarter with a plane does not have:

- Knots, resin cavities;

- Cracks along and across;

- Protrusions and recesses.

If minor defects nevertheless arise during processing, there is no need to rush to correct them immediately using an electric planer. Sometimes it is more rational to use a hand plane or sandpaper to refine a part element. It is necessary to carefully examine the edges of the workpiece; a crooked groove is obtained due to the unevenness of the edge.

The quarter selection is not performed in one pass; several times are needed. At the beginning of the passage, the pressure on the front of the plane should be stronger, and at the end, the efforts must be transferred back.

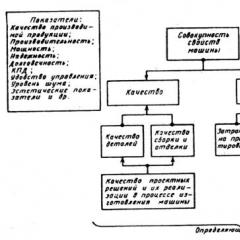

Determining how to select a quarter

Work can be done different ways. First - the tool moves along blackboard along. The second is that the workpiece moves along the tool; this type of work is effective for large volumes.

One of the frequently requested carpentry operations is cutting out quarters with an electric planer.

Selecting a quarter with an electric planer can be done in two ways: by moving the tool along the workpiece, or by moving the workpiece along the tool.

Blanks with a quarter cut out are used to make doorways, window frames, various furniture for home and garden. Doing the work yourself will allow you to purchase cheaper lumber instead of finished products at a higher price.

The quality of work will depend on the condition of the tool, the lumber used, and the experience of the performer. During your first attempts, it is advisable to carry out trial work on unnecessary scraps and, if necessary, adjust the plane.

Checking and adjusting the tool

A new or first-time tool must be checked and tested in use. It is undesirable to start manufacturing parts without preliminary preparation: you can ruin the material and damage the tool. The check should begin with a visual inspection:

- absence of mechanical damage to the housing, cord and power plug;

- free rotation of the drum with knives (check by hand with the plug disconnected);

- free movement of the power button;

- free movement of the front plate.

If there are no defects, you can conduct a test run of the tool. If vibration occurs during operation, the treated surface is of poor quality, waves, or scuffing, you need to check the sharpening and installation of the knives in the drum.

Checking and adjusting the position of the knives must be carried out for two planes: the main upper cutting edge and the side protrusion on the right side. The plane must be positioned with the drum facing up, and the front plate must be set to the position for the minimum cutting depth. Place one of the knives into the gap between the plates.

You can use a ruler or a piece of glass to check the gap. The glass must be laid in the gap between the plates. Rotate the drum with your hand and control the moment the edge of the knife touches the glass. The knife at the top point should be in even contact with the glass along its entire length. If misalignment is observed, adjustments must be made in accordance with the manufacturer's instructions. After eliminating the distortion, you need to check the side protrusion of the knife. Typically the size is 0.5-1.0 mm. If the knife does not protrude beyond the slabs, the plane will not be able to select a quarter. After adjustment, fix the knife and move on to the next one. It is important to set the same clearances for all knives, otherwise the tool will work with strong vibration and quickly fail. After completing the adjustment, you need to check the fastening of all knives again.

Return to contents

Selection and preparation of material

All lumber must be well dried. Raw wood is difficult to process; parts will change in size during use. When choosing a material, you need to pay attention to the following points:

- there should be no large knots or cavities with resin in the processing areas;

- the workpiece should not have transverse and longitudinal cracks or chips;

- The surface of the side along which the limiting stop will move must be smooth, without protrusions and depressions.

First, all surfaces of the workpiece must be planed or treated with emery cloth. Then apply clearly visible markings with a pencil or marker. For long workpieces, you can use a marking cord.

The workpiece must be placed on a hard, stable surface. The installation height should be convenient for work, movement along the workpiece should be free, without interference. It should be taken into account that the power cord will be pulled behind the tool, which should also move freely without clinging to anything. When selecting a quarter with an electric planer, not only the quality of the work, but also the safety of the performer depends on this. At a minimum, the workpiece must have stops in the direction of movement of the tool and on the opposite side to be processed. If possible, it is advisable to secure it firmly in all directions.

Return to contents

Working with a tool

Selecting a quarter with an electric planer can be done in two ways:

- moving the tool along the workpiece;

- moving the workpiece along the tool.

Many models include devices for installing the tool in a stationary position. For large volumes of work, this option will significantly reduce work time.

On the plane you need to install limiters according to the maximum dimensions.

To limit the depth, a special bracket is installed on the side surface. You need to loosen its clamp, set the maximum size using a ruler and fix it. The distance must be measured from the cutting edge of the knife in the upper position to the stop.

To limit the width of the planer, an additional limit bar is installed, which is included in the sales kit. The bar should be secured according to the manufacturer's instructions and set to the required size using a ruler. The distance must be measured from the corner of the cutting edge of the knife to the stop.

The tool should be placed on the workpiece so that the knives do not touch the material when starting, turn it on. After gaining speed, you can begin processing. When starting to move, you need to increase the pressure on the front part of the tool; when the plane reaches its entire length onto the workpiece, the force can be leveled out. When exiting, you need to press harder back tool. It is rarely possible to select a quarter in one pass, since the maximum depth when planing does not exceed 3 mm, and the depth of a quarter is usually from 6 to 10 mm. After the first pass, you need to inspect the resulting cut, adjust the tool if necessary and continue working. Movement for any use of the tool should be smooth, at the same speed.

If small protrusions form during processing, it is better not to try to correct them right away. It is more rational to refine minor defects later with a hand plane or sandpaper, so as not to spoil the entire workpiece.

In one of the previous publications, we already looked at methods of planing boards and bars with a regular hand plane. But working with hand tools is quite labor-intensive and, if necessary, planing a large number of boards becomes ineffective.

To speed up the process, it is more advisable to use a power tool. Modern electric planers are capable of performing large volumes of work with much less physical effort.

Let's find out how to use an electric planer correctly to get the job done with the quality we need.

Adjusting electric planer knives

An electric planer can be used to perform both rough processing of wooden planes and finishing, after which sanding may not even be necessary. Therefore, it is important to be able to adjust the knives correctly so that the planing depth provides the surface cleanliness you need.

An electric planer can be used to perform both rough processing of wooden planes and finishing, after which sanding may not even be necessary. Therefore, it is important to be able to adjust the knives correctly so that the planing depth provides the surface cleanliness you need.

On electric planers, the planing depth is set by switching the handle. The adjustment step can be up to tenths of a millimeter. Therefore, when buying a plane, pay attention to this parameter as one of the most important. Depending on what work you plan to perform, you should select a power tool with a sufficient adjustment step for this purpose.

Before you start processing the surfaces of boards or bars that you will use in the future, make several test passes on a workpiece that you won’t mind throwing away later. It is during these test runs that attention should be paid to possible processing defects.

Most often, such defects are beveled surfaces or incisions. Both of these indicate incorrect settings of the knives in the drum of the electric planer.

To eliminate the defect, it is best to contact the experts in a service workshop or a self-taught specialist who has already adjusted the electric planer knives more than once. But if you don’t have this opportunity, then you can try to adjust the blades of the electric planer yourself.

To do this, loosen the fastening of the knives on the drum using a hex wrench in accordance with the operating instructions for the electric planer, and very carefully set the knives to the correct position. To align the knives, apply a ruler and determine the desired position.

After adjusting the knives, all the bolts must be tightened securely and, turning the drum by hand, see if the knives touch the body of the electric plane.

Planing with an electric planer

Before you begin processing the wooden surface, the workpiece must be securely fastened. How well it is secured affects not only the cleanliness of planing, but also directly affects the safety of the work performed.

Before you begin processing the wooden surface, the workpiece must be securely fastened. How well it is secured affects not only the cleanliness of planing, but also directly affects the safety of the work performed.

The board or block being touched should not have even a slight play. Otherwise, when in contact with the rotating knives of the electric planer, the workpiece may be torn out and thrown to the side with force, which can lead to injury to both the worker and people nearby.

After the workpiece is securely fastened, you need to stand so that, starting to plan from one edge, you can freely move next to the workpiece parallel to the movement of the plane. The body position should not be tense, and nothing should interfere with holding the power tool firmly with both hands.

Before turning on the electric planer, its knives should not come into contact with the surface to be cut. Only after starting should you carefully move the knives from the end of the board and start moving forward.

With each pass, try not to tip the electric plane onto your toe or heel. The sole of the plane must always be positioned strictly parallel to the surface being processed.

The pressure on the front and rear handles of the electric planer should be the same. In this case, at the beginning of the passage you should press a little harder on the front handle, and at the end - on the back. This will avoid blockages. The required pressing force is determined only by practice.

While the electric planer is moving along the surface being processed, jerking, acceleration or stopping is unacceptable. Otherwise, the surface will not be able to be made perfectly flat and various pits will be visible on it.

The speed of movement of an electric plane over the surface being processed is usually 1.5-2 meters per minute. In this case, you need to make sure that the shavings removed by the plane do not get under the sole.

Selection of quarters with an electric planer

Often there is a need to select a quarter in the workpiece being planed. Modern electric planers have this option and can make this task much easier for you. However, when selecting quarters using an electric planer, there are also some features that should be taken into account when performing work.

Often there is a need to select a quarter in the workpiece being planed. Modern electric planers have this option and can make this task much easier for you. However, when selecting quarters using an electric planer, there are also some features that should be taken into account when performing work.

As you know, when cutting a quarter, the side stop of the plane moves along the edge of the board. Therefore, in order for the groove to be smooth, you should be sure that this edge does not have any bulges or dimples.

When planing a quarter, the pressure on the plane handles is slightly different from the pressure when planing flats. With one hand you need to point the plane forward, and with the other, press its side stop to the edge of the workpiece.

Safety when working with an electric planer

When used correctly, an electric planer will help you quickly complete large amounts of work, but if handled carelessly, it can also cause serious injuries.

As mentioned above, the workpiece must be securely secured before starting work. Otherwise, there is a risk of it being pulled out and injuring the worker or other people nearby.

During any inspections of cutting edges or adjustments of knives, be sure to completely turn off the power to the electric planer by disconnecting the electrical cord from the network. Any accidental start can leave you without fingers.

Start processing the surface by first turning on the plane and allowing the knives to reach maximum speed until they touch the board.

If you put the electric planer aside to check the surface you are working on, place it only on its side.

The electrical cord should not have significant kinks or tangles during operation. The electrical insulation must not be damaged, all current-carrying structural elements must be reliably insulated.

In the video below you can watch tips on working with an electric planer (click on the triangle to view):

***

Now you know how to properly operate an electric planer in order to process wooden surfaces with the desired quality. Next time we’ll talk about how to properly sharpen knives for an electric planer if they have become dull and the cleanliness of the processing has decreased.

An important part finishing is the beautiful design of the junction of the floor and the walls. This is exactly what skirting boards are used for. They allow you to create a smooth line between the floor and the wall, beautifully complementing the floor covering, and can hide various... Read.

In the publication about choosing a material for a roof, we already talked about metal tiles - a modern coating that enjoys well-deserved popularity today, and also examined in detail the different types of metal tiles offered by manufacturers on the market today. But... Read.

In the bath we lose a lot of fluid, which leaves the body through the sweat glands, cleansing our tissues of waste products that accumulate in them. Having thoroughly steamed in a bathhouse, you can lose up to several kilograms of weight. This is the weight that goes away... Read.

How to choose an electric planer

A plane is a carpenter's tool, without which it is impossible to process wood efficiently. It is mainly used for wood processing. Working with hand tools can tire a carpenter, so with large volumes of wood processing, their use becomes ineffective.

You can achieve greater productivity while maintaining high quality wood processing using electric models. They easily cope with a large volume of work, and do not tire the carpenter at all. Of course, their cost will be higher than hand planes, but most models include many additional features.

The use of an electric planer, in addition to ergonomics and reliable operation, provides the opportunity to use a fairly wide range of accessories and additional functions. An electric planer allows you to reduce physical costs several times. Before answering the question of which electric planer to choose, you need to know its advantages.

- versatility

- easy to use

- performing a large amount of work.

The use of an electric planer makes it easy to increase the cost of lumber. To use an electric planer for various purposes, the master must follow safety precautions. Most models have intuitive clear interface, so even a completely inexperienced master can work with it. The device allows you to reduce fatigue during work.

Calibrating the board with an electric planer

Design Features

The main working part of an electric planer is a drum rotating at high speed. In his body horizontal position special knives-blades are built-in. There may be several of them, but most often there are 2. The final quality of processing depends on the speed at which the drum rotates. When experimenting with various devices, experts advise choosing a speed of about 10–12 thousand per minute. Most models provide just such power.

Functionality of an electric planer

- electric motor;

- smooth sole (base);

- Locking start button;

- Handle with body;

- Mechanism soft start;

- Chip depth regulation system;

- Chip removal pipe;

- Limiter;

- Belt drive hidden by a casing on the side.

Types of electric planers

Manufacturers divide devices into amateur and professional. In addition, devices are divided into manual and stationary. The latter belong to miniature machines, while manual ones can be attached to a special platform and used as stationary ones.

Working with a manual electric planer

An electric planer, turning it over and attaching it to a workbench, can plan boards, just like on a planer

Despite the fact that this division is conditional, the choice of an electric planer should be based on how it will be used. This will allow you to choose the right platform type and power of the electric planer without spending extra money.

If the carpenter plans to use the tool exclusively for home work, you can use an electric planer weighing from 2.5 to 4 kg, with a power of 600 to 1000 W.

The functionality of different models also differs. Professional analogues remove up to 3 mm of canvas, while the width of amateur ones does not exceed 2 mm.

Video - comparison of electric planes, Russian company Interskol and American Dewalt

A carpenter can choose an electric planer with a built-in mechanism for controlling the number of revolutions depending on the load.

Sometimes manufacturers may indicate two powers - effective and maximum. Effective power indicators should not exceed 350 W. An indicator that is too low may indicate that it will be difficult for the craftsman to cope with hard, knotty wood.

What to pay attention to

The market offers many configurations of modern models of electric planers. Do right choice from all this diversity it is not easy. The choice of an electric planer should be based on the following important indicators:

- Engine power;

- Planing width and depth;

- Shaft rotation indicators;

- Availability of additional functions;

- The degree of heating of the electric planer during continuous operation;

- Device contents;

- Price.

Video review – Dewalt electric planer model D26500 – very popular

Knife drum speed

To perform high-quality work, the power must exceed 10,000 rpm. For a dense surface and roughness, this figure increases to 12000. This refers to the actual revolutions of the device, instead of those indicated in the passport. Before you buy electric plane, you need to find out whether the device’s speed drops during operation, as this may affect the quality of wood processing. Changes can form “steps” and “waves” on the surface. If there is no data on constant speed, it is better to look for another model, or choose one that has control electronics and engine power adjustment, which keeps the number of revolutions constant under any conditions.

Video review - how to plan a board correctly with an electric planer

Drive power

The cutter shaft receives only part of the energy consumed from the mains. Indicators of real output power, which is indicated in the technical data sheet, are indicated as 2, and sometimes more, less than the rated power. High-quality devices must have 350 W. Only it can provide the device with the necessary energy when processing a dense surface. It is best to choose the most powerful tool so that it can cope with all types of work. The highest power rating is 2000 W.

Planer blade length or planing width

The size should be selected based on the performance of future workpieces. Manufacturers produce electric planers with blade widths of 50, 75, 82, 102, 110 mm. Most often on the shelves you can find a knife with a width of 82 mm, since it is the most popular. Larger blades are rarely found on sale, and knives of a smaller size are called “pioneer”.

Set of blades for electric planer

Planing depth

The ideal depth is considered to be 3–3.5 mm. To operate each mm of blade, the device consumes more than one hundred watts.

Electric planer weight

To easily work for a long time, professionals advise choosing devices with a weight of 3–4 kg. Other configurations can cause discomfort and are not so easy to hold for a long time.

Electric planer weighing 3 kg Makita

Availability of additional functions

The only thing that all models have in common is the presence of a depth gauge and a side limiter; in all other respects they differ. For example, the presence of a dust collector. An ideal option for those who want to maintain cleanliness while working and not waste time on cleaning.

Electric planer DeWalt d 26500 with dust collector

Electric planers are often presented with a set of wavy blades and are intended for rough processing of wood. A carpenter can use it to thickness, plane the desired surface or chamfer. Some manufacturers include equipment for securely fixing the wooden sheet, which can be useful for choosing a quarter with an electric planer.

Video review of how to select a quarter using an electric planer, using the Festool EHL 65 model as an example

The degree of heating of the electric planer during continuous operation

This indicator is more likely to be useful to those who plan to plan and calibrate large volumes of lumber.

Chinese analogues of cheap electric planes overheat quickly; after 5 minutes of operation they must be turned off so that the motor cools down.

External characteristics of the electric planer

- The housing must consist of at least 2 parts - the main one, which hides the engine, and the lower base with a removable belt drive cover. The main frame is made in one block along with a handle and a pipe for removing chips. You should choose a device with a removable belt drive cover. Non-removable models can reveal imperfections. Such a device will make the process of replacing the belt impossible in the future and can cause a lot of other problems. As a rule, this applies to cheap models from little-known manufacturers.

- The weight of the plane must be balanced. Buttons for controlling functionality should be conveniently placed. The start key should be easily pressed with a finger in the working position of the hand with a full grip of the handle. If you need to use or move your other hand to turn the device on and off, it is better to refrain from purchasing such a model, despite the high performance and power. Processing the material with such equipment will be completely inconvenient.

- Before purchasing, be sure to examine the electric planer for the presence of grooves on the sole, thanks to which the chamfers are processed and air is removed from the working surface.

All devices are equipped with a pipe for chip removal, which can be with double-sided or single-sided drainage. The second option is the most convenient, but only if the case has a special switch.

Some devices are equipped with a bag to collect chips. Since it is not always possible to connect a drain pipe, this option is very convenient.

Manufacturers managed to supplement the equipment with devices that protect not only the surface being processed, but also the craftsman. A special heel has been created to protect the wood. During operation, it leans back, and after finishing, it closes the knives again. Thanks to this, the knives of the device work smoothly on any surface.

High-quality and reliable electric planer Festool HL 850 at a price of 45,000 rubles and an example of its work

Safety precautions during operation

Like any power tool, an electric planer requires compliance with certain rules.

- Do not place the cord near heat sources.

- If damage appears on the cable, it must be immediately replaced with a new one. Otherwise, the master risks receiving an electric shock.

- The electric planer should be plugged into a power outlet after the technician has made all the fine adjustments of the device.

- Before connecting the device to the network, you need to make sure that the position of the start button is in the off position.

- To protect your eyesight, the technician should use safety glasses.

- Processing the wood surface should be easy due to well-sharpened knives.

- The electric planer should only be used in relation to the power for which it is designed.

- The surface to be treated must be on special fastening surfaces, but not in the hands of the master. Tables that hold the part stationary are designed specifically for these purposes.

- You definitely need to pay attention to how the knives are protected from unintentional fingers.

- The start button should be located in such a way that the master can turn off the device at any time.

- Before choosing a quarter with an electric planer, you need to prepare special stops in advance.

Remember! Check the sharpness of the blades in a timely manner; if the blades become dull, the electric planer may bounce off the lumber, causing injury and severe damage to your fingers.

Video - how to replace the blade in an electric plane

Manufacturers of electric planers

Stores present a huge amount of goods from manufacturers, but only a few of them occupy leading positions. The cost, set of functions, and ease of use of models from different manufacturers may differ, but each of them is of high quality. Here are some of them:

The Russian manufacturer was able to show itself as a manufacturer of high-quality and functional equipment at an affordable cost. Of course, the tool is not endowed with super capabilities, but in terms of quality it easily outperforms numerous competitors. As an example, we can cite the powerful models of the manufacturer Interskol R-110/2000M and Interskol R-82/710.

Equipment from a German manufacturer is used by professional craftsmen and ordinary amateurs. Electric planers are of high quality and have many useful functions. The work performed by the tool is highly accurate and reliable, but the cost is higher in comparison with domestic manufacturers. The company offers a wide range of models, which also includes relatively inexpensive representatives. These include the extremely durable and adjustable Bosch GHO 15-82 and Bosch GHO 40-82 C L-Boxx.

It is one of the leaders in the electrical equipment manufacturing industry. Wide range of possibilities configurations of various models, combined with ergonomics and modern design, allowed them to become the most popular despite their high cost. The overwhelming majority of craftsmen give their preference to the Makita 1002 BA and Makita 1002 BA models. The last of them is especially in demand when working on concave planes.

Regardless of the type, class and type of power tool, they all work on the same principle. This advanced power tool can easily perform trimming, rough finishing, cutting edges, selecting quarters, and therefore is considered an indispensable assistant.

Based on these characteristics, you should always take into account the cost of the model. The better the quality of the tool, the higher its cost, and at the same time the guarantee that it will serve the master much longer.

Selecting a quarter with an electric planer

What can you do with an electric planer? The most primitive task is to plan the workpiece. And this is already good, but not enough. I want more. In addition, at a minimum, chamfering and cutting out quarters with an electric planer are also possible. However, before purchasing, ask whether the tool you choose has such functions.

Chamfer – bevel of the end edge of a part. It prevents splitting of the wooden surface in this place and accidental injuries from sharp edges. In addition, it is also used in pure decorative purposes. Perhaps almost all electric planers allow you to remove chamfers. Especially for this purpose, there is a V-shaped groove on their sole. Sometimes, even several. This allows you to cut chamfers of varying depths and thicknesses.

What about the folds?

For those who are interested, a quarter or a fold is a kind of step on the edge of the workpiece, which makes it possible to connect parts without grooves into an overlay. So, not all electric planers are suitable for rebating, but only some. To do this, they are equipped with a special parallel stop, which helps set the planing width and a rebate depth regulator, which is attached to the side of the tool opposite the stop. Typically, cutting a quarter with an electric planer is carried out in several passes. The standard average rebate depth is 6-10 mm. But there is an electric planer with a quarter cut and 20-24 mm. For example, the same Baikal E-313 easily reaches the 20 mm declared by the manufacturer in seven passes.

We remind you that the miter gauge used when making a rebate only moves along the edge of the workpiece. If it is not level, then the groove will be curved accordingly.

Therefore, it is recommended to guide the electric planer with one hand and press the stop itself with the other. Before starting work, the workpiece should be secured horizontally and stably to the base to avoid distortions and wobbles during work. Mark the width and depth of the quarter in advance. Try to work with equal pressure along the entire length of the passage. To do this, at the beginning, press more on the front of the electric planer, and at the end on the back. By observing these simple conditions, using an electric planer with a quarter cut, you will greatly facilitate and speed up your work.

Before selecting a quarter using a Rebir (electric) plane, you should install a limit bar by selecting the required distance using a ruler. When planing quarters, the force and direction of pressure on the plane handles is slightly different from the efforts made when planing flats. With one hand the plane is directed forward, with the other the side stop of the electric plane is pressed against the edge of the workpiece.

I found this assessment of how good an electric planer is for cutting a groove:

1. METABO But 0882 - rating 5 with a plus.

2. BOSCH GH015-82 - score 5 points.

3. SPARKY P 382 - rating 4.8.

4. MAKITA KR0810 - rating 4.5.

How to select a quarter in a board with a plane? - perhaps one of the most common questions among young masters. Not every electric planer can handle cutting a quarter. The kit must include a stop that sets the width of the fold, a depth regulator that is attached to the tool on the other side (which is opposite to the stop).

How to choose the right electric planer

Main features and types of electric planers

Unlike similar manual mechanical tools, which require the worker to apply quite a lot of effort, an electric planer has many advantages. This tool:

- makes work easier, since work does not require excessive physical force;

- increases productivity due to the presence of an electric drive;

- increases the accuracy and cleanliness of surface alignment;

- has a number of additional functions that allow you to remove a neat, uniform chamfer or make a quarter cut, that is, removing solid wood of the required size along the edge, which is very difficult to achieve with a conventional mechanical plane.

Among the features of the electric planer is its highly specialized focus. With this tool you can perform only a certain type of work on one single material - wood. Therefore, the greatest need for it arises among people involved in wood processing and the manufacture of wooden products. And in the arsenal of the ordinary home handyman it is rarely seen.

If you need an electric planer, you should understand that the productivity and quality of work performed by it will depend on the compliance of the technical characteristics of the device with the tasks for which this tool is purchased. This needs to be addressed Special attention when choosing an electric planer.

Today you can find several types of electric planers on sale, namely:

- manual with commutator motor

This tool uses a commutator motor.

This tool uses a commutator motor.

or stationary - with asynchronous.

The asynchronous motor used in the tool has larger dimensions and weight than the commutator motor, which affects the size of the machine

The asynchronous motor used in the tool has larger dimensions and weight than the commutator motor, which affects the size of the machine

The tool works only from the network

The tool works only from the network

or battery-powered, which do not require connection to a household electrical network (usually an 18-volt battery is used);

These devices use an 18 volt battery.

These devices use an 18 volt battery.

Design and principle of operation

The design of any electric planer is simple and straightforward, if you do not delve into the design of the electronic speed control system. Even externally, all hand-held tools are similar to each other, and consist of the following basic elements:

Design diagram of a manual electric planer

Design diagram of a manual electric planer

- Front movable support with adjustable height.

- Aluminum housing with removable belt gear housing.

- Front handle with planing depth adjuster.

- Electric motor of commutator type.

- Trigger with safety button against unintentional activation.

- Rear handle.

- Fixed rear support plate.

- A drum with knives attached to it. In most cases there are two knives, but there are models with more of them.

Bottom view of the electric planer. Three longitudinal grooves for air removal are visible on the sole

Bottom view of the electric planer. Three longitudinal grooves for air removal are visible on the sole

Some models of electric planers have a chip discharge pipe, to which a vacuum cleaner hose is connected, as well as removable parallel stops for adjusting the cutting width.

Some models have a chip outlet and removable parallel stops

Some models have a chip outlet and removable parallel stops

The operating principle of an electric planer is quite simple. Its working body is knives mounted on a drum. While moving along a wooden surface with the engine turned on, torque is transmitted through a belt reducer to the drum, and the knives cut off the top layer of wood. In this case, the thickness of the chips is set by the difference in height between the moving and stationary parts of the sole of the electric planer.

The planing depth is determined by the difference in height of the rear and front soles of the electric planer

The planing depth is determined by the difference in height of the rear and front soles of the electric planer

The planing depth is adjusted using a screw combined with the front handle of the tool. To obtain a high-quality, even surface, the electric planer must be moved at a uniform speed. Moreover, its power must be at least 600 - 900 W, and the rotation speed of the knife drum must be from 10 thousand rpm. The operating principle of the electric planer is presented in more detail in the following video.

Video: how to use a plane

How to choose the right electric planer: basic criteria

In order to choose the right electric planer from the wide variety of existing models, you must first decide on the mode of its use. If you need a tool to regularly perform woodworking work, you need to buy a professional electric planer. For occasional use at home, a household power tool will be sufficient.

The main characteristics and parameters that must be taken into account when choosing an electric planer include:

- engine power, which can range from 0.5 to 2.2 kW;

- planing width, determined by the length of the knives (models with knives 50, 75, 82, 100 and 110 mm are available).

- planing depth equal to 0.1 - 2 mm - for household tools and up to 4 mm in increments of 0.1 - for professional ones;

- rotation speed of the knife drum (in different types for electric planers it is equal to from 10 to 18 thousand rpm);

- weight of the tool - household electric planers weigh 2.5 - 4 kg, and the weight of a professional one reaches 9 kg.

For use at home or in the country, for small volumes of work, you need to choose an electric planer with a motor power of up to 1 kW, a planing width of 82 - 110 mm, and a rotation speed of 10 - 12 thousand rpm. The longer the knives, the fewer passes the tool will need to make to process a wide board. This means that the quality of its surface will be better.

In addition to technical characteristics, when choosing an electric planer, you should pay attention to such important details as appearance and some design features. The ease of use of a power tool and the quality of its work can be significantly affected by:

- Electric planer sole. It should be absolutely smooth, and have V-shaped longitudinal grooves (1 - 3 pieces) on the front, height-adjustable platform. After all, the air cushion formed during work does not allow you to remove chips of the same thickness. It would be good if there was a plastic stop at the back of the stationary half of the sole, which would serve as protection for the treated surface.

The support on the back sole protects the treated surface

Using a switch, the chip discharge pipe can be extended to the right or left.

Using a switch, the chip discharge pipe can be extended to the right or left.

Tools make it easier to pick out quarters

It is advisable to choose a tool equipped with stops

Transformation of an electric planer into a machine is convenient for processing long lumber

An equally important criterion is the price of electric planers. For home use, more budget models of medium power with a set of the most necessary functions are quite suitable.

Which brands and models are best to choose?

When choosing an electric planer great importance has a brand and model of the instrument. Products from more well-known brands are in increased demand and popularity compared to cheap Chinese products. Despite the higher cost, branded power tools continue to be in demand due to their reliability and quality.

Among the most well-known brands that are constantly in demand among consumers, both for home workshops and for professional use, the following brands can be named:

- Bosch from the German manufacturer, the Robert Bosch GmbH group of companies, which has production all over the world;

- Makita, owned by the Japanese corporation of the same name, which is famous for high-quality professional power tools;

- De Walt and Black & Dekker, produced by the same company Stanley Black & Decker, Inc. from USA;

- Hitachi from Japan;

- Interskol from a Russian manufacturer;

- Sparky, a brand from Germany, whose products are manufactured in German factories and in Bulgaria.

When choosing an electric planer, you should pay attention to the country in which it was assembled. Products of original origin have the best quality, reliability and durability. Unfortunately on modern market You can find Chinese counterfeits of well-known brands not only of Western companies, but also of Russian origin. These models even have Russian names “Grad” or “Bison”, which often confuses the buyer. You should immediately decide, so as not to run into a cheap fake, that it is better not to consider an electric planer costing up to 3 thousand rubles as an option for purchase.

The most popular models include the following.

Bosch GHO 15–82. with a planing width of 82 mm, which belongs to the category of professional tools, but is lightweight (2.5 kg) and is intended for finishing work. With this planer you can select a groove up to 9 mm, and with the help of the accessories included in the kit, transform the hand tool into a convenient planer. According to customer reviews, it is good for large volumes of work. But it is recommended to buy only an original German device or a European-assembled product.

“I purchased a bosch gho 15-82 plane. The test of planing 102 m2 of boards was passed perfectly. In general, I worked without a smoke break for almost half a day non-stop.”

Electric planer for finishing work

Electric planer for finishing work

Makita KP 0810 C. equipped with a soft start system. ensuring a clean start to the cut. This tool has high productivity, given the optimal ratio of time and roughing area. According to user reviews, the electric planer of this model does a good job of chamfering and removing quarters.

An ideal plane for cutting quarters and planing narrow products. It removes chamfers very well with the help of a special stop, which I purchased separately. Assembly Japan.

Equipped with a side rip fence and soft start system

Equipped with a side rip fence and soft start system

Bosch GHO 40–82 C 0.601.59A.760 It has a convenient ergonomic design of high-quality assembly. The presence of electronics makes it possible to provide smooth start and achieve a clean surface finish when planing hardwood boards. Not very suitable for processing timber and large volumes of work, due to the presence of only one blade on the drum, which will have to be changed frequently. But the machine is suitable for home use. Blades are changed quickly and easily. The tool is supplied with 10 interchangeable knives; together with the key required for replacement, they are attached directly to the body of the electric planer. According to customer reviews, this model is very convenient to use.

Small, light, rarely clogged even when he was given full depth. The fact that there is one knife is even better - savings. The knives are incredibly easy to change and you don’t need to make any additional adjustments.

I have a Bosch 40-82. Knives get dull pretty quickly. Otherwise, it is an exceptionally pleasant unit.

Hardwood Tools

Hardwood Tools

De WaltD 26500 K. This model is ideal for processing any wooden surface, including hardwood. Quartering and chamfering functions are available. When working, the tool makes little noise. With its help you can process boards and bars that are not too wide. The device has an electronic soft start system and can also be transformed into a machine.

The impressions are positive, before the purchase I was tormented by only one doubt, there is a lot of information on the Internet about problems with the support heel, as it turned out, all this is a little untrue, there is nothing wrong with the heel, but it does not work according to the same principle as other planes. I was also pleased with the set of planer, a suitcase, a bag for collecting chips, a nozzle for a vacuum cleaner, a guide ruler, a depth limiter for cutting a quarter, a key for replacing knives - this set is additional. accessories will not hurt. The power of the plane is beyond the eyes, it calmly takes larch to a depth of 4 mm, there is no drop in speed as such (of course they decrease under load, but this is not noticeable) The plane does not overheat.

Designed for large volumes of work with any type of wood

Designed for large volumes of work with any type of wood

Interskol R-102/1100EM- an inexpensive but functional and convenient electric plane with a wide sole (102 mm), designed for processing wide beams and boards with an uneven surface. It has the function of removing quarters up to 15 mm, and is suitable for large volumes of work. The model is interesting due to the presence of a soft start, adjustable rotation speed of the knife drum and a system for maintaining a certain number of revolutions under load. This tool is ideal for home and garden use, and has a lot of positive reviews from consumers.

The Interskol R-102 plane, in my opinion, is the most optimal choice both from the line of planes from different manufacturers, and among planes from the Interskol company. If you take a tool for the home, then there is no point in overpaying almost double or even triple the cost for Makita or Bosch, Interskol R-102 will last you until you want to buy a new one. Unlike its Interskolov brothers, the R-102 is equipped with overheating protection, which means that it is almost impossible to burn, the smooth start of the device reduces the chances of injury and increases the service life of the engine. The 1200 W engine easily planes even complex rocks wood, and with a knife 102 mm wide it is very convenient to process ten-bar timber. It is a pity, of course, that the R-102 was not equipped with a stationary unit like its brothers, but for me this turned out to be a solvable problem, I built it myself!

Video: how the electric plane Interskol R-102/1100EM works

Cordless tools

Using a power tool, including a plane, requires connecting it to an electrical network. which requires a certain connection between the work site and the existing electrical wiring. Of course, if you are far from connection points, you can use extension cords, but this brings with it some inconveniences. The way out of this situation is battery-powered electric planers. Outwardly, they are no different from ordinary ones. similar devices, except for the presence of a battery and its connection point, which are located on the rear vertical stand, behind the handle. Most of these electric planers operate on 18-volt batteries, but there are models designed to use a 14.4-volt battery.

The battery socket is located on the rear pillar, behind the tool handle

The battery socket is located on the rear pillar, behind the tool handle

Today, cordless planers are produced by almost all power tool manufacturers. This is due not only to their ease of use, which does not require connection to power distribution points, but also to a certain fashion for cordless tools. Battery-powered electric planers have similar characteristics, design and functionality, with an instrument connected to the network. Only their cost is significantly more expensive, therefore, in the absence of the need to carry out constant woodworking work far from sources of electricity, the purchase of such a plane is not economically feasible.

Non-standard types of planes

The emergence of non-standard electric planers is caused by the need to perform work that is not easy to do with a conventional tool, or it will take a lot of time. The non-standard nature of such devices is manifested in appearance, size and some design features. In the modern world power tool market you can find the following models of non-standard electric planers:

- electric planes with increased planing width, for example, model

The width of the sole is 312 mm, allows for finishing of wide surfaces

The width of the sole is 312 mm, allows for finishing of wide surfaces

Makita KP312S, which has a blade length of 312 mm and a powerful 2.2 kW motor, with the help of two rotating carbide knives it can process wide boards and timber with a high surface quality in one pass (models with a planing width of up to 350 mm are available);

The tool is designed for deep chamfering

The tool is designed for deep chamfering

V-neck like Wegoma FH71 or Virutex CE8

Specialized tool for planing concave and convex surfaces

Specialized tool for planing concave and convex surfaces

With this knife you can get a perfectly smooth surface.

With this knife you can get a perfectly smooth surface.

All non-standard electric planes have a narrowly specialized purpose, and can only be an additional power tool to a standard plane.

Safe work rules

The working element of an electric planer is sharp knives mounted on a drum rotating at high speed. This unit poses the main danger to the person working with the tool. Therefore, you should follow simple rules for safe handling and work with an electric planer, namely:

- work clothes should not have long, hanging sleeves;

- Before starting work, you need to make sure that the tool is in good working order and that the knives are securely fastened to the drum; this should only be done when the power cable is disconnected from the network;

- if necessary, clean and adjust the tool without plugging it in;

- before starting work, check the surface to be treated for the presence of nails or screws;

- When working, be sure to wear safety glasses to protect your eyes from chips;

- the workpiece must be securely fixed on the work table using a vice, clamps and other devices;

- Only those blades recommended by the tool manufacturer are allowed to be used;

- do not leave the electric plane connected to the network unattended;

- store the instrument out of the reach of children.

Following these simple rules will help protect you from painful injuries and injuries.

Typical malfunctions and methods for their elimination

Among the typical, particularly common malfunctions of electric planers, the following can be noted:

- sparking of the electric motor, which can occur due to wear of the commutator brushes, poor contact in wire connections or mechanical wear (damage) of the shaft;

- wear of the blades, which causes tool overload and can lead to engine failure;

- wear or rupture of the belt transmitting torque from the engine shaft to the knife drum.

It is better to entrust electric motor malfunctions to professionals who can diagnose the motor and determine the cause of the sparking. Replacing the commutator brushes alone may not do anything. Other typical faults can be fixed yourself.

The knives of the electric planer are mounted on the drum in special grooves; to replace them you must:

- Disconnect the tool from the power supply.

- Set the planing depth regulator to “0”.

- Having manually turned the drum so that there is access to the three knife mounting bolts, use a wrench of the required size to loosen the nuts of the bolt connection.

- Remove the blade clamp from the groove;

- Disassemble the clamp, removing the worn blade from it;

- Insert the new blade into the clamp and reassemble in the reverse order;

- Repeat all procedures for the second blade.

The process of changing knives is presented in more detail in the following video.

Video: replacing knives on an electric planer

After replacing the knives, adjust them. To do this you need:

- By placing a ruler or corner with its edge perpendicular to the cutting line, resting against the back and front of the sole, we determine whether the tip of the knife touches the ruler. On both the right and left sides, the knife should be in equal contact with the control ruler. This will ensure uniform chip removal across the entire planing width.

- If both planes of the sole and the tip of the knife are not on the same line, you need to loosen the bolts.

- Using the hex key included with the tool, you need to set the desired height of the left and right side knife, as shown in the video below.

- Having reached the desired level, tighten the bolts.

Video: setting up knives

The belt must be replaced in the following order:

- Disconnect the power cable from the electric planer.

- Remove the protective cover.

- Loosen the fastening screw on the pulley;

- Remove the belt and install a new one in its place.

- Reassemble the tool in reverse order.

Video: comparative review of planes

Today on the building materials market you can find slats, boards and timber with varying degrees of processing, without bothering yourself with the purchase of special woodworking tools. But it is much more practical, given the price of processed and unprocessed lumber, to purchase an electric planer for home use. Such a tool will always find application on the farm, and with large volumes of work it will quickly justify the cost of its purchase.

How to choose the right type of electric planer and maintain it correctly

Main features of the tool and its purpose

An electric planer is used to level the plane of a wooden surface and eliminate unevenness and roughness. This is achieved by planing - removing thin shavings from the outside. At the same time, the surface becomes smooth, “without a hitch.” A well-planed board becomes glossy and takes on a polished appearance. The natural texture of the wood is visible on the surface. Unlike sanding wood, in which only the top layer (up to 1 mm) is processed, when planing, a layer of up to 4 mm is removed. and more. Such processing can most accurately be called “scraping.”

Processing boards using an industrial thicknesser

Processing boards using an industrial thicknesser

Unlike a manual planer, an electric planer combines several basic functions - chamfering, quartering, rabbeting and others. In addition, with appropriate equipment, the tool is used as a jointer - a stationary planing apparatus mounted on a work table. An additional ruler and square allows you to level the workpiece and give it a rectangular shape.

Leveling a board on a jointer

Leveling a board on a jointer

Pros and cons of electric planes

Let us note the main advantages and disadvantages of this type of equipment.

- Planers are not suitable for leveling floors (scraping);

- Carelessness can lead to injury - the drum with knives rotates at very high speed;

- Does not replace hand tools To process corners and ends, they will have to be modified with an additional planer or folding plane.

- High performance;

- Does not require any physical effort;

- Possibility of use as thicknessing or jointing equipment;

- Qualitative quarter sample;

- Financial savings - planed lumber is almost twice as expensive as unprocessed lumber.

The design of an electric planer and the principle of its operation

The power unit of the device is an electric motor connected to a rotating shaft by a belt drive. The asynchronous type motor operates from a mains voltage of 220 V and 6 A. The power can vary from 500 W. up to 2000 W. Number of revolutions - from 10 to 18 thousand/min. The rotation speed depends on the gear ratio of the teeth in the gearbox.

Main functional units of the electric planer

Main functional units of the electric planer

Controls

Almost every electric planer is equipped with two buttons - one button to turn on the engine and the second - a protective button against unintentional start. There are two handles on the body for convenient control of the movement of the device along the surface being treated.

Unintentional start protection button

Unintentional start protection button

Chip removal system

Unlike a manual plane, in which chips are removed through a slot in the block, an electric tool is equipped with a convenient system for removing wood dust and sawdust. It is located, as a rule, on the casing on the right in the direction of travel and is a plastic pipe combined with the hose of a vacuum cleaner or dust collection bag.

The dust exhaust pipe is located on the plane body

The dust exhaust pipe is located on the plane body

Electric planer sole

The sole is the metal platform of the plane that slides over the workpiece. It is a flat and smooth plate consisting of two parts. The rear part (in the direction of travel) is fixedly fixed to the tool body. The front part is fixed using a planing depth adjuster. Thanks to this device, the user can set the thickness of the wood layer to be removed. For chamfering, triangular grooves are provided on the front part.

The front part of the sole regulates the depth of planing

The front part of the sole regulates the depth of planing

The sole is made of aluminum alloy and can be cast or stamped. Casting is characterized by more accurate dimensions and strength. The level of raising or lowering the sole is controlled by a special mechanism. Most often it is combined with a front handle, the rotation of which adjusts the position of the platform.

Knives and knife drum

The working part of the electric planer, which directly processes the wood blank, is called the knife drum. It consists of a metal cylinder with two or three grooves for attaching removable knives. Most often, tools use 2 knives, but there are models with one or three knives (for example, the SPARKY P382 plane).

Fastening knives in the knife drum

Fastening knives in the knife drum

The knives are secured using screw clamps. They are one-sided or two-sided. Single-sided knives can be sharpened yourself. The sizes of knives are divided into 5 types and are selected for the plane, depending on the size of the knife shaft. Standard sizes knives: 50, 75, 82, 100 and 110 mm. Replacement knives are sold in tool stores in sets of 2 pieces.

Set of replacement knives for MAKITA electric planer

Set of replacement knives for MAKITA electric planer

As for the material from which knives are made, two main groups can be distinguished:

- carbide knives;

- knives made of high-speed steel.

Carbide ones are designed for long service life, and, as the name implies, are made from high-strength high-carbon alloys. The main disadvantage of such knives is their high price.

High-speed steel is less hard, but its big advantage is the ability to sharpen. For the most part, craftsmen who regularly use an electric planer tend to use this type of knives. In addition, the cost of such knives is low. And if there is no way to sharpen them, they simply buy new ones.

Carbide steel knives for electric planer

Carbide steel knives for electric planer

To make the picture complete, it remains to add that instead of knives, shaped cutters can be inserted into the drum, with the help of which the wooden surface is given various shapes- wavy, jagged, etc. To work with cutters, certain skills are required; the movement of the plane must occur strictly in one line. It is not easy to find such cutters on the open market - most often they are made to order from tool turners. Sharpening a shaped cutter yourself at home is quite problematic.

Technical characteristics: how to choose the right electric planer

The choice of tool depends on the purpose. If you intend to operate an electric planer on a household scale, from time to time, there is no point in purchasing “heavy artillery” - professional tools that have high power and, accordingly, considerable cost. This equipment is designed for daily use with maximum loads and, therefore, has a large mass and high energy consumption. There is no point in using it to process a board 3 cm thick. It’s like driving a battle tank to buy bread from the bakery located around the corner. When purchasing, you need to realistically evaluate the scale of work that will be assigned to the tool.

When choosing an electric planer, you need to take into account the amount of work

When choosing an electric planer, you need to take into account the amount of work

It is best to navigate by technical specifications, which are given in the product passport.

Documentation is included with the tool, and it is best if it is in Russian. Among other things, this is evidence that the supplier company is not a fly-by-night company, but works for Russian market in the long term.

So, let's move on to an overview of the main parameters.

Appearance is not the main selection parameter

By appearance you can determine the degree of “professionalism” of the instrument. Many companies paint the plastic of the case in a certain color, emphasizing that it belongs to a certain category. For example, all tools from the German company Bosch are divided into green and blue. Green ones correspond to the level “for home use”, blue ones – “for professional use”. Some unscrupulous manufacturers (mostly of Asian origin) abuse this gradation and deliberately paint their products blue, trying to imitate a quality instrument.

Professional electric planer Bosch

Professional electric planer Bosch

Makita tools are traditionally blue. Hilti - red, Devalt - yellow, etc. Knowing the color, you can immediately distinguish a low-quality fake from the original.

Next distinguishing feature a good tool - ergonomics or usability. This is not only an elegant design, but also ease of use, compactness, and the absence of sharp corners. Large manufacturers around the world pay great attention to this, small imitator companies produce motley products that are not distinguished by convenience and quality.

The body bears the entire load during operation. The logical consequence of this should be the use of high-quality plastic for its manufacture. During construction, any tool sometimes falls on a concrete floor and is used in dusty conditions. A characteristic visual sign of high-quality plastic is gloss and the absence of thin, fragile parts. If a tool is sold in a case, this is a good sign; it is even better if it comes with spare parts (replacement knives, drills, graphite brushes, etc.) as well as an instruction manual in Russian.

Some online stores sell tools without technical documentation, citing the fact that the data is on their website. From the user's point of view, such a formulation of the question is not justified. It is not always possible to have a computer at hand to clarify this or that issue regarding the use of an electrical appliance.

Motor power

An important indicator of the “ability” of an electric planer is, of course, the engine power. The higher the power value, the greater the performance of the tool. Motors with a power consumption of 1.5–2.3 kW are installed on professional planes with blade widths starting from 100 mm. For a household level, a power of 500 to 1000 W is quite acceptable. When choosing a tool, you should take into account not only the amount of power, but also other parameters. For example, the predominance of soft wood species for processing implies one power, hard wood (oak, hornbeam, maple) - a completely different one. In construction, soft wood species (pine, spruce) mainly predominate. In the furniture industry, materials made from “heavy” wood species, which have high strength and decorative value, are more often used.

Planers with one blade differ favorably in terms of energy savings. The lightweight design of the knife shaft allows the use of lower power electric motors without compromising the performance of the tool.

Video: jointer from a conventional electric planer

Knife shaft rotation speed

The specificity of an electric planer is that the higher the rotation speed of the knives, the smoother and better the surface of the wooden workpiece is processed. Therefore, it is difficult to overestimate this indicator. The minimum acceptable speed is 10 thousand revolutions per minute. Rough processing involves 12 to 13 thousand rpm. A perfectly smooth surface is achieved at 15–18 thousand rpm. You should pay attention to the fact that in some devices, when the load increases, the shaft speed decreases - this will certainly affect the quality of processing. Therefore, some models are equipped with a speed maintenance system (for example, Makita KP 0810 C) - they plan at the same speed under large and small loads. Among other things, such a system protects the electric motor from overheating.

Planing depth

Planing depth is the maximum thickness of chips that a plane can remove in one pass. The higher this indicator, the faster and better the wood is processed. The planing depth is adjusted by moving the front (moving) part of the platform in relation to the rear (fixed) part. Standard offset range is 0 to 4 mm.

Planing depth regulator on the body of the electric planer

Planing depth regulator on the body of the electric planer

It is carried out by rotating the front handle around its axis. There is a graduated scale on the body, which allows you to adjust the required depth of immersion of the knives into the material. Adjustment step from 0.1 mm. up to 0.5 mm. In practice, with many planes, planing begins even in the zero position. This must be taken into account during work and adjustments made if the depth needs to be maintained accurately.

Planing width

The processing speed depends on the width of the knife. A 10 cm wide board can be leveled in one pass, provided that the cutting edge size is 100 or 110 mm. If it is smaller, for example 75 or 82 mm. you will have to go through it at least twice. Moreover, the quality will noticeably suffer. Therefore, when choosing from two tools with different planing widths, preference, as a rule, is given to the one with wider knives.

Planing width depends on the size of the knives and the knife drum

Planing width depends on the size of the knives and the knife drum

The size of knives for professional planes can reach up to 350 mm. Such devices are used only in production conditions. In households, the most common electric planers are those with blade sizes ranging from 82 to 110 mm.

Tool weight

The weight of the electric planer is of no small importance during operation. On the one hand, a heavy tool contributes to minimal physical activity from the human side. Under its own weight, the plane of the sole is pressed against the parts, inertia dampens small vibrations and vibrations. The user only needs to point the tool in the desired direction, and he does the rest himself. But if the weight of the plane is too large, it can become a burdensome factor during operation. For household tools, a weight of 3–4.5 kg is considered optimal. Professional models weigh several times more, but this is compensated by their greater resolution.

Additional structural elements

Which electric plane is better to choose for your home and garden?

There is no doubt that the choice of tool is determined by the volume and intensity of the proposed work, and the technical parameters of a particular model. However, the purchase may become a “pig in a poke” if you do not adhere to certain general rules choice.

- You can completely trust only well-known and respected manufacturing companies. It is best to buy equipment in company stores, from official representatives of the manufacturer. The warranty for such products must be at least 2 years.

- At the time of purchase, check the functionality of the tool. There are cases of factory defects and packaging. All problems associated with this disappear if detected at the time of purchase.

There are many models of the corresponding class for home use. Among foreign manufacturers, we can note such well-known brands as Makita, Bosch, Devalt, Status. Domestic manufacturers are also reaching world quality standards. The companies Interskol, Energomash, Stavr and others are increasingly winning fans not only among amateurs, but also among professionals. Moreover, the price of “our” planes is often an order of magnitude lower.

When a person purchases an electric planer, first of all he thinks about the even and smooth surfaces on the wood that the tool will provide. But time passes, appetites grow, and the functionality of a conventional electric plane is no longer satisfactory.

Sometimes you need to chamfer or select a quarter. A simple operation at first glance requires care and certain skills.

Seam using an electric planer: purpose and application

A quarter or another name for a fold is a selection in the form of a step along the edge of a board or beam. It is intended for the possibility of assembling blanks on an overlay. This simplifies the process and also eliminates the need to make a tongue-and-groove joint in the mating parts. Rebated boards are used mainly for the manufacture of floors or panel structures.

Rebating with an electric planer: all the pros and cons

There are different opinions about the advisability of sampling a quarter with an electric planer. Some consider this a waste of time, arguing that it is better and faster to make a fold using a circular saw or milling machine. Others say that the quality of the work will be better after the planer. Both are right. However, in order to make technological sampling on machines, it is necessary to have them available. Therefore, making steps with an electric planer, although a painstaking task, has the right to life.

It should be remembered, that not every electric plane is designed for making folds. When purchasing a tool you need to pay attention to this.

One more thing. If a person is not engaged in carpentry business and lives in an apartment, then he is unlikely to have to choose a quarter power tool. For those living in a private house, this option may come in handy, and more than once.

Seam using a power planer: tool

Making a quarter sample with an electric planer is not particularly difficult. To do this you need:

- choose a power tool with a rebate selection function;

- you need to have an angular stop and a cutting depth limiter.

Seam using an electric planer: step-by-step instructions

Step #1

First, the workpiece is placed on a carpentry bench and secured as tightly as possible with clamps. The fastener should be on the opposite side of the processing area.

Step #2

After this, the instrument is prepared. Set the angle stop at the required distance from the part. This way it will provide the required planing width and a 90° angle between the tool and the edge of the part.

Step #3

A depth stop is screwed onto the right side of the power tool.

Step #4

The cutting tool of the device should be installed as close as possible to the right edge of the sole.

Step #5

When everything is ready, turn on the electric planer and select the fold, pass by pass. Setting the maximum planing depth in one pass is not advisable. This point must be coordinated with the recommendations of the tool manufacturer.

Step #6

After the depth stop rests on the wood, work is stopped. The fold is ready.

If necessary, chamfer the edges of the part. This will help prevent the edges of the corner surfaces from splitting. For ease of chamfering, slots of different sizes are provided on the base of the power tool.

After reading the article, the reader will be able to learn about the purpose and use of rebates in carpentry, and will be able to make a selection of quarters with an electric planer independently.

Carpentry specialists often have to perform such an action as removing a quarter with an electric planer. A quarter is a notch that runs the entire length of the edge of the piece. If you make a fold in two parts, then they can be connected to each other with an overlay.

To select a quarter, you will need a plane with this function, a workbench, a vice, a pencil and a long ruler.

How to choose a tool for the job?

Modern tools of some brands allow you to make folds with minimal time and effort, and in fairly large volumes.

But when buying a plane, it is important to understand that not every tool can make a selection. You need to pay attention to the following parameters:

- processing width;

- planing depth;

- sole;

- type of knives;

- equipment;

- fold;

- additional functions.

The electric planer must be equipped with a regulator - a stop that allows you to adjust the width of the fold.

This indicator can have a significant impact on performance. The planing width is set according to the width of the sole.

When processing workpieces, several passes must be made. It is clear that with an electric planer with a sole width of 130 mm you will need to make fewer passes than on the same workpiece, but with a planer with a planing width of 82 mm.

In addition, there should be a depth regulator located on the side opposite the stop. Typically the change step is 0.1 mm. In some models, you can adjust the depth using a handle.

The electric planer comes with removable knives. When working with different materials you will have to select the required type. To work with parts made of hard wood, you will need steel knives marked TCT; for working with soft wood, HSS knives are more suitable.

The plane sole consists of two cast steel plates with one or more notches for bevel removal. Some models are equipped with a parking or stop that will protect the sole of the plane from the knives during idling.

The quarter is attached with a screw to the body of the electric planer. It is recommended to choose this element taking into account the height between the surface and the body of the plane. An additional stop (parking) allows you to create an intermediate rebate depth.

It is also worth considering the package: along with the tool, the kit should include removable knives for different types of wood and a key for replacement. When working with an electric planer, a large amount of dust and shavings often appears.

When choosing, it is better to take into account the presence of additional elements. Some designs allow you to qualitatively fix the tool with the sole up, which makes it possible to process the material as if on a compact machine.

Preparing for quarter sampling

Modern models of electric planers allow high-quality not only roughing, but also finishing processing of the workpiece. In this case, subsequent grinding is not required in many cases. But this result depends on how well the knives are installed. The cleanliness of the resulting surface is ensured by the depth of processing of the material layer.

The adjustment is made by moving the handle, and the value can often be tenths of a millimeter. If pitting or unevenness appears on the surface during testing, this may indicate that the blades need adjustment.

In order to select the correct value, the knife fastenings are loosened using a key and the knives are aligned correctly. The correct position is checked using a ruler. Then the bolts are well secured. After this, you need to rotate the drum, checking whether the knives are in contact with the body or not.

Since during operation the side stop slides along the edge of the material, you need to make sure of its quality: the stop must be smooth, without any defects. Marks indicating the width and depth of the quarter must be applied to the workpiece to be processed.

The workpiece must be secured to the workbench - not only the result of the work, but also your own safety depends on the quality of its fastening. The workpiece should not have any play, since during sampling it can be pulled out by the plane knives. A flying workpiece can cause serious injury not only to the worker himself, but also to those nearby.

Basic techniques for quarter sampling

After the block is securely fastened, you need to stand in such a way that it is convenient to move while moving the electric planer. The body should not be overly tense, and the sleeves and hems of clothing should not interfere with movement.