The most profitable material for building a house. What material to choose for building a house

A variety of building materials allows a person of any income to begin independently building a house. Depending on the selected material, the corresponding strategy and sequence of the construction process are used.

IN Lately There has been a trend toward construction options that are more accessible to average incomes. Among them, the most popular is frame house. Let's consider the following questions:

Modern Construction Materials for building a house

Today, building materials have all the necessary indicators to retain heat in the house. But some of them emit carcinogenic dust () or phenol-formaldehyde resins (particle boards), which are harmful to health.

Despite this, and mineral wool, and the slabs attract people with average incomes due to their affordable cost, as well as the ability to complete construction in a faster time.

Depending on whether bricks, blocks or wood are used for construction, a private house may differ not only in quality, but also in price. If a person with average income makes a choice in favor brick house, then he must keep in mind that others modern materials, used for construction, have higher heat retention rates. In this case, there will be a clear overexpenditure of funds.

Regardless of the material used for the walls, cement or cement blocks are used for the foundation. Only their number and amount of expenditure varies, depending on what material the house is supposed to be built from and how light it will be to determine the thickness and depth of the foundation.

The same can be said about the roof. The composition of the roof is selected depending on the requirements for heat conservation indicators.

Best material for building a house

Wood can be considered the best building material for a private house. But even this advantage will not be a key argument for people who have insufficient funds. Unfortunately, materials with high levels of environmental friendliness cannot yet be called universally available to residents of Russia.

Wood as a material has many advantages, but the main one is its high cost. For a person with an average income, building housing from such material is in most cases unaffordable.

When describing modern materials, one cannot help but remember that residents of some settlements use exclusively environmentally friendly materials for building houses (straw, clay, hay). But these options can be considered more exotic and less common in Russia.

If you use the option of block construction, then the insulation will be the same as for a brick wall - expensive, but the material itself will be cheaper, so a private house made of blocks is the most profitable in recalculating the final costs.

In addition, when block construction a private developer will significantly save on time costs. After all, laying blocks is much easier and faster than bricks.

Materials for building a frame house

Every good owner sooner or later faces some type of construction. Someone is building a garage, someone is building a bathhouse, and some are taking aim at self-construction big mansion. This is where the question arises about what is the best material to choose for building a house.

The main stages of construction include pouring the foundation and erecting walls. It is important for any owner to aesthetic appearance the construction was high level, the walls were warm, strong, and in general the costs of building materials were not very high.

The most popular materials for building a house

The modern construction market is rich and diverse. Let's take a closer look at the top five most popular building materials for building a house.

- Solid profiled timber.

- Rounded log.

- Brick.

- Foam blocks.

- Thermal panels.

What to give preference to? Each owner makes this decision independently, but for this it is worth studying all the pros and cons of each of the materials.

Tree

Wooden building materials for building a house have become very popular these days. Wood walls have low thermal conductivity, but stable heat capacity. Even if the house has not been heated for some time, with the furnace running, the resulting condensation will be absorbed into the wood. After this, the already heated air draws out moisture, and a special, favorable microclimate is created in the room. Coniferous species (pine, spruce, fir, larch, cedar) are often used in construction. In addition to the popular solid profiled timber, rounded logs, laminated veneer lumber, regular timber, and carriages are used.

Solid profiled timber

Material that has undergone special processing. The content of wood resin in profiled timber is very high, thanks to which buildings made from it are durable and are not exposed to aggressive environmental influences.

Even in the last century, when choosing finishing and building materials, rarely did anyone choose profiled timber. When erecting the walls, manual adjustment was required. Now, thanks modern technologies, the beams are processed on machines in such a way that they simply fit together perfectly, the gaps between them are minimal.

This environmentally friendly material is not too expensive. The walls retain heat inside for a long time; they can be erected in a matter of days. Smooth, machine-processed beams allow you to assemble a house like a puzzle.

Rounded log

When studying building materials for building a house, pay attention to rounded logs. Like timber, this building material is made from coniferous trees. Unlike the first, rounded logs allow the construction of more durable structures, all thanks to the shape of the material. Construction from rounded logs is also carried out in a short time.

Brick

The most popular building material for building walls is brick. Brick buildings are quite acceptable in appearance, very strong in strength, durable, and also environmentally friendly.

Sand-lime brick. This building material is very common. Buildings made from such bricks can last for decades.

Clay brick. It has always been considered a symbol of something stable, indestructible. This brick has increased strength, frost resistance, and immunity to aggressive atmospheric influences. However thermal characteristics Such building materials do not always live up to expectations.

To build reliable buildings, high-quality building materials are required. Brick factories offer a wide range of their products, which can be divided into three categories:

- Solid bricks, these include the following types: conditionally effective, ordinary, effective.

- Hollow bricks, the proportion of voids in them reaches 40%. Cladding products also fall into this category.

- as well as large-format stone-bricks. The high thermal conductivity of this category is ensured thanks to the honeycomb-shaped structural material.

Disadvantages and advantages of brick

During transportation, especially over long distances, a small percentage of products lose their presentation, brick materials To build walls, houses are crumbled. Their cost is quite high.

The ability of brick to retain heat is much less than that of wood. Walls built from conditionally efficient or solid brick always require additional insulation. This problem is solved by three options: a ventilated facade - installation of a suspended insulation system, a heat-insulating plaster system, as well as three-layer walls with a thermal layer.

The brick house is comfortable to live in. This design “breathes”, provides air exchange, and at the same time has active thermal inertia. Having warmed up, brick walls They retain heat for a long time and gradually release it into the room.

Foam blocks

If you need high-quality and at the same time inexpensive building materials to build a house, then pay attention to foam blocks.

Foam blocks have such qualities as heat resistance, high strength, and low weight. Sudden temperature changes do not affect walls built from foam blocks in any way. They do not crack or expand. There are many air bubbles inside the block, which increase the thermal insulation effect. For comparison: foam concrete walls have a thermal conductivity eight times higher than conventional concrete walls. The material is good not only for the construction of main walls, but also for internal floors. Thanks to this, the entire structure retains heat perfectly. Foam concrete structures do not require additional insulation. Heating costs are significantly reduced, by approximately 30%.

Advantages of foam concrete structures

- Due to the low weight, the pressure on the foundation is reduced.

- Savings in finishing. Regular wall putty is sufficient; plaster is not necessary.

- Reduced labor intensity. One 15 kg foam block replaces 20 bricks, total weight which is equal to 80 kg.

- Cellular foam concrete blocks have excellent sound insulation properties.

- Brick factories produce such building materials in sufficient quantities. The popularity of foam blocks is growing every day.

- In terms of environmental friendliness, this material resembles wood. The room maintains optimal humidity and the walls breathe. Unlike wood, blocks do not rot, do not burn, and do not rust like metal.

- Foam concrete is often used as a heat insulator; it can withstand high temperatures (up to +400 degrees).

- The blocks are very easy to process using ordinary hand tools.

Disadvantages of foam concrete

When we choose materials for the walls of a house, we try to study not only the advantages, but also their inherent disadvantages; foam concrete also has some. These include:

- Fragility of the material.

- Every three rows of walls must be reinforced.

- Foam concrete quickly absorbs moisture, which somewhat reduces thermal conductivity.

- To avoid dampness, you need to create waterproofing, moisture-resistant protection between the foundation and the walls.

- Vapor permeability of foam concrete. Vapor barrier is required.

Frame thermal panels

If you need inexpensive building materials to build a house, then you should pay attention to frame thermal panels. The advantages of this material include low thermal conductivity, relative strength and quick assembly. The downside is the lack of naturalness.

Thermal panels today are very often used for finishing frame-panel houses. Their design consists of extruded polystyrene foam (as a thermal insulation substrate) and high performance properties allow the use of thermal panels in the construction of houses using Canadian technologies. The most important characteristics of this facade material, which have ensured wide demand, of course, include the lack of moisture absorption, low thermal conductivity, high compressive and impact strength, resistance to fire and any biological effects. The material is easy to install and further use.

Finishing and building materials for the construction of the walls of the house must meet all modern requirements, then the structure will delight the owners for many years. Frame thermal panels provide an attractive, aesthetic, solid appearance building. It is for this reason that this material is very often used for the construction of cottages. lined up according to Canadian technology, finished with clinker panels, has the appearance of smooth, flawless brickwork.

If a building is lined with thermal panels, heat loss is immediately reduced by 30%, all thanks to the substrate, which consists of extruded polystyrene foam. The clinker tiles are connected to the insulation under high pressure with heavy-duty adhesive. The finest cutting of expanded polystyrene sheets allows for high-quality tight joints. In order for the facade to acquire a finished look, in addition to the main panels, you can purchase various additional elements to neatly decorate the corners.

We presented the most common building materials on modern market. How and what material to choose for building a house, give preference to price, naturalness, aesthetic qualities or technical specifications, you decide for yourself.

The external walls of a private house must be:

- Strong and durable

- Warm and energy saving

- Quiet

- Harmless to humans

- Beautiful

Which house walls are stronger?

Loads act on the wall of a house in several directions. Active forces tend to compress, move sideways and rotate the wall.

Compressive loads- these are vertical forces from the weight of the wall and the underlying structures of the house. These forces tend to crush and flatten the wall material.

Low-rise private houses are relatively light in weight. Wall materials, as a rule, have a fairly large margin of compressive strength, which allows them withstand vertical loads of a private house even with.

Horizontal loads and torques act as a result, for example, of lateral wind pressure on a house or soil pressure on a basement wall, due to the ceiling resting on the edge of the wall, due to the deviation of the walls from the vertical and other reasons. These forces tend to move the wall or part of the wall from its position.

The general rule for walls is the thinner the wall, the worse it is it withstands lateral loads and turning moments. If the wall cannot withstand the specified loads, then it bends, cracks or even breaks.

It is the small margin of resistance to displacement that is the weak point in ensuring the strength of the walls of a private house. The magnitude of the compressive strength of most wall materials allows you to make a fairly thin wall for a private house, but it is necessary to ensure the stability of the walls against displacement, often forces designers to increase the thickness of walls.

The resistance of walls to lateral loads is significantly influenced by the design of the walls and the house as a whole. For example, reinforcement of masonry, installation of a monolithic belt on the walls at the floor level, strong connections of external and interior walls among themselves, as well as with floors and foundations, create the strength frame of a building that holds the walls together and resists the displacement deformations of the walls.

In order to ensure the necessary strength and durability of a private house at reasonable construction costs, it is necessary to choose the right material and design of the walls, as well as the design of the load-bearing frame of the house, It is best to entrust this choice to specialists - designers.

Projects of private houses with walls made of masonry materials are available for sale. with a masonry thickness of only 180 - 250 mm. . Thickness can be 100 - 200 mm.

The walls of the house are warm and energy-saving - what's the difference?

In order for a person in the house to feel thermal comfort, Three conditions must be met:

The first condition is the air temperature in the room should be about +22 o C. To fulfill this condition, it is enough to install a boiler or stove of the required power in the house and heat it.

The surface temperature of the external walls in the house is always lower than the air temperature in the room. According to the requirements of sanitary and hygienic rules, temperature difference between air and surface outer wall there should be no more than 4 in the house o C - this is the second condition.

At the specified temperature difference, the surface of the outer wall in the house will be quite warm (+18 o C). There will be no “cold breath” from the wall; condensation or frost will not appear on the surface of the wall.

There will be thermal comfort in the house if the difference in air temperature in the room and on the surface of the outer wall is no more than d t<4 о C. Обе стены на рисунке не соответствуют этим требованиям при температуре наружного воздуха t н =-26 о С и ниже.

To fulfill the second condition, the outer wall of the house must have certain thermal properties. The heat transfer resistance of the outer wall must be higher than the calculated value, m 2 * o C/W. For example, for the Sochi region this value should be more than 0.66, for Moscow - 1.38, and for Yakutsk at least - 2.13.

For example, an external wall made of autoclaved aerated concrete (gas silicate) will be warm and provide thermal comfort in the house, with a thickness in Sochi - 90 mm, in Moscow - 210 mm., and in Yakutsk - 300 mm.

Third condition- the enclosing structures of the house must have. If the “clothes” of the house are blown by the wind, then there will be no heat, no matter how thick the insulation is. Everyone knows this from their own experience.

External walls with the above parameters will be warm and provide thermal comfort in the house, but they will not be energy efficient. Heat losses through the walls will significantly exceed the building standards in force in Russia.

In order to comply with energy conservation regulations, The heat transfer resistance of external walls should be several times higher. For example, for the Sochi region - no less than 1.74 m 2 * o C/W, for Moscow - 3.13 m 2 * o C/W, and for Yakutsk - 5.04 m 2 * o C/W.

Thickness of energy-saving walls from autoclaved aerated concrete (gas silicate) there will also be more: for the Sochi region - 270 mm., for the Moscow region - 510 mm. for Yakutia - 730 mm.

Aerated concrete (gas silicate) is the warmest material for masonry walls. The thickness of energy-saving walls made of more thermally conductive materials (brick, concrete blocks) should be even greater. (The figure above shows the heat transfer resistance of a brick wall with a thickness of 2.5 bricks (640 mm.) = 0.79 and one brick (250 mm) = 0,31 m2* o C/W. Compare with the values given in the examples and evaluate in which regions such walls will provide thermal comfort?)

Wooden walls made of timber or logs also do not meet energy saving requirements.

It should be noted that to comply with the requirements of building regulations for the heat transfer resistance of walls and other enclosing structures of the house not necessary for a private developer.

It is more important for the home owner to reduce overall heating costs.

It can be beneficial to sacrifice the energy-saving properties of walls, but increase the heat-saving parameters of ceilings, windows, and ventilation systems in order to meet the energy consumption standards for heating.

Heat loss through walls accounts for only 20 - 30% of the total heat loss in the house.

We must not forget about one more condition of an energy-saving house. The house must have a minimum- walls, ceilings, windows.

Which is better to make walls - single-layer or two-layer?

From the above data it is clear that wall materials allow you to build strong, thin and fairly cheap walls private house. But such walls will not provide thermal comfort in the house or have the required energy-saving properties.

Technologies for constructing walls of a private house are developing in two main directions:

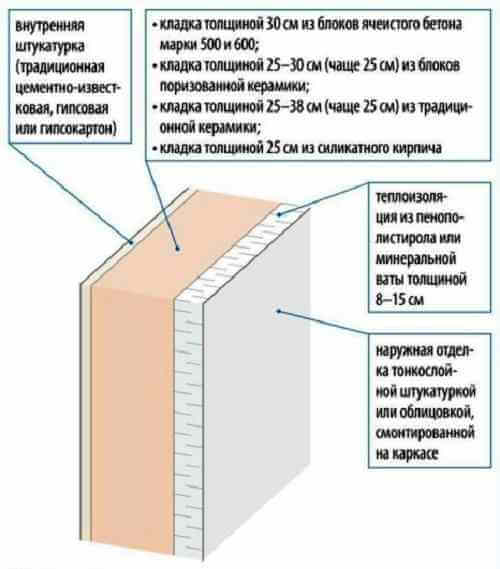

- Relatively thin and durable walls are insulated with highly effective insulation. The wall consists of two layers- a load-bearing layer that absorbs mechanical loads, and an insulation layer.

- For the construction of single-layer walls, materials are used that combine a sufficiently high resistance to both mechanical stress and heat transfer. The construction of single-layer walls made of cellular concrete (autoclaved aerated concrete, gas silicate) or porous ceramics is popular.

It should be noted that wall materials for single-layer walls have mediocre both mechanical and thermal properties. We have to improve them with various design tweaks.

A combination of these two technologies is also used when walls made of cellular and porous materials provide additional insulation layer of highly effective insulation. This combination allows make wall masonry and a thin layer of insulation. This can be beneficial for structural reasons, especially when building a house in a cold climate.

Single-layer walls of a private house

Not so long ago, almost all private houses were built with single-layer walls. The thickness of the walls of the house was chosen based on the conditions for ensuring thermal comfort and thought little about energy conservation.

Currently, for the construction of single-layer walls, materials with sufficiently high thermal insulation properties are used, to make the house energy efficient.

All materials for single-layer walls have a porous structure and low density 300 - 600 kg/m 3. As the density decreases, the heat-saving properties improve, but the mechanical strength of materials decreases.

There are several types of cellular concrete, which differ in the way they create pores (cells). The best properties for the construction of single-layer external walls of a house have density (grade) 300-500 kg/m3.

Aerated concrete blocks can have precise dimensions, which allows them to be laid on glue with a seam thickness of 2 mm. The ends of the blocks often have a tongue-and-groove profile and are joined without mortar in a vertical seam.

Aerated concrete has an open porous structure and therefore absorbs moisture well, but also dissolves easily.

Porous ceramics It is made from raw materials and in a way that is similar to the production of ordinary ceramic bricks. The difference is that components are added to the clay-based mass, which form pores when fired.

Hollow blocks are made from porous ceramics. The hollowness further enhances the heat-saving properties of block walls.

The thickness of the masonry of single-layer walls made of porous ceramic blocks is 38 - 50 cm. Porous ceramic blocks are laid using a special heat-saving mortar with a seam thickness of 10-15 mm.

As a rule, the exterior decoration of single-layer walls is. Cladding slabs made of natural stone or artificial products can be glued to the walls. Finishing using the ventilated facade method (cladding over lathing) is used very rarely.

Plastering of walls made of porous ceramics or expanded clay concrete from the outside is carried out using a traditional plaster composition with a thickness of about 2 cm. In addition to plastering, it can be done in other ways (see link).

The inside of the walls is plastered or...

It is faster to build a house with single-layer walls. In a new house with single-layer walls you can start living without waiting for the facade to be finished. This work can be left for later.

Walls with insulation - two-layer and three-layer

For installing a wall with insulation Almost any masonry material can be used— ceramic and silicate bricks, blocks made of cellular and lightweight concrete, as well as porous ceramics.

The load-bearing layer of a two-layer wall can also be make from monolithic concrete or wood- timber, logs. The choice of material is much more varied compared to single-layer walls.

For the construction of walls with insulation materials with higher mechanical strength and density are used than for single-layer walls. This circumstance makes it possible to reduce the thickness of the masonry of double-layer walls.

Wall masonry thickness from 180 mm. - depends on the properties of the materials used, on the design of the walls and frame of the house.

Walls are most often laid using ordinary masonry mortar, filling horizontal and vertical joints with mortar. The work is simpler and does not require any special qualifications from masons.

The mechanical strength of the wall material is, as a rule, sufficient for problem-free fastening of various structures to walls.

The thermal insulation properties of a wall depend mainly on the thermal conductivity and thickness of the insulation layer.

A layer of thermal insulation is placed outside ( double layer wall) or inside the wall, closer to the outer surface ( three-layer wall).

As thermal insulation, slabs of mineral wool or polymers - polystyrene foam, extruded polystyrene foam - are most often used. Less commonly used thermal insulation slabs made of cellular concrete and foam glass, although they have a number of advantages.

Mineral wool slabs for wall insulation must have a density of at least 60-80 kg/m3. If used for finishing the facade, then use mineral wool slabs with a density of 125-180 kg/m 3 or slabs of extruded polystyrene foam.

Mineral wool insulation is plastered with a vapor-permeable composition - mineral or silicate plaster.

Insulating a façade with mineral wool usually costs more and it is more difficult to work with. But a layer of wool insulation allows moisture to escape from the wall to the outside.

A continuous layer of thermal insulation on the outside allows block all cold bridges in double-layer walls without the use of special constructive tricks that have to be done in single-layer walls.

General thickness of two-layer walls (with plaster from 35 cm.) usually turns out less than a single-layer wall.

The width of the foundation walls (basement) is also smaller, which allows save on their construction. This advantage does not apply to three-layer walls. The width of three-layer walls and their foundations is usually no less than that of single-layer ones.

Exterior finishing of double-layer walls is carried out thin-layer plaster over insulation. Insulation boards, preferably made of extruded polystyrene foam, are glued to the wall. The thickness of the insulation layer is not recommended to be more than 150 mm. A layer of plaster 5-7 thick is applied to the insulation mm.

Wall surface with thin layer plaster more sensitive to point mechanical influences than a single-layer wall with traditional plaster.

For double-layer walls often use ventilated cladding on the frame. In a ventilated façade, mineral wool insulation slabs are placed between the frame posts. The frame is covered with cladding made of vinyl or plinth siding, wooden materials, or various slabs.

Attaching insulation to the walls, installing a ventilated facade - all this work consists of many stages and operations and requires skill, accuracy and responsibility from the performers. A variety of materials are used for work. Happy Holidays, dear reader!

watch this funny video

The time has come to explain why aerated concrete is the most suitable material for the walls of a country house and no other material can compete with it in terms of its totality of characteristics. I propose to take a look at all the building materials currently on the market (including rare and exotic ones) and make sure that you can’t think of a better material than aerated concrete for low-rise construction.

But in any case, from wooden wall materials, a frame house is the best thing to choose in our time. Thus, we actually get the fact that with all the variety of existing building materials, we have only two options left:

House made of cellular concrete (aerated concrete)

Frame house

All other building materials are, in principle, untenable and there is no point in considering them if you are building a house for the future for long-term and comfortable use. And now is the time to make a direct comparison of a house made of aerated concrete and a frame house.

Let me remind you that in both cases we are guided by the fact that the house will be built on a monolithic foundation slab, that is, the low heat capacity of the walls of a frame house is not relevant in our case. If you decide to build a frame house on a pile foundation, then soberly understand that the heat capacity of such a house will tend to zero and any heating shutdown in winter will lead to almost instant freezing of the entire house. If we are talking about a house for permanent residence and year-round use, it must have an extremely high heat capacity of the enclosing structures, because The comfort of using such a house directly depends on this parameter.

The main advantage of a frame house is the opportunity to get an incredibly “warm” wall at a minimum cost. This is directly related to the fact that lightweight insulation has a heat transfer resistance per centimeter of thickness that is 2-3 times less than that of solid wood or even aerated concrete.

The second advantage of frame houses is the speed of construction of the load-bearing frame of walls and roofs. In fact, the advantage is quite dubious if you approach the house as a complex object. Because the subsequent finishing of the frame house, firstly, will not be so fast, and secondly, you will also have to tinker with the engineering systems. But if you want to get a roof over your head here and now (it doesn’t matter that you still have to work and work under this roof so that the house finally looks like a home), then you can agree to a frame house. The same applies to the recently popular modular houses assembled in production. Their manufacturers position assembly in a hangar as an advantage for the customer, although in fact the customer should absolutely not care, because This does not affect production times in any way. But for the performer, assembly under the hangar roof is a big plus, because allows you to reduce costs and downtime associated with unpredictability of weather, if you consider the option of construction on the customer’s site. But on the other hand, the customer becomes severely limited by the too small sizes of individual modules, which are completely uncomfortable for subsequent use (for example, ceilings in a normal house should be at least 2.8 meters).

This is where the advantages of frame houses end and the disadvantages begin.

First and most important. Frame houses are now being built by all and sundry (since the cost of building a frame house is extremely low and you can make a lot of money), which requires special control over compliance with construction technology. Otherwise you can get this such a "barn", which will collapse at the slightest gust of wind. According to the link in the video, everything that could be violated was violated, but in fact, during a hurricane, with a very high probability, a well-built frame house will collapse to one degree or another and you need to be prepared for this. The calculation of loads for a frame house must be done more carefully than for a stone one, paradoxically as it may seem.

The second disadvantage of frame houses is the expensive finishing and installation of utility systems in an open way. After all, it is forbidden to lay electrical wiring in combustible structures, and therefore it will have to be done in an open way, which is very doubtful from an aesthetic point of view. In a house made of cellular concrete, everything is much simpler - all communications and wires are laid in the walls, which are then plastered. Absolutely the same as they do in apartments.

By the way, about ventilation. If you “forget” to do it in an aerated concrete house, then the high vapor permeability of the walls will allow you to somehow cope with excess humidity in the house, but in a frame thermos house without ventilation with a microclimate everything will be very bad.

What else?

The sound insulation of a frame house is as bad as that of an unplastered house made of cellular concrete.

Hanging heavy objects on walls is only possible on a supporting frame.

Mice and other pests can infest the walls of a frame house.

Fire hazard. Stone houses also burn, but extremely rarely this leads to the collapse of walls and ceilings. A frame house burns out instantly, despite various impregnations for wood (remember that electrical wiring in a frame house can only be carried out using the open method).

The durability of a frame house depends on the service life of the wooden frame (and without protection, the wood will begin to rot). While stone building materials (including cellular concrete) are eternal, cement-based materials only become stronger over the years.

If you compare fully finished houses of the same area, with engineering systems and finishing, you can make an amazing discovery. The cost of work and materials for a frame house is almost completely identical to the cost of work and materials for building a house made of aerated concrete. Of course, an aerated concrete house will be a little more expensive, because... during its construction it will be necessary to use mechanization, but this will be less than 10% of the total cost of all work.

Thus, we can conclude that aerated concrete is an ideal building material, which has no alternatives in principle. A frame house should only be considered if, for one reason or another, you do not have the opportunity to build a house from cellular concrete.

In the next part we will choose the ideal roof for a country house. Don't switch!