Frame house according to all the rules. How to build a frame house correctly

This design is also called "Canadian". Frame houses are unusual for our country, since it is in our blood to do everything thoroughly and reliably: first there were strong log cabins, then stone buildings, many of which are still standing. By the way, the prefabricated panel houses we use vaguely resemble the Canadian version.

Therefore, before dealing with foreign technology, it is worth finding out why it is attractive. It is worth noting that it is this type of structures, for example, in America, that makes up most of the individual housing being built. And "there" they know how to count money.

The advantages of frame construction

- The pre-fabricated technology for the construction of houses allows you to complete the work in the shortest possible time (from 3 to 5 months).

- The building has a much lower weight than similar structures made of wood (logs, beams) or bricks, reinforced concrete slabs. Consequently, the foundation is needed not as massive. And this is a significant reduction in the cost of the total cost of construction.

- The ability to install engineering communications directly "in the wall", which not only promotes the use of any kind of finishing material, but also "hides" from the eyes of various nodes, pipes and wires.

- The use of special (heavy) construction equipment is not required. This means that work can be carried out in a limited space, without the arrangement of access roads.

- The strength of the building. Subject to the technology, such a structure is resistant to the whims of nature (strong wind, a large layer of snow on the roof, etc.). Experts say that even a small earthquake will not be fatal for him.

- The ability to build on almost any type of soil.

- There is no shrinkage. This means that the entire production cycle continues without interruption - finishing starts immediately.

- Good thermal insulation with low wall thickness. This significantly reduces heating costs. One of the forums even said that on cottage just two oil coolers are enough. Moreover, this has been practically verified. The thermal conductivity of a "frame" wall is comparable to a bar (0.5 m).

- With good quality - low cost.

Frame houses are divided into 2 types: frame-panel and frame-frame. But the construction of frame wooden houses the first type is not always possible, since it is fraught with certain difficulties.

These models have a common component - the frame, the "skeleton" of the entire structure. But the methods of plating it differ. Consider the features of the technology for the construction of each structure.

The frame-panel house is also called "panel". It is built using the assembly method. That is, ready-made shields are mounted right on the spot, connecting them to the frame and to each other. Self-production elements are associated with high labor costs, and the quality of the "product" is not guaranteed. The production of such panels is carried out by enterprises specializing in building materials.

What is this product? The tongue-and-groove boards (butt-jointed) are enclosed in a sturdy wooden frame. On both sides, such an assembly is sheathed with either fiberboard or a board. Moreover, in the latter version, on the one hand, the finish is vertical, and on the other, it is a "sandwich". Steam and waterproofing layers are applied to the surface of the shield. What material is used must be checked with the manufacturer. Top - horizontal stripe of the boards, and the second row - again vertical. This is one of the possible options.

Such structures have differences not only in the technology of manufacturing panels (used material, its layout), but also in the way the building elements are connected to each other. A frame is being prepared to install the modules. As a rule, it is also made of wood (timber). But in recent times for the manufacture of the "frame" more and more use of steel galvanized profiles.

1. Making high-quality shields on your own is a rather troublesome and complicated business. Firstly, it is necessary to withstand all dimensions, literally down to the "millimeter". Secondly, the elements for fastening the shields. If you buy them separately, then it is not a fact that all of them will fit. Thirdly, right choice insulating materials and their laying for assembly. If you buy ready-made ones, then you need to find out what type of insulation is used, by what technology the modules are made.

2. It will not be possible to completely assemble a frame-panel house with your own hands. Construction equipment will be needed, first of all - a crane. It is impossible to manually lift bulky shields and, holding them in weight, to attach to the frame;

3. The machine needs free space to operate. To assemble the shields, you also need a place. By the way, this is a rare case when they gather at the construction site. After all, it will be necessary to deploy an almost full-blooded mini-workshop. And if they are going to be collected "somewhere", then they still need to be delivered. You will need a trailer or extended body truck + trailer. How can they drive up, turn around, unload?

4. It is necessary to stock up on a variety of tools, including special ones (puncher, electric screwdriver, and the like). Does it make sense to buy all this and spend a lot of money, if after the completion of construction, much more may not be needed?

5. Not every person understands all the intricacies of such construction, in its technology. This is the correct construction of the foundation, protection (heat, hydro, anti-corrosion, and so on). And also walls, floors, roof, And that's not all. For example, marking under doors and windows is a tricky task. If there is a mistake, then fix it later - sometimes it is quite expensive and not always feasible. From this point of view, it is better to make a turnkey order.

We are all human and, unfortunately, not all of us are decent. If the work is performed by the specialists of the company with which the contract has been concluded, then you should not rely 100% on their conscientiousness. It is better to carefully study this issue yourself. Then it will be possible not only to “be present” on the spot, but also to competently control the entire process.

As an example, some approximate prices for sets of panel houses (rubles / m2):

- one-story - from 9,000 to 10,000.

- two-story - from 8,700 to 9,500.

- with an attic - from 8,000 to 9,500.

With assembly on site - about 15,000 - 17,000 rubles. The cost depends on the specific project (amount of work + complexity).

The frame-frame model is more suitable for self assembly... Also, the first step is to equip the foundation. Lightweight tape is mainly used. A mortgage crown is assembled on it (made of a log or bar). Frame racks are installed on it. The recommended distance between them is about 1 m. This is dictated by the optimal distribution of the load on the base. Fastening of racks - with staples, large nails.

The connection between them (upper and lower) is with bars. For greater stability, diagonal jibs are placed. If the height of the walls is large, then you can additionally put horizontal ones.

After assembling the frames of all walls, the roof frame is being prepared. First - the rafters, then - the lathing for the installation of insulation (usually slabs) and the roof. Moreover, the latter must be installed immediately in order to cover the place of work and the installed structural elements in case of bad weather. Then - finishing the frame.

At the same time, engineering communications are being laid: sewerage, water supply, gas, and so on.

Such a structure will cost less than a shield one, on average by 15 percent.

The complexities of "self-construction"

1. One way or another, you will have to order a project. Even a professional cannot take everything into account on his own. You need to understand that representatives of different specialties always take part in this process: builders, heating engineers and many others. Indeed, a modern house should have heating, water, gas, a telephone, and much more.

If the construction is carried out by a specialized organization, then it carries out the whole range of measures. From the development of the project to the commissioning of the object. By the way, all the approvals with supervisory and other authorities (for example, power engineers, gas workers) are also her concern. The customer is relieved of all these procedures;

2. Increase in terms of work (purchase of material + construction itself). Much depends on people: their number, the possibility of daily employment, skills in this kind of business. Therefore, it may take 2 or 5 months;

3. Make a competent connection of parts. For example, the length of a board or timber will be less than the length of the wall. This means that we will have to build up. And how to do it correctly?

Issue price

Many are interested in how much it will cost to build a frame country house... For example, one-story option, with an extension and an attic, will cost about 450,000 rubles (with delivery to the place).

It should be borne in mind that the price is influenced not only by the design, but also by the materials that are used. Including - insulation, waterproofing.

Frame house building has a long history and is constantly evolving, new materials appear that contribute to a significant improvement in performance frame houses, increase their thermal properties and durability. One of the most significant advantages of a frame house is the speed of its construction at a relatively low cost. When building a frame house with your own hands, it is possible to use various finishing materials and combine them. Correctly and efficiently built frame house has good thermal insulation properties and durability.

Frame

The basis of a frame house, as its name implies, is a frame. Therefore, the construction of the frame is one of the most important and responsible work. The frame fulfills a load-bearing function and must have sufficient strength and rigidity. And in order to avoid further problems during finishing, it is necessary to maintain the exact geometric dimensions of the frame and monitor the vertical and horizontal levels of the frame elements - only then the materials interior decoration Will "lay down" evenly and tightly, provide a high-quality and beautiful surface of the walls, floor and ceiling of the future home.

The scheme of the frame device must be thought out and drawn in advance, an elementary project must be prepared, all the elements must be calculated and the nodes for connecting parts and elements of the frame must be determined. We will not dwell on the design separately, but we will indicate all the main points of the frame project using the example of construction.

We start by preparing the foundation for installing a frame on it. It is necessary to check the level strip foundation and, if necessary, level it with cement mortar. This work must be done carefully and carefully, be sure to remove all irregularities. It is necessary to ensure a tight fit, without gaps, to the foundation of the lower rim of the frame in order to further prevent cold air from blowing outside and, as a result, the formation of condensation. When the surface of the foundation has acquired the proper evenness, we arrange a waterproofing layer of waterproofing so that moisture from the concrete does not flow to wooden frame and proceed to laying the lower rim of the frame.

We start by preparing the foundation for installing a frame on it. It is necessary to check the level strip foundation and, if necessary, level it with cement mortar. This work must be done carefully and carefully, be sure to remove all irregularities. It is necessary to ensure a tight fit, without gaps, to the foundation of the lower rim of the frame in order to further prevent cold air from blowing outside and, as a result, the formation of condensation. When the surface of the foundation has acquired the proper evenness, we arrange a waterproofing layer of waterproofing so that moisture from the concrete does not flow to wooden frame and proceed to laying the lower rim of the frame.

As a material, we use a bar of 150 x 150 mm, pre-planed and treated with a fire-bioprotective compound.

Basic rules for the design and assembly of the lower crown (strapping) of the frame

Dear readers, design in this case is self-development elementary drawings, diagrams, drawings and plans of the future structure. For small houses and buildings, this is permissible with careful study theoretical foundations and materials. If you have plans to build a large house, we strongly recommend contacting professional designers.

1. The overall dimensions of the lower strapping should be 5-7 cm less than the dimensions of the foundation. This is necessary so that when exterior decoration it was possible to mount the ebb and external cladding boards of the house (photo 6, 7). This option provides a good appearance at home. Sometimes you have to meet with frame houses, the walls of which "hang" over the foundation. This combination of walls and foundation looks ugly.

1. The overall dimensions of the lower strapping should be 5-7 cm less than the dimensions of the foundation. This is necessary so that when exterior decoration it was possible to mount the ebb and external cladding boards of the house (photo 6, 7). This option provides a good appearance at home. Sometimes you have to meet with frame houses, the walls of which "hang" over the foundation. This combination of walls and foundation looks ugly.

2. The connection of the lower trim elements must be rigid and windproof. It is recommended to perform it "in a quarter".

3. It is more practical and convenient to install and fix the floor beams simultaneously with the installation of the lower trim.

4. The gap between the lower beams and the foundation insulation is sealed with foam polystyrene or oiled jute fiber gaskets.

Installation of the lower frame trim

Having laid out the previously prepared elements of the lower floor trim with cut-out quarters on the foundation, we check the overall and diagonal dimensions, as well as the horizontal level, and then proceed to the assembly of the elements using self-tapping screws and liquid nails (wood glue-sealant). After assembling the lower trim, we proceed to the installation of floor beams made of planed antiseptic timber 100 x 150 mm. We lay the beams with a step of 600 mm and fix them “in a quarter” to the lower strapping with self-tapping screws and liquid nails.

For the convenience of work and the reliability of the fasteners in the upper "quarter" we drill holes for self-tapping screws with a diameter of 5-6 mm. We use self-tapping screws 5 x 130 mm.

For the convenience of work and the reliability of the fasteners in the upper "quarter" we drill holes for self-tapping screws with a diameter of 5-6 mm. We use self-tapping screws 5 x 130 mm.

I advise, for the convenience of further work, at this stage to proceed with the construction of the subfloor: we fix the 40 x 40 bars to the floor beams, on top of which we lay the subfloor from the edged board.

We treat all structures and elements of the lower trim and subfloor with an antiseptic.

Basic rules for the design and assembly of the frame wall structures and top floor

1. The frame of wall structures consists of uprights, upper strapping, ties and enclosing structures of window and doorways.

The height of the rooms is determined by the racks (the length of the racks). It is recommended to calculate the distance between the posts based on the width of the sheets or insulation mats 60 or 90 cm.

It is necessary to immediately add the enclosing structures of window and door openings and internal partitions to the frame scheme. To do this, you need to think over the layout of the house in advance. Of course, frame technologies make it easy to change the layout of the premises, but it is better to do everything right at once, so as not to redo it later.

2. When designing and installing, it is necessary to take into account as much as possible all the subtleties of the subsequent installation of enclosing structures and finishing coatings. To save money and minimize construction time, it is better to buy window and door blocks, rather than order. It is necessary to find out or buy these blocks in advance, and when installing the frame of the fencing of the openings, arrange for specific blocks with mounting gaps of 10-15 mm. This will greatly facilitate, speed up and reduce the cost of work.

2. When designing and installing, it is necessary to take into account as much as possible all the subtleties of the subsequent installation of enclosing structures and finishing coatings. To save money and minimize construction time, it is better to buy window and door blocks, rather than order. It is necessary to find out or buy these blocks in advance, and when installing the frame of the fencing of the openings, arrange for specific blocks with mounting gaps of 10-15 mm. This will greatly facilitate, speed up and reduce the cost of work.

3. An extremely important point is to think over the fastening of the racks to the straps and other fastenings of the elements and frame parts to each other. It is, of course, cheap to use joints on nails, but unreliable and inconvenient - nails lead to cracking of the wood and loosening of the frame from hammer blows. Currently, self-tapping screws and screwdrivers are available and convenient, and a wide selection of metal corners and plates allows you to make connections firmly, quickly and inexpensively.

Frame fabrication and installation

So, it is necessary to correctly calculate the frame so that it has sufficient strength, rigidity and space inside the walls for insulation (150 mm). For the frame, it is necessary to use dry material so that when constructing walls in a layer of insulation, the material does not "snot", does not rot from the accumulation of moisture and lack of ventilation. To save money, you can use used boards and beams (for example, for the construction of a bath - the remnants of lumber from the construction of a house). The material for the frame device must be treated with a fire-bioprotective compound and all unrooted areas must be removed. Make parts in advance according to the dimensions from the schematic drawings. During installation, it is important to maintain geometric accuracy and avoid deviations of structures from horizontal and vertical levels.

As corner posts and posts at the joints of the upper strapping, we use planed antiseptic timber 150 x 150 mm. Install corner posts and fix them with temporary corner slopes, in the lower part of the rack to the strapping we attach them to standard metal corners 75 x 75 mm (width and height of the corner parts). These corners are quite enough to ensure the reliability of the fastening. More massive corners are not required, since the metal in the frame is a provocateur for the formation of condensation and cold bridges. Full-width corners will lead to metal cooling and moisture condensation. The corners must be attached to the inside of the racks - there they will be constantly warm (with the winter version of the house, including).

Next, we proceed to the installation of pre-prepared elements of the upper strapping from a bar of 100 x 150 mm. In the beams of the racks from a bar of 150 x 150 mm, we first cut out "quarters", or rather not "quarters", but 2/3 - 10 cm under the strapping bar. In these installation places, we mount the upper strapping beam. We also fasten the details with self-tapping screws and liquid nails.

After installing the upper harness, we check the geometric dimensions and set the corner posts according to the level, fixing them with constant diagonal slopes - ties, and we begin to install intermediate posts from a 150 x 50 mm board to the pre-marked places on the harness beams. We connect all elements with liquid nails and self-tapping screws, as well as galvanized metal corners.

We make the ties from bars with a cross section of 50 x 50 mm, and fasten the ties to the posts and straps with self-tapping screws 4 x 90 mm. We establish ties only in the corner sections of the frame - this is quite enough to ensure the rigidity and stability of the frame and the building as a whole. Ties made of bars with a cross section of 50 x 50 mm will not interfere with the insulation of the house - laying the insulation in the frame section.

At the end of the work on the structure of the wall frame, we mount ceiling beams... The pitch of the beams is determined based on the insulation used - if it is a slab mineral wool insulation with a width of 60 cm mats, then the pitch of the beams is respectively 60 cm, if a roll of mineral wool insulation, then the pitch of the beams can be increased to 90 cm. The section of the beams depends on the length of the spans. When planning the size of the premises, it is advisable not to swing the lengths of the premises over 4 meters, since spans up to 4 meters are easily covered by standard beams with a section of 100 x 200 mm. If this is an upper roof (attic) floor, then a cross-section of 50 x 150 mm or 100 x 150 mm beams is sufficient. For large spans, you will have to use special beams made of laminated veneer lumber, or install internal support columns.

At the end of the work on the structure of the wall frame, we mount ceiling beams... The pitch of the beams is determined based on the insulation used - if it is a slab mineral wool insulation with a width of 60 cm mats, then the pitch of the beams is respectively 60 cm, if a roll of mineral wool insulation, then the pitch of the beams can be increased to 90 cm. The section of the beams depends on the length of the spans. When planning the size of the premises, it is advisable not to swing the lengths of the premises over 4 meters, since spans up to 4 meters are easily covered by standard beams with a section of 100 x 200 mm. If this is an upper roof (attic) floor, then a cross-section of 50 x 150 mm or 100 x 150 mm beams is sufficient. For large spans, you will have to use special beams made of laminated veneer lumber, or install internal support columns.

We cut out “quarters” in the beams to connect them with the harness beams. We fasten the beams to the beams with self-tapping screws 5 x 130 mm and liquid nails.

When building frame houses, the question always arises: what to do in the first place after installing the wall frame? Installing wall cladding or roofing? It takes several days to install the cladding, and rain can spoil Decoration Materials... If you install the roof, and this will also take several days, then gusty winds can easily rip it off. We recommend in the case of small houses or suburban buildings, it is better to start with the roof.

Roof

When installing a roof, the most difficult and painstaking stage is installation rafter system... When designing this house, we decided not to complicate our work and abandon complex roofing, opting for a gable roofing system with a small outlet above entrance group(by the porch).

When installing a roof, the most difficult and painstaking stage is installation rafter system... When designing this house, we decided not to complicate our work and abandon complex roofing, opting for a gable roofing system with a small outlet above entrance group(by the porch).

There are many types, types and designs of roofing. For our future home, we have chosen again the simplest constructive solution- a roof with a load-bearing ridge girder. In this case, the main thing is to install exactly the ridge beam and then all the rafters will be the same, they can be made according to a template and then easily mounted. It is easier and more reliable to fasten the rafters to the beams on metal corners 50 x 50 mm on self-tapping screws, we install the corners on both sides of the rafters. The step and section of the rafters depends on the type of lathing and roof. For our future roof from soft tiles, the pitch of the roof will be taken as a standard 60 cm, the material for the rafters is a board of 50 x 150 mm.

By the type of roof insulation, they are divided into two types:

- cold with attic space - in this version, the upper ceiling of warm rooms is insulated, and the attic space is ventilated through ventilation grates in gables, or through roof eaves and ventilated ridge;

- insulated or attic - in this version, the roof is insulated. This is a more complex type of roof and we will talk about it in a separate article.

Roof fabrication and installation

We started with the installation of a ridge beam from a 100 x 150 bar, the eaves of the beam were sculpted and painted on the ground. The rafters were made from a 150 x 50 mm board, the visible rafter outlets were also sculpted and painted before installation, two sets of outer rafters were sculpted and painted completely. After repeated fitting and adjustment of the first set of rafters, the rest of the sets were cut in its image. The finishing slight adjustment was made during the installation (simple lumber does not allow to mount the harness and ridge girder with millimeter accuracy). Fastened the rafters metal corners to the ridge girder and the upper frame strapping, additionally fixed with liquid nails.

To avoid the painstaking work of filing the overhangs of the roof from below, we decided to arrange a flooring of pre-painted lining on top of the rafters, and use horizontal guides from the lining along the rafters for subsequent installation and connection OSB boards... When installing OSB, gaps should be left between adjacent slabs to compensate for thermal deformations of the slabs.

Painting the lining and visible parts of the rafter system on the ground greatly speeds up and simplifies the work. It was decided to make the roof of soft bituminous shingles. For this, a flooring of OSB plates is arranged, on top of which a lining carpet is first laid, and then the tile itself. Before installing the bituminous shingles around the perimeter of the roof, we installed metal end and cornice strips, giving the roof a finished look. Bituminous shingles are a fairly simple material to work with, one person can work with it, the main thing is to read and follow the detailed and competent installation instructions that are attached to the kit.

Painting the lining and visible parts of the rafter system on the ground greatly speeds up and simplifies the work. It was decided to make the roof of soft bituminous shingles. For this, a flooring of OSB plates is arranged, on top of which a lining carpet is first laid, and then the tile itself. Before installing the bituminous shingles around the perimeter of the roof, we installed metal end and cornice strips, giving the roof a finished look. Bituminous shingles are a fairly simple material to work with, one person can work with it, the main thing is to read and follow the detailed and competent installation instructions that are attached to the kit.

Basic rules for the design of exterior decoration and insulation of a frame house

1. Currently, there are many materials for insulation and exterior decoration of frame houses. The choice is yours, dear readers.

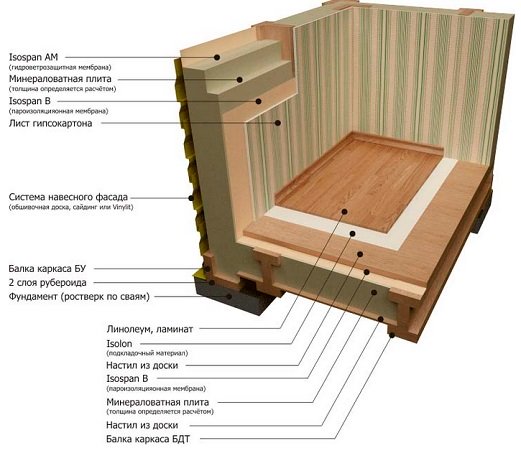

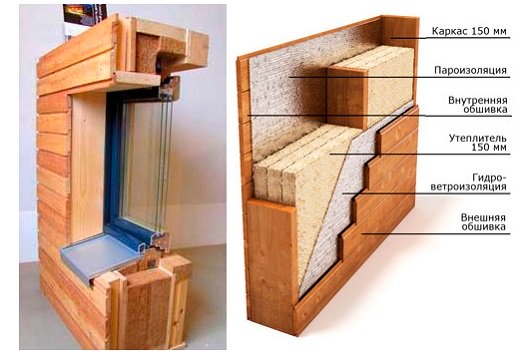

2. When constructing walls, it is important to observe the general technological rule for the composition of the enclosing structures:

- outside as a finishing coating, we use an inexpensive and practical material - imitation of a bar;

- before sheathing on the frame, we attach a hydro-windproof film;

- insulation is mounted inside the frame;

- from the side of the premises on the frame is mounted vapor barrier film and further any interior decoration.

3. For insulation, mineral wool slab or roll materials are used as standard. For small houses and buildings of seasonal residence, you can use cheaper roll insulation. The total thickness of the insulation layer in this case can be 100 mm (two layers of 50 mm each). For warm winter houses, the insulation layer must be at least 150 mm. When insulating, the main thing is to observe the uniformity of the insulation layer and the absence of voids and gaps. Therefore, it is better to use denser mineral wool slab insulation that is not prone to slipping. Rolled mineral wool lightweight insulation in the walls of frame houses has to be carefully fastened to the structures with a stapler and staples. We attach the outer layer of insulation to the outer finish, the next layers we attach to the posts and the upper frame of the frame.

Outdoor decoration

Outdoor decoration

The roof is ready - we proceed to the exterior decoration. Outside, we decided to sheathe our house with imitation timber. First of all, we install a steel outflow on the base, which will not allow atmospheric precipitation to fall under bottom rail frame. By the way, this is a general and obligatory rule that must be followed before starting wall cladding with any material. Installing an ebb after the end of the sheathing is an extremely difficult undertaking. For a frame house, it is extremely important to comply with the insulation technology. On the outside of the frame, we arrange a hydro-windproof layer made of a special membrane, which allows moisture to pass through on the one hand, and not on the other.

The membrane is designed so that moisture from the outside does not flow to the insulation and at the same time can escape from the insulation to the outside. As a construction expert, I cannot fail to note a very common mistake - the installation of the membrane with the inside outward and, conversely, as a result of which the proper functioning of the frame house is disrupted. To avoid this error, which can then be costly, you just need to pay attention to the instructions, in which everything is clearly indicated.

Advice from the company Ecoplat LLC

The main task of the windscreen is to create a surface that does not allow outside air to pass through (i.e. maximum tightness of the fit).

The membrane cannot provide a snug fit at the joints and to the frame, and therefore there will be gaps of up to 5-10 mm. This design can be compared to a window frame, where the outer glass was not only not placed on the sealant, but the corner was chipped off. Windproof slabs have resilience and elasticity, which allows them to compensate for both the different thicknesses of the frame elements at the joints, and the geometric curvature of the frame elements. Subsequent exterior wall decoration can take place throughout the year.

Most Finnish construction companies in the construction of frame houses, a windproof outer plate (soft fiberboard) is used. This is the key Finnish technology low-rise housing construction.

Due to their elasticity and elasticity, the IZOPLAAT windproof boards provide total protection to the house from cold and street noise for decades.

Windshield plates that are open to convection allow water vapor to pass through. What ensures drying building structure, prolongs the service life of wooden elements and preserves the thermal insulation properties of soft insulation. In the production of such boards, neither glue nor chemical additives are used. During manufacture, the structure remains porous and light, therefore, a good heat and sound insulating material is obtained. The boards are impregnated with a special wax compound to protect them from direct exposure to water. But they remain breathable and provide air exchange in the walls of the building by regulating humidity. Resin - a natural antiseptic - makes the boards resistant to decay. Their service life is 50 years, although in fact they have been serving people even in the Leningrad region for more than 60 years.

After installing the membrane, we set the first row of imitation of a bar according to the level. For durability, the first row of boards is treated with a fire retardant compound and painted on all sides. Before starting work, we painted all the boards once with a wax-based impregnation, we will apply the second layer of paint already in place. If the frame is mounted “on the level”, wall cladding works are rather quick and easy.

Warming

Warming

Treat with attention and thoroughness to the work of warming a frame house. The comfort of your stay in the house, as well as the durability of the house as a whole, depend on the quality and compliance with the insulation technology. For insulation, we used mineral insulation 5 cm thick, which was laid in three layers. When insulating wall structures, it is very important to firmly fix the insulation (we used a stapler for this) in order to prevent the insulation layers from settling or knocking down). The joints of different layers of insulation should not be done in one place.

The work of insulating a frame house is not the most pleasant and very dusty, nevertheless, it is a very important and crucial stage of construction. Careful and scrupulous laying of wall and ceiling insulation layers is a guarantee of impermeability and good thermal insulation, and therefore how warm your frame house will be. I mentioned this several times, because I have repeatedly seen ready-made frame houses, unsuitable for living, with decaying walls and ceilings, cold and damp - this is how poor-quality insulation subsequently manifests itself.

After the walls are insulated, a vapor barrier film is mounted on the inner surfaces of the frame. The installation of the vapor barrier is carried out in accordance with the instructions for the use of materials. The main thing is that the vapor barrier layer is continuous and vapor-proof.

At this stage, during the construction of the house, we took a technological break - we were simply tired. The work on the construction of a frame house is not physically difficult, but painstaking and responsible. Therefore, while writing this article, we also decided to take a break and continue the story in the next issue.

Text and photo: Alexander and Grigory Isakovsky

The rules or Code for the construction of frame houses are actually rules that describe in detail how and from what to build a frame house. Code can be translated into Russian as Code, that is, a set of rules for construction. You can sometimes hear the slang translation of Code as Code. Relationship to Code in North America akin to religion. If you decide to build a frame house there, you will need a thorough knowledge of the Code / Rules of the local state in the United States or a province in Canada. Any violations will be identified by the inspector and you will be ordered to eliminate them. You can be ironic about the rules that describe how many nails and in what order you need to hammer into the end of the board, but this is true. The whole process of construction of frame houses in America is carefully controlled by the state in the person of highly professional engineers with many years of experience in their specialty. This helps to avoid fatalities during construction and, as a result, forms a market for quality housing. When buying a frame house in the USA or Canada, you will not have to doubt the correct choice of the section of the lag for the overlap, since they were chosen by carpenters based on the Code tables of the local state and then checked by an inspector upon completion of the work.

Say, they say, he discovered America! We in Russia are full of officials of all stripes who only do what they check and prohibit. Yes, but there is a key difference between the bureaucratic systems of America and Russia. They check with us to ban, they check to correct errors. You will not be able to bribe an inspector in the United States with which you have identified inconsistencies in the Code / Rules of your foundation. As a result, everything will have to be redone, but your frame house will stand on a normal foundation. I see strict adherence to the Code / Rules as a compulsory necessity. The fact is that the active dominance of construction projects by labor migrants is typical not only for Russia, but also for America. Moreover, they faced this problem before us. Who works at our construction sites: Tajiks, Uzbeks, Moldovans and other citizens of the former republics of the USSR. Poor knowledge of Russian combined with a lack of professional carpentry education - feature builders of frame houses in Russia. Don't you think so in America? Nothing like this. Mexicans and other audiences from all over the world are building prefab houses under the strict guidance of a local foreman. In their knowledge of English and the availability of specialized education, they can compete with our Tajiks. The only way to build quality is to enforce Code's draconian rules. Moreover, the rules from our point of view can be absolutely stupid. For example, in the USA and Canada, you cannot build a frame house on a MLF or a columnar foundation. There are simply no such types in the Code for low-rise private houses. You can build a bridge across the strait or a skyscraper on a pillar reinforced concrete foundation, but two-storey house it is forbidden. But on the other hand, the rules in Code are written, as they say, on other people's mistakes so that they do not repeat themselves. That is why there must be one person at an American construction site who knows every line of the Code / Rules to the comma. Although in fact, learning to build according to the same rules, even the most illiterate migrant remembers the requirements of the local Code / local Rules a few months later.

You ask, why do we need this Code / these Rules? We live in another country and we don't have such problems. We can build a frame house on a MLF or a columnar foundation and it will stand for 100 years. Unfortunately, we are at the other extreme. Instead of strict rules - their complete absence. They build a lot of things: a meter step, boards of natural moisture, vapor barrier on both sides of the insulation, etc. It is because of this that such a negative attitude towards frame houses is formed in Russia. It is not within our power to correct this situation at the state level. We know perfectly well how the emergence of such strict rules will cost us - a complete stop of private low-rise construction in the country. But for his own home You can use the most important provisions of the Building Code, or at least be guided by (Code of practice for the design and construction of frame houses). True, it should be said that our Code of Rules is the selected provisions of the North American building code translated into Russian.

This will allow you to build without major mistakes. modern house using available materials and existing mercenary force. The section contains several documents that will be useful as a source of information. In all English-speaking, typical construction techniques are shown, taking into account compliance building regulations USA and Canada.

I will try to state the key points in human language. modern construction on frame technology.

The first stage is to check the geometry of the foundation and apply a frame house.