How to make walls in a frame house. The correct design of the walls of a frame house

Foreword

The walls of such houses are a rigid frame consisting of wooden posts, crossbars and struts, which is installed on the foundation and sheathed with boards on both sides.

Required tools and materials

BulgarianBeams BoersNailsNail pullerPlaned boardDrillPencilJigsawMetal cornerknifeHacksawSafety glassesVapor barrierPerforatorRoofing materialRouletteSelf-tapping screwsConstruction staplerLadderWheelbarrowGonExtensionLevelInsulationA circular sawScrewdriverElectric planer

BoersNailsNail pullerPlaned boardDrillPencilJigsawMetal cornerknifeHacksawSafety glassesVapor barrierPerforatorRoofing materialRouletteSelf-tapping screwsConstruction staplerLadderWheelbarrowGonExtensionLevelInsulationA circular sawScrewdriverElectric planer

Content

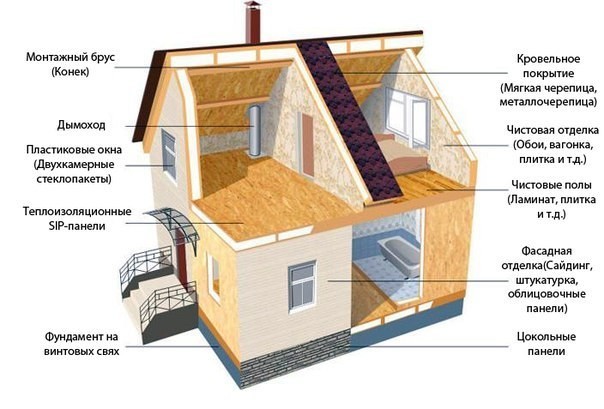

Walls frame house are a kind of layer cake, which uses a wide variety of "filling" as insulation and cladding panels. Depending on the construction technology of the frame structure, SIP panels, sandwich panels, wooden lining, particle boards and much more can be used.

The walls of the frame house in the photo

Frame houses are economical, durable, quick to erect and labor-intensive. The walls of such houses are a rigid frame consisting of wooden posts, crossbars and struts, which is installed on the foundation and sheathed with boards on both sides. It is best for each wall to be a separate frame. Typically, these frames are assembled on a suitable flat area near the construction site.

Look at the walls of a frame house in the photo:

The device of the walls of the frame house

When assembling, it is necessary to control that the distance between the axes of the racks is about 500-600 mm. If the wall of a frame house has an opening or is adjacent to other walls, the distance can be increased slightly. In the corners of the house, struts should be installed - this will increase the strength and rigidity of the structure. After assembly, the frame must be checked for squareness. Observe the device of the walls of the frame house.

The assembly of the assembled structures of the house begins with the basement piping. For this, as a rule, boards with a section of 50 × 100 mm, treated with antiseptic substances, are used. Preliminarily, a thorough marking of the walls of the structure being erected is carried out, then the boards are laid along the outer contour of the wall and connected to each other in the corners with nails. The horizontal laying of the boards is constantly checked using a level.

The direct installation of the walls is performed from the corner: one frame is installed on the basement trim, its verticality is checked and fixed with temporary struts, then a second frame is mounted at a right angle to it.

The lower and upper straps of the installed frames at the joints are securely fastened with boards. The rest of the frames are installed in the same way, controlling their verticality and the horizontalness of the upper strapping.

When the frame is installed, it is attached with nails to the basement trim and proceeds to sheathing and installing the internal partitions.

Flooring in frame house on the picture.

Assembling the walls of a frame house in the photo.

Insulation of walls of frame houses: video

Laying insulation in a frame house in the photo.

Styling thermal insulation material- another important stage. The operational qualities of the structure depend on how well this work is carried out. Before starting the construction of the walls, the foundation of the frame house should be covered with two layers of roofing material. The soil can be additionally insulated with expanded clay or slag. Upper part the foundation is lined with mineral mats.

Wall insulation frame houses shown in the video:

The house itself is insulated only after laying a layer of reliable vapor barrier material. Insulation should be attached to the walls of the house with special care (first of all, this applies to roll material). Also, make sure that the insulation does not interfere with normal air exchange.

Thermal insulation of the floor of a frame house in the photo.

Laying the vapor barrier in the photo.

"Pie" walls of a frame house

In general, the construction of a frame house is a "layer cake".

Frame wall wooden house and overlap in the photo: 1 - frame racks; 2 - counterrails; 3 - fibrous insulation; 4.5 - vapor barrier; 6 - wind protection; 7 - interior decoration premises; 8 - floor covering.

To make the "pie" of the wall of a frame house strong and reliable, adhere to the following recommendations:

- to assemble a wooden frame, use only dry edged timber and do not forget about struts;

- carefully treat the frame with compounds that protect it from decay;

- securely fix the insulation and close it with waterproofing and vapor barrier on both sides;

- for wall cladding, use lining, block house or any other suitable material.

Frame house is the most a budget option wooden house, based on the calculation of the cost of materials. However, its construction requires high precision and strict adherence to technology. Errors made will lead to the fact that the frame house will last less than a log or cobbled one.

What is the principle of house building technology from frame structures? Basically, the wall frame is a combination of racks and jibs, it is customary to build it from sufficiently strong and reliable materials, for example, wood or metal, after which the resulting space in the wall is filled with special heat-insulating materials.

We make a frame house with our own hands

A few decades ago, it was customary to use such simple materials as porous stone, clay, adobe in the walls, thanks to which the walls inside the frame house received an additional margin of safety.

On a note

Today, in order to accomplish this task, a decision is made to place more modern types of materials with better heat-insulating properties, lightness and durability.

The main advantages that the walls of a frame house have are economy, high thermal efficiency, as well as the efficiency of the structure, even a significant saving in area, which is associated with a decrease in the overall thickness of the structure. Next, it is proposed to consider the structure of the wall of a frame house.

How the walls of a frame house are arranged

The outer walls of the frame house are equipped as follows:

- The basis for the exterior finish is an OSB or isoplat plate. Elements such as counter-lathing, a gap for ventilation, protection from possible wind, made of a vapor-tight membrane are used. Used, independently installed racks,.

- A diffusion membrane is used as waterproofing. Used as exterior cladding walls are ordinary insulation, with additional sound insulation. Also, for exterior wall decoration, clapboard, block house or siding is used.

The internal walls of the frame house include a film for protection against dust, fixed (the humidity of the timber should be in the range of 14-16%). Additionally, the wall frame is treated with special antiseptic components and compounds, which increases the service life. The inner wall cladding of a frame house has a thickness of within 10 centimeters. Basalt insulation is laid between the outer and inner cladding, as a result of which a cake of the wall of the frame house is formed.

Stages of construction of a frame house

Having considered what construction they have interior walls frame house, it is worth indicating how their construction is carried out, finishing work is carried out. So, the frame house is being assembled in several separate stages.

Design

At this stage, the master agrees with the future owner of the facility all the technical points, a decision is made on the planning, an estimate of the future project is drawn up. The thickness of the walls of the frame house, which can reach up to 600 mm, is also determined at the design stage. This value is set based on the analysis of the materials and components used (first of all, insulation). For example, for the regions located in the north, it will be necessary to use cotton wool 200 mm thick, in the south, 100 mm will be enough, taking into account the peculiarity of the climate.

Preparing for installation

On preparatory stage it is necessary to perform regulated work with the frame. It is best to get wood in advance, and be sure to pay attention to the material being treated with a special antiseptic composition. It is best if these are edged, unplaned boards. Layers of roofing material are laid on the foundation, after which the beds for the lower strapping of the frame house are mounted. The logs themselves are placed on the edge, after which they rest on the harness with their ends.

Installation of walls of a frame house

The walls of the frame house are assembled at the bottom, after which they are installed on the lower strapping by means of shields. It is recommended that the shields be attached to the strapping exclusively with ordinary nails, while the structure will not collapse, there is no doubt about it. When the frame of the first floor is ready, the frame of the second floor can be erected using a similar technology. In the same way, the prepared sets of boards are installed on the upper strapping. The corners of the frame house are controlled, the correctness of their geometry is checked.

Insulation of the walls of a frame house

One of the important stages of construction is the insulation of the walls of a frame house. As a rule, for these purposes it is best to use foam, however, this is a budget option, for objects of more solid cost, you can use the same Rockwall.

Insulation begins from the floor, the foam plates are laid directly on the slats, previously nailed to the logs. In turn, it will be necessary to lay a floor from OSB sheets on the logs, after which the partitions and walls themselves can be placed on it.

At the last stages of work, the installation of the roof, the arrangement of the roof, the installation of waterproofing and wind protection elements, and the strengthening of the finished structure are carried out. To ensure proper vapor barrier, it is customary to use special membranes that can reduce the likelihood of moisture penetration.

On a note

Reinforced polyethylene, which was previously actively used in construction, has proven itself quite high as a material for vapor barrier wooden houses... Its advantages include a low cost, for budget construction this is the best option.

Recently, mastics have been widely used, which are applied to the walls and floor of the house immediately before the start of external finishing. What is noteworthy is that for applying the mastic there is no need to install the wall lathing, the composition can be applied in several layers, but each must be allowed to dry out. When the main part of the work is done, the "box" is ready, you can immediately start finishing works indoors.

Frame house building is gaining more and more popularity. For self-construction of housing, you need to know what is the structure of the walls of a frame house, its roof and floors.

What frame houses are built from

There are several types frame buildings, but all of them are united by the same principle of building a building. The basis of such houses is a frame made of wood or metal. Manufacturers offer a wide variety of prefabricated steel construction projects. This type of buildings is optimal for the construction of inexpensive housing and utility rooms.

Houses based on metal structures are distinguished by unsurpassed rapid erection, but they have one significant drawback: the metal skeleton of the building needs high-quality insulation. This is especially true for regions with harsh climates.

Timber frame houses are much warmer and do not require large heating costs. For the construction of the skeleton of the building, a beam with a section of 10x10 or 15x15 cm is used, boards with a section of 10x5, 15x5 and 20x5 cm. The frame elements are connected to each other using metal brackets, self-tapping screws and nails.

For the formation of walls and ceilings, durable moisture-resistant sheet materials are used: plywood, OSB, asbestos-cement slabs. Any heat insulators are suitable for insulation: mineral wool, glass wool, ecowool, polystyrene foam, expanded polystyrene, adobe, sawdust, foam concrete.

Frame walls and ceilings need waterproofing. For this purpose, roofing material, steam and waterproofing membranes, dense polyethylene are used. During construction, the following tools will be required:

- trimming saw for cutting wooden frame elements at a certain angle;

- circular;

- Bulgarian;

- it is advisable to have a thickness gauge for fitting the boards and beams to one size, which will greatly facilitate the construction process;

- cordless screwdriver.

Frame house wall cake

Frame walls consist of several layers:

- external cladding;

- hydro and vapor barrier;

- frame elements (corner and intermediate posts, vertical and horizontal battens);

- heat insulator;

- inner cladding.

The structure of the frame house allows you to erect walls of any thickness. This requires the observance of one condition: the width of the racks of the skeleton of the building must correspond to the thickness of the thermal insulation layer. In this case, all building code requirements will be met.

For regions with a warm climate, the optimal solution is walls 10 cm thick. mineral wool or foam. For areas with cold and long winters, the requirements are different. Here it is necessary to build frame walls with a thickness of 20-25 cm and pay special attention to high-quality insulation, which guarantees the absence of cold bridges.

In those buildings where polystyrene (expanded polystyrene) is used as insulation, the wall diagram of a frame house provides for a ventilation system. This need is due to the low vapor permeability of the foam. In rooms without ventilation, the level of air humidity inevitably rises, which leads to discomfort in living.

Construction of the corner of the wall of a frame house

Depending on the type of insulation chosen and its thickness, the frame wall has the following thermal resistance parameters:

- mineral wool 150 mm thick - R = 3.2;

- mineral wool 200 mm thick - R = 4.3;

- foam sheet with a thickness of 10 cm - R = 3.7;

- foam sheet with a thickness of 20 cm - R = 5.

The points of greatest heat loss are located in the corners of the building, therefore, special attention is paid to the arrangement of these frame elements. Corner posts are built from a solid bar or double boards, connected at right angles to each other.

The walls of the frame house are located on bottom harness fastened to the foundation with steel brackets and anchors. The joining of the inner lining to the frame is carried out through intermediate racks made of boards. The same material is used to sheathe the outer sides of the lower and upper straps, the ends of the floors.

During construction, special attention is paid to the tightness of the joints of the corner elements of the building. To ensure high-quality thermal insulation, it is recommended to prepare the lumber using a planer. This will allow you to get boards and beams with a perfectly flat surface. This approach will ensure the maximum quality of the walls of the frame house.

The main stages of the construction of walls

In the construction of frame houses, two technologies are used: assembly of a building from piece materials and ready-made large-sized elements.

In the first case, the preparation of racks and cladding is carried out directly at the construction site. In the second, factory materials are used - sandwich panels.

The walls of a frame house are built either on the lower strapping laid on the foundation, or on the lower floor ready for use. The second construction option is called "platform frame". Both methods of erecting the walls of a frame house provide the building with maximum strength and tightness.

Regardless of the chosen construction method, wall installation begins with the installation of corner posts. Preliminarily, markings are applied on the lower strapping or overlap, in accordance with which the lower crosspieces of the frame are laid. For this purpose, boards with a thickness of 4-5 cm are used, the width of which is equal to the thickness of the heat insulator.

After two are exhibited corner posts, they are connected with boards or a bar of the upper harness. This is done until the perimeter of the walls of the frame house is built. After that, proceed to the installation of intermediate racks and the formation of window and doorways... The strapping of these building elements is carried out using double planks.

Intermediate racks are set in increments of 50-60 cm. If sheet polystyrene (expanded polystyrene) is used as insulation, they are guided by the width of the canvases. This will avoid the hassle of cutting the insulation material and save it.

The technology of building a frame house allows you to use both screws and nails as fasteners. Sheathing from OSB or plywood is easier to perform using the former. For the device of a frame wall, they traditionally choose OSB boards 9-15 mm thick. It is important to purchase a moisture-resistant material - this will provide the highest quality waterproofing insulation.

Building a frame house with your own hands is a fun and easy process. For the installation of lumber, no lifting equipment is required. All work is done independently. The structure of a frame house is very simple, which is one of the advantages of this popular technology.

More articles on this topic:

The most simple and fast technology for building walls at home is frame. Moreover, such structures are distinguished by excellent thermal insulation characteristics, seismic resistance, and durability. And of course, one cannot fail to note the financial side of the issue. A frame house is an economical solution due to its special design and the use of inexpensive materials.

What is a frame wall?

It is a technically uncomplicated but effective design including:

The device of a frame wall may have its own distinctive features, for example, the use of metal racks, but the structure itself remains unchanged.

Stages of construction of a frame wall

Remarkable is the fact that to build frame wall anyone can do it on their own and this will not cause any special problems. Moreover, there is no need to have a special education or vast experience in this field to work.

So where to start?

The lower harness and logs must be treated with an antiseptic!

Walls can be erected from piece elements, that is, by installing each load-bearing beam in turn or by prefabricated structure. In other words, fragments of the frame are prepared in advance, which are then attached to the beam of the lower strapping.

Also one of the types frame construction is the construction of a house from ready-made panels (boards). They are produced in the workshop according to a pre-agreed project. Such panels are delivered to the site assembled, that is, they have window openings, places for installing doors, etc. It remains only to fix the shields to the frame and the walls are ready. This technology can significantly reduce the time of work, but it has limitations on the variability of execution. In addition, the panels can be heavy and may require a crane to mount them.

Wall structure

When the installation of the frame is completed, then you can proceed to the device of a multi-layer wall structure. Here, each of the constituent elements plays a specific function, therefore, it is necessary to observe a special construction technology.

Exterior finishing options

Of course, the outer walls of the frame structure can hardly be called aesthetically attractive. However, after finishing, they cannot be distinguished from their more expensive wooden or brick counterparts.

Traditionally, walls are decorated in two ways:

Also practiced exterior decoration in the form of masonry decorative bricks... This design option will give frame building elegance, sophistication and a unique appearance.