Painting aerated concrete. Exterior finishing of a house made of aerated concrete: options, tips

Blocks made of aerated silicate or aerated concrete appeared on the market relatively recently, and in a short time they could become a very popular material in both private and industrial use. low-rise construction. Simple technology allows you to build a house in a very short time, but when the time comes finishing works, many people wonder what materials and methods can be used. To clarify this issue, we will understand the features and methods of carrying out facing and painting work, and also tell you about what can be used to decorate the external walls of a house made of aerated concrete.

Features of gas silicate walls

The porous structure of aerated concrete has significant advantages in the form of excellent heat and sound insulation, however high vapor permeability does not allow us to call this material ideal.

It is no secret that the content of water vapor in the warm air of residential premises is much higher than in the external atmosphere. When passing through a wall made of gas silicate blocks, air at room temperature gradually releases heat, so the outside of the house is at ambient temperature.

Temperature changes in the thickness of the wall contribute to the condensation of water vapor, which causes a constant accumulation of moisture in the mass of gas silicate. Side effects in this case are a decrease in thermal insulation ability, a decrease in frost resistance cycles, and the development of fungal microorganisms on the surface of the walls.

To avoid waterlogging of the material, it is necessary to increase the vapor permeability of the outer surface of the wall, for which they uselow porosity finishing materials. At the same time, the diffusion capacity of the internal surfaces of the walls is reduced using special facing materials.

The peculiarities of porous blocks force strict adherence to construction technology: finishing of external walls begins only after all “wet” work in the interior of the aerated concrete house has been completed.

Single-layer aerated concrete walls. Exterior finishing options

Finishing of external single-layer walls of houses built from aerated concrete is carried out using one of the following methods.

- By coloring. The work uses façade putties or paints with high vapor permeability. At the same time, the appearance is greatly influenced by the quality of preparation of the wall surface, so the interblock seams are pre-troweled or an imitation of their jointing is done.

- Putty with special mixtures, intended for cellular concrete. The work is performed in one layer with a thickness of no more than 5 mm.

- Plaster light facing compositions for gas silicate blocks.

- Arrangement ventilated facade any type, which is covered with block house, siding and other decorative coatings.

- Cladding decorative bricks . The laying is carried out with an air gap of 3 to 5 cm.

Exterior finishing of a house made of aerated concrete is carried out in strict accordance with the principles of reducing vapor permeability from outside to inside the room, therefore The use of simple mortar and film-forming paints is not permitted.

Finishing facades made of aerated concrete and gas silicate blocks with plaster compositions

On the market you can find many dry plaster mixtures from domestic and foreign manufacturers. The simplest of them are lightweight cement-based building compounds. A lime additive is added to more complex mixtures with increased viscosity. It is more convenient to work with astringent solutions, but their cost is slightly higher.

Features of light plasters

To increase the vapor permeability of the plaster, manufacturers do not use the usual quartz sand. Light plaster mixtures contain porous mineral fillers and marble granules. This helps reduce the load on the prepared base and increases the diffusion capacity of the material.

Finishing a house made of aerated concrete. Photo

The advantages of light plasters include quite high coefficient of thermal conductivity, which ranges from 0.250 to 0.321 W/mx?K. Thanks to this, even a thin layer applied to the wall allows for a slight increase in thermal insulation.

The disadvantages of facade plasters include low strength, therefore, manufacturers do not recommend using such compositions for finishing the basement and basement walls of houses built from aerated concrete.

The use of mineral plaster compositions requires taking into account the features of these materials:

- increased resistance to shrinkage cracks;

- reduced mechanical strength compared to conventional plaster;

- improved heat-saving properties;

- increased vapor permeability.

The use of lightweight compounds reduces the load on the prepared base of the wall surface. This makes it possible to apply them in a thicker layer, which allows you to eliminate even significant unevenness.

Work order

When starting to decorate a house made of aerated concrete, keep in mind that in loaded areas with a high probability of shrinkage phenomena (corners of buildings, openings, etc.) it is best to reinforce the layer of plaster with mesh. In addition, it is imperative to adhere to the recommendations of the mixture manufacturer regarding temperature, humidity, preparation and application conditions.

The work is performed in the following order:

- First of all, eliminate all the shortcomings of masonry blocks: fill unevenness, eliminate chips, etc., for which they use the same solution as when constructing the building frame.

- Coarse grater overwrite uneven areas, then sweep away dust and dirt using a brush.

- Primary layer of plaster apply with a metal grater. It is important to achieve uniform thickness and uniform composition.

- Cut off reinforcing mesh of the required size and, using the same tool, press it into the bottom layer of the plaster mixture.

- Additional primer layer level out surface of the wall and allow it to dry.

- Thin finishing coat eliminate all irregularities, after which the plaster is structured with a trowel (if this type of decoration is necessary).

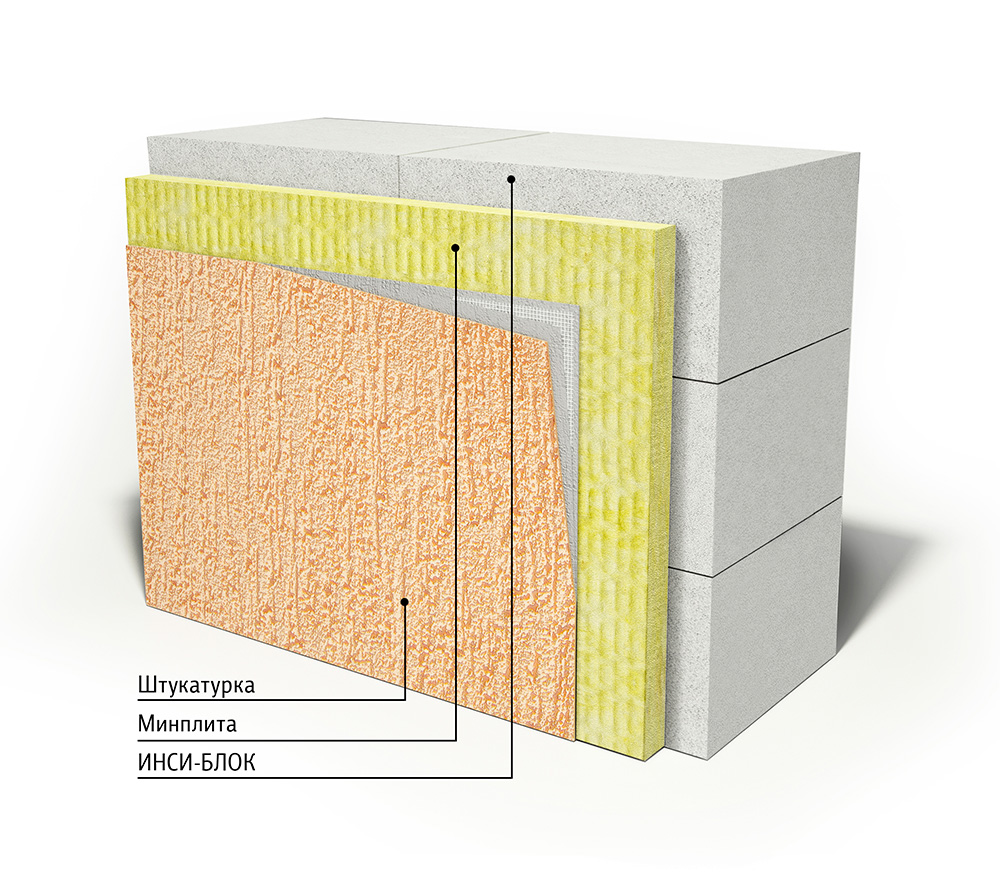

Often, polystyrene foam boards are glued to walls made of cellular concrete in order to increase thermal insulation. In this case, the plastering process does not differ from the method described above, and this technique is called a wet facade.

The use of bricks for exterior facade decoration

When planning to decorate a house made of aerated concrete with brick from the outside, the necessary prerequisites for successful work are created at the very first stages of design. First of all, this concerns foundation building - its width should provide good support for both building blocks and facing bricks. By the way, it should not protrude beyond the foundation by more than 30 mm.

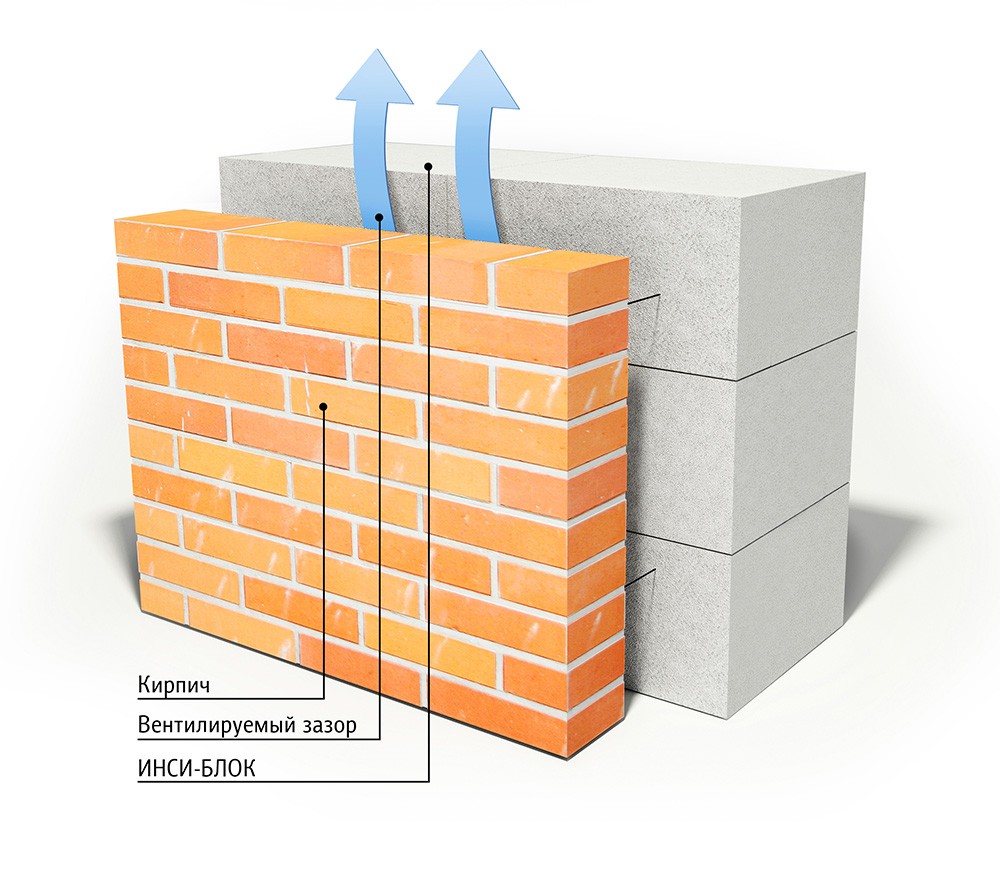

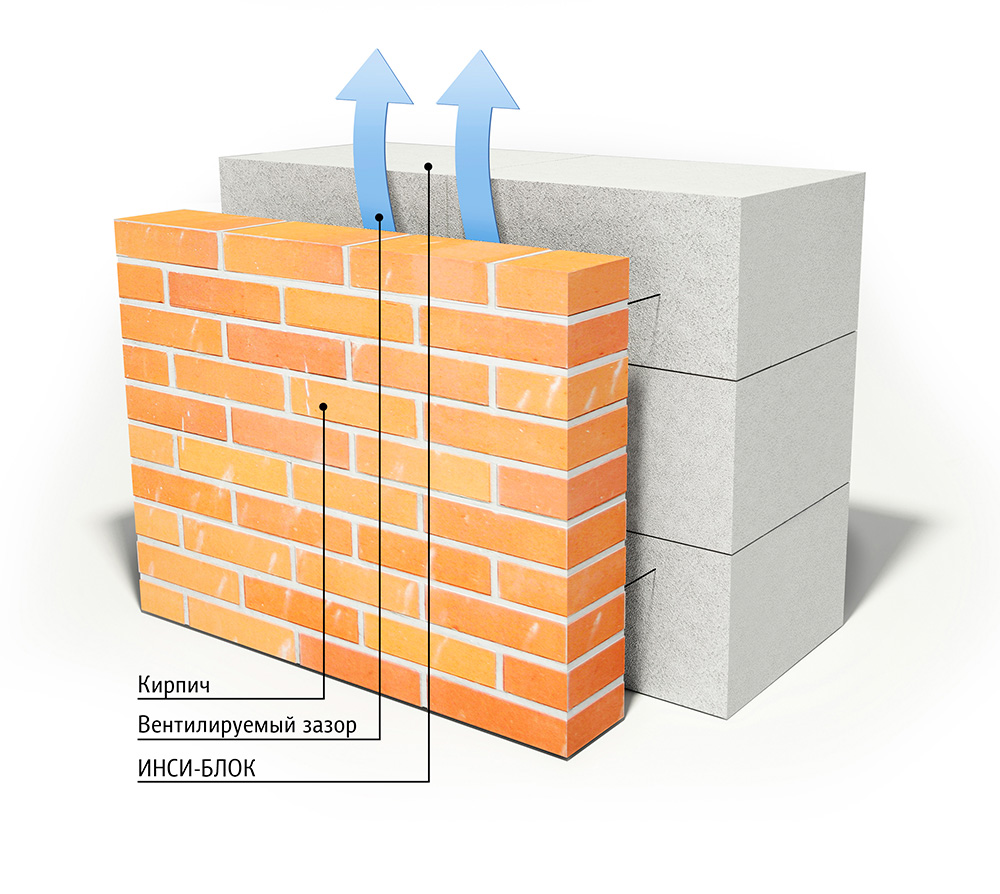

It should be understood that the jointing of brickwork reduces vapor permeability, lowering its value lower than that of aerated concrete blocks. To eliminate the formation of condensation at the junction of surfaces with different physical properties, a gap of 3-5 cm wide is left between the brick and aerated concrete. The width of the air gap is determined based on the scale of construction and the size of the building.

It will help to avoid getting cement-sand mortar into the remaining thermal insulation gap polystyrene foam sheet required thickness. It is installed in the masonry area and moved as necessary.

It is best if the air gap is equipped forced ventilation . For these purposes, the brickwork is not made monolithic, but with special holes - the so-called vents. Their area must be at least one hundredth of the entire area of the masonry.

Ventilation ducts are located at the base level and under the eaves of the building. In this case, you should not leave holes that are too wide - it is enough not to fill the vertical seams with mortar after a certain distance.

If there is insufficient ventilation, during the cold period the air temperature in the gap will be higher than outside, and condensation may appear on the surface of the masonry hidden from view. Also, moisture can penetrate inside by diffusion through the facing layer, so for brickwork it is important to ensure good waterproofing of the base.

If the building is not intended for living in the cold season, you can refuse to arrange an air gap. In other cases, failure to comply with the requirement to provide a gap is fraught with an increase in the humidity of aerated concrete and, ultimately, a decrease in thermal insulation. If this argument turns out to be unconvincing for you, then be sure to use finishing materials with low diffusion ability indoors.

Methods for attaching brickwork to a wall made of cellular concrete

The brickwork is attached to the aerated concrete wall using connections, installing them at the rate of up to four connections per 1 square meter. m of surface, and the openings are made with a top crossbar. As a support, you can use steel corners or several reinforcement bars, extending onto the walls at least 250 mm.

You can attach brick cladding to a wall made of cellular concrete as follows:

- Leaving embedded elements during the construction of walls.

- By attaching perforated strips or bandage tapes made of galvanized or stainless metal to the surface of gas silicate walls. You can use a material of arbitrary width, for example, a 20-mm electrical installation strip with a thickness of 1.5 mm, which is simply nailed to the surface for more durable fastening.

The first method is used when laying cellular concrete blocks on a mortar. For fastening you can use:

- flexible facade connections from basalt plastic, which are installed to a depth of at least 9 cm in masonry joints gas silicate blocks;

- special galvanized mesh, which is also placed in interblock seams during the construction of walls. By the way, the protruding parts of the masonry mesh can be used as additional support when insulating buildings with basalt or mineral wool;

- spiral nails;

- rods or nails from stainless steel or galvanized metal, which are hammered into building blocks in pairs in the form of the Latin letter “V”. The length of such fastenings is at least 120 mm, thickness - from 3 to 6 mm.

A method involving the use of perforated strips is used when installing cladding with glue. By the way, finishing a house made of aerated concrete from the outside with porcelain stoneware is done using exactly this method.

Cladding on a wall, or, in other words, a ventilated facade, is considered the most progressive and rational method of finishing the external walls of houses made of aerated silicate or aerated concrete. For such purposes, many sheet or molded finishing materials are used - siding, lining, block house, porcelain tiles, metal or plastic sheets, etc.

To secure this type of cladding to a surface aerated concrete walls, use a system of guides (if necessary, followed by sheathing), which provide the necessary clearance. The structure is mounted using nails, dowels or anchors.

When finishing a house made of aerated concrete, a system of vertical guides made of wooden slats is most often used, the outside covered with horizontal moldings - wooden lining or block house, siding, etc.

Cladding with sheet materials is done with lathing, which is nailed to the guides or secured with self-tapping screws. Often the gap between the finish and the wall is insulated with mineral or basalt thermal insulation.

When building a house from aerated concrete, an excellent option for exterior finishing is ready-made facade systems, in last years literally flooded the building materials market. Such sets are equipped with all the necessary fastening and guide elements, and their high reliability allows the structures to be used not only in private buildings, but also in the construction of multi-story buildings.

Painting a façade made of aerated concrete blocks

Painting the walls of houses built using aerated concrete is budgetary method of exterior finishing and can be done both using special textured paints and façade putties. Of course, such a finishing method must be planned in advance, since painting requires special care and accuracy from the mason.

Before starting painting, unevenness and damage to the blocks are filled, seams are rubbed, and the surface of the walls is leveled. Painting begins after complete removal dust and dirt.

Exterior finishing of a house made of aerated concrete. Photo

For facades made of cellular concrete, manufacturers of finishing materials produce special textured, vapor-permeable paints. As a rule, even an inexpensive emulsion of this type costs a tidy sum if it needs to be finished large area. You can reduce the cost of painting a house made of aerated concrete by more than 10 times by using exterior facade putty, for example, the popular inexpensive composition of the brand “ Prospectors" The mixture is diluted with water in the proportion of 20 kg of dry composition per 7.5 liters of liquid and stirred until the consistency of sour cream is obtained. If it is necessary to obtain a certain color, a color for water emulsions is added to the putty.

Putty Apply to the wall in the same way as paint - using a roller or wide brush. This material dries quite quickly, which must be taken into account during the work process. It may not be possible to obtain a uniform surface color in one pass. In this case, the facade is repainted.

As you can see, there are many options for exterior finishing of houses made of aerated concrete and gas silicate. Which one to choose to protect and decorate the surface of the building is up to you to decide. It is only important to approach the work with all responsibility and accuracy, and then the appearance of the walls will delight you with a durable and beautiful finish for many years.

Finishing a house made of aerated concrete. Video

Houses made of aerated concrete in modern construction firmly entrenched in the position of economical and affordable housing, and perhaps this is due to the fact that aerated concrete is relatively inexpensive material, quite lightweight, yet distinguished by high thermal conductivity properties.

Aerated concrete - type building material, namely the type artificial stone, which is a type of cellular concrete. For the production of aerated concrete blocks, cement is used in combination with lime and quartz sand, to which an aluminum gas former is added. The resulting dry mixture is mixed with water, and as a result, a chemical reaction occurs, during which hydrogen is formed and the cement mortar foams. The solution is poured into molds, and when the reaction has passed and the solution has “set”, it is cut into blocks of the required sizes and dried at a certain temperature in autoclaves or a drying chamber.

By purpose, aerated concrete is classified as follows:

- structural (this type of aerated concrete is used for the construction of partitions and for external walls, and it is also used to strengthen walls in the areas of floors between floors);

- thermal insulation (it is used only as insulation, as it is saturated with a large number of pores, thanks to which it retains heat perfectly);

- structural and thermal insulation (has the best combination of density and thermal insulation, used for the construction of houses with a height of one to three floors).

The main advantages of houses made of aerated concrete blocks

One of the main advantages of houses made of aerated concrete blocks is that they belong to the category economical construction housing. The relatively low cost of buildings made of aerated concrete is due to the following factors:

- such houses are lightweight structures, which eliminates the need to build a massive foundation;

- the ratio of convenient sizes and light weight allows you to avoid serious waste on lifting equipment (crane, loader) and reduce overall labor costs;

- aerated concrete blocks are very easy to cut and saw, so it is not difficult to lay communications and follow the design (corners, turns);

- the speed of construction undoubtedly saves money on paying specialists (it takes about a month to erect a box of such a house);

- houses made of aerated concrete retain heat well, so it is not advisable to spend unnecessary expenses on additional insulation.

The economic advantages also include the fact that heating such a house will require less heat consumption than for houses made of other materials.

And another interesting feature is the thickness of the walls, which is less than, for example, brick.

Exterior finishing options for aerated concrete houses

Exterior finishing of a house made of aerated concrete is necessary both to give a magnificent and unique look to the structure, and for additional strength.

Many options can be used for finishing houses made of aerated concrete: this includes plaster, stone cladding, and façade cladding. hanging panels(siding, lining and others).

Finishing the facade of the house with plaster

A particularly common and popular way to finish any building, including the façade of a house made of aerated concrete, is plaster. This is a relatively inexpensive type of coating.

Cement-based plaster mixtures are used for exterior finishing of buildings.

Before starting plastering, it is necessary to treat the walls with a special solution - a primer, which will improve the adhesive properties of the applied plaster to the aerated concrete slabs of the wall. It is recommended to prime the walls at least twice, then allow the surface to dry. A special roller is used to apply the primer.

Then you need to prepare a plaster solution.

The dry plaster mixture you have chosen must be poured into a specially prepared container and diluted with water to the required consistency. Manufacturers always indicate the ratio of water and dry mixture on the packaging. The solution should be homogeneous, without lumps. To achieve uniformity, a drill is used for mixing, on which a special mixer attachment is put on.

With the prepared plaster solution, you first need to fill the chips or dents on the surface of the wall and rub them in using a trowel (a special device for plastering work).

After this, the surface of the wall is mandatory must be cleaned of accumulated dust and dirt.

A plaster solution is applied to the cleaned wall using a metal float and carefully leveled over the surface. This will be the first (draft) layer.

It is necessary to apply a special reinforcing mesh over the first layer of plaster and press it well into the solution. This action will also help to perform a half-grater. Many experts also recommend additionally securing the mesh with screws.

An elastic mesh made of fiberglass (light, non-flammable, and quite durable) is well suited as a reinforcing mesh. You can also use galvanized chain-link mesh, which has very small cells.

The mesh is needed because the distance between the seams of the foam concrete slabs is large and it is simply not enough to efficiently perform the functions of a kind of mesh. The reinforcing mesh additionally protects the surface from the formation of cracks.

The completely plastered wall must dry completely, after which the finishing coating stage begins. To do this, a thin layer of textured plaster is applied, which will give the façade the intended structure. The application and uniform distribution of textured plaster is also done using a trowel.

Wall decoration with vinyl siding

Finishing houses with vinyl siding is currently very popular; the option is quite inexpensive, but the appearance of the building is neat and attractive.

Additional thermal insulation can be used under the siding; the option of using expanded polystyrene boards is quite rational.

Expanded polystyrene boards are attached to the wall using liquid nails and are additionally secured with special dowels “with caps”. Then the siding is attached to these slabs using roofing screws.

If you have chosen soft materials as insulation, then a wooden sheathing is created on the wall under this insulation, into the cells of which the insulation is inserted. They stretch it over soft insulation vapor barrier film, which is attached using a stapler.

Then the siding is mounted on top, attaching it to the sheathing with wood screws. The siding strips are measured to the dimensions required for installation, and the excess along the length of the siding strip is easily cut off with a jigsaw or hacksaw.

Siding begins to be laid from below. To begin installation, a starting panel is installed parallel to the base of the house. At this stage, you definitely need to check with a level how evenly it is laid. All other siding strips will be aligned to this panel.

Stone cladding

There are also many supporters for the cladding of houses brickwork. This finishing option is much more expensive than those described earlier, and also requires special calculations and the involvement of specialists. Of course, the brick will serve as both finishing for the house and additional insulation.

If you prefer this type of cladding, then this decision must be made even before building the box, in order to correctly lay the foundation, which should protrude 50 cm from the width of the wall.

The cladding is done with special bricks laid in one layer. As a rule, such bricks are placed close to aerated concrete slabs, but without being rigidly fixed (due to the fact that these materials, depending on the increase or decrease in temperature, have different tendencies to compress or expand). Can be put facing brick and with a slight indentation from the wall, filling the resulting distance with insulation. Such a house will turn out to be the warmest.

Painting the facade of aerated concrete house with paint

You can also focus on a fairly simple, economical option for finishing a house made of aerated concrete - painting it. But before this, the walls are primed, and a layer of vapor-proof putty is necessarily applied to them.

Also, do not forget about making the surface even: all seams must be rubbed, protrusions must be carefully sanded.

Special paints are also selected, suitable for this type of finish.

Video - exterior decoration of a house made of aerated concrete

For construction own home can be used different materials, but aerated concrete is especially popular. It has excellent thermal insulation properties and allows you to get really warm house, the main advantages are added: low cost, speed of installation, speed of construction and safety for others. There are few disadvantages, and one of them is the limitation in the choice of materials for finishing (for example, the usual use of cement plaster is not suitable, it cannot be coated with film-forming paints). How then to cover the outside of a house made of aerated concrete, and what materials are better to choose for it or alternatives from foam blocks or gas silicate?

Why not every material is suitable for finishing

Aerated concrete blocks are distinguished by their porous structure (the pores are evenly distributed throughout the block, approximately 80% filled with air or gas), hydrophilicity (the ability to absorb moisture) and increased vapor permeability (this unique ability of porous concrete ensures the rapid removal of moisture from the room). When sawing blocks during the construction process, open pores appear on the surface and, if they are not covered with a suitable protective layer, they will become wet, oxidize under the influence of rainwater, fill with dust, and darken. As a result, the house will lose its visual appeal and lose its thermal insulation properties. Be sure, when choosing what to cover the outside of a house made of foam blocks or aerated concrete, you should take into account the described physical features material, and do not use finishes that prevent the diffusion of water vapor from the room to the outside. It is important to maintain the wall’s ability to “breathe”.

Thus, in the exterior decoration of a house made of gas silicate blocks, you should not use cement mortar, foam plastic, or film-forming paints.

What facing materials can be used

Having excluded prohibited materials from the list of applicable materials, you can choose the best way to cover the outside of a house with foam blocks from the following list:

- siding;

- lining;

- face brick;

- decorative rock;

- mineral plaster (specially designed for aerated concrete);

- grouting the joints followed by the use of façade textured paint (vapor-permeable).

Features of cladding with siding, imitation timber, clapboard

The most convenient, reliable, and fastest in terms of completion time is the exterior finishing of a house made of foam blocks with sheet panels, i.e. siding, imitation timber, clapboard. In this case, a ventilated façade is created and it is possible to provide additional insulation for the house (for example, using mineral wool - the cheapest, most practical and durable material).

Before lining a house with foam blocks from the outside, a wooden sheathing is made on the walls of the building, onto which the sheathing sheets are then attached.

Application vinyl siding, imitation timber or lining allows you to as soon as possible design an attractive and fashionable exterior of the building. These materials are durable, you can install them yourself, and they do not require additional decoration. They are recognized as the most optimal and rational solution for various structures (for example, they are suitable when asking the question: how to sheathe the outside of a slag-cast house).

Brick cladding

Among the options for sheathing foam block house outside, facing brick is recognized as one of the best. It has the highest strength and durability among all existing facing materials; such a house will be especially warm (which is especially important). But the use of bricks should be foreseen at the design stage and more solid foundation, because the weight of such a structure will be much greater.

Considering that the vapor permeability of cellular blocks and bricks differs significantly, between blocks and facing masonry a gap of about 3 cm should be left (this can easily be provided by a special protective sheet that protects the foam blocks from the masonry to protect them from splashes cement mortar). For the gap (it is also called the “air gap”), ventilation must be provided; for this, it is enough to leave several empty seams in the upper rows of the masonry (under the eaves). Also, when choosing aerated concrete or brick for finishing the external walls of a house, you need to worry about waterproofing the base.

Application of plaster compositions

If you choose the best way to cover the outside of a house with aerated concrete, based on the price component, then it will be cheaper to use a special plaster composition developed specifically for cellular concrete instead of sheet panels or bricks. Mineral plasters are perfect; they do not contain quartz sand, but are based on a lightweight filler (this can be perlite sand and some others), which ensures vapor permeability to the material. The quality and strength of the plaster remains high, providing excellent resistance to mechanical damage, environmental influences and the formation of shrinkage cracks. Such compositions are applied in a thick layer, carefully smoothing out all the unevenness of the walls being coated.

Having chosen plastering, in the question: how to sheathe the outside of a block house, do not forget about the need for mesh reinforcement in problem areas (at block joints, kinks and joints of profiles, corners of the building facade, in the area of window openings).

Painting facade textured paint

Facade textured paints are also perfect for decorating the walls of a house made of foam blocks, aerated concrete and gas silicate; their advantage is a wide color palette. You can replace the paint with a thin layer of special vapor-proof putty (such as, for example, “Prospectors”), after the coating dries, the wall will acquire a neat appearance. At the same time, do not forget about pre-grouting the joints and eliminating surface unevenness.

The best way to sheathe a balcony from the inside - the best options

The outer walls of the house are the foundation of the entire structure, so they must be made of a reliable base. Therefore, they are often built from aerated concrete, because this material has high strength and wear resistance, but there is one significant drawback - its unpresentable appearance. In addition, it absorbs moisture like a sponge, so over time it begins to crumble, crack and collapse. It is for this reason that it must be protected. Typically, the finishing of the facade of a house made of aerated concrete blocks undergoes additional finishing, during which they use various materials. But initially it is worth considering the basic qualities of the materials.

Often, when building houses, cottages, and residential buildings, a block of aerated concrete base is used. Aerated concrete is a type of building material, namely a type of artificial stone, which belongs to the cellular type of concrete. It is made from concrete, which is combined with lime and quartz sand. All this is diluted with aluminum blowing agent. The components are diluted with water, after which a reaction is observed that releases hydrogen and foams the cement mass. The finished solution is poured into special molds. After the entire reaction has taken place and the solution has completely set, it is divided into blocks and dried in intended ovens for this purpose. The result is ready-made aerated concrete for building houses.

Aerated concrete blocks

Houses made from these blocks have the following qualities:

- houses made of blocks are light in weight, so there is no need to build a massive foundation;

- due to the fact that this material has an optimal ratio of light weight and size, during construction there is no need to order additional equipment for lifting loads, which as a result saves money and reduces labor costs;

- the block can be easily cut, sawed, there will be no difficulties when laying the subsystem, communications and other important parts of the house;

- rapid construction of buildings made of aerated concrete. It will take about 1 month to build one box of a house from this base;

- no additional finishing for insulation is required, because aerated concrete has excellent thermal insulation properties. For this reason, houses made from this base are always warm and cozy, especially in the cold season.

Options for finishing facades made of aerated concrete blocks

However, despite the high quality of aerated concrete, it still breaks down over time due to various negative influences. weather conditions. And the appearance is not always pleasing to the eye. Therefore, you should beautifully design the façade of aerated concrete. It can be finished with a variety of materials, from brick to ordinary plaster. But in order for the cladding to be able to protect external walls from negative factors, extend the life of the building, and also give it a presentable appearance, it is worth carefully familiarizing yourself with the features of each material for the facade finishing of aerated concrete buildings.

Brick

Finishing the external walls of a house made of aerated concrete with bricks greatly improves its appearance, makes it presentable, and makes it much more beautiful and brighter. In addition, various color solutions bricks, will allow you to choose the material that will fit perfectly into the style landscape design. But during finishing it is necessary to use no ordinary brick, because it can put extra pressure on the blocks.

In addition, so that the finish can last a long period, during construction work You must follow several important rules:

- Before installing the brick on the block, you need to prepare the mortar. To do this, it is thoroughly mixed, this will help to avoid sand settling, all components will be distributed evenly. After installation, the brick will adhere well both to each other and to the gas blocks;

- The mixture should be spread evenly. This will make the seams stronger;

- to enhance the strength of the entire structure, the thickness of the seam should be at least 10 mm;

- If mortar gets on the brick during the laying process, it should be removed immediately, otherwise it will dry out and ruin the entire aesthetic appearance of the building.

Scheme for finishing aerated concrete facade with bricks

Scheme for finishing aerated concrete facade with bricks Siding

When choosing a material for finishing block houses, you should choose siding. This material has good qualities that allow it to maintain the quality of the entire structure for a long time. Advantages of siding material:

- the base of this material is heat-resistant, so this material does not deteriorate as a result of temperature changes, it can withstand severe frosts or extreme heat;

- has high moisture resistance. Rain, snow, hail will not have a negative impact on this base;

- When finishing a house with this material, a gap remains between the siding facade and the walls in which an insulating base can be installed.

For insulation, two types of insulation can be used:

- materials with a soft base - various versions of mineral wool;

- products with a solid base - polystyrene foam with an extruded base or polystyrene foam.

By appearance the result is an ordinary ventilated façade, only, unlike a subsystem with ventilation, it has a reduced cost and is no different in properties. In addition, during installation it is necessary to comply with certain requirements, since the aerated concrete block has low strength. For this reason, the “frame-wall” fastening units require additional strengthening.

When strengthening, the dowel should expand with a self-tapping screw, for this reason it must be chosen 1-2 mm smaller than the dowel. The standard dowel size is about 6 mm. The mounting depth must be at least 50 mm.

Scheme for finishing a wall made of aerated concrete with siding

Scheme for finishing a wall made of aerated concrete with siding Plaster

The finishing of aerated concrete walls can be done with a variety of finishing materials, not only siding and brick. Plaster is often used for finishing aerated concrete bases. To decorate a house, you should not choose ordinary cement mixtures, because the block will immediately absorb all the moisture from them, which will ultimately cause the destruction of the material. In addition, after drying, multiple microcracks form on the surface of the plaster. For this reason, you should purchase special mixtures that are used specifically for aerated concrete blocks. These mixtures are based on additives that prevent the absorption of moisture into the aerated concrete material.

Wall finishing with plaster is carried out sequentially:

- The first step is to prepare the working surface of the walls. It consists of cleaning the surface from dust and excess solution;

- after this, the walls need to be primed with a special mixture, which is intended for aerated concrete material;

- the next stage is to create a plaster mesh. To do this, you can use a fiberglass or metal mesh with small cells;

- install the mesh to the wall using self-tapping screws;

- the presence of a mesh guarantees high-quality adhesion of the plaster to the wall surface. If it is not installed, then after some time the work will have to be redone again, because the layer of plaster may come off over time;

- after this you need to knead the solution. Dry ingredients are poured into the container, water is added to them, everything is mixed;

- after that we proceed to plastering the walls;

- When the entire finishing process is completed, you can begin cladding the facade. To do this, you can paint it completely or paint individual parts.

Scheme for finishing aerated concrete facade with plaster

Scheme for finishing aerated concrete facade with plaster

Protective painting

After finishing the facade with plaster, it is necessary to paint it. This will give an expressive, bright look to the entire structure. The most economical option would be to use special paints or vapor-permeable plasters.

Features of facade painting are as follows:

- In order to paint the facade, the desired color should be added to the plaster. Then the walls need to be finished with the resulting mixture;

- if suddenly you don’t like the color, you can dilute the mixture with another color and paint the facade again;

- the coloring mixture is applied with a special roller or brush;

- If unevenness, various connecting scars, or seams appear during painting, they must be carefully rubbed down. Next, using a plane, everything should be sanded;

- If you are already planning painting in advance, then it is better to purchase an already processed block.

Paint protection

The final stage after plastering should be protective covering walls with a special composition. Typically, hydrophobic compounds are used for painting, which contain special water-repellent components. These compounds are called water repellent. But there are special compositions for aerated concrete material. Mixtures that are used for finishing brick and concrete are not suitable for this material.

Treatment of painted facades with hydrophobic mixtures:

- hydrophobic mixtures can be applied using a regular paint brush or roller;

- They should be applied to the blocks in a small layer. This layer will be enough to protect the walls from dust adhesion and from the effects of various negative precipitation;

- Application should be made to the entire surface, including corners and other hard-to-reach places.

Ventilated facades

A ventilated facade is considered the optimal way to finish walls made of aerated concrete. For wall cladding using this method, a large amount of sheet or linear finishing material is used - siding, lining, block house, porcelain stoneware slabs, sheets of plastic or metal base.

Finishing features of the ventilated base:

- In order to install such cladding on a block, it is necessary to use a system of guides; if necessary, a lath is made. This facing will provide clearance;

- the entire structure is installed using nails, dowel or anchor type fasteners;

- during finishing of the facade from aerated concrete block Systems with vertical guides with wooden base slats are often used. And on the outside they can be sheathed with horizontal materials - clapboard made of wooden base, block house, siding;

- cladding made of sheet material is usually made together with sheathing, which is nailed to the facade and secured with self-tapping screws;

- the resulting gap between the cladding and the facade is insulated with mineral wool and basalt thermal insulation.

On sale you can find ready-made facade systems made of sheet material. They are already equipped with everything necessary. Their high reliability makes it possible to use them for the construction of private buildings, as well as for multi-story structures.

Finishing buildings made from aerated concrete base is a mandatory requirement for the building to last for a long period. You can use various materials for it - brick, plaster, siding. The main thing is that the material is of high quality and wear-resistant. Also, its installation should be done correctly so that in the future it does not move away or crumble.

A well-built and well-designed house will not only please the eye for many years, but will also significantly reduce unforeseen expenses for various minor imperfections and miscalculations in the project. Therefore, when thinking about what to use for exterior finishing of a house made of aerated concrete, be sure to take into account the structural features of the blocks and use appropriate finishing materials.

Why “dress” the house?

Finishing the facade of a house from aerated concrete blocks has two main goals: to protect it from the adverse effects of the external environment and to decorate it visually. Protection is required due to technical features of production and structural composition. The fact is that blocks are cut during the production process after the formation of a porous structure. This means that some pores become open and, in fact, represent holes into which moisture easily accumulates. As you know, when water freezes, it expands, and molecular forces can easily break fragile internal partitions, which will lead to the formation of microcracks. The building, of course, will not collapse, but the first line of defense will already be broken.

Features of porous materials

One of the significant advantages of aerated concrete is its vapor permeability. It is an order of magnitude higher than even in buildings built entirely of wood. This advantage can easily be turned into a disadvantage by using materials for external work that are not vapor permeable or paints that create a continuous film on the surface.

Therefore, the exterior finishing of aerated concrete walls is carried out using special lightweight plaster systems that do not prevent the seepage of water vapor. If you block this exit, then the moisture that could not get out will remain in the wall and will gradually destroy it from the inside.

The best way to decorate the outside of the house

The modern market provides a wide variety of specialized finishing elements, both in terms of material and in a wide range of price categories. Here are just a few of them:

- Siding.

- Lining.

- Hanging decorative panels.

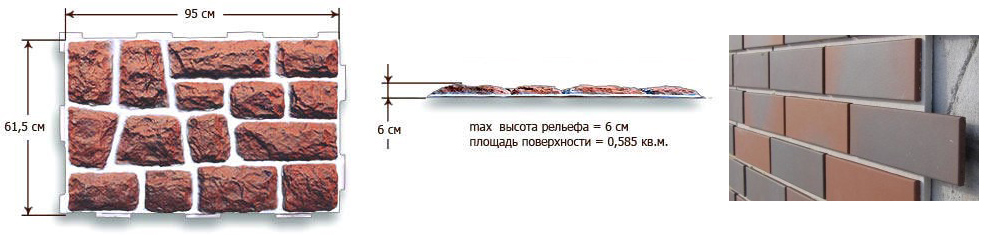

- Clinker tiles.

- Cladding with natural stone (air gap required).

- Finishing for jointing (subject to the use of textured paint).

- Decorative plaster.

Panel technology

Finishing with siding, clapboard or decorative panels requires the installation of sheathing. It is made of wooden slats measuring 6x4 cm. To facilitate the work process, it is better to make all calculations in advance. For example, let's take a working surface area of 15 m2.

- When making calculations, do not forget to subtract door and window openings.

- The slats are installed in increments of 30 cm. Thus, for this area, we will need 51 m of slats.

- Every 40 cm they must be secured with a screw to a dowel. Total - 128 pieces.

- To install the panels we use nails (preferably aluminum). Based on 1 nail per 300 mm – 170 pieces.

- Be sure to add 10% to 15 m2 of facing material. They will be used to adjust the size. Total - 16.5 m2.

The price of siding ranges from 180-320 rubles per m2.

Lining costs from 140 to 220 rubles per m2.

Big choice decorative panels also determines the wide range of prices for them. The cost of panels ranges on average from 200 to 1000 rubles per square meter. If you carefully carry out the preparatory work, carefully installing the lathing on the dowels, installation of the panels themselves is quite easy and quick.

Working with clinker tiles

Finishing of external walls with clinker tiles should be planned as early as initial stage construction, since the foundation must be calculated taking into account the width of the tile itself and the air gap that is necessary for ventilation of the walls. The material should not be allowed to overhang even a few centimeters beyond the foundation.

To ensure that the solution does not get into the provided air gap, during the installation process you can place a sheet of foam plastic there and move it as the work progresses. To ensure ventilation, small gaps are left in the seams between the tiles. There should not be too many of them - only about 1% of the total area. It is better to make vents in vertical seams under the eaves and close to the foundation. Thus, external finishing aerated concrete will not interfere with the necessary steam circulation.

Use of stone

In this case, it is necessary to resort to the technique of a suspended ventilated facade. It is attached to the load-bearing layer on the wall of the building. The frame is made of aluminum or stainless steel. Between it and the wall you can put an additional layer of mineral wool insulation. Finishing aerated concrete house natural stone occurs in the following order:

- Mark on the wall at the level of the mounting point.

- Drill holes.

- Strengthen the metal frame with dowels.

- Install a layer of insulation (if planned).

- Install the facing stone.

Approximate calculation of consumption per 1m2:

One of the most economical design methods is to finish the outside of the aerated block for jointing. It involves highlighting the seams between blocks. This selection is performed by deepening the grooves of the seams or applying paint to them. It is also advisable to consider this option during the initial construction planning. Because, in this case, it will be possible to first remove the chamfer from the blocks and subsequently the jointing will turn out to be original and beautiful.

Joining

It is better to use acrylic paint. It has excellent water-repellent properties and sufficient vapor permeability. It is preferable to highlight the seams in a contrasting color or a darker shade.

The average price of 10 liters of acrylic paint is 400 rubles. This amount is enough to treat 100 m2 of wall. For greater reliability, it is recommended to apply two layers of paint.

Decorating the exterior of your home is a necessary step to protect the building. The ability to vary materials will allow you to do both a budget option and create your own unique style. It can protect your investment by preventing external factors from destroying what has already been done, and it will benefit from emphasizing the originality expressed in the individual design of the facade.

| Articles |