Walls from osb. Is the OSB dangerous to humans? Laying of decorative floor covering from OSB.

OSB (OSB in transliteration) or OSB sheets are in demand in rough repair and construction work. To obtain a non-trivial result, they are occasionally used in finishing, finishing... What is stopping people? First of all, rumors that OSB boards are unhealthy. Let's try to figure out how dangerous they are to humans.

To this end, the district administration conducts an inventory of the areas covered by this Agreement, in order to plan and gradually include appropriate resources in the budgets of the subjects in each period to comply with the provisions of this Agreement.

The district administration will facilitate private sector actions to actively participate in the implementation of green roofing technologies in the city. This Agreement applies from the date of its publication. It is best to keep the panels in a closed room with good ventilation.

Brief description of OSB

Oriented strand board is a building and finishing material, 86-90% consisting of large finely planed wood chips up to 25 cm long and no more than 4 mm thick shavings. The rest of the total mass is thermosetting synthetic resins, special additives and additives.

Manufacturers offer 4 types of slabs for different purposes:

The storage principle is shown in the figures. Planks with straight edges are combined on the beds, leaving a 3mm gap around the perimeter of the panel. When laying a wall or installing "floating floors", leave a space of 12 mm between the wall and the panel. The planes should be planted parallel to the main axis, the corners of the plates should not be aligned. Long edges that are not found on banks should have drain edges, an appropriate support or a connecting hook. If there is no roof on the ceiling, then there must be drainage holes so that rain can drain out of the water.

In the case of ground floor wooden coverings that come into contact with the ground, it is necessary to protect the wind from the lower part of the roof and install additional waterproofing on the ground. Use a 51mm long nail or 45mm to 75mm piece to secure the boards. Nails are placed every 30 cm in the intermediate supports and every 15 cm in the panel joints. To increase the strength of the floor, the boards must be adhered to the layers using castable adhesives containing chemical thinners.

- OSB-1 - thin sheets for packaging, furniture blanks, temporary structures, etc.

- OSB-2 - used in rooms with normal humidity (no more than 60%). Applications: interior roughing, including leveling floors, walls, ceilings and primary cladding (utility boxes, roof sheathing in warm attics, SIP panels, etc.).

- OSB-3 - moisture resistant boards that can be used both outside and inside premises (in the bathroom, kitchen, bathhouse, laundry, etc.). Can be used as a leveling layer when exterior decoration under plaster, thermal panels, facing clinker plates or bricks, siding and other types of curtain walls

- OSB-4 - reinforced high-density slabs used to form load-bearing structures.

Basic physical and technical characteristics of OSB are shown in the table below:

Before installing the plate, it is recommended within 24 hours. maintain it in the installation environment. It is recommended that the moisture content of the panels does not exceed 15%. With this level of humidity, mold and fungi are avoided. Can be used in very humid environments, both indoors and outdoors. This is the most popular board in construction industry... In this case, you may need to grind the edges further to get a smooth, flat surface. Edged panels are of three types: even-edged board; Plate with groove and groove on both edges; groove plate and groove on all four edges.

The advantages of OSB are widely known through advertising:

In the pluses, we also write down the low coefficient of change in geometric dimensions with changes in temperature and humidity. Thanks to this characteristic, the material can be mounted with minimal gaps around the perimeter of the room.

The panel used for roofing or flooring must be marked with a footer. Table with indicative distances between beds and panel thicknesses used for living quarters. Leave min. Between panels as well as doors or window openings... Gap 3 mm For a distance of 400 mm and 600 mm between the uprights, it is recommended to use a 12 mm wall. It is recommended to fill the walls with stone wool for additional insulation. For fixing the wall panels, it is recommended to use nail nails with a length of 51 to 75 mm.

Now let's look at the disadvantages of OSB:

- High percentage of slabs swelling in direct contact with water. This indicator for sheets of some manufacturers reaches 25%;

- Difficulties with laying communications and replacing insulation under the mounted OSB sheets;

- Combustible or fire hazardous material. The risk of fire is slightly reduced when treated with fire retardants (Rogneda, Novbytkhim);

- Biodefeated. Mold, fungi, rodents and bugs are dangerous for the stove;

- High price. OSB from well-known manufacturers (Egger, Glunz) is 30-60% more expensive than gypsum board or chipboard in similar dimensions.

The disadvantages of the material are not limited to this list. According to market research, potential buyers consider the harm of these stoves to human health the biggest disadvantage. The main criterion here is the concept of "environmental friendliness". Let's take a closer look.

Nails hang every 10 cm at the outer corner of the wall. Leave a 3 mm gap between the boards without a trowel and grooves for the board to work. The board must be placed on at least two supports, and its joints must be on the supports. Workers must comply with labor safety requirements when assembling panels. If the roof structure has protruding pipes, the panels should be located 12 mm from the pipe. Roof installation must comply with safety regulations to ensure high occupational safety.

Before installing the panels, it is necessary to check whether the rafters are in the same axis, regardless of whether they are level and level. Curved or uneven rafters will have a significant impact on the final look of the roof. Blocks that drip in the rain must be dried and protected from biological corrosion until the roof is covered with a roof. Unheated areas under the floor or in the attic should be well drained. Install panels with long edges perpendicular to the rafters. After the flat ends, the joints should be supported.

OSB sheets - harm or benefit?

An environmentally friendly product is a product that, according to research, does not harm the environment and users. Applied to OSB greatest harm people can bring formaldehyde, phenol and methanol fumes. Where do they come from?

Approximate distance between rafters, depending on the thickness of the plates used for roof structures with a slope of more than 14 °. Oriented wood board. These are several layers of wood chips coated with advanced technological resins and reinforced by hot pressing. They are laid perpendicularly in three or five layers, which are oriented using an electric field or, more simply, mechanical vibrations. Layers arrangement: outside - along the axis, inside - transversely, mixed with liquid additives and pressed by powerful rollers.

The thing is that synthetic resins such as phenol-formaldehyde, urea-formaldehyde, melamine-formaldehyde and many others are used as a binder.

The advantages of polymer binders make it possible to produce inexpensive, high strength products. But the disadvantages of their use are so significant that they repel potential buyers. This is, first of all, their toxicity both before solidification and after.

It is a sheet of building material glued to an uneven number of layers of wood. The top layer of the highest quality is called the good side of the plywood, and the lower bottom layer is called the bad side. Veneer is a wood board made from a thin sheet of wood, the layers of which are parallel to the wood layers. The lantern is obtained by gluing layers of wood so that adjacent layers of fibers are perpendicular. The fan sheets are bonded with high temperature adhesive and are difficult to access.

Both panels have similar resistance and are equally easy to drill through forged nails if needed. The more expensive options are worth considering if your focus is on durability and efficiency. Plywood has all the advantages of the wood from which it is made, and it is also enhanced with its layered structure. Due to wood as an ingredient, plywood has a certain elasticity and withstands short-term higher loads - it is useful, for example, in strong wind conditions.

Poisonous flammable gases such as formaldehyde, phenol, benzene, methanol and others are emitted. They belong to allergenic, mutagenic and carcinogenic substances, provoke skin diseases, as well as diseases internal organs, including reproductive, respiratory and cardiovascular systems, eyes.

Although many GOSTs and SNiPs were canceled or underwent serious processing towards mitigation, some construction and Decoration Materials still have to undergo a sanitary and hygienic examination. Based on the results, a certificate or conclusion is issued for each batch. The document specifies the test methodology, limit values (MPC) and the results obtained. They can be used to judge how harmful one or another product is.

This function is also required for sub-floors. Plywood structures distribute pressure evenly to the opposite side, thereby reducing pressure. Due to cross-construction, plywood sheets remain sufficiently resistant to changes in temperature and humidity. This is especially important when you need to cover a floor or other high humidity area.

Strength, rigidity and, at the same time, ease of use are the attributes that make plywood for floors, walls, formwork and beams. The properties are similar to plywood, but at the same time it is more cheap stuff... Thickness - the best choice when laying frames or beams. You can even fix it around the edges of the board.

In the Russian Federation today, it is customary to mark OSB and its analogues according to the European standard DIN EN120, which determines the emission class of formaldehyde and some other toxic substances:

- E3 - up to 30 mg per 100 g of dry matter;

- E2 - 10-20 mg;

- E1 - up to 10 mg;

- E0 - up to 6.5 mg.

For example, let us give the maximum permissible concentration for formaldehyde in atmospheric air - 0.003 mg / m 3, and in household water - no more than 0.05 mg / l.

Don't panic if a chair, doorknob, or any other object has damaged the drywall wall - everything can be repaired. And you can repair it yourself, without the help of a specialist. It only takes a little effort, time and - as always -.

The first impression is created by the appearance: a human face, the body - the facade. However, in the house, unlike the person whom we most often judge with the mind, we look at the whole: internal and external. This is why the design and installation of the enclosure should be equally oriented towards exterior and interior decoration. One way to do this is to choose a brick for decoration that suits any style - classic, modern or eclectic.

In accordance with this classification, OSB of the E0-E1 class is produced by such giants as Glunz (Germany), Norbord (Canada),Egger(Austria)... The harm is minimal, and the advantages are obvious, therefore they are recommended for use inside residential premises with subsequent cladding (including children's rooms, hospitals).

To give a building an ecological look or add more naturalness, its façade can be covered with lighting materials. Wood siding is the oldest type of sawdust, which today is considered a serious alternative to the choice of facades. Cork flooring is a lesser known type of wood flooring. Like any other wood floor, this flooring has advantages and disadvantages. So worth a try in your home? Introducing the pros and cons for cork floors.

Products marked E2-E3 (Kronospan, Kronopol) can only be used for outdoor work, including roof cladding of non-residential attics, bearing structures in temporary houses, etc.

Serious manufacturers, as a rule, willingly provide their products for additional voluntary checks. Thus, the Austrian company Egger periodically receives a Blue Angel certificate confirming the environmental friendliness of its products.

Wood floors today are no longer simply carved from logs, dried planks that have been used by mankind for centuries. By using modern technologies there are different types of wood floors, which differ in appearance, durability and installation features. The most common are solid wood and multi-layer wood floors. We asked the experts what are the different types of wood floors and how to choose the most suitable option for your home.

The bath is ideal for shellfish colonies, as the wettest, most unventilated and warmest rooms are best suited for these mushrooms. Mud baths not only look aesthetically unattractive, but they can also be hazardous to human health. It releases harmful compounds that are carcinogenic, can cause allergic diseases, and stimulate various lung and respiratory diseases. So how do you stop this parasite from appearing in the bathroom and how to deal with it?

Unfortunately, a rare Russian plant can boast that its products are tested for harmfulness and comply with the high standards of DIN EN120. OSB from many manufacturers does not pass the tests. The Federal State Healthcare Institution "Center for Hygiene and Epidemiology" published data some time ago independent expertise OSB boards (manufactured in the Russian Federation): the formaldehyde content in the ambient air at +20 ° C is 0.067 mg / m 3, that is, 22 times higher than the MPC norm.

Homes are places where we want to feel calm, relax and avoid outside noise. Properly equipped home audio isolation has two main benefits: it prevents unwanted outside sounds and allows you to create an oasis of your own silence or sounds inside - listen to music freely, enjoy the sound effects of a movie, and not worry about expressing emotions during a neighbor's sports competition. Soundproof walls are very important, but living in multi-storey building, special attention should be paid to the correct installation of the linings.

If you are going to buy OSB, you can determine the harm of products:

- Pay attention to the smell of the sheets. Toxic fumes give the characteristic harsh "aroma" of formalin or cheap plastic.

- Ask the seller for a copy of the certificates certified by the blue seal of the supplier or directly from the manufacturer.

- Inspect the packaging if possible. Large factories mark it and additionally complete it with inserts with basic information.

Do not save on your health - in order to minimize harm, choose products labeled E0-E1 from trusted manufacturers.

Particleboard and veneer are widely used in construction, furniture industry and decoration. Today they no longer meet the requirements of the times. Wood - widely used construction material ancestors. Its use has changed over time since the tree has serious flaws. Various linear building elements were made from wood.

Laminated boards of glued strips 3-7 mm wide, wood-based panels from the base of the wood floor to the floor and furniture industry, fiberboard insulation, plywood finishes and building elements. In the wake of World War II, amid a shortage of wood, small pieces of wood were taken from waste. Armin Elmendorf first described them, and later patented the invention. On the market, the product turned out to be a plate plate. It was a randomly crafted 50mm thin and thick slab.

Before talking about the technical details and intricacies of the inner lining of OSB or OSB plates (they are also OSB, OSB sheets), it is worth considering the feasibility of this event. Indoor installation of OSB boards takes place in two cases, namely:

- If you have frame house and the frame is not sheathed yet.

- If the pattern and texture of OSB boards are an element of decor.

If you just need to align the walls, then drywall is better suited for this purpose, since it is cheaper and more convenient to work with during installation and further finishing.

House exterior cladding technologies are outlined in the article:. Here we will consider the issue of the correct installation of OSB plates on the walls inside the house.

The choice of plates for mounting OSB on walls inside the house

When using any material inside the house, including OSB boards, you should pay attention to its harmlessness to the health of the inhabitants of this house. It has already been 34 years since the appearance of OSB boards, and all these years the debate about the environmental friendliness of OSB boards has not stopped. In fact, there are grounds for these disputes, since indeed, when gluing wood chips, polymer resins containing formaldehyde are used. But formaldehyde is also found in many other surrounding things, for example, in fabrics in chipboard furniture, combustion products, etc.

OSB slabs on the walls inside the house.

To exclude the poisoning of people with formaldehyde, enlightened Europeans established control over the production of OSB boards and divided the harmfulness of boards into classes. Plates with formaldehyde emission class E1 are harmless to human health and are used in the construction of residential buildings. Therefore, when buying OSB panels, choose a reliable and trusted manufacturer, as your health may depend on it. The Austrian four-star hotel Arlmont, the interior decoration of which is replete with OSB panels, will say better than any words about the environmental friendliness of OSB panels.

Hotel Arlmont, in interior decoration OSB sheets are used.

Hotel Arlmont, in interior decoration OSB sheets are used. OSB slabs are divided into water resistance classes:

OSB-1 is the class of board most exposed to moisture and has the lowest strength. Such boards are used for the production of furniture.

OSB-2 is a class of boards with the same moisture resistance as OSB-1, but more durable. Such boards can be used for wall cladding in dry rooms.

OSB-3 - moisture resistant boards with high strength. They are suitable for installation in wet areas. But with prolonged contact with water, they are deformed.

OSB-4 - boards with maximum moisture resistance. They are able to withstand prolonged contact with water.

OSB4 boards are not widely popular due to their price, which is on average twice as high as that of OSB3 boards. Therefore, OSB3 boards are widely used. If they are treated with a primer or painted with paint, then such plates become resistant to prolonged contact with water.

More details about the various characteristics of OSB sheets can be found in the article:.

Wall cladding of a frame house from the inside

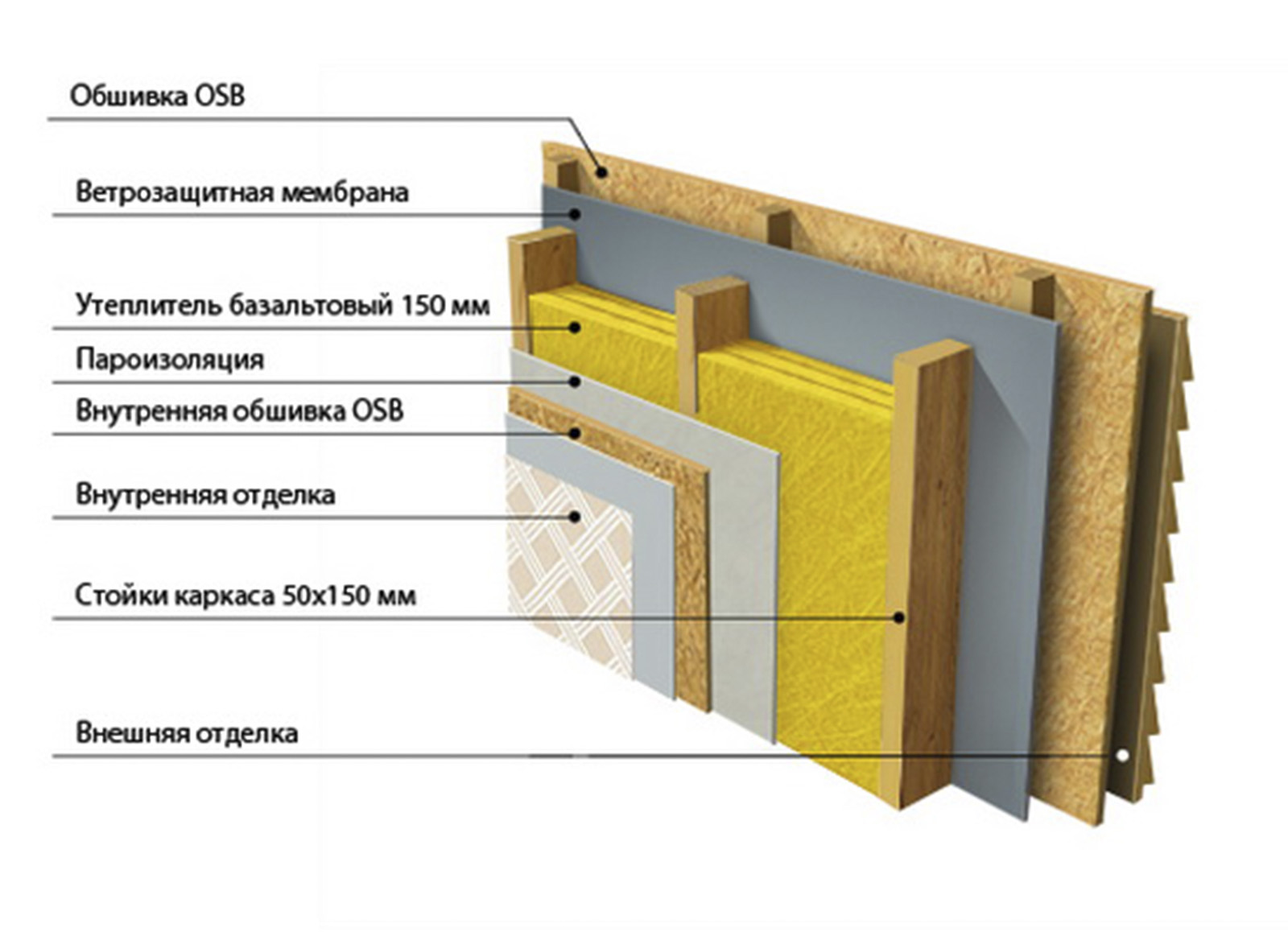

Before proceeding with the interior cladding frame house, it is necessary to insulate the walls, close the frame from the outside and the insulation with a vapor barrier.

It is recommended to insulate the walls mineral wool, and better than slab, since it is easier to work with it than with expanded polystyrene, it holds better in vertical structures and does not sink down, which happens with fiberglass insulation. Other heaters are not excluded and are also suitable for insulating the walls of a frame house. For more information on various heaters, see the article:.

After the walls are insulated, they must be closed with a vapor barrier. A vapor barrier membrane protects the wall from moisture penetration into it, which will keep the house frame and insulation dry. The vapor barrier is attached with an ordinary construction stapler, with an overlap of 10-15 cm and glued together with a special double-sided tape.

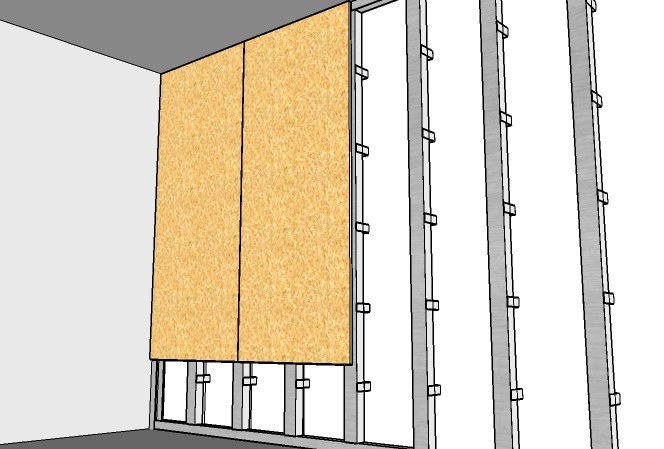

An example of the construction of a wall of a frame house. On the inside, the frame is laid vapor barrier film, OSB plates are attached on top of it.

An example of the construction of a wall of a frame house. On the inside, the frame is laid vapor barrier film, OSB plates are attached on top of it. The sheathing itself is made as follows, the sheets one after another are alternately screwed to the frame of the house. The gap between the sheets is 3 mm. Sheets are screwed with self-tapping screws for wood with a length of 35-40 mm. All holes (for windows, doors, mounting holes) are cut with a jigsaw.

Decorative wall cladding with OSB plates and lathing

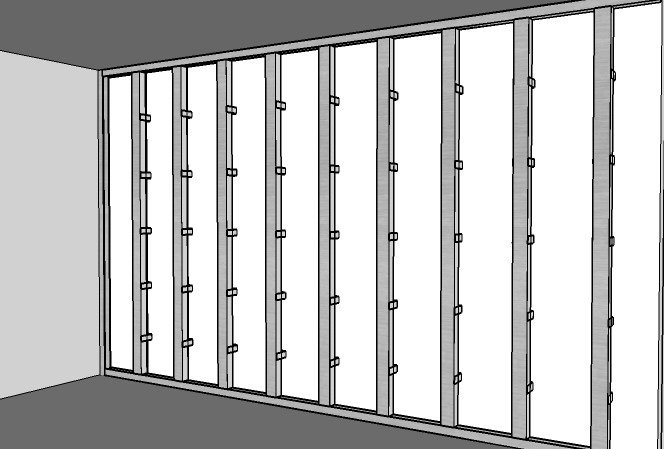

It is best to use a metal profile as for plasterboard as a lathing. It is easy to install and does not deform like wood. When choosing wooden battens for lathing, it is better to use dried wood blocks, because such bars bend and twist less when they dry out. Installation technologies in both cases are not fundamentally different, therefore, we will consider them using the example of lathing from metal profiles.

In order to sheathe the inner walls with OSB boards, you need to start by installing the sheathing on the walls of the room.

The crate mounting technology is as follows:

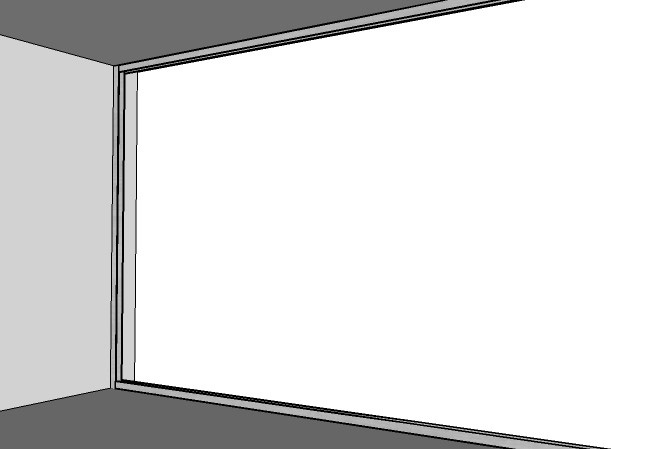

1. First, you need to install the starting profile, which is mounted on the adjacent walls, floor and ceiling as in Figure 1. On the sides, the profile should stand strictly vertically and close around the perimeter with the upper and lower profile.

Figure 1. The starting profile is mounted to the adjacent wall. And it closes with the upper and lower profile.

Figure 1. The starting profile is mounted to the adjacent wall. And it closes with the upper and lower profile. 2. After installing the starter profile, it is necessary to make the markings on the wall for the suspensions. Since the suspensions will hold the vertical posts of the sheathing, it is necessary to mark in such a way that two solid OSB sheets close in the middle of the profile, you also need to install one profile in the center of each solid OSB sheet.

The hangers are attached to the wall. The crate is attached to them.

The hangers are attached to the wall. The crate is attached to them. 3. Mount the profile. It is important when fixing the profile on the suspensions, to control the plane of the sheathing with the rule, so that in the future there is no "hole" or "belly" on the wall.

Installation of OSB boards on inner wall using crate.

Installation of OSB boards on inner wall using crate. After installing the battens, screw the OSB panels onto the self-tapping screws with gaps of 3 millimeters between them. The gaps allow in the future to avoid deformation of the boards due to their expansion with changes in humidity. After installation, the finished walls can be varnished or tinted according to individual preferences.