Modern plasters for facades. Acrylic plaster. Features of the use of acrylic plaster

Not only its external attractiveness depends on what materials were used for finishing work on the facade of the building. A well-finished facade also has practical significance, significantly increasing performance characteristics the entire building, reducing heat loss during the cold season, simplifying the process of maintaining the building and, ultimately, extending its life. One of the most common and popular finishing methods is plastering the facade with various compositions, which can be tinted in the required color or painted later. Currently greatest distribution received two types of plasters - mineral and polymer, and the latter have the greatest number of advantages when exterior decoration buildings for any purpose.

To use a color system, you must also consider the following points. Pigments chemically degrade and do not provide sufficient protection. Because of the bad climatic conditions, as well as inadequate work on other building structures, as well as detailed errors in planning, For example, a canopy that is too small, damage can be aggravated. Inorganic color pigments are not as strong as those mentioned above. In Westphalia, paints are usually more vulnerable than on southern facades, since they are exposed to direct sunlight throughout the year.

Acrylic plasters for facades - easy application, excellent results

Acrylic decorative plaster is simply an ideal finishing material for newly built houses, which still shrink during use, which often leads to the formation of small cracks in the walls of the building. If the facade is plastered at this stage mineral composition, a web of clearly visible, small cracks inevitably forms on its surface, which spoil appearance Houses.

If paint is colored with white pigments, it tends to fade. All coating materials are now optimized by the manufacturer to ensure lightweight stability. Small surfaces look brighter. The protection of pigments is reduced by removing the binder. This results in increased degradation or leaching of organic color pigments. The combination of inorganic and organic color pigments can result in distinct color changes. Overflow of paints and plaster, processing defects or alkalinity from the substrate also favor early or increased chalking, even in the case of paints with a higher limit.

This scenario is completely excluded if acrylic plaster was used for finishing, which has such advantages as:

- high degree of elasticity, which prevents cracking during long-term use;

- high degree of resistance to sudden temperature changes;

- forms a vapor-permeable coating that does not interfere with natural air exchange;

- high degree of adhesion to any mineral substrates (concrete, brick, etc.);

- the dried composition practically does not absorb dirt and dust, keeping the facade clean for a long time;

- easy maintenance - just rinse the facade with water from a hose;

- possibility of tinting (computer or independently) in any color.

In addition, it can be applied in a base color, and acrylic is suitable for painting later. facade paint on plaster, which is also tinted at the request of the owner of the house. The main disadvantages of the material include the impossibility of plastering facades insulated with mineral wool, as well as some labor intensity of the application process itself, since acrylic facade plaster must be applied immediately to the entire surface of the wall (in 1 day), since otherwise minor differences in the color of the coating are possible.

Acrylic plasters for facades - easy application, excellent results

For binders that are susceptible to yellowing, color shifts may also occur. This can be noticeable not only in the pigments, but also in the binder. Additionally, all coatings, whether organic or inorganic, change color due to environmental influences such as acid rain, dust, dirt, grime, etc.

Alkalinity from the substrate can accelerate the chemical degradation of organic pigments. Likewise, fading and washes can lead to color changes such as light veils. This fact is based on the binders used and is not a deficiency. In the case of calcium carbonate fading, it is possible that this may occur soon after completion or only after several months.

Unlike other types, acrylic facade plaster for exterior use allows tinting in fairly intense, saturated colors, since it allows the introduction of a maximum amount of coloring pigment into the composition.

Proper surface preparation is the key to excellent results

When using acrylic plaster for exterior use, it is important to properly prepare the existing surface. This will not only create a high-quality surface, but also facilitate the process of applying the composition. The preparation process usually does not take much time and financial costs, especially if the facade of a newly rebuilt building is being prepared for plastering.

Finally, it can be stated that each façade covering material changes due to external influences as well as the substrate. However, these changes can be minimized by choosing a coating system adapted to the structure and external influences, with the help of a specialist and the manufacturer, as well as professional processing of this system. Especially in bad economic times, there are significant price differences when it comes to painting jobs. Since today very good colors are often coated, another or third coat is required to achieve required thickness layer of color, thereby fulfilling its main function, protecting the subsoil and structure can.

In order for the acrylic polymer plaster to adhere to the base firmly and for a long time, it must be thoroughly cleaned of all types of contaminants, especially oil stains, drops of bitumen, etc. The facade should be examined very carefully to identify foci of fungal infections (mold). If they are present, treatment with special antifungal compounds will be required, after drying of which the entire surface must be treated with an acrylic primer. Moreover, if the base is old and loose, the soil is applied in two to three layers, with intermediate drying of each of them for at least 1.5 to 2 hours. After this, you can proceed directly to plastering.

Acrylic facade plaster

At the same time, work should also be done, particularly moisture protection, to prevent further damage. Tables and Applications of Paint Systems give a rough overview of which paint system is suitable for which substrate and how to beat that system during an upgrade. However, the final color system should only be determined by an expert after peer review.

Silicone resin emulsion paints should not be confused with silicone resin paints, as they are often referred to as such. The difference is that silicone resin emulsion paints dissolve in water, while silicone resin paints dissolve in solvents. Silicone resin and silicone resin emulsion paints are the most modern class products for exterior paints. They combine the positive properties of mineral and dispersion-bound coatings. This means that they are very water repellent, but they are also very permeable to water vapor, such as silicate paints.

Applying acrylic plaster with your own hands

Despite some nuances of working with the finished composition, the question of how to apply acrylic decorative plaster practically does not arise, due to the relative ease of the entire process. It is most preferable to work with this solution on a less than sunny day, so as not to speed up the drying process. If a tinted composition is used, then it is immediately necessary to determine the wall of the building, which can easily be plastered within one day, without long breaks in work.

They are not only weather resistant but also resistant to air pollution. Its dirt-repellent effect makes it extremely durable. Only the color palette is somewhat limited. Animal glues were used to paint decorations on stone reliefs and Egyptian tombs. In Roman times, glue was mentioned along with eggs, milk, vegetable juices and rubber as a binder. In the Middle Ages, the production and use of glue in painting techniques was often described.

Suitable suitability of paint systems

It started in Europe industrial production adhesive paints. At the time, however, more lime-based paints were preferred as lime paints had enormous brightness and thus suited the taste of very strong interior painting.

Application of colored coatings

The first visible element of the house is its facade, which must be impeccable. With a wide range of colors and finishes, exterior covers combine protection and finishing.In the event that a standard, flat surface on the facade is undesirable, and the owner of the house wants to highlight his building, acrylic decorative pebble plaster ceresit ct 60 can be used. Having all the advantages of facade acrylic plaster, due to the presence of a filler made of marble chips of a certain fraction, it allows make a textured surface of the “bark beetle” type. Acrylic decorative bark beetle plaster is applied in almost the same way as the standard version, with the only difference - after application it is rubbed with a steel float. By making circular movements you can get a clearly defined pattern, and its final appearance will depend on the movements of the grater.

Facade plaster allows you to standardize, protect and decorate external walls. It consists mainly of cement mortar or is applied in one to three layers directly on the support. Apart from the aesthetic aspect, its role is mainly to waterproof the masonry, allowing it to breathe. If some pre-assembled or stacked concrete can be left untreated, it is necessary to cover it with concrete block, hollow brick, perforated block or cellular concrete masonry; in fact, these materials do not have sufficient impermeability.

Advice ! It is better to paint pebble plaster in the desired color right away, since it is quite difficult to paint a relief surface with a brush or roller; you will need a spray gun.

Ceresit acrylic textured plaster, after drying, forms a vapor-permeable and fairly elastic coating that reliably protects the building facade from adverse atmospheric influences. It is worth remembering that after application, acrylic bark beetle plaster needs protection from direct exposure to it sun rays, for which it is advisable to shade it with an awning/protective net for 1-2 days. It is also undesirable to moisten it during the drying process. In addition, decorative acrylic pebble plaster can also be used to decorate the walls of corridors, kitchens, loggias or terraces.

The absorption of water by capillarity, coded in three classes, partly determines the level of waterproofing. This protection is more or less high depending on the number of layers and the final thickness of the coating. For example, on a facade that is heavily exposed to rain, it is preferable to choose a coating with low capillarity.

The characteristics of facade coatings must be taken into account

But the exposure of the house is not the only selection criterion. The nature and internal characteristics of the substrate are the elements that determine the type of coating used; the latter must necessarily be compatible with its support in order to have a guarantee of strength. Price per square meter depends on various factors: type of façade to be covered, surface, height, protective coatings etc.

Acrylic plaster - outside and inside the building

Acrylic decorative plaster is suitable not only for protecting the facade. Some of its types are also used to create luxurious interiors. For example, acrylic Venetian plaster allows you to quickly create surfaces that imitate ancient palace decors. Acrylic plaster for interior work can be used on any substrate (plasterboard, concrete, plastered surfaces). Due to its high environmental friendliness, it can be used in any room of the house, including children's rooms, and how to apply it to the wall yourself is shown in the video

What kind of support coverage?

Coatings on new substrates are available in two families: traditional or monolayer. Traditional plastering and multi-layer coatings and mortars prepared on site. It is characterized by a three-layer application: the tapestry serves as a grip, the covering body provides flatness, waterproofing the stand and decorative finishing. This coating can also be applied in two layers if it is mechanically sprayed. A single layer coating, much quicker to sell, is formulated to provide both a dressing and a waterproofing and finishing finish.

Advice ! If you have no experience working with Venetian plaster, you can pre-treat a small section of the wall or apply it to a piece of plywood or chipboard - this way the principle of creating a pattern will be clear.

Despite some difficulty in application, the process of finishing a facade with acrylic plaster is possible by machine - when using special systems, the plastering process is not only significantly accelerated, but also the adhesion strength of the plaster to the base increases significantly. This effect is observed due to the fact that the composition is thrown onto the wall of the building under significant pressure, penetrating into the smallest pores and cracks. By machine you can easily process a large cottage within one working day.

For these substrates there are lime plasters, stucco plasters, stucco plasters and air-lime plasters and plasters for exposed stone facades. Finally, there are also special solutions for old facades made of wet clay and for buildings classified as historical monuments, which benefit from special rules. The application is done manually or mechanically.

Respect the use of coatings

Each coating type matches the exact application. Therefore, it is necessary to observe the specified dosages and mixing times, as well as the thickness of application, in order to guarantee waterproofing. The rules regulate, by means of different dosage tables for each layer to be obtained, the drying time between different passes and the minimum thickness that must be observed. This information can also be obtained from the manufacturer.

Quite often, homeowners doubt which type of plaster, mineral or acrylic plaster, will be more appropriate, practical and durable. It is quite difficult to give an unambiguous answer here, since mineral (for example, cement) plaster has fewer restrictions on the quality of the base, can be applied at negative temperatures (moderate), and the cost of such material is much lower. But the cement composition cannot be tinted, since it has a dark initial color, and it will need to be painted after application. Acrylic paint for exterior plaster work is suitable for this, to which the pigment of the desired shade is first added.

To avoid possible violations the standard defines coatings and their compatibility with various materials facade. Thanks to a single technical document cement mortar, hydraulic lime and air lime, gypsum mixture and air lime are applied to the following supports: new or old masonry, clay brick, stone, stone type installed on low-strength mortar or gypsum, concrete, autoclaved aerated concrete. The covering, which does not consist of a base of hydraulic or capillary binder, must be stopped at a height of at least 15 cm above the ground. This value differs depending on whether the masonry cut-off capillarity is more or less high. As for gypsum, highly dosed with hydraulic binders or with low capillarity, it can be applied to the level of the finished floor. The final thickness of one layer should be from 12 to 25 mm on neat masonry and from 15 to 18 mm on general masonry. In no case should the final coating thickness be less than 10 mm. As for the multilayer coating, the average thickness of its body is from 15 to 20 mm. Depending on the desired final appearance, the thickness of the top layer is usually between 5 and 8 mm. Customizing facades has been in vogue for several years, so manufacturers have developed additional accessories to achieve different finishes.

If we talk about which plaster is better, acrylic or silicone, the latter option will cost more, but it is the silicone composition that allows you to introduce various fillers into the composition, thanks to which you can experiment with the surface, independently creating the necessary texture, for example, a “fur coat”, a lamb” etc. Silicone plaster can also be initially tinted, or painted after it has been applied to the base.

Now you can reproduce the design in cool plaster thanks to stamps and other stencils that imitate different materials. To avoid mistakes, manufacturers indicate on their packaging the resistance class of the coating, the type of substrate for which it is intended, method of application, color, etc.

Opinion of an expert on façade visualization

Facades should be repaired every ten years, however, due to the cost of the operation, repairs on a healthy wall are carried out every 15 years on average. Some manufacturers provide technical data for their products. They are free to download and provide information to help you make informed choices.

Acrylic plaster is an ideal choice for those who want to save on finishing and insulating the facade. These mixtures are made on the basis of acrylic resins, which allows you to obtain a strong and durable coating. The warranty period declared by the manufacturers is at least 15 years. But to achieve such indicators, it is necessary to correctly select and apply the finishing composition.

Mistakes that should not be made when installing façade plaster

Depending on the application method and finishing methods, an infinity of results can be obtained from “raw” to “fine talohe”. Otherwise, protection from weather conditions becomes ineffective and the final rendering is unsightly. Find out more: Construction Quality Agency.

Prepare the facade before updating it

The facade cleaning is more or less light, depending on the state of the support, says Helen Heintz. The idea is to get the substrate clean and healthy before applying plaster or paint. “The first step is to clean the façade and rinse thoroughly.” Using a high-pressure cleaner or a brush and jet of water, remove any imperfections, and loose parts should also be removed, explains Stephanie Deplechin.

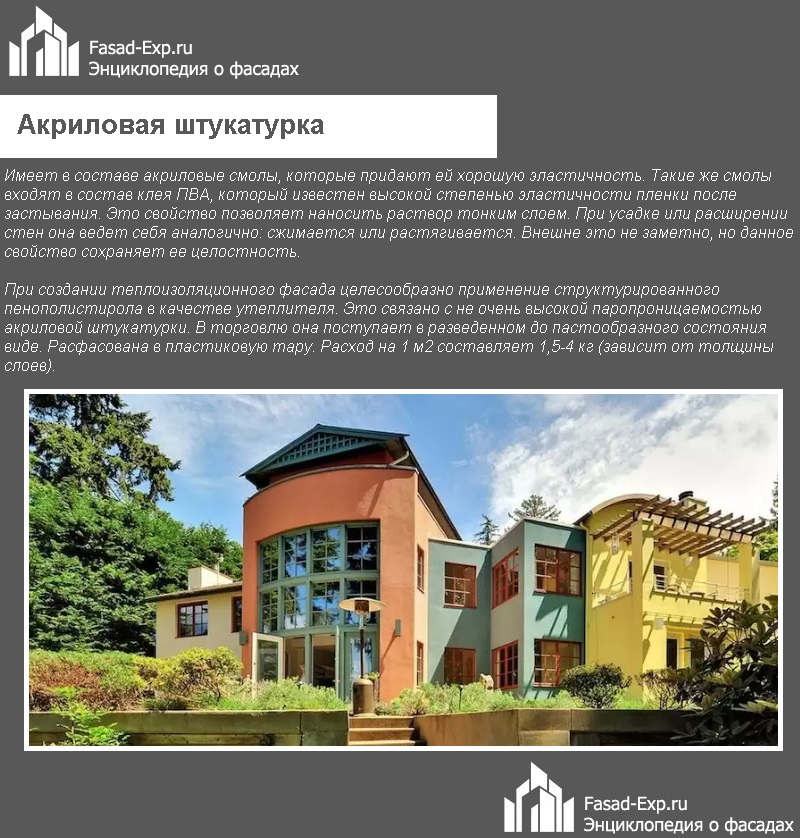

Characteristics and features of acrylic plaster

Acrylic plaster is a ready-to-use water-dispersion mixture. This material consists of about 10 components, the main one of which is acrylic resin. It is this that ensures (after hardening) the strength of the mixture applied to the walls.

The market for finishing materials pleases with the abundance and variety of plaster mixtures. Acrylic stands out from the crowd in that it has several significant advantages:

- affordable price (more expensive than mineral mixtures, but much cheaper than silicone and silicate);

- excellent vapor permeability;

- moisture resistance;

- frost resistance.

When choosing a composition for finishing a facade, you should understand that there are no universal solutions. The brand and manufacturer of the mixture is chosen depending on the operating conditions of the building and the tasks that the finishing material must solve in a particular case. Thanks to a wide range of acrylic mixtures, you can choose a composition for any conditions:

- with high humidity;

- with a significant amplitude of daily and annual air temperature fluctuations;

- With high level dust formation;

- with an abundance of hot sunny days.

Acrylic plaster is highly impact resistant and has the property of repelling dust, which makes it possible to use this finishing material in industrial areas with fairly high levels of air pollution. The distinctive feature of acrylic surfaces is that they are sprayed with water from a hose. Therefore, maintaining the façade is quite simple.

Technical characteristics of plaster mixtures based on acrylic resins

One cannot fail to note such an advantage of acrylic plaster as its elasticity. Thanks to this property, the composition is easily applied to any surface: wood, brick and stone, foam plastic, porous materials (gas block and foam block), fibrous materials (slabs mineral wool), OSB panels. There are two types of plaster mixtures:

- repair ones, intended for sealing cracks and cracks;

- decorative, designed to create a highly aesthetic facing surface.

Decorative acrylic plaster "bark beetle"

Acrylic plaster combines all the advantages of the listed types of mixtures. Thanks to the resins included in its composition, it provides durable protection to the load-bearing base. In combination with fiberglass mesh, it is used to strengthen walls and other surfaces. Decorative properties plaster is provided by various fillers included in its composition.

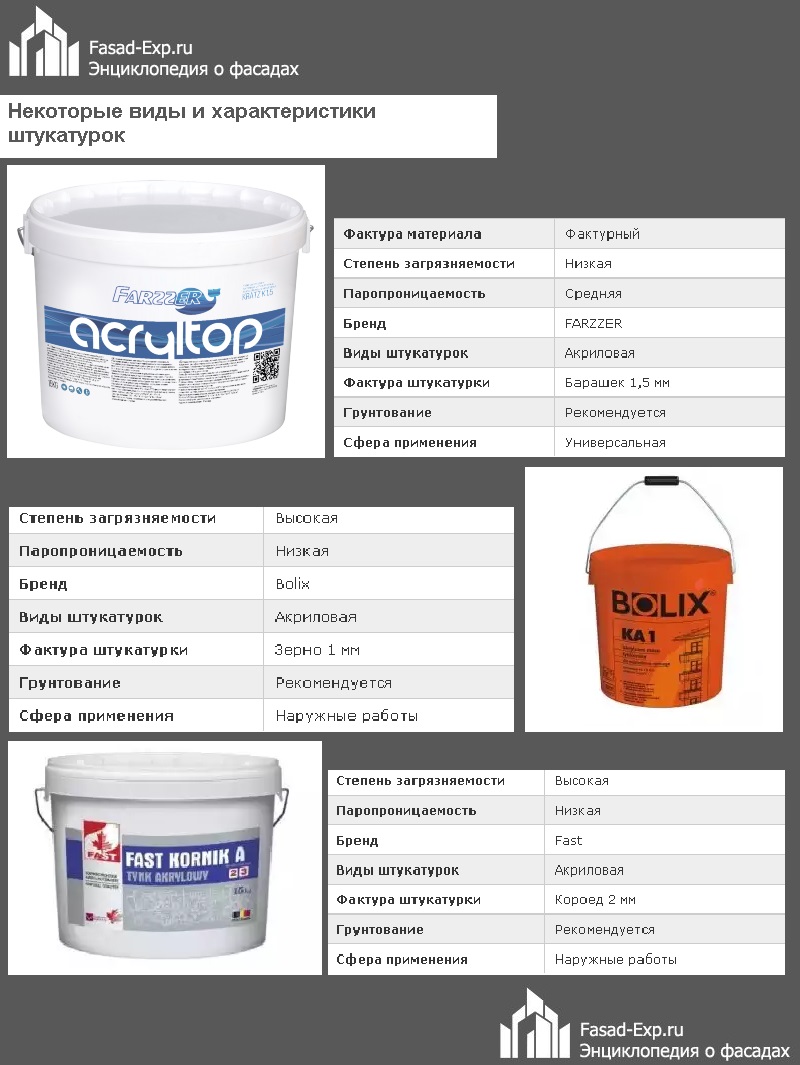

Types, brands and manufacturers of acrylic plaster

The same plaster mixture can be presented on the market under different names. The name of the composition depends on the manufacturer. As a rule, all companies producing finishing mixtures give their products a name that will be distinctive feature this product, its brand. This name often coincides with the name of the manufacturer. For example, the Ceresit company produces a wide range of building mixtures, including acrylic-based compositions.

The most famous brands of acrylic plasters are:

Video - Characteristics of acrylic plaster

The main classification of acrylic plasterers is carried out according to two parameters:

- for interior work;

- for external work.

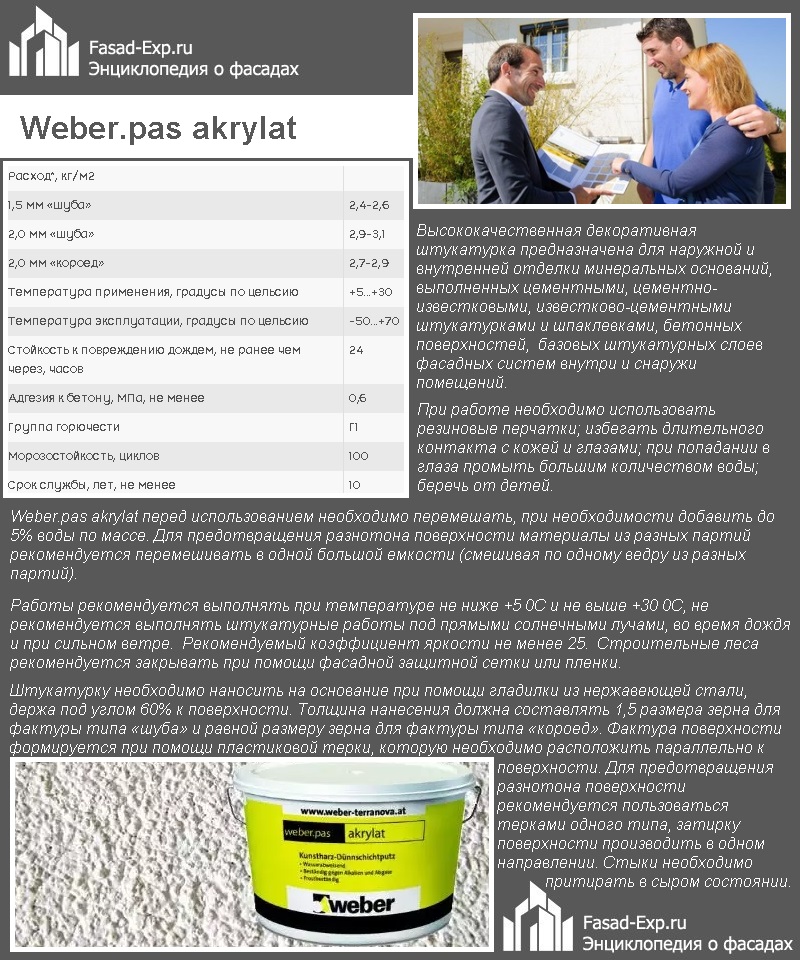

The former differ from the latter in the degree of moisture and frost resistance, the presence of special additives that enhance the protective properties finishing material. Acrylic plasters for facade work are widely used in all climatic zones. There are mixtures that can be used with equal success for interior and exterior work. For example, Weber-Vetonit, “Pass acrylate” line. It consists of three types of acrylic plasters: “Fur coat 1 mm”, “Fur coat 2 mm”, “Bark beetle”.

Mixtures of any type are ready for use immediately after purchase, but if necessary, you can tint the composition and add components to it that prevent the development of fungus and mold. To obtain the desired shade of color, water-soluble dyes are used.

Features of the use of acrylic plaster

The main problem with applying acrylic plaster is that it dries quite quickly. Therefore, you need to work quickly and efficiently. Experts recommend practicing a little in applying acrylic mixtures before starting the main scope of finishing work.

Obtaining the same color of the plaster mixture

When adding pigment, you need to take into account that the acrylic plaster mixture after drying loses its color saturation, like any other water-based composition (for example, water-based paint). You need to be prepared for this and add a slightly larger amount of tinting pastes to the mixture than is required for other types of plaster compositions.

There are color selection programs that allow you to see on the monitor screen the result of mixing a certain amount of color and plaster. This is the most convenient way to select the proportion of dyes for a large volume of work that requires the use of several containers with acrylic plaster. The exact dosage of pigment will allow you to get the same color for all batches. Given software Available at all points of sale of building finishing materials.

Video - Ticiana acrylic roller plaster, tinted

Strengthening the protective properties of acrylic plaster

Acrylic plaster can be given additional properties that will help protect walls from moisture and insects. For this purpose, various antiseptics and water repellents are used.

If the façade is made of concrete, you can use Kartotsid-compound.

This antiseptic is effective means protection against biological damage. It can be added to dry and wet building mixtures. “Kartotsid-compound” is made on a water basis, so there are no obstacles to its use with acrylic plaster. To impart protective properties to the mixture, it is enough to add 5% of the antiseptic to it based on the total volume of the finishing composition. After which the plaster is mixed with a drill equipped with a metal mixer.

Preliminary priming of surfaces

To enhance the adhesion of the plaster to the load-bearing surface, priming is performed. It consists of applying special solutions to the walls that improve the quality of the finishing layer.

In order to get the maximum effect from using a primer, choose compositions (primer and plaster) from the same manufacturer. In this case, you can be sure that all the components of these materials will be ideally selected to achieve the best result.

There are no special primers for acrylic plasters. Use those that are suitable for processing external walls from a specific type of material. If the facade is brick, you will need a composition for working with brick, if it is wooden - with wood. You can learn about the purpose and properties of the primer from the information posted by the manufacturer on the product container.

But for working with acrylic plaster mixtures, the following primers are recommended: “Facade-soil”, “Proacryl-soil”, “Proacryl-Contact”, “Akrial-soil”.

Facade-Grunt - water-based acrylic primer for facades and walls

All these compositions can be applied to walls using a paint brush, roller or sprayer.

Methods of applying acrylic plasters

There is such a category of acrylic plasters as thin-layer. These mixtures are intended for manual creation decorative facing surfaces. Thin-layer compositions have unsurpassed plasticity and are applied easily and quickly. To obtain thicker layers, machine application is used. In this case, dry mixtures are needed, which are diluted with water in the required proportion.

Three types of machines are popular in Russia and neighboring countries: PFT, Putzmeister and Kaleta. These units can be equipped with bunkers of different capacities: from 50 to 280 kg. The package includes a compressor, hoses for supplying the mixture, and working guns. There are multifunctional devices that can work with different types mixtures, regardless of the size of the filler included in their composition.

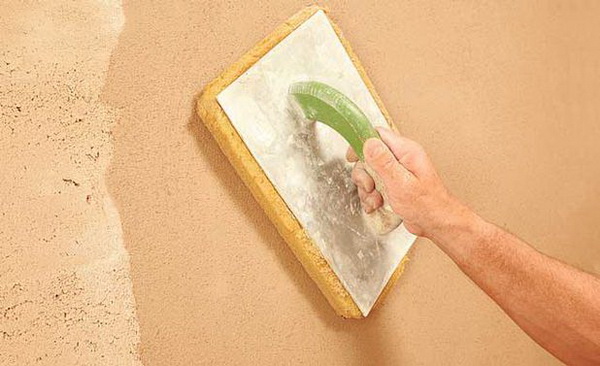

But the use of specialized machines does not eliminate the need for manual labor. After spraying a layer of plaster on the walls, it is leveled using a trowel or spatula. If necessary, use tools to obtain a textured surface.

![]()

Applying acrylic plaster mechanically

Finishing the facade is a significant amount of work. Therefore, it is rational to use special equipment to decorate large buildings. This approach will help complete the finishing work much faster than with the manual method of facing the facade.

The first thing you need to do is choose the right plaster mixture. Its composition must necessarily include special hardeners and additives that ensure crack resistance and strength of the layer. Among these components:

- acrylic resins;

- silicone;

- fungicides;

- liquid glass.

When using a machine application method, you need to know the rules for preparing the mixture and operating the equipment. Therefore, when choosing this method of finishing a facade, they traditionally invite a team of specialists who are familiar with all the nuances of this technique of facing work. But if you have the desire and the necessary equipment, you can complete this task yourself.

First of all, you need to remember a few rules.

- To apply the plaster layer, it is necessary to choose an area of such size that there is no need to move along the wall with the gun turned on.

- Work begins from the corner of the building.

- Before starting work, several test applications are performed, thereby checking the performance and capabilities of the equipment.

- The thickness of the applied layer depends on the speed of movement of the gun. Therefore, all movements must be uniform and smooth.

- The jet from the gun should be directed perpendicular to the wall surface.

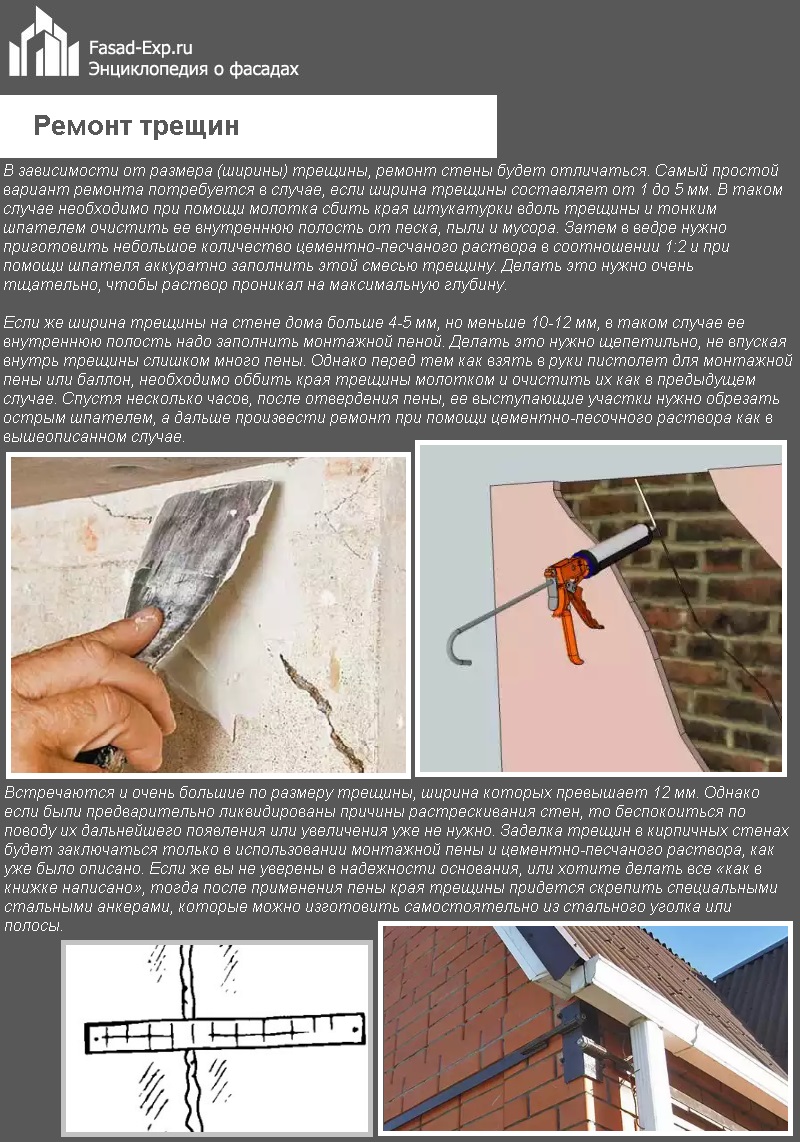

Before you start finishing works, preparing the facade. If there are cracks, they are cleaned of dirt and dust, and all small particles are removed.

Mating places different materials(for example, brick and concrete), reinforced and protected by reinforcement construction mesh with a mesh section of 1x1 mm. The mesh is secured using a cement-sand or adhesive building mixture.

Next, we begin priming the walls. Choose the most convenient tool for the job: a roller, a paint brush or a spray gun. The priming process is simple and straightforward: the wall is covered with a layer of mortar, trying to fill all the pores and cracks with it. If the surface is complex, apply a second layer of primer. This is done after the first layer has completely dried. The required time interval can be found in the manufacturer's instructions.

Work order

Step 1. The plaster application apparatus is connected to the water intake point. If it is not possible to connect to a centralized network, use a large container of water.

An important point: the water must be clean. It is undesirable to use technical liquids, as this will worsen the appearance of the plastered surfaces.

If there are various salts and chemicals in the water, they may react with the substances included in the dry mixture. This can lead to the plaster composition losing its properties: plasticity, frost resistance, crack resistance.

Step 2. Pour the required amount of mixture into the hopper (this information is in the manufacturer’s instructions).

Step 3. Pour in the required amount of water, turn on the apparatus and prepare the solution.

Step 4. Hold the gun at a distance of 20-30 cm from the wall surface and turn on the device.

Step 5. Direct the jet at the wall and move the gun along the work area.

Step 6. After one strip of plaster layer has been applied, begin applying the second. In this way the entire area of the wall is plastered.

Step 7 After the plaster has almost completely hardened, trim irregularities and sagging. This is done using a rule or a spatula with a wide metal blade. The tool is pressed against the wall and, pressing on it, lowered down.

![]()

Step 8 Wet the surface with water and grout the leveled layer. To do this, use a spatula or trowel. You can smooth the wall using a paint brush with elastic bristles. Regularly wetting the surface, using circular movements of the hands, perform the final leveling of the walls.

Video - Plastering walls by machine. PFT Wall Plastering Machines

Applying acrylic plaster manually

All work is carried out at positive air temperatures (not lower than +5°C).

Step 1. Preparing the walls.

If there is an old finishing coating on the facade, it is removed. The walls must be fairly clean and free from efflorescence, moss, and mold. If there are stains from oils or flammable liquids, wash with water to which special substances are added: detergents.

If there is mold on the walls, treat the facade with agents that prevent its formation. An excellent choice is the antifungal agent SEPTOBUD 1008. Before applying it, take a stiff brush or scraper and clean the wall. Then rinse it thoroughly with a stream of water from a hose.

If there are cracks in the walls, seal them with cement-sand or putty-repair mortar. If the load-bearing surface is fragile and there are wide cracks, a fiberglass mesh is built in. For shallow and narrow cracks, putty-leveling compounds can be used.

Step 2. After the repair layer has dried, begin priming the surfaces.

Step 3. After the primer has dried, plastering is performed. The composition is applied to the wall using a spatula or stainless steel grater. If acrylic plaster is filled, the thickness of the layer should not exceed twice the cross-section of the grain. If the filler is small, the layer thickness should not exceed 8-10 mm.

To avoid differences in color and structure on surfaces, work should not be interrupted for more than 10 minutes. If the facade area is large, it is divided into several fragments, which are plastered alternately. In order for the mass to be homogeneous and have one color shade, new portions are regularly added to the bucket with the mixture, which are thoroughly mixed with the remainder.

During work, they try to prevent the mixture from getting into the eyes and respiratory system. If necessary, use safety glasses.

To give surfaces a certain pattern, textured rollers, stencils, and brushes with stiff bristles are suitable.

One of the most simple ways decorate the facade - use wave-like hand movements to create a relief in the form of waves on the walls. Many acrylic plasters are textured, that is, they themselves create a decorative surface. To obtain it, proper application and leveling of the composition is sufficient.

Video - Applying acrylic plaster