Facing brick in the room. Decorative facing bricks: types, application in the interior, installation rules

The Plitka-Kirpich company offers to buy brick tiles of its own production for interior decoration. Large selection, high quality, delivery and reasonable prices.

Our assortment includes brick-like tiles for interior decoration made of concrete and gypsum in various shades, which allows you to choose the material for finishing the interior of any room - living room or bedroom, corridor, bathroom or kitchen. Brick tiles will look appropriate anywhere, because they go well with many other finishing materials: wallpaper, lining or plaster.

Prices for our tiles

As a direct manufacturer, the Plitka-Kirpich company not only guarantees the high quality of its products, but also offers an affordable price for brick tiles.

The cost depends on the material from which it is made, and on average is:

- imitation brick made of concrete - from 1250 rubles. for 1 m2;

- gypsum tiles – from 700 rub. for 1 m2.

In our company you can order decorative brick-like tiles not only in Moscow, because we deliver throughout Russia using transport companies. It is also possible to pick up products from our company’s warehouse. You can familiarize yourself with the delivery conditions in the corresponding section of our website.

In addition, Plitka-Kirpich specialists provide Additional services for professional installation of brick-like tiles, which allows you to transform the interior country house or apartments quickly, efficiently and inexpensively.

What is this tile?

Brick tiles are in demand construction material, used not only for decorating facades, but also for interior decoration. Thanks to the many colors and textures, it can complement any interior, especially if it is made in the loft style.

The catalog presents brick-like tiles for interior decoration in a variety of color scheme, and choose suitable option you can use a photo. We offer to buy tiles for the wall, made in the form of noble white masonry, classic dark red brick, or cladding to look like old brick.

Decorative cladding imitating brick has a number of advantages that distinguish it from other types of finishing materials.

Advantages brick tiles made of concrete manufactured by our company is:

- Aesthetics and attractiveness. Each tile has a clear geometric pattern, smooth and clear lines, and a large selection of colors and textures.

- Strength and durability. Concrete facing tiles are resistant to mechanical damage and scratches, it is less susceptible to wear and tear compared to other types of finishes.

- Light weight, such facing material does not create additional load on bearing structures houses and foundation.

- Versatility. Decorative tiles that imitate brick look harmonious in rooms for completely different purposes - they are widely used for finishing both residential rooms and commercial and office premises, as well as restaurants, hotels, cinemas, etc.

- Eco-friendly and easy to care for. The facing tiles produced in our company are an environmentally friendly and safe finishing material. It is easy to clean from dust, is of high quality and is made from raw materials of natural origin.

In addition, we offer affordable prices for all our products and guarantee their high quality, strictly controlling and monitoring every stage of production.

With the right design approach, a brick pattern will fit perfectly into almost any style. Facing tiles made to look like old, darkened brick will fit perfectly into an interior in the Baroque or avant-garde style. And a small fragment of white brickwork Suitable for modern or minimalism.

Solid Brick wall characteristic of the loft style, which is based on the imitation of abandoned premises and workers' housing. It is the loft that involves decorating the room almost entirely with brickwork. To decorate in a loft style, you should use decorative tiles, the color of which is as close as possible to the natural material.

You can use brick-like tiles to accent one of the walls of a living space, decorate a hallway, bathroom, shower or steam room. Besides this, this decorative material can be ordered for laying out an “apron” in the kitchen or finishing the fireplace and the wall next to the hearth.

We offer high-quality decorative brick-like tiles in a variety of colors that are suitable for finishing any interior. Profitable terms, delivery throughout Moscow and throughout Russia, installation and quality assurance. Call!

Among the advantages of this type of cladding are:

- extending the service life of the facade;

- increase in thermal insulation performance;

- ease of masonry;

- the ability to replace damaged tiles without dismantling neighboring ones;

- original look.

Decorative brick can be used for interior and exterior decoration. Indoors, it is often used to decorate openings, both arched and window. The brick finish of the fireplace looks original.

Selection of decorative bricks

Our catalog contains a fairly wide range of decorative bricks, including about 70 varieties. These are tiles with smooth, rough and rustic surfaces, available in a wide range of colors.

An impressive size range is no less important. Each type of tile differs from others in length and width. In addition, the thickness may vary within 10-27 mm. It’s quite easy to buy decorative bricks from us. You can purchase the cladding you like in 2 ways: through the online store, as well as in our specialized stores. All these addresses can be found on our website on the “Stores” page.

Decorative brick for façade cladding is a clinker series of decorative facing stone that completely imitates the texture of German clinker. The catalog presents the textures of facade tiles with different surfaces: antique brick, Viennese clinker, Roman brick and more than 50 options for decorative bricks in various colors. The textures of facade tiles fully convey appearance hand-molded bricks, while the price of decorative facing brick much lower than for German clinker.

Decorative brick finishes are chosen if you want to highlight certain areas in the interior or to fully decorate one or more walls. The main difference between the material used and standard facing products is its smaller thickness and lighter weight. The cladding technology is similar to the process of laying tiles, but some stages (marking, installation of corner elements, grouting joints) require a more careful approach. The price of the material depends on the decorative effect and raw materials, the average cost square meter finishing costs 1000 rubles excluding the costs of specialist services.

The assortment is represented by rectangular products reminiscent of standard ceramic bricks, but with a relief front surface. Being one of the varieties decorative stone for interior decoration, they have the same dimensions and shape, with the exception of patterns that imitate a combination of spoon and bonded masonry. In this case, there is no need to comply with standards; the dimensions offered by the manufacturer take into account only the external effect.

Most often there are options with a length ranging from 17-29 cm, a width of about 5-6 and a thickness of 7 to 25 mm. Decorativeness is achieved by experimenting with color and type of surface: the front side can be matte or glossy, convex or concave, have a complex relief, rounded and broken edges. Typically, products are produced complete with arched, corner and additional elements, which allows for a unique interior decoration.

Overview of finishing options

Depending on the raw materials used and manufacturing technology, there are:

- Ceramic decorative brick made of clay, quartz chips and sand, produced by high-temperature firing.

- Gypsum-based artificial stone is a molding material that can be created with your own hands if desired.

- Cement brick - manufactured according to the same principle (strength building of the mortar in molds), but containing thermal insulating fillers - expanded clay or perlite chips.

All of them are united by their execution in the form of bricks and their intended purpose – exclusively interior decoration. These products are not suitable for cladding facades due to their low moisture resistance and more porous structure, which allows the walls to breathe. Strength, weight, durability and other performance characteristics vary for each variety.

1. Pros and cons of gypsum.

Decorative finishing made from this material is valued for its lightness, ease of installation, a large selection of textures and colors that are pleasant to the touch, resistance to high temperatures, environmental safety and control of humidity levels. Gypsum brick has good compressive and bending strength; under appropriate operating conditions, the resulting coating will last for many years. But two significant disadvantages such as fragility and hygroscopicity limit the use of this material even for interior decoration. However, this option is in demand when finishing walls in rooms with a humidity of no more than 65%. Of all types of decorative facing bricks, gypsum has the lowest cost. It is definitely recommended to buy it if you doubt the load-bearing capacity of the walls. The scope of application also includes finishing of the fireplace area and chimneys.

2. Ceramics.

A time-tested option for decorative bricks, which has characteristics similar to tiles and is optimal for cladding areas with frequent exposure to moisture. Distinctive feature This variety is fired during production; it differs from standard clinker only in thickness. The technology makes it possible to obtain durable, moisture- and frost-resistant and practical products that do not change their properties during operation.

The disadvantages of ceramic decorative bricks include high cost; this is the most expensive variety. The optimal area of application is considered to be areas exposed to temperature changes: chimneys, fireplaces, stoves, loggias and verandas. The minimum service life of ceramic bricks is 30 years; this finishing option is selected for a long time.

Separately, we consider porcelain stoneware - a decorative stone obtained by semi-dry pressing and passed through double-firing ovens. In addition to clay, its composition includes crumbs from hard rocks. This is the most expensive variety, the minimum cost for facing 1 m2 is 2000 rubles. But small porcelain stoneware products are rare (and mainly from foreign manufacturers); most often the products are in the form of square tiles or panels (from 30x30 cm), only imitating brick.

3. Features of decorative cement stone.

The traditional composition of this material includes Portland cement, strength and coloring additives, and a lightweight filler with thermal insulation properties. The base may also include polymers and acrylic resins that enhance water-repellent properties. Despite all the advantages, they are not always safe for humans; before purchasing such products, it is worth checking the instructions for approval for interior decoration.

This is a highly durable and moisture-resistant variety; the only drawback is the weight. Cement-based decorative bricks are recommended to be purchased for finishing rooms with high humidity, but in general the scope of application is almost universal. To enhance water protection and extend their service life, it is recommended to coat them with special varnishes or protective compounds that seal pores.

Performance characteristics

When choosing decorative bricks for interior decoration, in addition to dimensions, weight and color, attention is paid to the main operational parameters. On average they are:

Decorative brick-like stone is in demand when decorating living rooms, corridors and hallways, kitchens, and, less often, bedrooms (the material looks like a single mass and can overwhelm people). He focuses on panels, corners, mirrors, door and window openings and is relevant when it is necessary to zoning a room. An original visual effect is achieved when lining fireplace areas, areas near fountains, kitchen aprons, bar counters and niches. It should be remembered that the interior with such decorative finishing requires enhanced lighting or combination with white and light materials.

Installation features

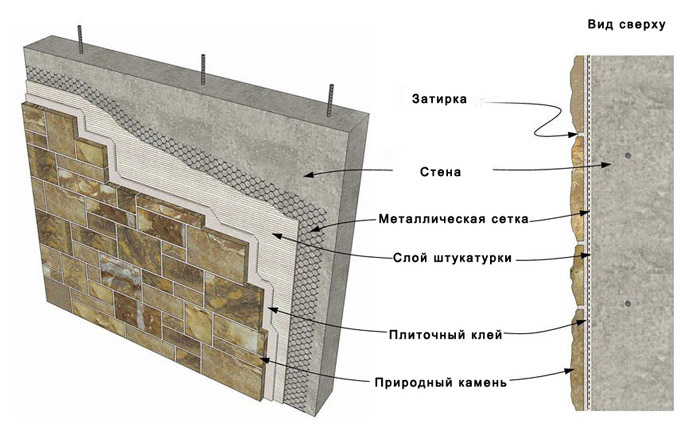

The main stages of cladding include:

- Calculation of material taking into account the occupied space in the interior. A mandatory reserve of 8-12% is provided.

- Preparation of the base: leveling and applying primers to improve adhesion and protect decorative bricks from fungus.

- Marking, installation of auxiliary stripes and crosses.

- Laying bricks, starting with the frame and corners.

- Grouting and washing of joints.

- Treatment of the external surface with protective varnishes or primers (recommended, but not mandatory step).

Particular attention is paid to preparing the plane. Decorative brick is placed on a flat, hard and non-shrinking base, cleared of debris and foreign stains. Checking the level, eliminating defects and leveling work are mandatory. There are two options: plastering or covering the walls with sheets of plasterboard with a thickness of 12.5 mm or more. Such stringent requirements are due to the significant weight. Experienced builders recommend carrying out an inspection - temporary installation of several bricks and inspection of their condition within 3 days.

Treatment with antiseptics that close the pores can significantly save the adhesive composition. Highly absorbent walls are coated twice. During the installation process, the humidity of the working surface is monitored; in hot conditions, experts recommend wetting it and the products themselves. After the primer has dried, you can safely begin marking, taking into account the thickness of the joints or butt placement.

Framing and corner elements are installed first. Despite the strict geometry and identical dimensions of decorative facing bricks, skipping the marking stage or performing it without a preliminary sketch is not recommended. The main goal is to lay the entire material (the ease of cutting with a grinder or jigsaw does not at all guarantee the quality of the edges). For corners, it is advisable to purchase rusticated stone or special elements, this way they will look neater. If the budget does not allow this, then in this area the brick is placed end-to-end or with edges cut at an angle of 45° (which significantly complicates the finishing process).

The choice of direction for laying decorative bricks depends on the type of seams: when jointing it is more convenient to move from top to bottom, when installing end-to-end - vice versa. In the first case, the mortar does not get on the products; in the second, the risk of the mass sliding is eliminated. When facing heavy and thick bricks (over 15 mm), it is recommended to take breaks every 3 rows and check their condition before resuming work. The adhesive composition is applied to only one row. As with standard masonry, decorative bricks are placed offset, but without the mandatory minimum of a quarter size. The material gives a lot of scope for creativity; bricks of different colors, textures, and thicknesses can be placed side by side, but the optimal option is considered to be the usual option with a shift of vertical seams of 5 cm.

The final stage of cladding is grouting, which begins after the adhesive composition has hardened. Majority modern species glue allows you to carry out grouting work within 24 hours after finishing the walls with brick. All auxiliary strips are carefully removed along with excess glue. The seams between the decorative bricks are filled with mortar using a construction gun or a finger wrapped in fabric. The color is selected taking into account the perception of the overall picture.

Price

| Brand name | Manufacturer | Material | Dimensions, mm | Weight kg/m2 | Price per sq.m |

| Riga brick | The perfect stone | Artificial cement-containing stone | 221×64×14 | 27,5 | 1020 |

| Town Brick TB-22/R | Red stone | 213×65×10 | 16 | 1000 | |

| Slimbrick | Eurokam | 210×50×7 | 9,7 | 997 | |

| Variorock KardoLong | 475×75×18 | 24,8 | 1570 | ||

| London brick | White Hills | 240×65×15 | 21,5 | 950 | |

| Bruges brick | 210×65×20 | 18,5 | 930 | ||

| Dolomite wall | Kamrock | 305×75×20 | 29,4 | 1150 | |

| Clinker brick | Thin-walled facing clinker | 192×55×15 | 18,4 | 1100 | |

| Casavaga under brick | Casavaga | Gypsum tiles | 210×50×9.6 | 7,5 | 640 |

To transform the interior of a room, it is necessary to carry out high-quality Finishing work. But we must not forget that the correctly selected material will play a key role. Currently, a product called decorative brick, which is distinguished by its aesthetics, practicality and reasonable price, is gaining increasing popularity.

Exist different kinds decorative bricks, which differ in their characteristics and areas where their use would be most justified.

Of course there are more types of this product, but they are less popular.

Advantages and rules of choice

Any artificial brick for interior decoration has the following advantages:

- Long service life. The durability of the material is measured in decades. Even the gypsum option, which is considered the most susceptible to mechanical stress, will provide pleasure for many years if used correctly.

- Sound and heat insulation. This is one of the additional properties that characterize the product. Of course, the amount of this protection is different for each type and largely depends on the available size.

- Environmental friendliness. The material does not emit toxic substances, which meets existing safety standards.

It is necessary to take into account that bricks can be produced in the form of separate fragments, the sizes of which are made by each manufacturer, as well as panels. The latter option allows installation much faster and easier. It often acts as false panels, hiding various communications objects.

Decorative brick is an environmentally friendly material that allows you to create an additional layer of sound and heat insulation

Decorative brick is an environmentally friendly material that allows you to create an additional layer of sound and heat insulation When choosing a material, it is advisable to take into account some features:

- Acrylic brick has a lot of positive properties, it is characterized by a rich color palette, lightness, and the absence of the need for additional finishing. But the price makes it less accessible.

- The clinker variety is different good properties and does not require additional finishing. However, it requires a larger solution flow rate, as well as better preparation basics. In the interior, clinker looks much heavier, but more impressive.

- The ceramic version has mechanical strength and resistance to water and moisture. Withstands high and low temperatures, as well as their changes. Does not deform even under strong mechanical loads. But it has a high cost and significant weight, which is why the material must be laid only on durable surfaces using reinforced adhesives.

- Porcelain stoneware brick has excellent characteristics and the longest service life, reaching 40 years. However, it is characterized by high cost, exposure to ultraviolet waves and heavy weight.

- Plaster products are the most affordable and popular way to transform a room. But there are some nuances. Less mixture is required for installation, but the elements require treatment with paints and varnishes and do not withstand mechanical stress.

Naturally, the last option is the most frequently used, because its price is several times lower than the others. If desired, it can be made at home.

Use in interior decoration

Decorative bricks for interior decoration are used for laying in various rooms of a house or apartment. It should be borne in mind that this option requires a more strict approach, because its use differs from stone.

This is the main mistake of many who decided to fill the interior with this material. We must not allow ill-considered chaos.

This is the main mistake of many who decided to fill the interior with this material. We must not allow ill-considered chaos. Interior decoration with decorative bricks

Design options for living rooms, bedrooms and offices

There are certain rules that will help you tile the surfaces of these rooms most correctly.

On a note! It is important to take into account the play of light. Therefore, additional lighting is thought out in advance, which can now be beautifully mounted in various objects.

Solutions for kitchens and bathrooms

- Facing bricks for interior finishing of the kitchen area are the most commonly used solution. The main thing is to achieve the correct design. After all, many consider such masonry in the kitchen to be an excess that spoils the entire interior. This feeling occurs when, in a small room, almost the entire surface is finished, and dark colors are used.

So:

So: - It is better to divide the kitchen into zones; even a small room can benefit from laying the material along the work surface. Both light and dark shades will look good. It is better to give preference to the clinker variety, it washes well.

- Previously, it was considered quite popular to cover the walls in the kitchen halfway. This method can still be used now, but combinations with other materials must be taken into account to avoid a feeling of institutionalization.

Panel options are well suited for the bathroom; they successfully mask all communications. You just need to take into account that for this you will need to build a sheathing. And also, if gypsum products are used, they need to be further processed.

Decorating a bathroom with decorative bricks

Decorating a bathroom with decorative bricks Corridors, arches and doorways

It should be taken into account that small rooms and narrow corridors cannot be completely decorated with such decorative material.

Facing bricks are laid only in a certain part, for example, in places of increased contamination (taking into account the additional impregnation of the gypsum version). Solutions look very good when installation is carried out around arched structures and doorways

. It is possible to obtain an excellent effect, and lightness is achieved through the use of light shades.

Styles Suitable for Brickwork

- Seys lined with brick look most successful in the following styles:

- Loft. This style differs from the others in that it almost completely replicates the interior of old factories, storage and production facilities. That is, this is a kind of industrial design. Brick can occupy all the walls in such a room. It must be combined with other elements - beams, hanging ropes, twisted wiring in an old winding.

- Minimalism. An urban movement that tries to combine the incompatible. Therefore, decorative masonry is often presented in bright colors. Only one wall is covered with it, which is opposed to the rest. They are available in gray or white colors.

- Country. The style is responsible for the creation of a country house, where decorative facing brick appears for the interior decoration of the walls, which are a continuation of the fireplace. We need to try to achieve distance from urban housing, to create a cozy primitiveness.

Gothic (neo-Gothic).

Gothic (neo-Gothic). Masonry is laid literally everywhere, but in combination with other contrasting interior objects. Premises for this style should have high ceilings.

Decorative items are laid out quite simply, so even a novice craftsman can handle this task, which will save on work. First of all, you need to prepare tools and consumables:

- Tape measure, ruler, pencil or marker for marking the wall.

- Brush, brush, aluminum profile and fasteners, drill, and primer for preliminary work.

- Level and plumb line to check correct installation.

- Spatula, plastic crosses, adhesive composition for basic work.

- Joint grout and rubber spatula for finishing work.

Important! When calculating the amount of material, it is necessary to add about 10% of the reserve in case of fighting and trimming.

Preliminary stage

First of all, prepare the surface. Old coatings are removed from it, leveled with plaster or putty, rubbed and dust removed, and then treated with a primer. Then the finishing material is laid out on the floor in one layer and various elements are selected according to pattern, thickness and texture to imagine how the final result will look on the surface.

Preparing the surface for installation of decorative bricks

Preparing the surface for installation of decorative bricks Markings are applied to the walls. To do this, step back from the floor at a distance equal to half the width of the brick. Draw a horizontal line, checking the building level, and install the metal profile on the dowels along this line. This structure will serve as a support for the brick so that it does not “float” while the mortar is still wet. Next, the location of each cladding element is drawn on the wall, taking into account seams of 1-2.5 mm. The bricks are treated with a primer and left to dry.

Installation procedure

Laying false bricks is as follows:

Provided that the walls are smooth or have been previously leveled, this is a fairly simple procedure that does not require specialized education or experience. The main thing is not to get carried away during experiments, so that the interior does not turn out too bulky and rough. It is important to remember the basic rules for decorating different rooms and maintain a balance of colors and shades.

Decorating the interior surfaces of the walls of a house is practical, beautiful and individual. Used for these purposes different material, but the most popular today is decorative facing brick for interior decoration. A fashionable “trend” in style – loft embodies all the diversity and possibilities of a piece product. And in order to select the cladding, it is good to know the technological features of the finishing, types and capabilities of products.

Types and characteristics of material

Do not confuse facing brick and facing stone. Despite many similar qualities, types for interior decoration have their own characteristics. Unlike stone, brick has a stable shape, although it is also varied in texture. Besides, color solutions brickwork will not be as variable as stone, but this adds its own charm to the finish. It is also good to remember that piece material has its own mass, which will definitely have to be taken into account when laying the foundation for construction.

At its core, decorative brick combines two qualities: the format and strength of an ordinary building product, and high quality indicators artificial stone. The production of decorative bricks for interior decoration is allowed from such raw materials as:

- Gypsum chips and powder;

- Ceramics;

- Porcelain tiles;

- Acrylic;

- Synthetic substances.

As for color resolution, as can be seen in the photo, it can be:

- White/red standard brick;

- Shades of brown: from sand to darker tones;

- Red-brown;

- White with a sandy tint;

- Gray and all its halftones.

Interesting! Today, an aged decorative product is gaining popularity, especially appropriate in the interior of country mansions and large studio apartments.

Gypsum brick

This is one of the most affordable finishing materials, produced quite simply. Distinctive features products:

- Practicality;

- Reliability;

- Durability;

- Variability of formats, designs;

- Non-corrosion;

- Resistance to temperature changes.

Important! Decorative gypsum bricks are not moisture resistant resistant material. To minimize this factor, the surface of the piece product is coated with a special compound or a layer of protective varnish.

According to texture characteristics, it differs as follows:

- Matte. Characterized by a lack of shine and treatment with a protective agent over the entire surface;

- Glossy with an even shine and varnish finish;

- Ragged. Does not have a flat top;

- Raised. Can be supplemented with an imitation of a natural stone pattern;

- Convex/concave.

As for the size range, gypsum cladding for interior decoration has gradations like ordinary brick, and the size of a standard double brick. Another advantage of the cladding is the price - it is extremely affordable for the buyer and several times lower than a ceramic piece product. In addition, the material can be made by hand. To do this you will need:

- Gypsum dough;

- Forms for products (required size);

- Mold lubricant;

- Hardener for gypsum;

- Dye.

How to make a piece product:

- Prepare gypsum dough (it is sold dry, it must be diluted according to the instructions).

- Mix the mixture thoroughly.

- Add paint of the desired shade to the dough, stir again so that the dye dissolves evenly and there are no streaks left.

Advice! If, on the contrary, you need an interesting pattern, put the dough into the molds, pour in a little dye and knead with a long stick - this will provide an incredible pattern for each element and make the lining individual.

- Transfer the mixture into molds, let it stand for a while, about 18-20 hours until hardened.

- Using a soft hammer and tapping, remove the brick from the mold.

The cladding is ready and it is best to immediately coat the entire surface with varnish or a water protection agent. This way the bricks will last longer. Even with the most conservative estimates, the process of making bricks is much cheaper than buying a finished product. Another plus is that you can make unique collections, and the whole process will be extremely inexpensive and will not take much time.

Important! You can make gypsum decorative bricks for interior decoration with your own hands even without special purchased molds. The variability of formats will only add individuality to the cladding. An additional advantage is the ease of installation and dismantling of elements.

Ceramic decorative brick

This kind finishing material has been used in interiors for quite some time. Its properties are similar to ordinary ceramic tiles:

- Strength, reliability;

- Practicality, long service life;

- Resistance to moisture, pollution;

- Resistance to deformation due to temperature changes;

- Minimal exposure to significant mechanical loads;

- Frost resistance.

The naturalness of the material also has a huge advantage of brick over all other types of products. This finishing brick is indicated for use in sanitary areas with increased requirements for environmental cleanliness of the cladding. In terms of its textured qualities, ceramics have a lot of surface options:

- Matte;

- Glazed;

- Embossed;

- Convex/concave.

But torn ceramic bricks are not found.

Porcelain stoneware facing brick

The obvious and main advantage of the product is its highest strength. During the manufacturing process, the blanks are fired many times, which gives the structure of the material high strength and practical characteristics - porcelain stoneware brick is almost eternal, so a loft finished with such material is more likely to become morally obsolete than to deteriorate externally. The raw materials for the products are clay, granite chips and a natural binding solution, so the coating is not only beautiful and durable, but also clean, which allows it to be used in kitchens, bathrooms and other rooms where special environmental friendliness is required. Among other advantages, ceramic finishing bricks have the following advantages:

- Immune to moisture, temperature changes;

- Resistance to dirt – the cladding surface is easily cleaned from any dirt.

The variety of shapes and wide range of shades allows you to choose the design for any room in your house or apartment.

The most important qualities of a piece product are stability of shape and color over time, as well as a long service life - at least 40 years. Moreover, ceramics look great not only on wall panels, but also on the floor, as they are the most practical and durable cladding material.

Installation of decorative facing bricks

To decorate your home beautifully, you don’t have to spend a lot of time and money. A step-by-step work plan, photos, video materials will help you cope with the process yourself in the most short time, however, a lot depends on the design that the owner wants to reproduce. In any case, you need to start with preliminary cleaning of the surface where the cladding will be installed.

Advice! If the walls are not even, the problem can be solved using wall or ceiling type plasterboard, but the material should only be used for its intended purpose. GCRs are mounted on metal carcass in the form of a thin sheathing using self-tapping screws. After laying the sheets, putty the joints and sand them after drying.

But often plasterboard cladding is not the most the best option, for example, if the apartment is small, space is lost if the sheathing is installed. You can level the wall panel with plaster. The method is very labor-intensive and requires skill and patience. It also happens that despite the apparent evenness, the surface hides a lot of defects (for example, if the house is old). Tapping will allow you to check for hidden flaws: under impacts, the peeling or swollen plaster will crumble, all that remains is to repair these local holes.

Advice! Instead of regular plaster, local delaminations can be easily repaired with putty. The principle of applying layers is usual, but the drying process is much faster. After the mixture has dried, the areas are sanded.

After the wall leveling work is completed, the surface of the entire panel is primed, Special attention attention should be paid to the boundaries of applying new plaster or putty.

Important! If the wall has a layer of paint, it is difficult to glue decorative bricks; you will have to either remove the paint or make several shallow pinholes in the wall (with a hammer), where the mortar will go in and provide better adhesion between the brick and the wall.

The video shows an alternative option for creating imitation brickwork.

If the paint layer can still be removed, the entire surface is washed, dried very thoroughly and then primed.

Installation of decorative brick will require the following components:

- Adhesive composition or cement mortar. Moreover, the glue must be chosen depending on the type of cladding used: ceramics, gypsum or something else.

- Level.

- Beacons in the form of crosses.

- Tile cutter

- Ruler/tape measure.

Gluing begins by preparing a solution of cement (from M400), sand and water. If gluing will be carried out using an adhesive composition, then it is prepared strictly according to the instructions. The elements are cut to the required size using a tile cutter.

Now like this:

- The lower starting bar is determined.

- The first row of layout is carried out, which starts from the corner.

- Any laying technology can be chosen, but it is better that each upper brick covers two lower ones, that is, the middle of the upper element falls on the seam between the two lower ones.

- Apply glue or cement mixture onto the wall surface and back side material using a spatula.

- The uniformity of the distance is ensured by cross beacons.

- After the mixture has dried, the seams are treated with decorative putty.

Advice! To avoid treatment with decorative putty, you can immediately add a coloring pigment to the mixture. The good thing about this method is that many coloring compositions offered by manufacturers have various components that add plasticity, protection from moisture and increased adhesion properties to the mixture. Thanks to such additives, decorative bricks laid, for example, on the walls of a bathroom or kitchen, will “sit” especially well and resist moisture and other influences.

The general principle of decorating wall panels with facing material is reminiscent of laying out tiles. There is nothing complicated in the process; you can do it yourself. All that remains is to think over the decor, look at the photo, and choose best option for arranging your own home.

Important! When choosing a material, you need to pay attention not only to how much this or that type of cladding costs, but also the material of manufacture and how long the cladding will “stand” without the slightest loss of aesthetics and quality of the elements.