How to build a house is a very modern project. Cheap DIY house

IN Lately All less people wants to live in a cramped and stuffy city, preferring to move to his own Vacation home. It would seem, what problems? You just need to sell your apartment and buy real estate outside the city. But this property, alas, costs several times more than the largest apartment.

Interior walls with plasterboard system

The result is a floor that is beautiful, environmentally friendly, easy to maintain, and most importantly, durable. In the past, raising a new wall was a tedious job and not for everyone. In addition, it reduces work time and cost. It is a metal construction system of galvanized steel and plasterboard for interiors and fiber cement for wet areas such as bathrooms and kitchens. We can use plates with thicknesses ranging from 6 to 12 mm.

Very simple: we must draw a line on the ground and another on the roof, in the place where we put the steel rails, which must be secured with screws. We then place the other rails vertically and fix the gypsum boards to one side of the metal structure. Once this is done, we will fix the gypsum boards to the other side of the structure. Finally, we place drywall tape into the joints and then caulk.

Don’t despair, there is a way out - to build a house on your own. If you look at it, there is nothing complicated in building a house; the main thing is to draw up an action plan and strictly follow it.

Like copper, zinc is very durable material: In rural areas it can last up to a hundred years. Generally, zinc does not need any maintenance or treatment throughout its life, although good placement on the ceiling is important.

In addition, zinc is corrosion-resistant, extremely versatile and provides a pleasant appearance. All this makes it the material of choice for home construction projects. On the other hand, zinc is 100% recyclable, as more than 90% of the zinc used in the construction industry is recycled. Ideal for roofs, this material lends itself to traditional and modern designs, whether for new construction or remodeling.

Is a cheap house real?

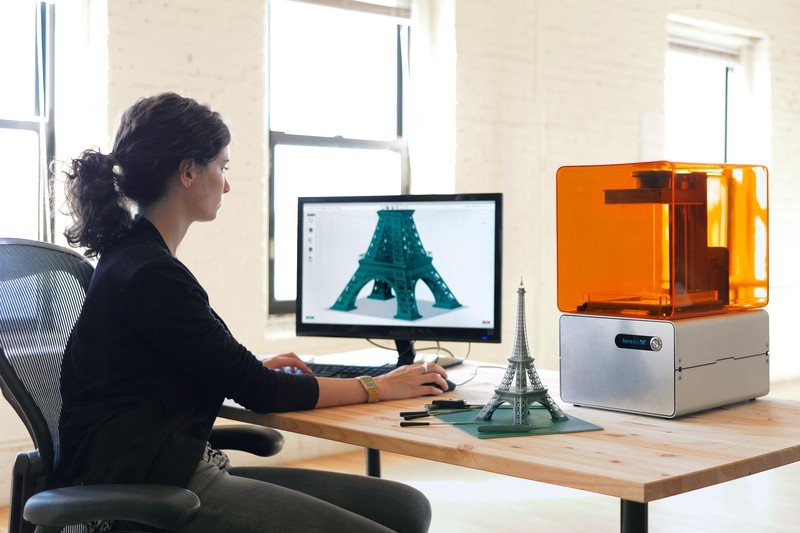

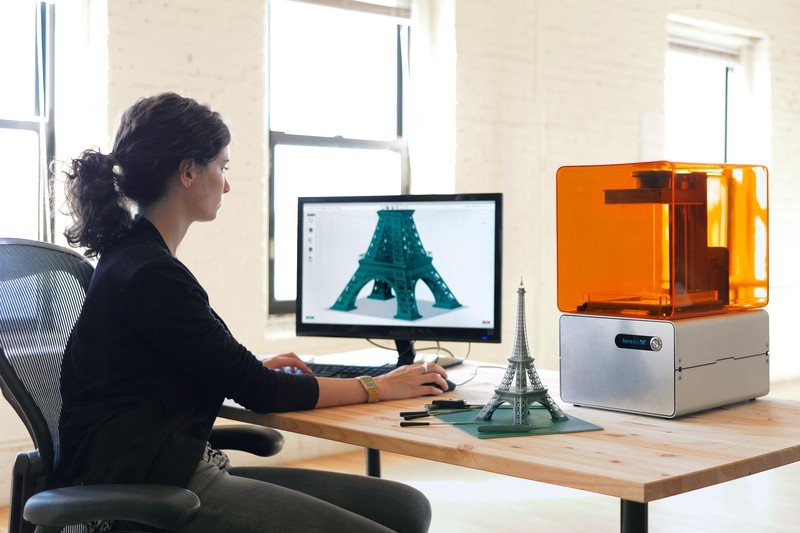

The problem of cheap housing is becoming more and more urgent. Many scientists have worked on it, and some have achieved some success. Among them, it is worth noting Berok Khoshnevis, a professor from the United States who developed a 3D printer. This device is capable of building a house with a total area of 300 m² in one day. Agree, not even the most experienced team is able to invest in such a time frame.

They are an excellent alternative to reduce time and cost and are very resistant to deformation. In turn, they act as acoustic insulation and prevent the penetration of cold and heat. In addition, they serve both indoors and outdoors.

Mainly for covering frames wooden houses, flooring, double T-beam fabrication, metal staircase cladding, cornice cladding, floor board fabrication, ceiling cladding, interior construction and specially treated wall and partition cladding.

But a 3D printer (in fact, as well as its operation) is very expensive, and not everyone can afford it. Therefore, during construction, it is more advisable to use a less expensive way to save money - use cheap building materials.

The steel structure is a key part of the rigid part of the structure. It is selected for its advantages in terms of operation, cost of materials, financing, etc. Metal structures are highly resistant to stress thanks to steel, and they are also cheap, to the point that they are almost equal to traditional materials. Of course: the cost of construction is something else. Use a screw more than nails. Finally, unlike wood, steel does not rot or warp, so the walls remain perfectly straight and there is no reason to replace the home's foundations at all.

Cheap house with your own hands: where to start?

Let's say right away that unauthorized construction must be legalized and you need to register it as property. To do this as quickly as possible, follow all state standards. First of all, draw up a competent plan of the site and your future home (it is better to entrust this matter to a qualified architect). In this regard, utilities are distributed, the method of pouring the foundation and building materials are selected. Having a plan in hand, you can easily implement the project inexpensive home in life.

This tells us how important the architect is in diagnosing and executing the design. As much as a physician is necessary to treat a disease, an architect is essential to carry out the work while the problem is revealed and the variables and conditions are absolutely clear.

This architect tells us, through personal example, the possibilities that can be acquired in the discipline, demystifying the role of the architect and, finally, referring to the fact that cheap always turns out to be expensive! Are you thinking about building a house? Would you like it to be good, beautiful and cheap? Take an architect, a good architect.

In addition, during preparatory work, determine the order of construction. It will look something like this:

- pouring the foundation;

- construction of a “box” of a house;

- carrying out all necessary communications;

- laying the floor;

- roof construction (preferably in autumn or spring).

By following simple technology, you can easily build a cozy, inexpensive home.

There are some stupid people who could make their own house without architects. They consider the architect to be the lesser evil. They are the same ones who self-medicate rather than see a doctor. There are few of them, deeply ignorant. They spend a lot of money at the pharmacy. And for the last time they go to the doctor.

The architect is the server of society. This is someone who seeks beauty through architecture and solves the problems of society and tries to make people happy for those who work. He asked me for a house with absolute privacy in a small pine forest surrounded by family houses in the province of Cadiz. You must listen carefully to the patient and do all the necessary tests. But the diagnosis is made by the doctor and the patient must obey. The solution was very simple: a 6x18 m rectangle raised with structural walls.

Stage one: foundation of the house

Step 1. First of all, decide what type of foundation is suitable for the soil in your area. Dig a meter-long hole; if the soil is sandy, clay or rocky, and there is no water at the bottom, then you can safely build strip foundation approximately 70-80 cm deep. But if there is still water, then the depth of the base should exceed 1 m.

There are two lower ones inside cross walls, 4 meters from the edges, to create a bedroom and bathroom on one side, and a kitchen and second bedroom on the other. To illuminate the 6 x 10 central space, 2 x 2 fixed glass openings at the four corners provide continuity of this central space with the two patios. To circulate and ventilate this central space, there are two opaque doors in the center, on the main axis. The two bedrooms and kitchen are illuminated and connected to their patios through transparent doors.

There is a skylight in the bathroom. All in just over 100 square meters. The own house follows the best traditions of the region in which the house is inserted, Andalusia: front courtyard entrance and rear patio. In each yard two lemon trees are planted symmetrically. There is a small pool in the backyard. The sound of water also contributes to the beauty of spaces. From the outside, the house appears to be completely closed only by the front door.

Step 2. Then remove the top layer of soil and mark the perimeter. Based on the markings, dig a trench of the required depth and fill the bottom with a sand cushion.

Everything was built with structural masonry, which is the cheapest and simplest for these dimensions. The entire floor is with a simple slab, well insulated and waterproof. The lid is made using a simple ceramic plate. Entire floor, interior and exterior, Capri Cordoba limestone, polished.

The walls are whitewashed, giving these spaces a wonderful luminosity. Even the bulbs are simple: white bulbs on the walls, protected on top by plain glass. The house was built in a reasonable time by Conegito, a caretaker, wise and kind, so little remains. As a guard, Diego Corrales, who did very well. Because a shipowner is also necessary, just as a doctor needs a nurse. Helped me too good friend from Chiclana Miguel Vela.

Step 3. Build formwork using boards or plywood. Then mix the foundation mortar using cement, crushed stone and coarse sand. In this case, the thicker the solution, the stronger the base (ideally, the consistency should be like thick sour cream). Make the width of the foundation 20 cm larger than the width of the walls. Be sure to reinforce it with metal reinforcement.

Architects always talk about loci of genius, about place. For this house seemed to have been there forever. The house was very interesting. What did you have in this house that no others had? Because in the understanding of the place, as in the materials and colors, and in the treatment of light, as in the typology, in the type of house, this is a traditional Andalusian house. The secret is that it was made by an architect who understands light, scale and proportion. An architect who knows that to achieve victories, beauty is necessary before utility and meet with firms.

This small house with an area of 100 square meters, which looks great. We were delighted: the owners, the builders and the architect. So enchanted was it that in a short time we built another house on the same line, Guerrero's house, for one of his brothers.

Step 4. Install a waterproofing layer - this will prevent the formation of cracks on the foundation and, therefore, increase its service life. Use roofing felt for this, laying it in two layers at ground level. After this, build the base to the required height.

Of course, most of the blame goes to the exceptional photographer who took the amazing photos. He set up the tripods and cameras and we just waited for the light. Slowly, very slowly, the clarker stood up and the photographer began pressing buttons. As a result, this set of beautiful images with mysterious light is almost impossible to explain, where he took the breath of this house well. Architect: Alberto Campo Baeza.

Photos of Gaspar House: Hisao Suzuki. Construction of a garage allows you to shelter your car or vehicles, have space to tinker and get extra room to store or store anything not used in everyday life.

Step 5. After the insulating layer, lay the foundation with concrete blocks or bricks. Make ventilation holes in two walls opposite each other to prevent increased humidity in the floor. Then give the structure a little time to dry and lay waterproofing (here you can use any available material).

But building a garage is not improvised and it is very important to plan for it on many levels. Is a building permit required? What type of garage? What is the cost of building a garage? Do you need a professional? What other costs should you consider?

Determine your needs before building a garage

We answer all of these questions in this comprehensive guide to building a garage. Determining its needs is the first step and it is very important to plan its surface area, the layout of its garage, but above all to predict the cost of building your garage.

Before you even think about getting a job, you need to think. Do you need electrical outlets, heating, ventilation, or a sink?

- Are you going to use the garage to park your car?

- Will it also provide storage space?

- Do you plan to tinker with it and build a bench?

- Are you planning to turn it into a living room in a few years?

Note! The final drying and shrinkage of the foundation will occur only a few months after construction, so do not rush to build the walls.

Stage two: walls

There are two ways to build walls.

- A more reliable and, accordingly, more expensive method is to build reinforced columns in the corners of the future house. Collect the reinforcement rods into a “bundle”, install them in the corners and fill them with concrete. In this case, you first need to build wooden formwork and only then start pouring.

- If you cannot use the first method for one reason or another, then when building walls, simply strengthen them with reinforcement.

For walls, use one of the following materials:

If the size of your garage and, more specifically, its area is more than 20 m2, you must apply for a permit by submitting a preliminary declaration of works to the urban planning department of your municipality. This threshold can be increased to 40 m2 if your garage is attached to the house.

The construction of your garage will in any case be subject to the regulations in force in your municipality. We advise you to ask your city council as soon as you have a project. For example, ask about the gap between your garage and house or your neighbor's fence or what you can or can't do if you're in a subdivision.

- foam concrete;

- brick;

- shell rock;

- adobe;

- clay and glass bottles.

The cheapest of them is foam concrete, but it will not allow the walls to “breathe”. Shell rock is more expensive, but it is what experts recommend when building inexpensive houses. In this case, window and door openings will need strengthening, so equip them with metal corners.

Build a cinder block or a prefab garage?

This step should not be taken lightly if you want to avoid any unpleasant surprises. When you have a valuable document, you can think about the work and of course start them. You have several options to make your garage. Often it is your wallet that will have the last word and your overall upgrade budget, but not only that. If you decide to make your own garage and you have never done any masonry in your life, then it is advisable to create a prefabricated wood garage. Otherwise, a cinder block garage may be considered.

The already finished “box” needs to be insulated. Use glass wool and brick for this. Lay the brick on the outside of the “box” so that there is a small gap between it and the shell rock. Fill this gap with glass wool - such material will not only insulate the house, but also protect it from the penetration of insects and rodents.

Making a Prefabricated Wooden Garage: Advantages and Disadvantages

IN last years Wooden garages are becoming more and more attractive, and many are choosing to choose this type of construction rather than undertake the more complex work of making a cinder block garage. Advantages of a wooden garage. . The main reason for the success of this type of garage is its aesthetic appearance. Wood is a noble, warm, beautiful material that adds value to a home.

Building a wooden garage is much easier, especially if you are not a great craftsman. To make your life easier there is wooden kits for the garage. All you need to do is follow the manufacturer's instructions. It may cost less than a rigid structure, but be careful, this is not always the case.

Note! Not all partitions can use drywall or brick. There should always be in the central part of the house load-bearing walls, built taking into account the underlying communications (that is, with places left for them).

For load-bearing partitions, use metal profiles - install them, cover them with plasterboard and plaster them.

Stage three: communications

Any house, even the cheapest one, needs water supply, heating and other communications. In this case, all communications must be carried out in advance by agreeing with specialists - this will guarantee the safety and correctness of installation.

Heating

Use a gas boiler as a heat generator. This will significantly reduce heating costs, especially in winter. And due to the fact that the cold comes mainly from the ground, give preference to “ warm floor“- make it from plastic pipes and fill it with concrete screed. This way you will heat the entire house, but if this does not seem enough, then install the main heating system.

Another heating option is alternative, based on the use of solar and wind energy. By building a solar battery with your own hands, you will not freeze in your home even in winter.

Water supply, sewer system

Lay both communications before finishing and pouring the floor. Decide in advance on the location of rooms and household appliances that need drainage, and lay the pipes in accordance with the plan.

If central sewerage and water supply are not available, you should think about building a small septic tank, for example, from Eurocubes or concrete rings, as well as water supply. You can build a well or drill a well as a source of water. However, the second option will hit your pocket hard.

Stage four: floor

Upon completion of installation of communications, fill the floor with concrete screed. Then cover with any suitable material - linoleum, tiles, laminate, etc. However, it is recommended to use tiles as the most practical and damage-resistant material. It is easy to clean, and when using “warm floors” it will never be cold. Moreover, you can choose the cheapest tiles and cover them with cozy paths.

Stage five: roof and ceiling

At this stage of work, build a concrete belt around the walls to secure the beams. Then, after laying the beams, fill the bottom with boards. During construction two-story house It is better to use concrete slabs for flooring.

For the roof, first assemble the facing grid - this is necessary in any case, regardless of what you choose roofing material. The lattices can differ only in the different spacing of the beams. It is recommended to use one of the following materials (due to financial considerations):

- ondulin;

- metal tiles;

- corrugated sheeting;

- slate.

Eco-friendly materials include wood, straw, and reeds.

Whatever material you choose, the roof must be insulated. Use glass wool for this - this is the most affordable and easiest to install material.

![]()

![]()

Completion of construction. Interior arrangement

Construction of the roof is the last stage of building a house. Next you can start interior decoration. There are a lot of technologies and methods for interior arrangement; almost all existing design projects can be implemented with your own hands at low cost.

In a word, everything depends only on the richness of your imagination. Stretch ceilings can be an excellent option - having a relatively low cost, they visually expand the free space with their glossy finish. They perfectly reflect light, creating an extraordinary effect.

Arches and openings also look good in the interior (they can be easily assembled from plasterboard and metal profiles, or use wood and clay). Cover the walls with textured wallpaper (painted wallpaper, as they are also called), which you can make yourself. Various plasters are quite cheap. Decorating a house with wood looks great.

If you approach the matter competently and with soul, then building and arranging your own family nest will not cost much. The main thing is to clearly know what you can save on and what it is better not to do.

What you can't save on

- Don't skimp on technical supervision. Read at least a thousand articles on construction, but without experience you will still not be able to control the quality and understand the essence of construction work. Engage an engineer or an experienced builder - in general, someone you trust.

- Don't skimp on communications. Heating, water supply, access to the yard, etc. are necessary elements of a comfortable life. Don't neglect any of the systems!

- Do not skimp on the project - it must be drawn up by a specialist, taking into account the climatic conditions of your area. Be sure to tie the project to specific construction conditions. Thus, it often happens that the developer did not want to pay the designers for tying the foundation, having listened to the advice of the contractor (who the more expensive, the better), as a result of which the foundation was created with too large a margin of safety. Binding will minimize the cost of building the foundation of the house.

We also note that construction and design should be carried out by different people with different opinions and interests. This will allow you to make the right decision and avoid unnecessary expenses.

Video - How to build a house inexpensively

Having your own home is the dream of many, seemingly unattainable, since the cost of building a house costs a pretty penny. But modern building materials and construction technologies debunk this myth. As the practice of numerous new buildings shows, you can build a house on a budget, durable and reliable. The cheapest houses have their own characteristics and characteristics.

Signs of a Cheap Home

Compliance with certain conditions allows you to reduce the cost of the entire construction by up to 30%.

Features of budget houses:

- convenient, compact, modern, functional layout (up to 95% of usable area) – the possibility of saving up to 20%;

- high-tech construction works and modern building materials – up to 40%;

- simple and functional external and internal decoration, no frills - up to 10%;

- gable or five-slope roof;

- one floor;

- small area and the possibility of transformation (add rooms);

- no basement;

- slightly buried foundation (usually lightweight if climatic conditions permit);

- simple finishing both inside and outside (facade – cement-lime plaster).

Regarding the decoration, there are numerous non-standard windows, a complex multi-slope roof, many partitions, floors, external decorative elements in the design, etc. all this significantly increases the cost of construction and finishing works, thereby increasing the estimate and introducing unnecessary expenses.

Building a house and saving

The cheapest houses can only be built by yourself, using your own strength, attracting specialists only for specific work, which, due to low qualifications, is difficult or impossible to do on your own. But up to 90% of all the work can be done yourself.

The main condition for maintaining any budget is strict control. Control over prices for construction materials and their purchase, over the work carried out by a hired team, quality control of construction materials, work performed, and so on.

Where you can save money and where you can’t

Build a house yourself cheaply, how you can save:

1. Savings by choosing a simple, functional, standard residential building project that will take into account wishes and climatic conditions (making changes, replacing certain building materials for more budget analogues, the project should be finalized for specific conditions by specialists). The house must also be economical in further operation: the costs of heating, maintaining and maintaining it must be acceptable.

2. Simple Decoration Materials, simple plumbing, etc.

4. Hiring a crew. If it is not possible to do the construction yourself, or to carry out certain work, then they hire a team. To save money, time and nerves, you need to choose carefully by talking with recent employers, reading reviews, etc. It is also necessary to conclude an agreement. It spells out all the nuances of the work: deadlines, the final result of the work performed (quality, size and volume of work), the cost of the work, penalties for violation of deadlines, the responsibilities of the parties (providing accommodation for the team, tools, materials, electricity, etc.), parameters for monitoring hidden work, its quality, fines, etc. if the conditions stated in the contract are not fulfilled. If at any stage of construction the contract was violated by the team, then it is better to break the contract with them and hire a new one or finish it yourself (completely redoing the work will be much more expensive).

5. Foundation. You can save on the type of foundation: for small houses(up to 40 m²) can be used pile foundation(the most economical, but also not so reliable), for larger houses and with heavy walls, a strip one is used, which creates sufficient support for the walls (it is the most expensive). A way out of the situation can be a strip foundation on piles, which will be more budget-friendly and will retain all the advantages of both components.

Carrying out preparatory work for pouring/installing the foundation, done on your own, also reduces construction costs: digging trenches/pits, installing formwork (if poured), pits for piles, etc.

And yet, you need to correctly calculate the width of the foundation strip and the required number of piles to support the entire structure plus a small margin (an overly weighted foundation takes additional money and time that could not be spent on it).

6. Walls. The frame of the house can be made from cheaper materials: timber/logs, foam blocks, frames. The latter option is more budget-friendly, but compared to the above, it is not the most durable (although, with proper assembly, it can last for decades). Frame houses(or Canadian type) have become popular recently due to the low cost and speed of their construction. Since the climatic conditions in Canada and Russia are largely similar, the cheapest houses do not need any special modifications. The material for the walls largely depends on weather conditions(the severity of the house), therefore, first of all, attention is paid to the thermal conductivity and reliability of the house being built.

7. Roof. We will talk about roofing material. Most a budget option– bitumen tiles, corrugated steel, metal tiles. It is possible to use other materials at your discretion or due to climatic conditions, etc. Enough has been written on the Internet about the advantages and disadvantages of each type of material, so we won’t dwell on it.

No savings:

1. Quality of materials – the quality of the housing being built will directly depend on their quality.

2. Registration of documents and construction permits. It is better to complete all the paperwork BEFORE the start of construction, so that you do not have to legalize self-development later in court. Completed documents will facilitate faster installation and connection of communications to the site.

3. The foundation, namely the quality of it and the work performed to fill it.

4. Roof. The reliable roof frame is made of wood (beams), something better and more reliable has not yet been invented. These expenses are completely worth it.

5. Communications. When establishing communications, it is better to immediately use modern systems inlets/outlets (plastic pipes, high-quality electrical cables, professional connection, etc.).

6. Technical supervision of the project (invited engineer or experienced, trusted builder). If the work is performed by a team or an inexperienced builder (themselves), then technical supervision is necessary. Because theory without practice is not yet an experienced builder. A specialist’s view will help to avoid mistakes, defects and oversights in the work, and will also greatly simplify communication with contractors.

Economical houses are not a dream, but a reality. The cheapest houses can be built by yourself, but where and how quickly depends only on opportunity and skill.

Share material with your friends on in social networks. We will be very grateful to you.