How to calculate the cost of building a house from foam concrete blocks?

Foam concrete is aerated concrete with a porous structure. It is thanks to the cells that the blocks are lightweight and have good thermal insulation characteristics. Do-it-yourself turnkey construction of a house from foam blocks is much faster than when using bricks. The main thing is to accurately calculate the required number of blocks of foam concrete and other materials. You can carry out all the calculations either yourself, or contact the company, where a detailed estimate will be drawn up.

To determine the amount of foam concrete, you need to know the height, width, length of the outer and inner walls of the house and the parameters of the block. First, you should calculate the number of foam concrete for the load-bearing walls, and then for the partitions inside the building. Suppose, for example, it is planned to build a house from foam blocks with the following dimensions:

- wall height - 3 m;

- length - 10 m (square).

First, you need to calculate the number of foam concrete blocks for one row of 4 walls. To do this, add up the lengths of the outer walls - 10 + 10 + 10 + 10 = 40 m. To calculate the number of foam blocks, the resulting number is divided by the length of one. So, for example, if foam concrete blocks measuring 20x30x60 cm (height / width / length) are used, then the third number is used for the calculation - 60 cm (0.6 m). As a result, it turns out - 40 / 0.6 = 66.6 pieces, that is, 67. So many pieces are needed to build one row around the entire perimeter of the house.

Now the number of rows is determined. For this, the height of the walls is divided by the height of the foam concrete blocks - 3 / 0.2 = 15. 15 rows of foam blocks will be needed to build a house with walls 3 m high. After that, the total number of foam concrete is calculated. To do this, the number of rows (15) is multiplied by the number of blocks for one row - 15x67 = 1005. So many pieces are needed to build a house with dimensions of 3x10x10 m.

Since door and window openings will be arranged in the walls of the house, the number of foam blocks decreases. But given that foam concrete has low strength characteristics, part of the material may be damaged or split during loading, transportation and unloading. Therefore, it is better not to subtract this amount from the total so that there is a stock.

What does the construction cost depend on?

How much does it cost to build a turnkey house from foam blocks? This is influenced by the following factors:

- From the size of the building, area m2.

- The number of floors, the presence of a basement.

- Location, distance from the city.

The average price for building a house from blocks is from 14,000 rubles per m2. If you carry out the work yourself, then the cost will be lower, since you do not have to pay for the labor of builders. But you should do everything with your own hands only if you have some experience in this area.

The price of blocks is influenced by their size. The more parameters, the higher the cost. So, for example, a foam block 20x30x60 cm costs 94 rubles, and 20x40x60 has a price of 127 for 1 piece. Also, prices vary depending on the density and frost resistance.

If you contact the company, they will help you calculate the cost of building a house from foam concrete. Moreover, in some organizations, estimates are made free of charge. It will include all the costs of building materials for the foundation of the house, walls, ceilings, as well as all other types of work. Having in hand a detailed document with all prices, you can adjust costs so as not to overpay.

The cost of a house for permanent residence depends on its architectural plan, size, number of floors, the presence of a basement, facing material, and so on.

Features of construction from foam blocks

A foam concrete house should be insulated from the outside, not from the inside. If you carry out insulation inside, then the dew point will change. Due to the appearance of condensation, foam concrete walls will collapse faster. For insulation, it is best to use mineral wool thermal insulation, since they perfectly pass moisture through themselves, especially since the price per square meter is quite low.

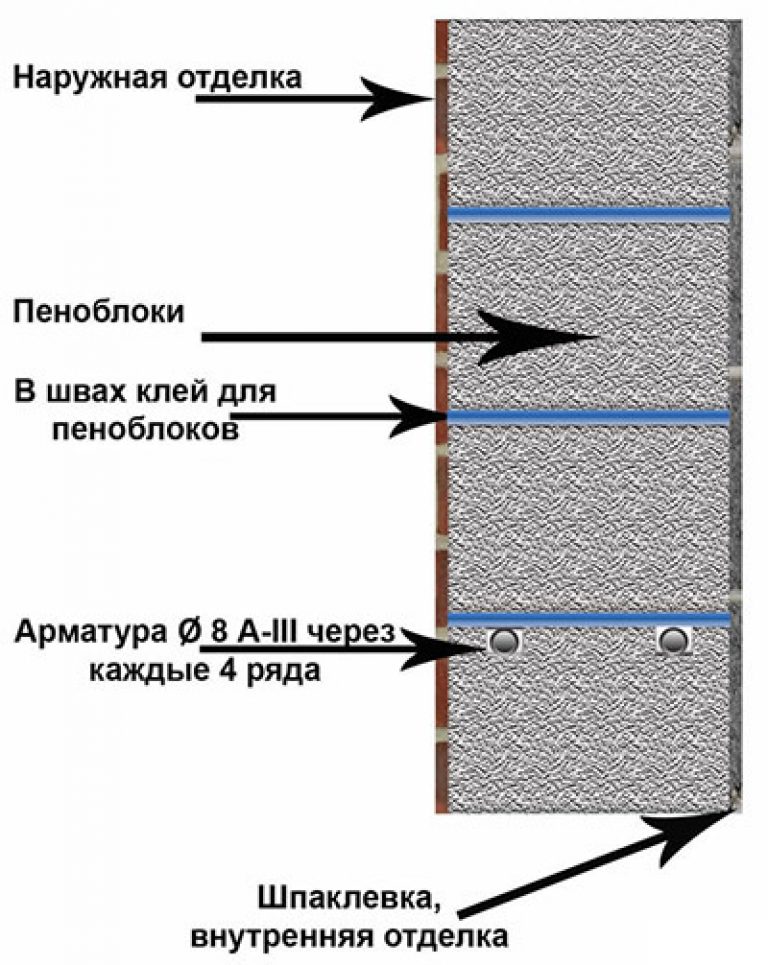

A waterproofing material must be laid between the base of the building and the first row of foam concrete. Thanks to him, the foundation will be reliably protected from moisture that appears due to precipitation and a rise in the groundwater level.

For 1 day of work, it is recommended to lay no more than 5 rows so that the masonry can grab and not move during further construction. Every 2 rows, it is necessary to lay down a reinforced mesh to increase the strength of the entire structure. For laying foam blocks, it is better to use not an ordinary cement-sand composition, but a special adhesive mixture. Dilute it only according to the manufacturer's instructions. Its price is higher than that of the mortar, but the seams are much thinner and more beautiful, and the masonry is also faster.

What to look for when choosing foam blocks?

It is best to purchase foam concrete blocks in one batch at once according to previously made calculations. Before buying cheap foam concrete, you should pay attention to its quality. All sides should be smooth and even, without chips or depressions. To check this, you need to put 2 foam blocks on top of each other. They should fit snugly, without gaps, then a minimum amount of adhesive solution is required for their laying. Their sizes are also checked. All foam blocks must be the same, then the laying will be even.

If small cracks are visible in the foam concrete, then, most likely, the production technology has been violated. Such blocks can be inexpensive, but such material is not recommended for use at home. They will collapse under the weight, and the other part will completely crumble during transportation.

You also need to pay attention to the color of the foam blocks. They should be light or dark gray. For the construction of an economy-class house from foam blocks, material with a density of 700-1000 kg / m3 is required. Cells in good quality aerated concrete should be rounded and not oval. When the foam blocks rub against each other, crumb should not crumble from them. If so, then the solution for their manufacture was not prepared correctly.

Before you start building a house from turnkey foam blocks, you should study their characteristics and operating requirements. They have a low bending index, as a result, due to the heaving of the soil in winter, cracks appear in the blocks. Therefore, you first need to build a monolithic foundation or strip base, buried below the freezing level. It is also necessary to make a blind area with insulation.

It is cheapest to build a country house from a foam block, since you can buy it cheaply and carry out all the work and calculations yourself. Or contact a company engaged in the construction of turnkey houses. They will build a house in the shortest possible time and in accordance with all established standards. To keep costs down, you can deliver all the building materials yourself.