Do-it-yourself phased frame construction: how difficult is it?

Despite the development of the modern construction market, offering the services of both large and small developers, there are always those who prefer not to blindly trust, though experienced, but completely strangers, but to carry out frame construction with their own hands. Moreover, independent construction will reduce a third of costs, which is important in the context of today's inflation and the global crisis. Anyone with an average income can build their own house.

DIY frame house is the best choice

What you need to know about wireframes

What is a frame building? This is a type of building based on a frame. What is it made of? It can be made either from wood (boards, beams, laminated veneer lumber) or from metal. The frame is the basis for future walls, floors and roofs. In accordance with, the frame is protected from moisture, and sheathed with OSB plates, making it almost hermetic. The result is a multi-layer wall that has high thermal insulation values and a small width. You can build a frame in a week with a couple of assistants. Drawings can either be ordered from engineers or made by yourself.

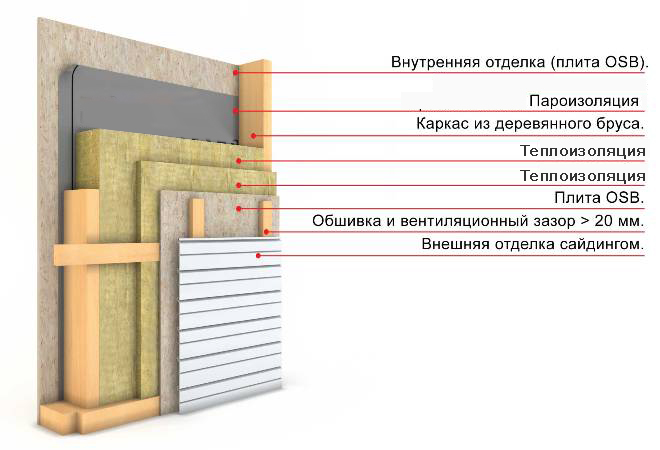

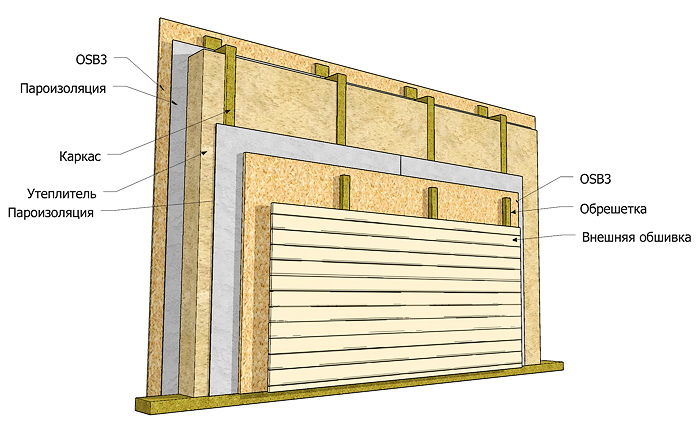

Basic wall layers:

- interior finishing done at the end

- OSB-3 plate

- vapor barrier membrane - it is used for flooring from the side of the house

- waterproofing, which is most often mineral wool

- external insulation can be made in the form of foam - optional layer

- OSB slabs make the wall cake complete

The outer layer of additional insulation with foam is not required, but it is better to insulate the leeward side. With the help of foam sheets, additional wind protection is created. If you do not want to insulate the entire wall, lay at least a basement with foam plastic - the coldest place in the house. You will move the dew point and protect your walls from condensation and mildew.

The roof of a frame house can be made in various ways. It can be single-slope, gable, almost straight or sharp, in addition, the design of the rafter system may differ due to the size of the house. It is difficult to build it alone, but 2-3 people can easily cope. It is made from a bar or board.

The foundation can also be made and chosen at your discretion. You will find a description of all suitable types of foundations for a frame house, but most often the choice is still on houses with a pile foundation and. Read about the construction of a frame house on a pile foundation.

Why build with your own hands

The main advantages of a home built with your own hands are:

- Savings, since you do not have to pay for the work that you can do yourself: assembly of the frame, installation of the rafter system, external and internal decoration, etc.

- Confidence in the quality of materials. Without which there will be no good home? No quality materials - especially boards or beams. If you are building a house with your own hands, you know for sure that your materials are of high quality. After all, you will not buy cheap Chinese materials for yourself that are unsafe and do not have certificates?

- The quality of work. You have nowhere to rush, so you will work conscientiously. There are no other orders waiting for you, for which you will receive money, so you do not seek to complete the construction, ignoring the stages of frame construction.

Making a quality wireframe is your goal.

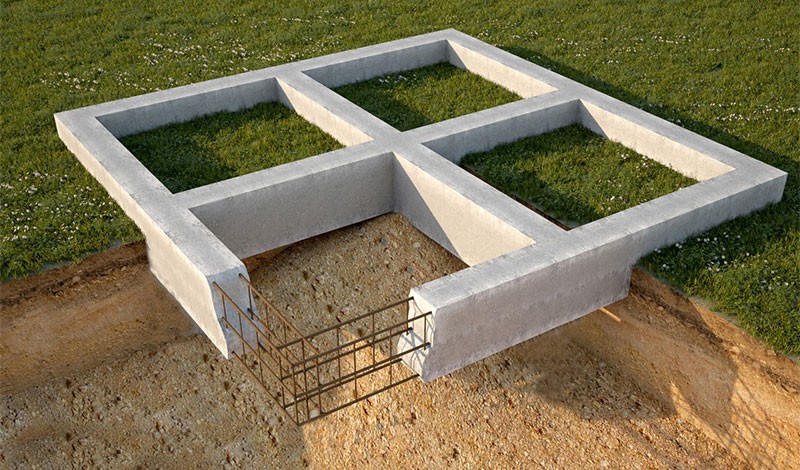

Foundation yourself

If you have in your hands a plan of the future house and all the drawings, it is time to build the foundation. First of all, you need to decide which foundation is right for you. To do this, you need to analyze your land. You can do it yourself - by digging a hole about one and a half meters and looking at the soil in section. Ideal if your soil is sandy or ASG-like. Such soil itself acts as a drainage, diverting water to the side, which minimizes the likelihood of shrinkage.

If the soil is mostly clayey, the foundation will suffer from seasonal fluctuations and soil movements. The water that the clay absorbs expands when it freezes, and the soil and foundation rise. This mobility causes deformations, and we see cracks in the walls and decoration. We'll have to do extra drainage with a sand cushion.

Strip foundation - a reliable foundation for the house

If the soils are sandy, you can put the simplest unburied foundation - for example, columnar. The worse the soil, the more reliable the foundation should be, therefore, for clay soils, it is better to choose a strip one. The screw pile is universal, it can be used on any soil.

If you have opted for a strip foundation, which is chosen by most independent builders, do not forget to sink reinforcement or mesh in it for reliability and anchor bolts to which the harness will be attached during its construction. You should make a cement foundation during the warm season. Formwork for the foundation is most often made independently from a board.

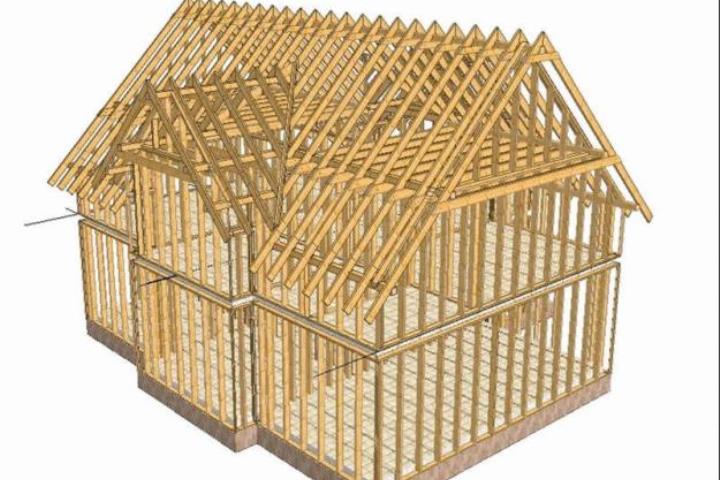

Frame yourself

When the foundation is finished, we proceed to the strapping. For this, beams or boards are used. The most important thing in strapping is the corner joints. They can be of several types, but the most common ones are with the formation of grooves. The stability of the frame and the uniformity of pressure distribution on the foundation depend on the reliability of fastening the piping. If boards are used in the harness, they are connected in three.

Read about how to properly strap a frame house.

The frame should be assembled from corner posts. They are a wooden beam connected to a harness. You can make a frame from a board, but this is undesirable. The racks must be reinforced with struts. It is not necessary to reinforce the rest of the vertical beam with struts, since the horizontal lintels give the struts stiffness.

The racks are installed at a distance of about one meter from each other. We make a wider distance only in the area of door and window openings, strengthening the frame with crossbars. The crossbar also allows the load to be distributed more evenly on the foundation. You will find details on assembling a frame house.

What kind of timber to take for the frame? It should be a bar made of quality wood. It is advisable to use glued laminated timber, but in our reality, when frame houses are chosen by the middle class, they often use technical drying or natural moisture timber. Pay attention to the type of wood from which you will assemble the frame. It is best to use softwood, oak or ash. Coniferous varieties, thanks to natural resins, additionally protect the wood from insects and pests, besides, in such a house there will be a fresh coniferous smell for a long time.

Examine the timber or boards externally: it should not have dark spots, mold, it should be even. The quality of the frame installation largely depends on the evenness of the timber, but most often it comes across slightly twisted - with natural drying, any tree is twisted.

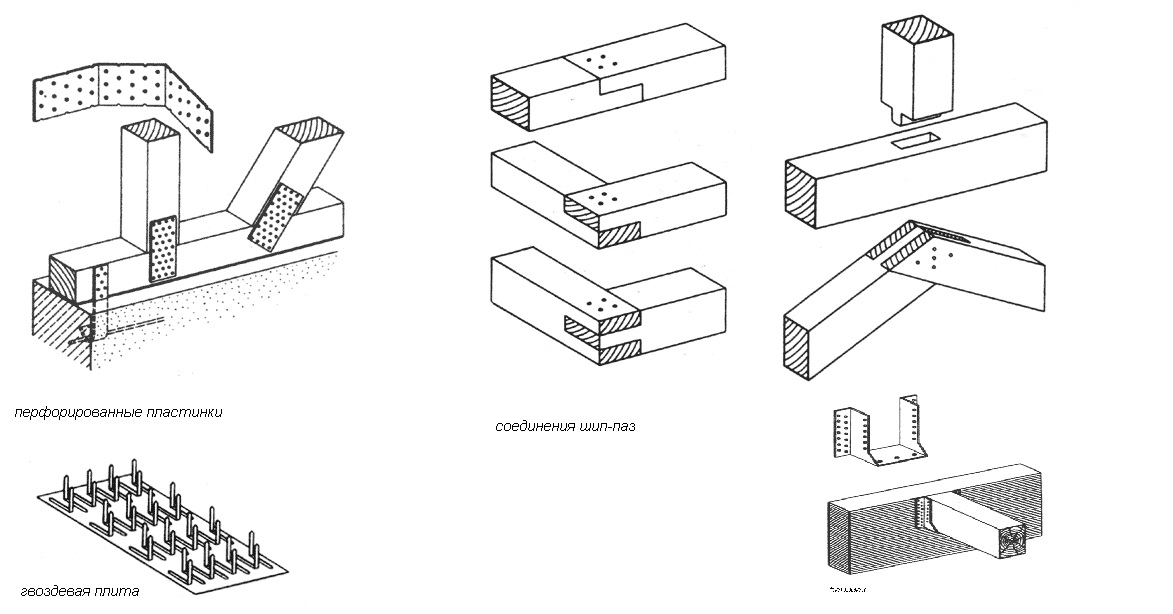

The frame is fastened with self-tapping screws, nails and metal corners. The use of metal corners is preferable, but they must be lubricated with a septic tank or any lubricant before use. When oxidized, the metal causes damage to the wood.

Choosing a roof for your home

Most often, those who decide to start building with their own hands make an ordinary gable roof. This option is relatively easy to implement, while the attic space can be made heated and residential, or left as an attic.

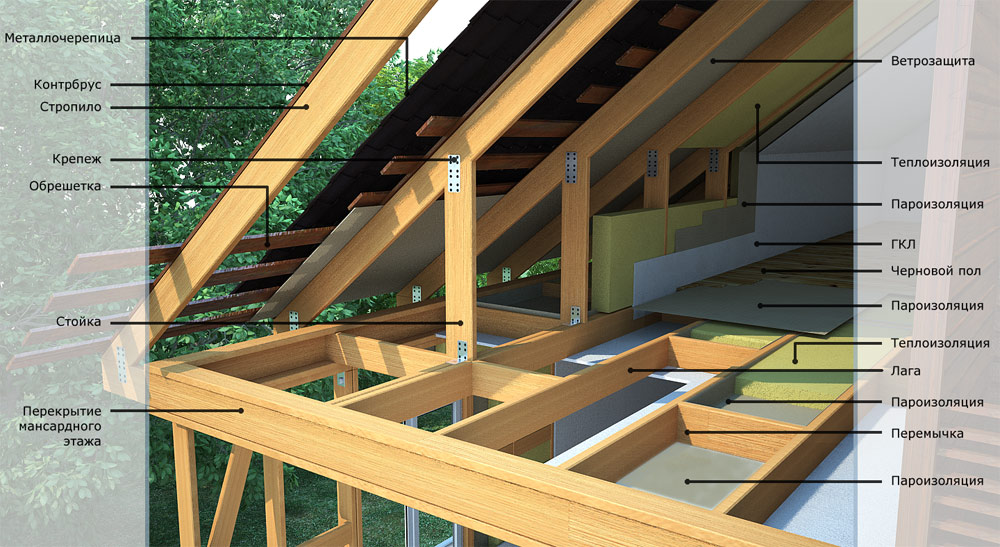

Roofing in a frame house - the main elements

Installing it is as follows:

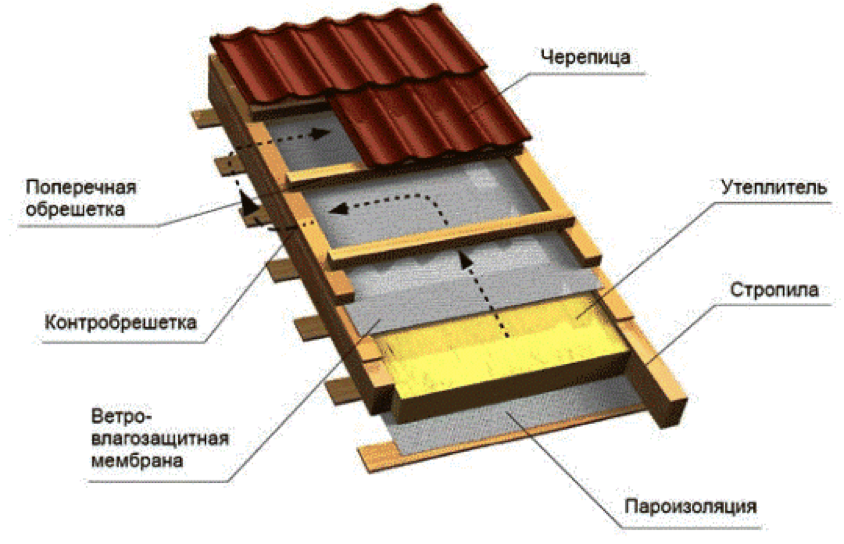

- Rafters are mounted, which are fixed with roofing nails, self-tapping screws, metal plates and corners. The rafters are placed from a board or timber.

- In order to calculate the step, it is necessary to proceed from the size of the rack, most often it ranges from forty to 100 cm.

- The size of the spans ranges from two and a half meters to 5 m, the exact figure depends on the section of the wooden beams.

- The support for each rafter is made by a Mauerlat, whose cross-section is 10 cm. The Mauerlat must be fixed rather rigidly, since this is the main support on which pressure comes from the entire roof.

The method of attaching the Mauerlat can be different, like.

To connect all the rafter legs, you must use the toothed board pads.

Important: if the spans are more than five meters in size, it is extremely important to install supports under the rafters.

To decide on the option of the lathing, it is necessary to take into account what kind of roofing will be used, that is, what kind of material will be laid.

Some materials require continuous sheathing, such as shingles. For it, OSB sheets are used. If you decide to stop at a metal profile, you can use a crate with a 50 * 50 mm bar. The timber is spread in steps of about 50 cm.

Any construction is completed and.