Floor options on the ground on a strip foundation

There are several technologies for flooring on the ground, depending on the operating conditions, the preferences of the owner. The floor covering can be laid on a wooden base or on a concrete screed, slab. In the latter case, the slab is either attached to the strip foundation, or a floating screed (self-leveling, dry) is used.

To save the construction budget, the basement of the building is most often covered with floor slabs, which automatically become the base of the floor. The monolithic structure is located above the soil that does not freeze in the most severe frosts, saturated with groundwater and radon radiation. Without high-quality natural ventilation, the concrete slab begins to collapse, the health of residents deteriorates with an enlarged radio telephone.

Therefore, ventilation holes are created in the strip foundation or plinth, which cannot be closed even in winter. In projects of cottages with a low basement there is not enough space for natural ventilation, the holes are covered with snow in winter. In this case, the only way to build a floor is ground technology.

Communications are traditionally connected through the lower level, therefore, to ensure maximum maintainability, it is wiser to lay duplicate sleeves, to conduct additional water supply systems, gas pipelines, sewerage systems in them. In case of clogging of the main pipelines during the operation of the house, in this case it is not necessary to open the slab / screed, it is enough to shift the risers into the backup life support systems.

What the developer needs to know about the construction of the floor on the ground

This technology has a high operational resource only if the requirements of the joint venture standards of 2011 with the number (previously SNiP 2.03.13-88) are met. To understand the construction of the "pie" of the floor on the ground of the first floor of the building, it is necessary to consider the Factors acting on the poured slab:

- The heaving forces that are commonly used to frighten individual developers do not appear under most buildings. Cottages based on slabs, tape bases, grillages, resting on the ground or buried in it, give off some heat to the lower level. With normal insulation of foundations (pasting the outer walls of the base with extruded polystyrene foam), the geothermal heat of the bowels is always preserved under the sole of the house.

- In any project, there must be drainage and / or storm water drainage, which drain flood, ground, and melt water from the load-bearing structures of the cottage. Therefore, the high humidity of the ground under the house is most often an aggressive advertisement, urging the developer to increase the construction budget to combat a non-existent danger. In fairness, it is worth noting that in the absence of stormwater and / or drainage systems, the soil under the building will indeed be constantly wet.

- Even in the absence of heaving forces, the ground under the house will sag in 90% of cases during operation. The sub-floor slab, tied to the strip foundation, will be hanging on it, which is not particularly scary with normal reinforcement. In this case, the floating screed will drop lower together with the floor, which will require dismantling and re-manufacturing of the slab. Therefore, backfilling is used not with soil extracted at the stage of the excavation, but with non-metallic materials with obligatory layer-by-layer compaction with a vibrating plate or manual ramming of every 20 cm of sand, crushed stone.

- The geotextile layer recommended by many companies under the backfill cushion in this case is not only unnecessary, but also harmful. The soil will not be compacted, the efficiency of the screed / slab will be reduced to zero. Non-woven material is used only in the manufacture of pillows before laying external engineering systems (sewerage, water supply), paving parking lots with paving stones, sidewalk paths. In this case, the filtering and drainage properties of geotextiles are relevant.

Thus, when choosing a technology for flooring on the ground, especially on a strip foundation, it is necessary to correctly position each layer of the "pie". This will provide the maximum resource, ease of use, high maintainability of the structure.

What layers are needed and their relative position

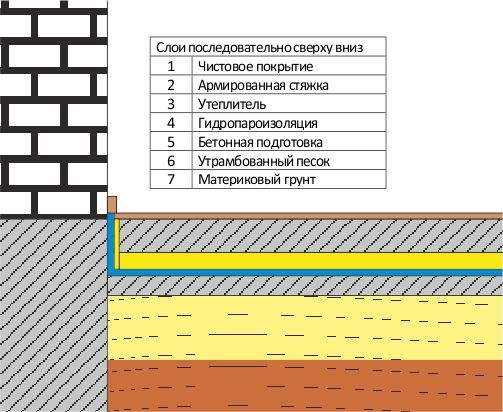

With a limited construction budget for a self-leveling screed / slab for a floor on the ground, the minimum required layers are (from top to bottom):

- reinforced reinforced concrete screed - most floor coverings can be laid on it (linoleum, laminate, carpet, porcelain stoneware, floorboard, cork, tile) or underlay for parquet (multilayer plywood);

- insulation - reduces heat loss and operating budget (fewer heating registers can be used);

- waterproofing - does not allow moisture to penetrate into the heat insulator from the ground;

- sub-base (concrete preparation) - films, roll materials, membranes are often used as waterproofing, which are easily damaged when reinforcing, pouring the top screed, with builders' shoes when laying a heat insulator, therefore, a slab (4-7 cm) of low-strength concrete is poured;

- pillow - with vibration compaction of nonmetallic material, stability of the geometry of the lower layer is achieved, on which the floating screed will rest.

A plastic wrap between the screed and insulation is optional.

According to the standards of the joint venture for residential buildings, a 60 cm pillow is enough (3 layers of 20 cm each). Therefore, with a significant depth of the pit, which is made for a strip foundation, it is more expedient to fill it with the same soil up to the design level, also with layer-by-layer compaction.

A building on a slab foundation has a floor-on-ground structure by default. Therefore, before pouring the slab, it is enough to perform the following measures:

- to provide duplication of engineering systems - additional sleeves with a piece of sewer + water pipe;

- make a pillow - excavation of 80 cm of soil with 60 cm of backfill;

- perform waterproofing - film or roofing material;

- lay a heat insulator - usually 5-10 cm of expanded polystyrene, which retains its properties even when wet, immersed in water.

It is possible to plan a construction budget for a cottage only at the stage of project preparation. Therefore, the floor on the ground must be laid in the documentation at the initial stage.

Ground floor construction technologies

If, for the above reasons, there is no floor slab in the project, which is necessary for fixing the floor cladding of the first floor, several options for arranging the sub-base are possible. At the same time, pouring a screed from low-strength concrete is recommended in all cases, without exception. The main plate or adjustable joists, necessary when choosing parquet or floorboard, will subsequently rest on it.

Self-leveling screed

Scheme of a concrete floating floor on the ground

The maximum resource of the structure is provided by a self-leveling floating screed on the strip foundation of the building. The technology looks like this:

- filling the pit with sand - periodic filling with compaction every 10 - 20 cm;

- rough screed - reinforcement is not necessary, under the concrete of the M100 brand (5-7 cm layer, 5/10 mm fraction filler), you can lay a film waterproofing;

- hydro-vapor barrier - membrane, film or roofing material in two layers with launch on a monolithic strip foundation by 15 - 20 cm;

- insulation - preferably extruded polystyrene foam, which retains its characteristics even in water;

- finishing screed - reinforced with a mesh (cell 5 x 5 cm, wire 4 mm), poured with concrete M 150 (crushed stone fraction 5/10 mm, river sand or washed quarry sand, without clay).

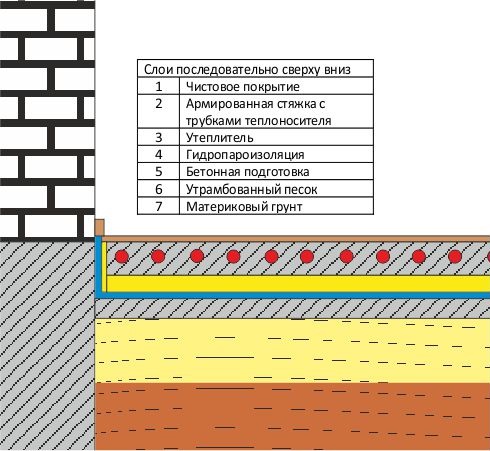

Also, in the construction of the self-leveling floor, you can easily arrange a warm floor, for this you need to lay polyethylene or metal-plastic pipes for the coolant in the upper screed. Each contour of the warm floor must be continuous, i.e. pipe connections in a concrete screed are not permitted.

Scheme of a concrete floating floor heating on the ground

When the ground level is below 2 m, according to the operating experience of the site from 3 years, in the floor structure on the ground, the absence of lower waterproofing is allowed, the thickness of the sand cushion is reduced to 15 - 20 cm.In this case, the maximum level of ground water should be taken into account, according to statistical data for the region ... Any facing materials can be placed on the screed.

Wooden logs

A budget option for ground floor technology is the construction of an adjustable floor:

- a concrete screed is poured onto a pillow made of nonmetallic material (layer-by-layer compaction of 20 cm), covered with waterproofing;

- logs are exposed on adjustable supports, the upper part of which is cut off after installation;

- a heat insulator is laid inside (basalt wool or extruded polystyrene foam);

- the floorboard or laminate is laid directly on the joists; a layer of plywood is required for facing with parquet.

Supports must not be mounted on ground or non-metallic material. However, a concrete screed without reinforcement is cheaper than any other technology.

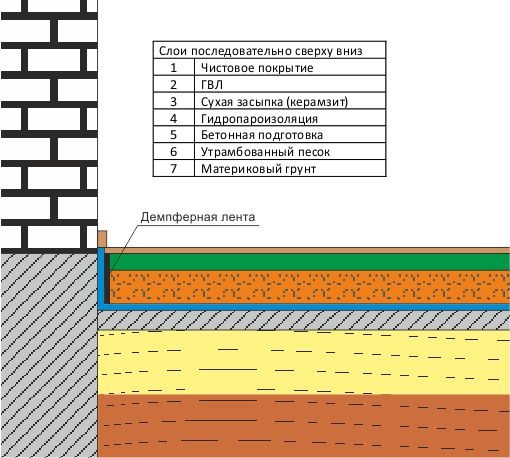

Dry screed

The floor on the ground can be made using the dry screed technology. At the initial stage, the design is similar to the previous case (pillow + rough screed + waterproofing). After that, the sequence of actions changes. The manufacturer Knauf offers a ready-made solution for a dry screed of the following type:

- positioning beacons - special strips or profile from gypsum plasterboard systems, fixed with putty solution;

- backfilling of expanded clay crumbs - the gaps between the beacons are covered with this material along the waterproofing layer;

- laying GVL - special two-layer plates attached to each other with glue and self-tapping screws.

Scheme of a dry floor on the ground using Knauf technology

The ZIPS company offers an original solution for a dry screed on a strip foundation of a different type. Expanded clay chips are here replaced by mineral wool glued to the gypsum fiber board (also two-layer). After installing the gypsum fiber panels, 12 mm plywood is laid on top of them, on which it is also convenient to attach any floor covering.

These technologies are successfully applied both for the first floor and for any next floor in a multi-storey building. In both cases, in addition to thermal insulation, sound insulation of the premises is provided.

Features of the self-leveling screed technology

When building a floor on the ground, several nuances must be taken into account:

- inside the contour of the foundation tape, the roots are removed, the fertile layer is removed, which is not suitable for tamping;

- polyethylene film transmits radon, so it is better to use polycarbonate, vinyl acetate, PVC modifications, stacked in two layers;

- it is imperative that the waterproofing does not allow steam to pass through, i.e. was a hydro-vapor barrier (or just a vapor barrier), because moisture in the soil is also in a vaporous state, including;

- it is recommended to run the film on the tape base along the perimeter 15 cm above the projected screed (subsequently trimmed with a knife);

- the insulation is launched at the height of the slab to be poured; above this level, a damper tape is used, which provides sound insulation from structure-borne noise.

The floating screed of each floor in the house is created for several purposes. Cutting off the slab from the walls allows you to compensate for internal stresses inside it, prevent cracking from possible shrinkage of wall materials, isolate the noise transmitted to the power frame of the cottage by generators, compressors, boilers, and other power equipment.

Advice! If you need contractors, there is a very convenient service for their selection. Just send in the form below a detailed description of the work that needs to be performed and you will receive offers with prices from construction teams and firms by mail. You can see reviews of each of them and photos with examples of work. It is FREE and non-binding.