Thermal insulation of aerated concrete

Aerated concrete, as a building material, was invented back in 1924, but only from the 80s it began to be widely used for the construction of buildings, both private and multi-storey buildings. There are many reasons for the increasing popularity of blocks made of air-bubbled cement-sand composition, for example, low weight, so the construction of a very large foundation is not required. But its main advantage is the low cost of the material and work with it, which makes it possible to build inexpensive housing.

What is aerated concrete? Aerated concrete is a type of aerated concrete - a building material with closed and non-communicating pores evenly distributed throughout the volume, which have an approximately spherical shape with a diameter of 1-3 mm. In the production of aerated concrete, the following are used: cement, quartz sand and specialized gas formers. In addition, gypsum, lime, industrial waste, for example, metallurgical slags, are sometimes added to the composition of the mixture during its manufacture.

Advantages of aerated concrete

One of the most important points in such construction is the insulation of a house from aerated concrete, since this material, although it has a low thermal conductivity (according to GOST 31360-2007), while the thickness of the walls made of aerated concrete does not exceed 40 cm and additional thermal insulation from the outside or from the inside will help significantly increase energy savings and save the owner money during the stay.

- excellent thermal insulation properties;

- low weight, which makes it easier to carry out work and shortens their time;

- the possibility of mounting on glue - convenient;

- vapor permeability: the porous structure allows the vapor to escape;

- enough* high strength;

- good sound insulation;

- fire resistance;

- environmental friendliness - b safe for health, does not contain toxic substances;

- low cost.

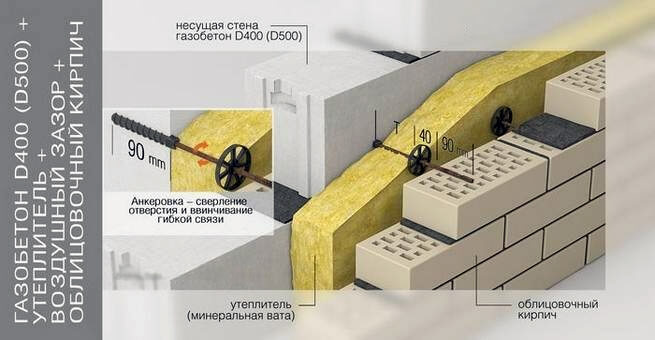

Note. The structural and thermal insulation grade D500 is intended for the construction of houses up to the 3rd floor. Its bearing capacity is sufficient to withstand the load of the entire structure of the house and floor slabs. At the same time, in the places of support of floor slabs and other loaded elements, it becomes necessary to erect a reinforced concrete belt or ordinary brickwork, which are cold bridges.

Disadvantages of aerated concrete

- High fragility (use of special fasteners).

- High hygroscopicity, which reduces thermal insulation properties.

- Low frost resistance - D500 is recommended for climatic conditions not lower than -18 ° C.

Thermal conductivity of aerated concrete - indicators

According to GOST 31360-2007, which specifies the technical characteristics, composition and dimensions of aerated concrete blocks, the thermal conductivity of its types is 3-5 times lower than that of solid bricks. This means not only that the wall thickness can be 1.5-2 times less, but also much less insulation is required - again, savings.

Table 1 shows the values of the thermal conductivity index from GOST for aerated concrete.

Table 1

Comparison of thermal conductivity of aerated concrete and other building materials is presented in table 2.

table 2

| Construction material | Density, ρ kg / m3 | Thermal conductivity in dry condition, λ0 W / (m / ºС) | Thermal conductivity at 4% humidity, λА W / (m / ºС) |

|---|---|---|---|

| Autoclaved aerated concrete D500 | 500 | 0,12 | 0,141 |

| Expanded clay concrete | 800 | 0,231 | 0,35 |

| Reinforced concrete | 2500 | 1,69 | 2,043 |

| Solid clay brick | 1800 | 0,56 | 0,81 |

| Hollow clay brick | 1000 | 0,26 | 0,439 |

| Solid sand-lime brick | 1800 | 0,70 | 0,87 |

| Wood (pine, spruce) | 500 | 0,09 | 0,18 |

| Mineral wool | 150 | 0,042 | 0,045 |

| Expanded polystyrene | 35 | 0,028 | 0,028 |

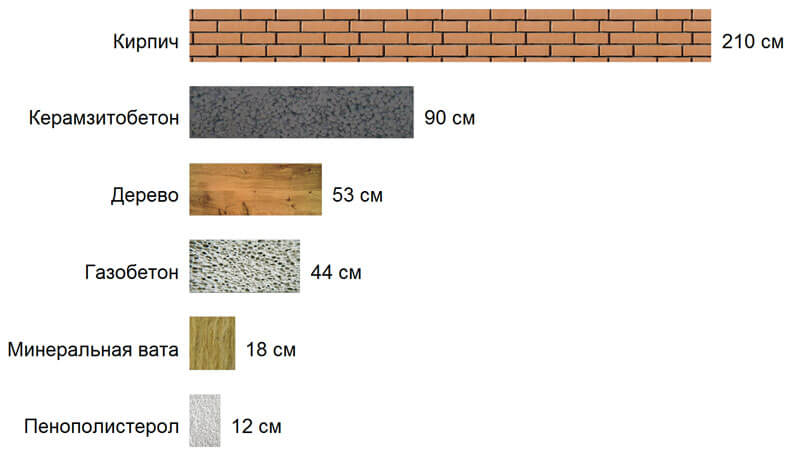

The same thing, only in visual representation - the thickness of the thermal insulation is clearly visible.

Thermal insulation of aerated concrete: inside or outside?

In cases where it is realistic to insulate walls from aerated concrete both outside and inside, it is always better to give preference to the first method.

Firstly, the internal volume of the building is significantly reduced due to the thickness of the insulator.

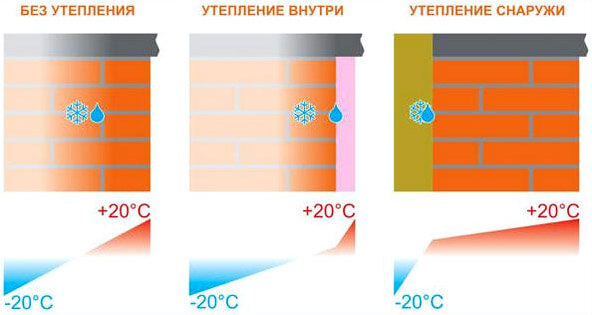

Secondly, in cold weather, the walls do not warm up well and cool quickly from the outside, and the accumulated condensation in slabs, wooden floors or bricks repeatedly freezes and thaws, which negatively affects the integrity of the entire structure.

Thirdly, the peculiarity of the structure of aerated concrete requires a mandatory ventilation device between the insulation layer and the wall - otherwise mold and fungus will appear.

When designing an external structure, the layers should be located with a decrease in their vapor barrier and an increase in thermal insulation capacity in the direction from the inside out.

Dew point displacement without insulation, as well as with internal and external insulation

Dew point displacement without insulation, as well as with internal and external insulation Under certain conditions and good vapor barrier and ventilation systems, the installation of an internal insulation is allowed.

Therefore, facade insulation is most often used from the outside, in addition, this approach significantly increases the level of sound insulation of walls, insulation and a protective film protect aerated concrete from the destructive action of moisture, and finishing allows you to make a beautiful facade in any style.

Options for thermal insulation of aerated concrete walls

It is possible to insulate aerated concrete blocks with almost any insulation:

- extruded polystyrene foam;

- expanded polystyrene;

- mineral wool;

- ecowool;

- warm plaster.

Thermal insulation of aerated concrete houses with foam

Of the advantages of this method of thermal insulation from the outside, we can name the low price of the material and ... That's it! Then there are some disadvantages: the foam does not "breathe" at all, does not allow steam to pass through, and therefore it requires a ventilation layer on the frame. This, of course, requires additional financial (and rather large) costs, which means that it will not be possible to save on foam plastic, although its cost is almost 2 times less than that of mineral wool. Expanded polystyrene sheets are fixed directly to the facade wall using glue and dowels.

Extruded polystyrene foam (the most common: penoplex) is, in fact, the same foam, only significantly more expensive in price. The difference lies in the technology for creating granules. Experienced builders do not recommend using this material for finishing outside, since a ventilation frame is also required, as when working with foam.

The technology of insulation with expanded polystyrene is simple and you can do the work yourself. It consists of the following stages:

- preparation of the surface of the facade wall - cleaning with a stiff brush and removing dust;

- alignment of irregularities on the wall (if any);

- reinforcement of window frames - gluing fiberglass mesh so that it sticks out at least 10 cm (after installing the insulation, the mesh is bent and fixed);

- each sheet of expanded polystyrene must be greased with an adhesive (only for outdoor work!), level the glue with a spatula, attach and fix with 2-4 plastic dowels with large umbrella caps.

Very important! Each sheet should be exposed with a slight offset to avoid cracking after finishing the facade.

The following finishing materials are suitable for a wall made of aerated concrete insulated from the outside:

- siding;

- any ventilated facade (on a wooden or metal frame);

- decorative tiles and artificial stone;

- plastering and painting (wet facade).

Thermal insulation of aerated concrete houses with mineral (basalt) wool

Thermal insulation with mineral wool - rolled or, preferably, with mineral wool slabs (easier to use) - this is the best way. This material has good vapor permeability - there will be a healthy atmosphere in the house, it is lightweight and easy to install. In addition, mineral wool insulation guarantees at least 70 years of operation at home without the need to replace the insulation - while the foam “gets old” after 20-25 years.

The technology of insulation with mineral wool practically does not differ from the installation of expanded polystyrene sheets. Only after the glue has solidified, a fiberglass mesh is laid on the insulation layer, a layer of glue is applied again, and then the entire heat-insulating cake is fixed with dowels.

Video # 1. Insulation of walls made of aerated concrete - construction subtleties

Thermal insulation of aerated concrete houses with ecowool

This is a relatively new, but very effective, way of insulating houses from the outside. Ecowool has a uniquely low thermal conductivity - its 20 cm layer is similar to a 1 meter thick wall. Insulation is applied by wet spraying or dry blowing. This requires a special installation - it can be rented, or better - to order a turnkey work in a company offering such services. Ultimately, this method of insulation will cost about 25% more than mineral wool, but the advantages of ecowool are much greater.

The facade of a house made of aerated concrete when insulated with ecowool is preferably decorated with siding. In this case, a siding frame is first installed on the walls, and then ecowool is sprayed. After hardening, the wall is leveled, waterproofing, wind protection is installed and siding is installed.

Warming of aerated concrete houses with warm plaster

This method of aerated concrete facades has a lot of advantages. Such a layered system provides a level of thermal insulation 4 times higher than conventional plaster. In addition, it is a relatively inexpensive option for thermal insulation of buildings.

The most commonly used system consists of 3 layers, with rigid attachment to the base with glue and a disc dowel:

- the first layer is internal, heat-insulating, made of expanded polystyrene, mineral wool or other material with low thermal conductivity;

- the second is a basic plaster-adhesive layer, reinforced with fiberglass mesh;

- the third is an outer, protective and decorative layer. You can choose one of the decorative plasters: acrylic, mineral, silicate or siloxane. Additionally, decorative facade paints can be applied on top.