Carriage houses

Norwegian technology for the construction of residential buildings appeared in Russia not so long ago, but instantly earned an excellent reputation. Developers who are interested in the Norwegian carriage have made and continue to compete with firms that are building houses from round logs. What is the specificity of building houses from a gun carriage? You will learn about this and much more in this article.

It is not difficult to guess that the technology of the Norwegian gun carriage came to us from distant cold Norway, whose inhabitants know a lot about ways to warm their homes. This is one of the main reasons that the technology has taken root so quickly and successfully in the frosty Russian climate, especially in the northern regions. What is a Norwegian gun carriage? A carriage is a log dried in a certain way and processed using a special technology. In other words, a gun carriage is not a log by itself, but a tree that has been handcrafted in a particular felling style. This style was formed in ancient Scandinavia, when the Vikings built their settlements along the shores of the cold seas. No strong north winds could blow through these walls and destroy their strong dwellings. But this became possible not only thanks to the carriage, but also to the nature of the assembly - the Norwegian "castle". The Norwegian castle or "tricky castle" is a unique system for connecting the carriage, thanks to which a powerful blank wall is obtained without a single gap. The technology excludes the occurrence of drafts, freezing of corners and other "classic" troubles associated with the construction of housing made of wood. Moreover, the shrinkage of such a house plays only in favor of the strength and durability of the structure - the stronger the shrinkage, the more reliable the "lock", which means the warmer the whole building! That is why wooden houses from the gun carriage are chosen by those who want to settle in a picturesque, environmentally friendly and warm home for many years. It is worth talking a little more about the way the carriage is processed. It appeared not by chance, but for the sake of economy. Even the ancient Scandinavians knew that the larger the log, the stronger and warmer the house. But a thick log is worth it, so a method was invented that made a log house from large logs cheaper. A pine log was chopped off from both ends, the resulting slab was used to arrange the roof and floor. Thus, the entire array was used in the work without a trace. The rafters and internal partitions were also erected from a carriage. There were no attics in the old houses from the gun carriage, and today many people prefer to follow this tradition. The roof was made flat, meadow grasses grew on it and goats grazed. Grass and turf effectively protected the house and kept warm during the winter. Plus, to be sure, this sight looks very picturesque!

Carriage productionProjects of houses from a gun carriage can be completely different, but often customers prefer the classic version with a flat horizontal roof. For construction, wood is used from 28 to 50 cm in diameter. The price of a carriage house depends on the project and the diameter of the logs. The carriage is made in this way: first, the lateral parts of the log are cut off, then the bark is removed from the remaining semicircular sides. Further processing is carried out manually: a groove is selected on the semicircular part and a corner bowl is made. Previously, this was done with the help of axes, today the work is facilitated by a chainsaw. At first glance, a carriage house can be confused with a log house, but it looks more harmonious and powerful because of the high crown, made in the size of the original log.

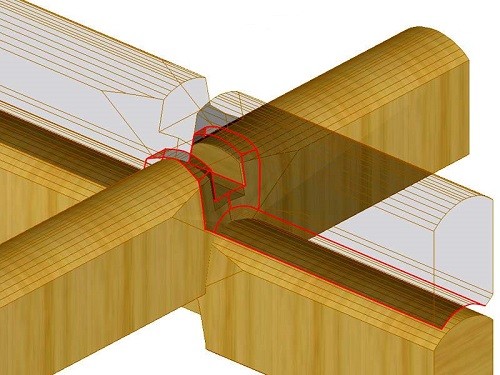

Due to the fact that the raw material for the carriage is thick logs, much less crowns are required for the construction of walls than for the construction of a log or log house. This is a significant advantage, since fewer crowns reduce the risk of cold bridges to a minimum, increasing the durability and heat saving of the house. During the construction of a Norwegian carriage house, special attention is paid to corner joints. Since these are the weakest parts of a wooden house, they freeze through and are blown through most often. There are many ways to connect logs in the corners, but in this case, the aforementioned "Norwegian lock" is used, the advantages of which we will talk about below. Carriage mounting methodsThe method of connecting the carriage is determined even during planning, since it determines the nature of the building structure and requires different approaches. For the construction of houses from a gun carriage, two types of connection are used: "Norwegian castle" and "Canadian cup". These are two completely different types of wood processing. The efficiency and economy of these compounds surpassed even the traditional Russian cutting technology. Norwegian castleWhen the "Norwegian castle" is connected, the logs are joined into a "bowl" - a depression that holds each log firmly in place. The ends of the logs protrude beyond the perimeter of the log house, which automatically creates protection from the wind and makes the corners warmer. Most developers are inclined to believe that this is the best way of connecting logs invented by man. In the bowl of the log, a thorn is made and an opening for it in order to nullify the penetration of air and the formation of drafts. When a newly built house shrinks, the internal curtains and spikes are squeezed to the limit, therefore such a "lock" is also called self-wedging. The logs are pressed against each other so tightly that the need to caulk the walls completely disappears.

Another serious point when using the "Norwegian castle" is the natural moisture forest, from which a carriage is usually made, does not deform from internal pressure during shrinkage. You can make any roof, even from heavy metal tiles, or lay sod and graze goats, as the ancient Scandinavians did - the powerful rafter system will support any weight! Norwegian rafters are built from chopped gables in all rooms on the second floor. The pediments are connected to each other by a system of logs known in professional circles as "lay down" and "horse".

Any dwelling made of natural moisture forest will shrink, for this reason it is necessary to wait from several months to a year before heating the house and starting interior decoration. Otherwise, cracks will appear in the logs, they will bend, and all the work will go to waste. You can move into the houses from the gun carriage immediately after the end of construction. The fast pace of construction and quick commissioning is another significant advantage of this technology. Canadian cupAnother way to handle round logs is called the "Canadian cup" or "Canadian felling". A special technology allows you to preserve natural properties and natural structure. Manual chopping does not damage the strong outer layer of the wood, making the carriage more immune to environmental influences. The main difference between the "Canadian felling" and the "Norwegian castle" is that there are overhangs near the cuttings. The cup itself is trapezoidal. Due to this and the presence of obstructions during the shrinkage of the house, the corners are wedged as tightly as possible, keeping warm and neat cut. The "Canadian cup" gives a very precise fit of the logs, which eliminates the formation of gaps between the crowns. Thus, the wall of the log house seems to be a solid mass, and the insulation does not come out and does not absorb moisture around the edges. This connection also does not require re-caulking. This video shows how round logs are processed using the "Canadian felling" technology: Advantages of carriage housesFrom the foregoing, it becomes clear that the houses from the gun carriage (photo) were created for those who want to thoroughly settle down on the site and build a house that would serve as a reliable and warm shelter for several generations. Today, the trend towards an eco-friendly lifestyle, a craving for nature, peace and tranquility is manifested in such a phenomenon as downshifting - people leave cramped city apartments and move to the suburbs and villages. But it is not enough just to get away from the dusty highway and factory emissions, you need to ensure yourself the most comfortable and comfortable life. That is why the houses from the gun carriage are gaining more and more popularity every year. Their advantages are obvious, and the quality justifies and pays for all the costs.

Among the main advantages of carriage houses are the following:

|