Construction of houses, brick cottages - prices

The best price for building a brick house!

Construction of houses, brick cottages - prices

A brick house is the most popular option for the construction of cottages and in low-rise housing construction in general. A variety of brickwork patterns and a wide range of facing bricks on the Russian market make it possible to create real masterpieces of architectural creativity - beautiful, respectable mansions with an individual design and layout.

Nevertheless, it should be borne in mind that brickwork, especially with a significant wall thickness, exerts a solid load on the foundation. Therefore, it is extremely important to have a professionally executed project, calculated and "tied" to the building site, taking into account all the features of its soils. It is with the calculations that both construction and cooperation with the "Cottage-Expert" company begins, the main field of activity of which is cottages in Moscow and the Moscow region, turnkey construction. Our specialists are ready to develop a project for a brick house of any size and layout, and if the customer already has one, then draw up an estimate for materials and the necessary work to implement this project. Reasonable and constant cost of construction of each object is the principled position of our company.

The cost of building a brick house. Price per m2

| List of works | "House box" | "With external decoration" | "For finishing" |

|---|---|---|---|

| Cost (work + materials) |

RUB 17,000 / m2 |

RUB 24,000 / m2 |

RUB 29,000 / m2 |

What is included in the price: |

|||

| Foundation: slab 300mm, concrete M300, reinforcement AIII d12 | |||

|

Wall construction: Rauf porous ceramic bricks for external and internal load-bearing walls. Armopoyas (d12 fittings). Reinforced concrete lintels |

|||

| Construction of smoke and ventilation ducts | |||

|

Reinforced concrete floors |

|||

| Roofing: metal tiles, metal profiles, ondulin | |||

| Roof insulation: 200mm insulation, vapor barrier | |||

| Rehay metal-plastic windows, entrance metal door or solid pine | |||

| Exterior finish: decorative facade plaster (Bark beetle and analogues) | |||

| Plinth finish | |||

| Engineering systems: hot and cold water supply, heating, sewerage, electrical work | |||

| Finishing "for finishing": floor screed, interior partitions, slopes, ebb, sills, plastering and puttying | |||

The foundation of a brick house

The type of foundation that is chosen for the construction of a brick house depends mainly on the bearing capacity of the soil.

- On sufficiently solid soils, a columnar foundation can be used - brick or stone supports, reinforced concrete pillars - with bandaging and the subsequent erection of a grillage. The same applies to bored piles.

- It is possible to use a strip foundation - monolithic or from reinforced concrete blocks.

- On heaving, loose, unstable soils, a pile field is arranged or a monolithic slab is poured. The latter type of foundation is the most laborious, requires a large consumption of concrete solution and is very expensive.

- Recently, screw piles have become popular, the installation of which is easy and quick, and leveling is not difficult for experienced builders. Pile foundations are indispensable for construction in areas with difficult terrain and with a high level of groundwater occurrence, in wetlands. You can create a pile field at any time of the year.

The specialists of the "Cottage-Expert" company will analyze the results of a geodetic survey of the site, study the wishes of the developer in terms of number of storeys and layout, and then recommend the optimal design of the base - the most reliable and durable and, at the same time, economical.

Photos of built houses

Brickwork technology

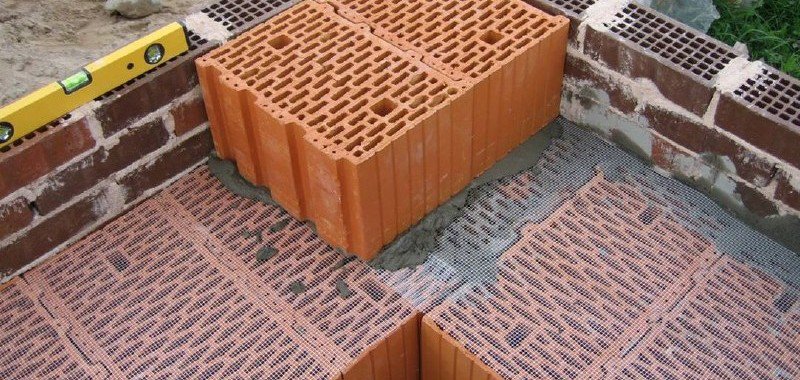

Before proceeding directly to the laying of the bearing walls, waterproofing is performed by laying one or two layers of waterproofing material on top of the grillage (the simplest option is roofing material). The standard ratio of sand to cement in masonry mortar is 4 to 1. It is recommended to choose fine-grained sand. To avoid the inclusion of large fractions (stones, shell fragments, organic particles), it is pre-sieved.

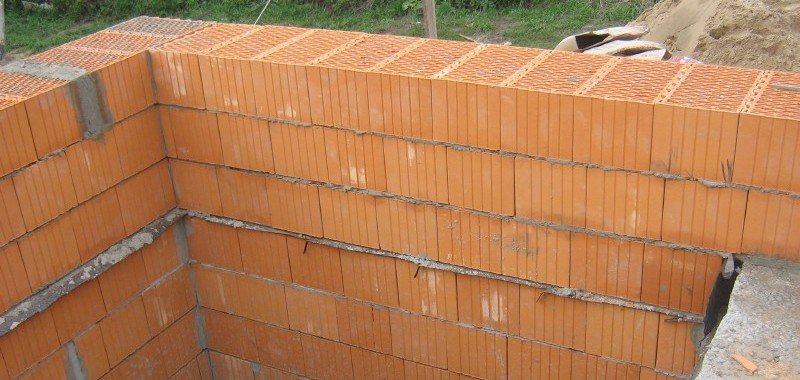

Masonry is distinguished by the thickness of the brick wall, by the system of dressing the seams and by the filling. The thickness of the wall can be from 120 mm (in half a brick) to 640 mm (in two and a half bricks). According to the suture dressing system - single-row, multi-row and three-row. By filling, they distinguish between solid masonry using bricks for backing up and lightweight, when insulation is used for backing up.

It is very important, when building a brick house, to gradually and evenly load the foundation. They begin to lay the masonry from the corners of the structure, focusing on the lace stretched along its outer border. The corners, which are called the "corner of the outer verst," are raised by 4-5 bricks, maintaining the thickness of the horizontal seam of 12 mm with the help of ordering - a wooden bar or a metal profile with divisions. The width of the vertical seam is 10 mm, it is maintained by fitting the bricks to each other with light blows from the handle of a trowel or a special construction hammer. After laying a couple of rows of the outer verst, one or two rows of inner versts are laid in exactly the same way. The space between versts is filled with brick or insulation.

The brick is laid apart (the classic version of the masonry), every fifth or sixth row is reinforced with a metal bar 5-8 mm thick. Each row of bricks laid is checked with a level for horizontalness. After laying all the corners, they are connected, leading the masonry along the perimeter. At the same time, they are guided by the position of a specially stretched fishing line.

Openings, partitions, finishing

In the places of joining with the internal partitions (according to the project), in each row 4-5, a brick is laid across the wall, releasing it inward by 120 mm - the internal walls will later be tied to these protrusions. On the sides of the door and window openings, the outer verst of the masonry is pushed inward by 120 mm. This technique is called "quarter". The upper lintel of the openings can be factory, reinforced concrete, or cast on a specially installed formwork directly during the construction of the wall. To arrange a "quarter" along the upper border of the opening, they resort to stepped filling or lay ready-made lintels at different heights. Such arrangement technology is necessary for a beautiful and reliable installation of window structures and door frames.

If the project provides for wall decoration with siding, drywall, wall panels, then the seams are aligned flush with the laid bricks. For plastering walls, it is advisable to leave the joints unfilled to a depth of 1 cm for more reliable adhesion of the plaster layer to the wall. In the event that the masonry automatically becomes the surface of the facade of the house, it is necessary to embroider the seams as the wall is being erected. With the help of jointing, the seams can be made convex or concave - at will, but they must all be of the same thickness, and the wall is perfectly flat.

The advantages of a brick house

Developers choose brick as the main material, since houses made of it are characterized by maximum durability and strength, not inferior to monolithic buildings, but at the same time provide a more comfortable microclimate in the premises. A brick cottage "breathes", its walls are non-flammable, keep warm, are distinguished by good resistance to damage by fungus and other harmful microorganisms. It is also important that brick houses, even without additional external cladding, are able to withstand the influence of aggressive natural factors for decades - wind loads, temperature drops, exposure to sedimentary moisture and numerous freezing cycles.

Turning to the "Cottage-Expert" company, you get a brick cottage, built in compliance with all the necessary standards and technologies. We also provide a long-term warranty for all work performed.

We also build houses from,