Foundation slab on tape and pouring a monolithic slab

At the stage of building design, it is necessary to carefully consider the base option. In this case, you need to rely on the features of the soil at the construction site and on the total weight of the structure, which will ultimately create a static load on the frame.

Often, a slab foundation based on a strip is erected as a basis for a house. At first, such a frame has the form of a closed loop made of reinforced mortar poured into the formwork. Most often, the parameters for the strip foundation are taken at the rate of 300x350x400 mm. After that, the solution is also poured into the remaining space along the entire perimeter in the form of using reinforcement technology. Such a foundation is also called floating, since it is located at a shallow depth and, depending on the movement of soil layers under the house, makes identical movements. Thus, such a slab foundation preserves the integrity of the entire house, relieving the tensile or compressive load from it.

Important: before proceeding with the installation of the floating base, it is necessary to carry out detailed and scrupulous calculations. Making the slightest mistake threatens the subsequent destruction of the very foundation and then the building.

Advantages and features of the slab base

When deciding to mount a tape-type foundation with a monolithic slab, it is necessary to clearly understand what positive and negative sides both the masters and the owners of the future house will have to face. The main advantages of the tape-type monolithic basis are:

- High foundation strength. The technology of reinforcing the concrete cushion-slab increases the ability of the foundation to withstand increased loads.

- The ability to erect a building both on simple soils and on soil with unsuitable features for construction (peat, clay, loam, high groundwater, etc.).

- Long service life of the foundation, calculated in tens and hundreds of years.

- The ability to build houses of any number of storeys and purpose on this basis.

- Reducing the cost of arranging the floor on the ground floor, since the cast-in-place slab is already the floor.

But with all its positive aspects, the strip-type slab foundation also has some disadvantages. These are:

- The need for more accurate and thorough complex calculations;

- Excessive consumption of building materials;

- The need to attract additional workers or a large expenditure of time and effort for the construction of such a foundation-slab;

- The laboriousness of the process when preparing a pit for pouring a monolithic slab inside the strip base;

- Relatively high cost of work, in contrast to the device of a standard strip foundation.

Load calculation

To build a strong and reliable tape-type foundation with a monolithic slab inside it, it is necessary to correctly calculate all the parameters of the future house and the basis for it. It is unlikely that it will be possible to independently make such calculations without having an engineering education. Therefore, it is best to entrust this stage of work to a professional architect.

As a rule, design work is carried out taking into account the following parameters:

- Features of the soil (by taking it for analysis);

- The size of the building according to the plan of the house;

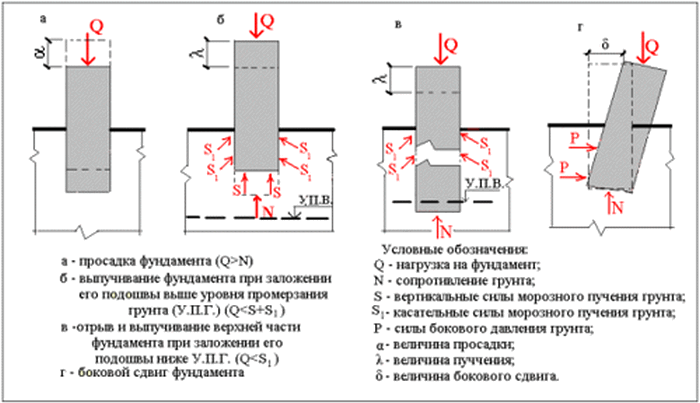

- Calculation of the possible tilt of the building during its operation;

- Calculations for possible squeezing of the foundation and its punching;

- Calculation according to the deformation scheme.

Start of work on the installation of the floating base

First of all, according to the plan of the house, the tape contour is poured. Under it, it is necessary to prepare a trench of the given parameters, on the bottom of which a sand cushion is laid.

The next layer will be a waterproofing material, and then the process of formwork and grouting will begin. However, it is worth knowing that the strip foundation is of two types:

- Monolithic - filled from the prepared solution;

- Prefabricated - assembled from ready-made reinforced concrete blocks.

For the second version of the base device, the involvement of special equipment and a greater expenditure of funds will be required. In addition, it is always worth remembering that the strip foundation is also distinguished by the type of load on such options:

- Shallow... It is used if the building will have one floor and is erected from light materials (foam blocks, timber, sandwich panels or bricks). In this case, the depth of the concrete blocks or pouring the mortar is from 50 to 70 cm. Moreover, this type of base is suitable for weak or non-powdery soils.

- Recessed foundation the tape type is used for high-rise buildings and made of heavy materials on slightly loose soils. The depth of the location of such a base should be 20-30 cm higher than the depth of soil freezing in the area.

Important: you can arrange a monolithic foundation slab inside the strip base only after it has completely dried out and some shrinkage. This may take about a month.

Requirements for the floating slab device

The scheme of the slab device inside the tape base is quite simple, but subject to certain requirements. So, in order for the internal monolithic floating cushion to meet all technological requirements and reduce the load on the finished building, you need:

- Pour the solution around the entire free perimeter inside the tape frame;

- Observe the structure of the fill, the proportions of the mortar, the thickness and other parameters of the monolithic base;

- After the mortar has dried, it is necessary to provide waterproofing of the pillow on all sides and thermal insulation on the floor side.

Important: you can also waterproof a monolithic slab inside the strip base from below before pouring the solution into the formwork.

Waterproofing is first carried out using roll materials on top of an arranged sand-crushed stone cushion. The joints should be overlapped, processing the edges with a gas burner to melt them and securely adhere to each other. It is also important to leave overlaps here to protect the end sides of the slab from moisture. The upper part of the inner floating slab is waterproofed with bitumen mastic or spraying or coating materials.

The solution is prepared on the basis of cement grade M300.

Slab pouring technology

The installation diagram of a monolithic base inside the strip frame looks like this:

- First, along the entire perimeter of the closed loop, a layer of soil is removed to a depth of about 30 cm. At the same time, it is not yet necessary to take the land away from the site.

- The bottom of the prepared pit is covered with geotextile in such a way that the edges overlap, and the walls of the pit are also protected with material.

- The next layer of the cake is sand and crushed stone, a total of 20 cm thick. Loose ones should be slightly moistened and tamped well.

- Further, according to the project of the building, they make the wiring of all plumbing communications, leaving the protrusions of the pipes above the level of the future slab. The pipes can be well insulated.

Important: before pouring the solution into the formwork, it is necessary to charmingly check the operability of all mounted communications. Otherwise it will be too late later.

- Formwork is made from wooden panels for pouring mortar.

- The next step is to reinforce the structure.

Reinforcement technology

Steel rods with a diameter of 8 to 16 mm are used as reinforcement for a monolithic slab. And the larger the cross-section of the reinforcement should be, the greater the estimated load on the foundation. In addition, the pitch of the steel rods in the reinforcing mesh also depends on the same parameter. As a rule, it is done at a distance of 30-40 cm, but if the load is high, then the distance between the rods can be reduced.

- Two horizontally arranged nets are constructed from the rods by knitting.

Important: you can also use welding technology to create a reinforcing frame. But it should be remembered that welding violates the strength characteristics of steel.

- The finished lower mesh should be located at a distance of at least 5 cm from the sand and gravel cushion. In no case should the reinforcement be touched by bulk reinforcement. Stands or any blocks can be used as supports.

- The upper mesh is also connected to the longitudinal rods by knitting. The diameter of the longitudinal rods can be 6-8 mm.

- After the reinforcement is fully assembled, you can start pouring the concrete in compliance with the level. For high-quality shrinkage of the solution and the removal of all air bubbles, you need to use a deep vibrator.

- After the mortar has dried, it is necessary to additionally waterproof the upper part of the slab.

Important: the solution dries for about a month. But for this time it is necessary to cover the slab with roofing material in order to avoid its premature drying. And for the best result, you need to periodically moisten the poured monolithic pillow.

The foundation erected in this way is a reliable and solid foundation for building.