The foundation on bored piles: device and calculation

For the construction of baths in Russia, a columnar or tape type of foundations is often used. But a more modern option is a bored base, which is due to a number of its advantages. This option can be called ideal for areas that are on slopes or have problem soil. If the building on the territory is quite dense, then the described structure allows the construction of a two-story bathhouse without consequences for the soil and adjacent buildings.

Features of the device

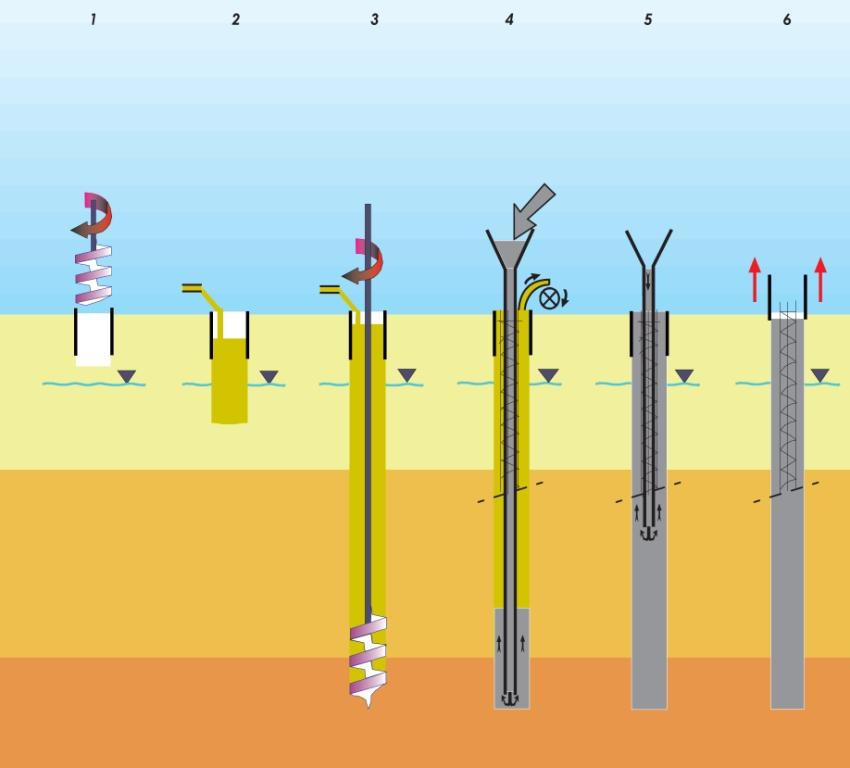

Bored piles do not forcefully drive into the soil and do not damage the layers - they grow out of the soil. The work involves drilling wells where a pipe or removable formwork is placed. The interior space is filled with mortar.

If we are talking about soft ground, then it may be the only possible option. One of the main tasks of the pillars and piles is the support on a solid layer of soil, which is not compressible and is located below the freezing line and groundwater. In some regions, such soil is deep enough. Bored piles are capable of reaching such a line by keeping a sufficiently large bath on themselves.

Piles can be installed together with insulation. As a result, it is possible to obtain a more expensive but reliable design. For this, polystyrene foam is used, which has a rigid structure. It is fixed on waterproofing and covered with soil. Expanded polystyrene is an excellent shock absorber for forces Even the strip base on bored piles does not disturb the communications installed on the site earlier. In such a building, however, there will be no basement, but for a bath this is not a problem. Another advantage of such a foundation is its long service life - the structure is ready to serve for over 100 years.

Calculation

The calculation of bored piles is carried out at the first stage. For example, the width can be determined taking into account the thickness of the future walls. For a frame construction, there is no need to deepen the base too much, because the walls will be thin and light. If you plan to build a real Russian steam room from a bar, then the foundation will need to be made 40 mm more in order to ensure an even distribution of the load.

For example, the support area will depend on the pile diameter. If the last parameter is 15 cm, then the first is 177 cm 2. With a bearing capacity of 1,062 kg, concrete will be needed, the volume of which is 0.0354 m 3. For reinforcement, you will have to prepare 3 rods, while the consumption of reinforcement per linear meter will be equal to 7 pieces. With an increase in the pile diameter to 40 cm, you will have to make a support with an area of 1 256 cm 2. In this case, the bearing capacity will be equal to 7 536 kg, and the volume of concrete used - 0.251 m 3. 8 vertical bars should be used, 18 of them are needed per running meter.

As an example, we can consider the option of building a foundation for a house, the weight of which is 60 tons. The diameter of the piles will be 20 cm. One rack will be able to withstand a weight of no more than 1,884 kg. If you divide 60,000 kg by this value, you get 31.84 pieces. This number should be rounded up to the nearest whole number, resulting in 33 piles. If the filling is carried out without casing, then you will have to buy reinforcement and concrete, the total cost of which will be 13,717 rubles. In order to get this value, 32 must be multiplied by 428.68 rubles.

Marking, drilling and formwork manufacturing

If you decide to build a foundation on bored piles, then first you will need to mark the site. Supports on the territory can be located in the form of a solid wall or in a checkerboard pattern. Sometimes they are installed under certain areas of the building. Then you can start drilling wells. One will take several hours.

The most productive drills in Russia today are Japanese and Korean-made drills. With the help of them, you can build bored foundations in a short time. The installation of bored piles involves the manufacture of formwork, which you will do in the next step. It is necessary in order to exclude soil shattering. Under normal geological conditions, it is possible to do without formwork; in this case, concrete is poured into the created well, which facilitates the process. You will need to make the formwork on the ground. Roofing material will act as a formwork here, which rolls up in the form of a pipe.

You can choose the diameter of the bored pile taking into account the above calculations. The supports must be durable and strong so that their bearing capacity is high enough. But do not be too zealous, installing supports on every square meter.

You can do the piles yourself. They are made on site, so there is no need to worry about the need for storage space. Supports are quite common today, the bases of which are expanded to 50 cm, which is facilitated by technological methods. They allow increasing the bearing capacity of products up to 5 tons. A brick building can be built on such a foundation.

Pillow work and reinforcement

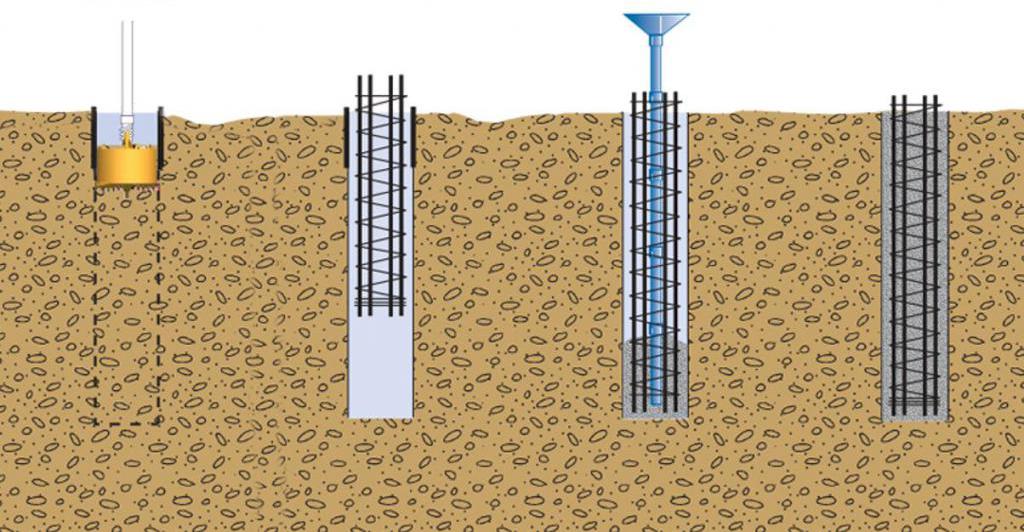

A foundation pillow is a must. It is made from crushed stone, sand or concrete mixture. The substrate is compacted, and then the well is filled with basic material. In order to ensure the strength of the piles, you can use reinforcement, which is knitted into a single structure with the help of a grillage.

In order for the piles to be strong, reinforcing cages are made for them. For this you need to use 12 mm rods, which are connected to each other. You can also use ready-made triangular frames, which are purchased for floor beams.

Installation of piles

Bored piles are installed in the next step. It is necessary to deepen the products by 1.5 m more in relation to the soil freezing line. You can determine the depth of freezing in a certain area using a geological map. The prepared well with formwork and reinforcement is poured with M-200 concrete.

To eliminate voids, the reinforcement is lifted inside the well several times. If you use the technology with the expansion of the base, then after pouring the first portion of the mortar, the formwork must be raised by 30 cm, which will allow the concrete to fill the base. With this technology, further construction can be started only after a few days. The supports should be waterproofed with bitumen mastic or roofing felt to prevent destruction.

Features of waterproofing

Bored piles are waterproofed to prevent the absorption of cement laitance. covered with durable plastic wrap or roofing felt. The latter option is preferable. If you plan to use the film, then weld it and make a cover out of it, which will act as an excellent barrier for the foundation. This method is suitable for solid ground. In other cases, cardboard, metal or asbestos-cement pipes can be used.

More about the features of the fill

If you plan to use the technology described in the article, it is better to make bored piles by pouring concrete from a mixer. This way you can handle large volumes in a day. The foundation is poured, which should be diluted in small portions. This should be done as soon as you start tamping the previous layer.

Wells can be filled with concrete mixed with stone, limestone, cobblestone or sandstone. Such a filler must have high strength. This applies to rubble stone. In order to ensure a better compaction of the solution when installing bored piles, a special drill should be used, which creates mechanical vibration. During construction, this will eliminate even the smallest voids in the concrete. To improve the result, it is better to use a quality one that is fed into the mold by a hydraulic machine that provides the desired level of pressure.

Pile frameworks: what you need to know

The frames of bored piles can be up to 12 m long. The diameter of the longitudinally located reinforcement varies from 8 to 42 mm. The production frame has a diameter that is equal to the limit from 250 to 800 mm. Working whips of reinforcement inside the frame are used in the amount of 4 pieces. It is based on coiled rebar, the diameter of which varies from 12 to 14 mm. The winding step can be varied from 100 to 300 mm.

Finally

When starting work on a bored foundation using hand tools and hole drills, you must be prepared for the fact that these fixtures have diameter restrictions. For example, you can drill a hole up to 40 cm without any problems. Most manufacturers of drilling tools have such equipment.

But if you plan to use augers and cutters, then their diameter may be 50 cm, but they are produced by only a few manufacturers, whose products you can find on store shelves. If the hole will have a larger diameter, then you will have to dig the hole manually. The formwork is installed inside, and after stripping the formwork, it will be necessary to check the quality of the casting and carry out external waterproofing.