Slab foundation construction

The most important building element is its foundation. The reliability and durability of the entire structure and the safety of people living in the house depend on its quality.

The foundation is a monolithic slab capable of withstanding maximum loads, suitable for installation in areas subject to uneven ground movements, frost heaving, with a high level of groundwater.

When the soil moves, house building will rise and fall together with the slab base without loss of integrity and strength.

A house on a slab monolithic foundation will not shrink, even if construction is carried out on difficult ground.

The concrete layer in the floating foundation must be at least 100 mm

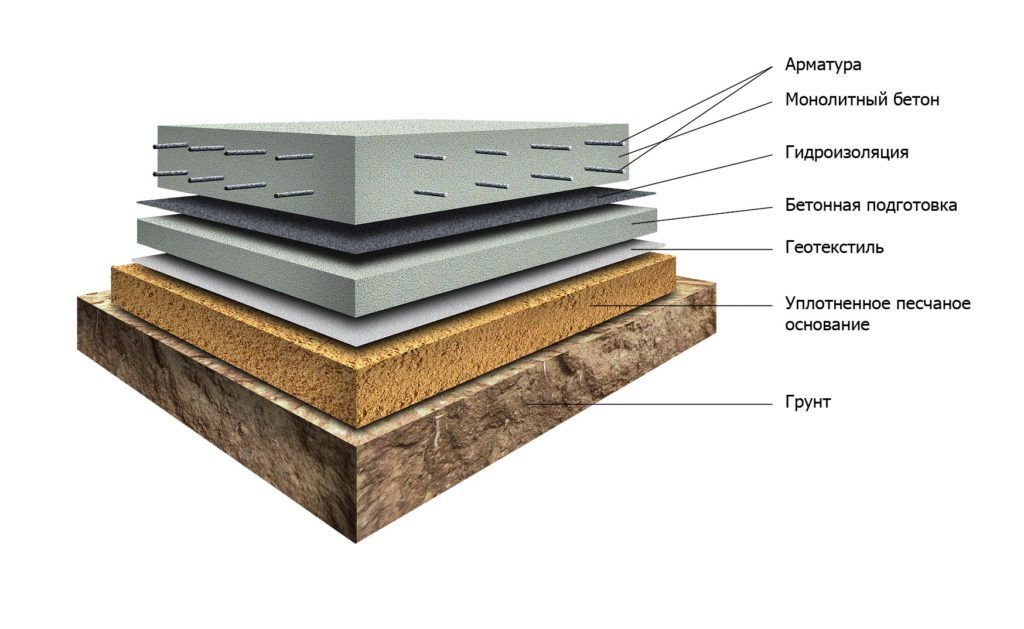

The concrete layer in the floating foundation must be at least 100 mm The floating foundation has a fairly simple structure, consisting of several layers:

- sand pillow;

- geotextile;

- crushed stone;

- concrete layer 100 mm thick;

- waterproofing;

- insulation;

- polyethylene film;

- concrete slab.

Tiled foundations are expensive due to the fact that the base is poured over the entire area of the building. A large amount of concrete and reinforcement is consumed.

Tiled foundations are expensive due to the fact that the base is poured over the entire area of the building. A large amount of concrete and reinforcement is consumed.

But in some cases, when a large deepening of the strip foundation is required, the device of the slab will be cheaper due to less land work and building materials.

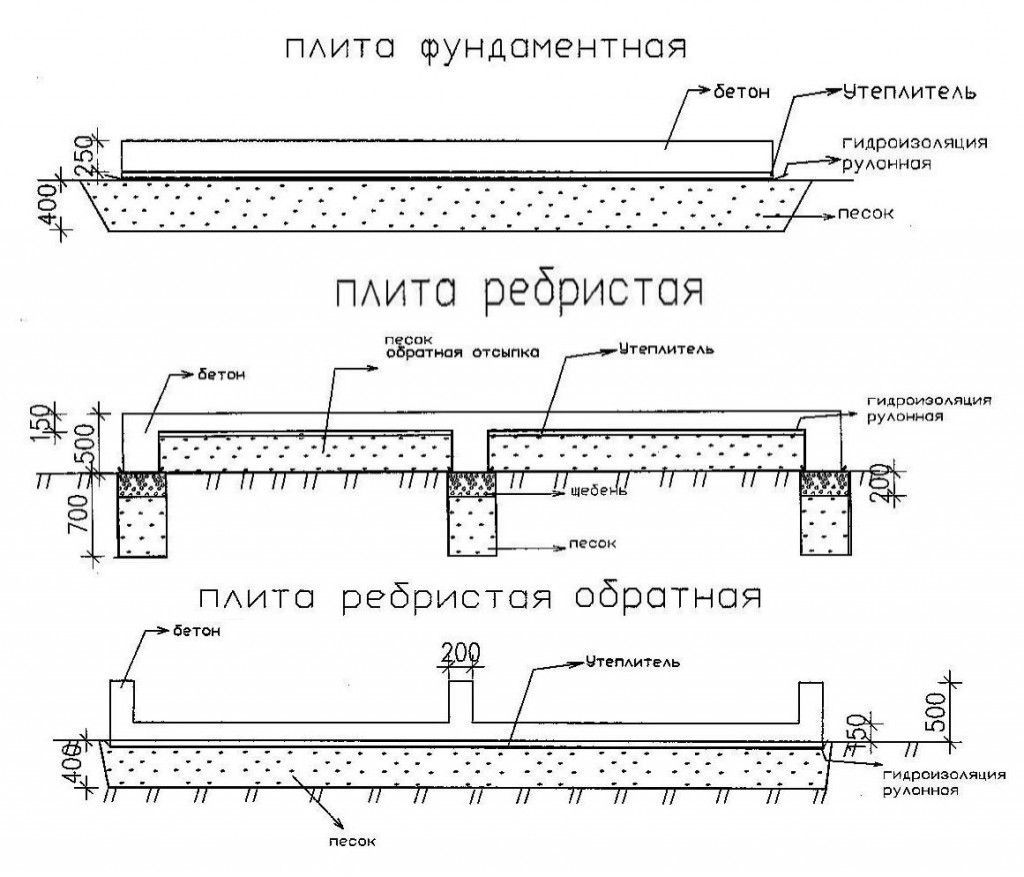

The types of foundations on the slab and their characteristics are presented in the table:

| № | View | Characteristic |

|---|---|---|

| 1 | Classical | It is a reinforced concrete slab, which is poured on a sand cushion. Depending on the operating conditions, the structure can be made with or without insulation. The fertile soil layer is completely removed and the excavation is covered with gravel and sand by 2/3. |

| 2 | Stiffened foundation slab | This option is used in Russia to strengthen the structure for the construction of buildings with a large weight or operated in harsh climatic conditions. Reinforced stiffeners are arranged under the load-bearing walls. |

| 3 | Swedish stove with built-in underfloor heating | The most expensive option. The device uses a fixed formwork made of expanded polystyrene, which retains heat from electric heating elements. Communications are carried out on a sand cushion to the device of a monolithic slab. It is important to correctly perform the calculations and strictly follow the installation technology. Communications are acquired from expensive materials with a long service life. After the completion of construction, it will be impossible to repair the pipelines, as they are under a thick layer of concrete. |

After you have studied what a floating foundation in the form of a monolithic slab is and what types there are, you need to consider all the advantages and disadvantages and choose the most suitable base option.

Advantages

A slab foundation can be erected on any, even unstable soil

A slab foundation can be erected on any, even unstable soil A monolithic slab foundation has many advantages:

- erection is available on any type of soil, including peatlands and swampy areas;

- the floating foundation is arranged above the freezing point of the soil, the sand cushion under the slab does not allow the soil to act on it during frost heaving;

- monolithic reinforced concrete floating slab is not subject to shrinkage;

- suitable for the construction of multi-storey buildings;

- withstands floating soils, the slab moves with the house, thanks to which its structure is not disturbed;

- the structure also serves as a floor on the ground floor, this allows you to save on its construction.

A slab foundation for a house is one of the most reliable and durable, but sometimes its construction is not economically viable.

disadvantages

The relief on the site for such a foundation must be even

The relief on the site for such a foundation must be even A floating foundation cannot be considered as a universal option for all construction projects.

Like any other foundation, it has disadvantages:

- not suitable for installation on building sites with a slope;

- difficulties arise if you want to build a house with a basement on a foundation of concrete slabs;

- problems may arise with the repair of communications carried out under the foundation;

- the construction of a slab foundation in winter will require additional investments for heating the cement mortar and maintaining a positive temperature at the construction site.

The main disadvantage is the high price, therefore, the floating foundation is only suitable when it is impossible to mount the strip base.

Insulated plate installation

A gravel pad will protect the slab from soil pressure

A gravel pad will protect the slab from soil pressure The construction of a monolithic foundation includes several stages. It is necessary to calculate all the loads, prepare the surface of the construction site and only then mount the monolithic concrete foundation.

The insulating layer allows you to save significant money on heating the room during operation. Here is a step-by-step instruction on how to make a monolithic foundation with your own hands.

Preparatory work

Assemble the formwork and install the reinforcement

Assemble the formwork and install the reinforcement The area under the foundation slab should be at least one meter wider than the building area on each side.

Preparation stages:

- They clean the area from debris, mark the location of the slab and completely remove the fertile soil layer. The depth of laying differs depending on climatic conditions, type of soil, proximity to groundwater, and other factors. Most often, the thickness of the base is 200-300 mm, during operation in difficult conditions it is buried up to 500 mm.

- When the pit is ready, its bottom and walls are leveled. Drainage pipes are brought out along the edges, through which rainwater will flow, thereby protecting the building from excessive dampness.

- Spread the geotextile in overlapping strips. The material should cover not only the bottom, but also the walls.

- The ropes are pulled on the driven stakes strictly in a horizontal plane, they are guided by them when sand and crushed stone are poured.

- A layer of sand with a thickness of 200-300 mm is poured. Distribute evenly around the entire perimeter, moisten and tamp well.

- Crushed stone is poured on top in one run, distributed over the site, tamped tightly.

- Conduct communications. Ditches for them are dug in the rubble a little wider than the embedded pipes. The pipeline is covered with sand. The surface is leveled. For more information on installing the slab, see this video:

If the communications are laid before the crushed stone is tamped and compacted, the pipe can crack.

Formwork device

The form for a solid foundation from a slab is most often made removable. But if the installation of underfloor heating is provided, it is better to use non-removable polystyrene formwork.

Formwork is carried out from boards with a minimum thickness of 200 mm and beams. The elements are fastened together with self-tapping screws so that the heads are located outside. Then it will be easier to disassemble the form.

Be sure to install strong supports so that the boards do not disintegrate and do not deform under the influence of the concrete mass.

Waterproofing

Geotextile

Geotextile To protect the base from moisture seepage from groundwater through the pores of concrete, you need to cover the entire surface that will be under the slab with a waterproofing material. You can use roofing material, dense film or geotextile.

The material is laid in overlapping strips so that it overlaps the edge of the previous strip by 150 mm. They make an approach to the walls of the pit with a ledge beyond its edges.

Reinforcement

The diameter of the wire mesh must be at least 12 mm

The diameter of the wire mesh must be at least 12 mm The device of a monolithic foundation slab includes reinforcement with a mesh of a metal rod with a diameter of at least 12 mm. The reliability and durability of the entire building depends on high-quality reinforcement. The mesh is laid in compliance with the level and beacons are installed, according to which the height of the concrete pouring is determined.

The rods are tied together with a wire so that cells with a diameter of 150-200 mm are formed. It is not recommended to use welding, since the joints corrode faster, and may burst when the soil moves.

The rods are tied together with a wire so that cells with a diameter of 150-200 mm are formed. It is not recommended to use welding, since the joints corrode faster, and may burst when the soil moves.

The thickness of the mesh depends on the thickness of the slab and must be completely submerged in the concrete. Sometimes laying is required in several layers.

Places with the highest bearing load are additionally reinforced with metal rods.

The mortar must contain cement grade M300 or higher

The mortar must contain cement grade M300 or higher Pour a monolithic reinforced concrete slab in one go. To do this, order a cement slurry from the factory or need several workers who will have to quickly mix and feed large volumes of concrete. Cement is used grade M300 and higher.

The most reliable method involves conveying the concrete directly from the mixer, through the hose, into the formwork. In this case, a free access of the car must be provided from all sides of the site.

The second option is to feed the cement slurry through a wooden gutter. It will take several people who will push the solution through each meter until it reaches the pouring point.

The second option is to feed the cement slurry through a wooden gutter. It will take several people who will push the solution through each meter until it reaches the pouring point.

After pouring, the solution is compacted with a deep vibrator or a metal rod so that air comes out and there are no voids left.

The surface is leveled with a long wooden or metal strip.

The slab foundation for the house dries completely within 30 days.

Caring for the stove before it hardens

Before drying, the board must be covered with polyethylene.

Before drying, the board must be covered with polyethylene. To prevent the solid foundation from cracking during the drying process, you must follow the rules:

- the monolithic plate should not dry out sharply, it is covered with plastic wrap, moistened with a spray bottle every day;

- when carrying out work in winter, the structure is heated with thermal carriers;

- the formwork is removed no earlier than the concrete gains 70% strength.

When performing the installation technology, the foundation made of a monolithic slab will last more than a hundred years without losing its integrity.

Precast concrete foundation

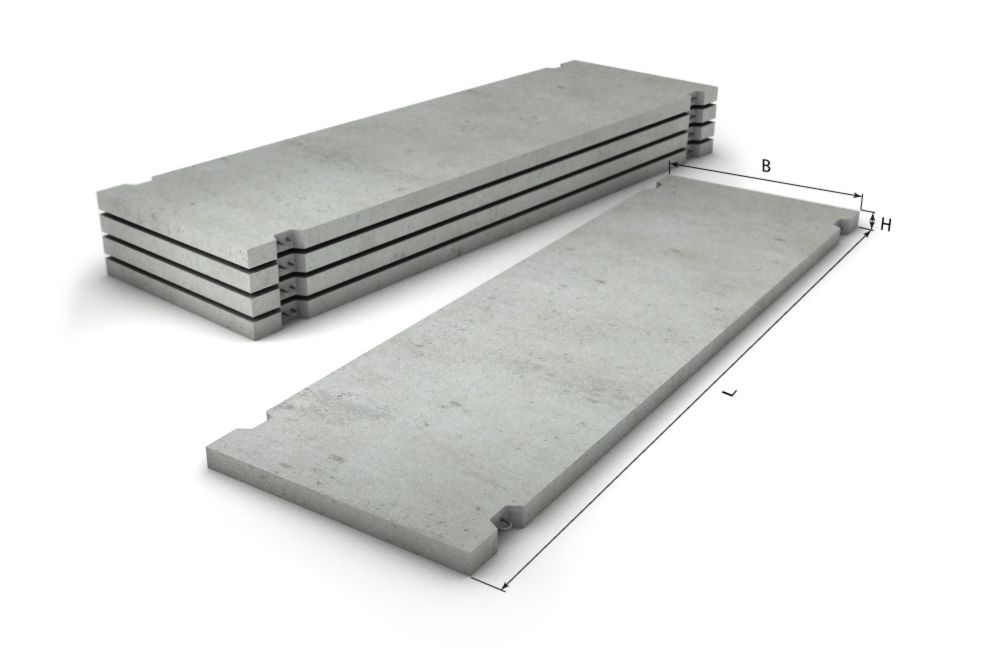

A strip prefabricated reinforced concrete foundation is arranged from blocks assembled into a single whole.

A strip prefabricated reinforced concrete foundation is arranged from blocks assembled into a single whole.

Such a base is mounted around the perimeter of the house and under the supporting structures.

Depending on the type of soil and other factors, it differs in depth by:

- A shallow prefabricated reinforced concrete foundation is arranged under buildings made of light building materials, at a depth of 600-700 mm.

- The recessed base is mounted under brick buildings, above two floors, for houses with garages, basements and basements. Deepen the blocks below the freezing point of the soil.

The second option is more durable and reliable, but its device will cost more.

Installation technology

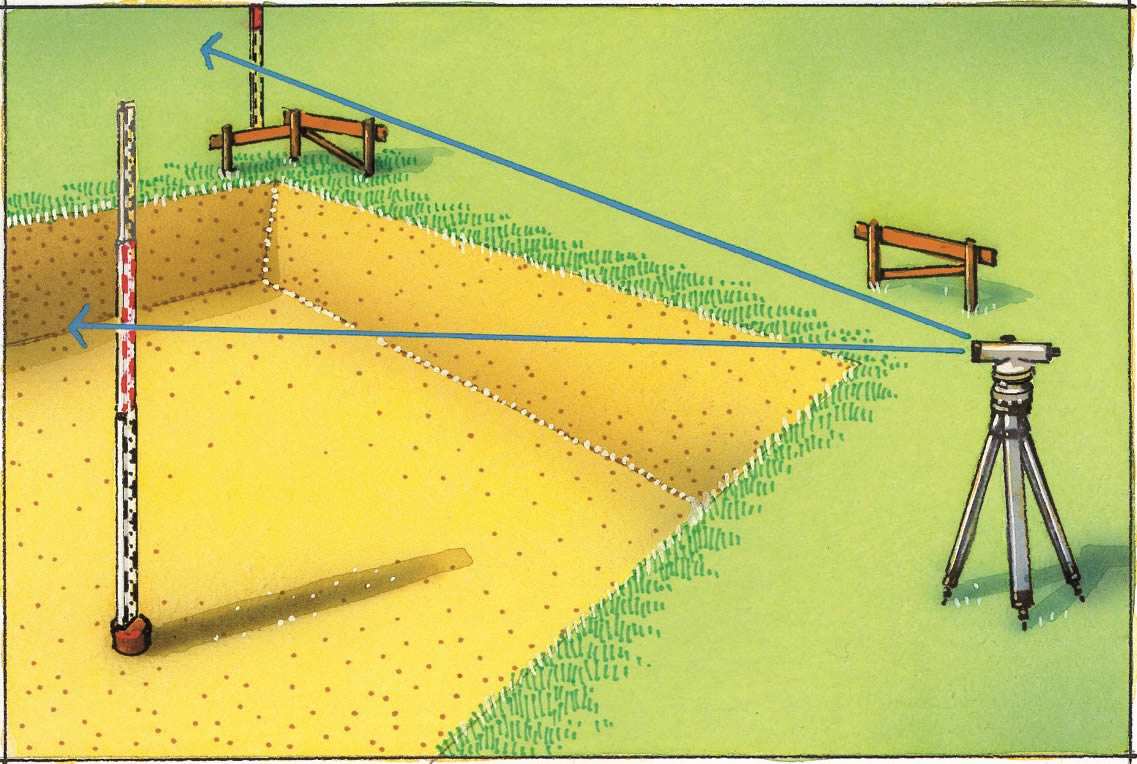

First, they calculate the depth of the foundation and determine how much building materials will be needed. After that, they begin to mark the site. According to the project, a drawing is made on paper, then the markings are transferred to the site. For more information on the foundation from locks, see this video:

They clean the construction site from debris and level it as much as possible.

The stakes are buried in the corners of the building and the edges of the load-bearing walls, and a rope is pulled between them. All work is performed in compliance with the level.

Preparatory stage

The trench is dug according to the markings

The trench is dug according to the markings Step-by-step instructions for preparing a construction site for a foundation made of concrete slabs:

- According to the markings, they dig a trench manually or with the assistance of equipment.

- The bottom and walls are leveled, cleaned.

- At the bottom, a sand cushion is arranged, 150-200 mm thick. The sand is moistened and tamped tightly.

- Sometimes it is required to pour a thin layer of concrete, 100 mm thick.

- Waterproofing the entire surface of the trench.

The strength of the foundation will depend on the quality of the preparatory work.

Foundation device

The joints of the blocks are coated with bitumen

The joints of the blocks are coated with bitumen For the installation of the foundation, you will need to attract special equipment.

- Reinforced concrete blocks are laid from the corners, tightly to each other along the entire perimeter of the trench.

- To increase thermal insulation, the joints are coated with bitumen or cement mortar.

- The next rows are laid with an offset of the joints.

- The internal gaps between the reinforced concrete and the ditch are filled with sand, moistened and compacted well.

- Carry out waterproofing and thermal insulation of the foundation. For information on which basic to choose, see this video:

To strengthen the structure, a reinforcing mesh is placed between the rows on a special adhesive composition.

When choosing the type of foundation for a house, it is necessary to carry out all calculations for the volume of concrete, thickness, depth, etc. Based on the indicators obtained, the economic benefit of installing a slab base is determined. Do not forget that the structure also serves as a floor, this allows you to save on the rough screed.