Monolithic foundation slab device

The monolithic slab foundation is called floating due to the fact that when the soil moves, vibrations diverge along the surface of the slab, protecting the structure from shrinkage and cracking.

The reinforced concrete structure, arranged under the perimeter of the building, is one of the most reliable types of foundations, since it has the largest supporting area. In this article, we will consider what a monolithic foundation is, the stages of its construction with your own hands.

The monolith foundation is used in individual, civil construction, suitable for the foundation in multi-storey buildings.

For some geological factors, it is the best option:

- during construction in swampy areas of the soil;

- at a high level of location of underground sources;

- the soil is unstable, prone to heaving;

- in seismically active areas;

- at a great depth of soil freezing;

- peat bogs are present.

If it is planned to arrange a basement or basement in the house, the stove will not allow it to be made. The only way out is to build a deeply buried foundation made of a monolithic slab, which will serve as the basement floor.

Advantages

The slab foundation is reinforced over the entire area

The slab foundation is reinforced over the entire area

The device of a monolithic foundation slab requires reinforcement over the entire area. This contributes to the fact that the base moves simultaneously with the soil: when the soil freezes, it rises, and when the temperature rises, it goes down.

Advantages:

- reliability, durability;

- the ability to withstand the mass of a multi-storey building;

- service life 150 years;

- protects the building from uneven shrinkage and cracking.

The disadvantages are the high cost of the foundation made of a monolithic slab, the complexity of the calculation of the bearing load and the large amount of land work.

Views

Monolithic foundation device

Monolithic foundation device

Depending on the geological conditions of the site and the type of construction, monolithic foundations are used:

- The box-shaped one gets its name from the fact that its edges are connected by floor slabs, the result is a closed rectangle. Such a base is able to withstand heavy loads, its ribs are made of the same height as the walls of the underground part of housing construction.

- A solid monolithic slab is used in buildings without basements and basements.

- Ribbed cross slabs are used in the construction of multi-storey buildings. The ribs are made of reinforced concrete blocks or cast in the form of a monolithic structure equal in height to the base.

- For seismically active areas, there is a special installation technology: during concreting, reinforcement ribs are arranged from in-situ concrete, the reinforcing cage of which is intertwined with the frame of the concrete base.

For areas prone to deep soil freezing, a monolithic slab foundation is an economically viable option.

Calculation of the parameters of the base

First, we study the characteristics of the soil, the depth of the location of underground sources, the freezing point, calculate the dimensions of the slab, the amount of metal rod (reinforcement).

First, we study the characteristics of the soil, the depth of the location of underground sources, the freezing point, calculate the dimensions of the slab, the amount of metal rod (reinforcement).

We calculate the load from the building, taking into account the total weight at the end of construction, together with household items, people and snow, which may be on the roof in winter.

Factors to consider when choosing parameters for mounting a foundation slab:

- the depth of the foundation;

- thickness of the slab, its area.

Coefficient table depending on the type of soil

Stiffeners must be installed under load-bearing walls and ceilings. For private construction, a plate thickness of 150 mm is sufficient with the laying of one row of steel rods.

The area of the foundation must be larger than the dimensions of the bottom of the building.

DIY erection

![]() A do-it-yourself foundation slab helps to save significant amounts of money. The only thing is to study the technology for performing work and calculate the parameters depending on the load.

A do-it-yourself foundation slab helps to save significant amounts of money. The only thing is to study the technology for performing work and calculate the parameters depending on the load.

The slab structure should be reinforced with steel rods. Its optimal thickness is from 100 to 250 mm. The slab base serves as a floor in the house; in order to save on heating during operation, it must be insulated and sealed.

Preparatory stage

We prepare the building site, make the markings on the ground according to the plan. We mark the perimeter of the future foundation with pegs. We stretch the rope between the timber and check that the opposite sides are parallel to each other. We control the coincidence of the diagonals.

We prepare the building site, make the markings on the ground according to the plan. We mark the perimeter of the future foundation with pegs. We stretch the rope between the timber and check that the opposite sides are parallel to each other. We control the coincidence of the diagonals.

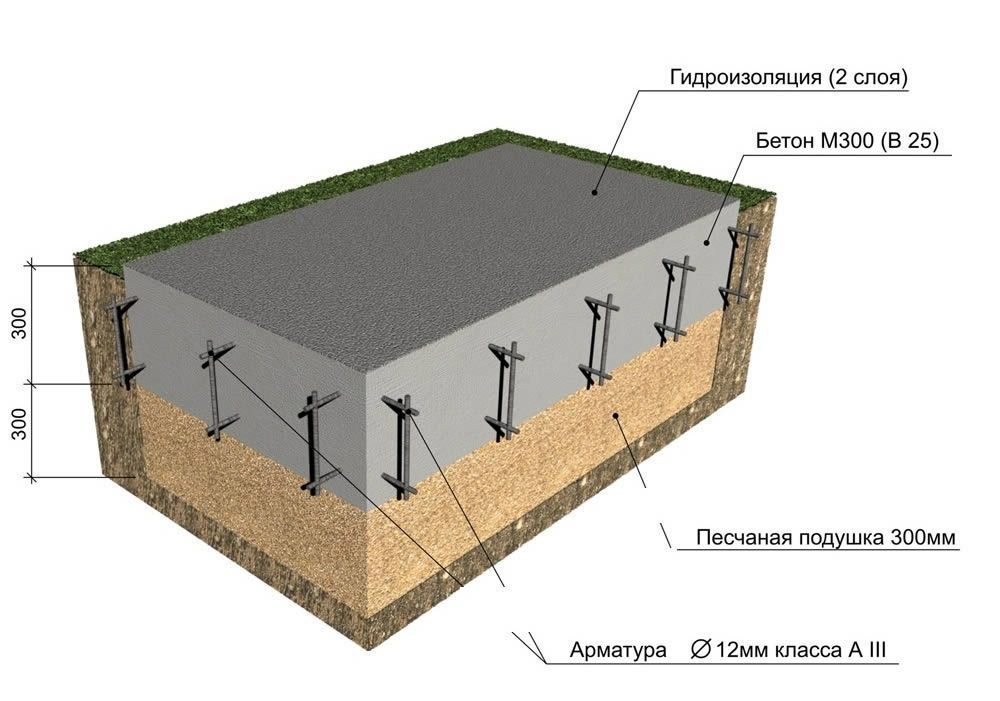

We dig a foundation pit up to 50 cm deep for construction without a basement. We align the bottom, check the location in the horizontal plane using a level. With a close location of groundwater, the bottom is covered with a layer of clay, crushed stone, sand of a coarse fraction of 100-200 mm. We compact each layer with high quality.

Along the perimeter of the pit, pipes for the drainage branch are equipped, and the places for carrying out communications are provided.

Geotextiles are laid on a sand pillow

Geotextiles are laid on a sand pillow We cover the well-tamped sand cushion with geotextile so that it protrudes at least 1 m on each side.Fill with a thin layer of concrete mortar (up to 70 mm) to create a dense, even base under the monolithic slab.

When the concrete is dry (2-4 weeks), a waterproofing layer is laid. As a cheap material, you can use dense polyethylene or arrange penetrating insulation.

In order to insulate housing construction as much as possible, we lay a layer of dense polystyrene 10 cm thick.

Reinforcement

Rows of reinforcement are laid perpendicularly

Rows of reinforcement are laid perpendicularly The diameter of the rod used depends on the dimensions of the slab. If it is less than 3 m in length, horizontally lay a steel bar with a cross section of 10 mm; for vertical reinforcement, we use material with a diameter of 6 mm or more.

We lay the rows perpendicular to each other. The size of metal cells should be no more than 100 mm. The optimal diameter of reinforcement for one-story houses is considered to be 16 mm. The rod is used smooth and ribbed.

For the construction of the foundation for multi-storey buildings, we use reinforcement with a diameter of 40 mm. According to the standard, the plate is reinforced at the ends with a U-shaped steel profile.

In places of the greatest load from the supporting structures, the reinforcement step is halved. High-quality reinforcement includes a bunch of wall frame and slab base.

Pouring the slab requires the installation of the formwork. As a removable form, a board and a bar are most often used, as a non-removable form - expanded polystyrene, which simultaneously performs the function of insulation. For more details on the process, see this video:

It is preliminarily required to make auxiliary structures through which the concrete solution will be supplied.

Concrete pouring must be continuous

Concrete pouring must be continuous The best option is to pour the base using a concrete pump. To obtain a reliable base, the solution must be poured continuously and evenly. To prevent the reinforcement from corroding, it must be completely covered with concrete. When the area is filled with mortar, it is compacted with a vibrator or punctured to expel air bubbles.

To prevent the slab from cracking during drying, we regularly moisten it and cover it with plastic wrap.

The formwork is removed after the base has completely dried, this time depends on weather conditions and takes about a month.

For the device of a slab base in the northern regions, special mixtures are added to the concrete solution that increase the resistance to temperature extremes. The foundation is made with thickened edges, which serve as stiffeners.

Prefabricated device

The prefabricated reinforced concrete structure is less durable than the monolithic one. Does not require installation of formwork and reinforcement with reinforcement. It is assembled from ready-made reinforced concrete slabs, which are installed with a crane. The distance between them is filled with concrete. For more information about the insulated Swedish plate, see this video:

The durability of the building is due to the high quality of the materials used for the construction of the monolithic slab base. The installation of a medium-sized slab takes about 20 cubic meters of concrete.