Finishing of facades with facing bricks. Smart finishing of facades with bricks and clinker tiles in the Moscow region - Fasadika.

Updated:

2016-08-30Today we want to talk about facing bricks for the facade and show options for finishing a house using these materials. They can significantly transform the appearance of your home, increase its service life, and provide effective protection from external factors. Currently, facing the facade of a house with brick is very popular. After all, facing the facade with brick allows you to make drastic changes without major work. A high-quality brick facade breathes new life into buildings.

Types of facing bricks

When choosing facing bricks for the facade, the consultant is obliged to show you the finishing options. Facade facing bricks are offered in a fairly wide range. Facade bricks presented on the market of facade finishing materials today have several varieties. Presented facades brick house The photos already look great. In fact, everything looks even better. We want to show and talk about the most popular options that can complement the facade of your home with beauty and reliability. Plus, we’ll touch on the topic of laying facade bricks if you want to change the facade of the house yourself. You can finish houses using facing bricks or use decorative brick. Although in our time, brick façade finishing is no less in demand. The advantage is that a brick-clad façade looks great and costs less.

Work on finishing the facade of houses using facade bricks is carried out from the following types of material.

- Sand-lime bricks. The most affordable, easy-to-manufacture options for facade bricks. At the same time, the material is characterized by excellent thermal insulation characteristics, protects the house from external influences. Sand-lime bricks are widely represented on the market of facade materials, do not require complex finishing operations, and are a budget solution.

- Hyper-pressed. Their distinguishing feature- this is excellent strength, a low percentage of water absorption, which is no more than 6 percent, and resistance to temperature changes and frost. These characteristics are determined by the components that make up the hyperpressed brick for façade finishing. It consists of shell rock and limestone. Offered in a wide range, differing in color and shape. This finish allows you to transform appearance at home, get away from the usual appearance of a building with brickwork.

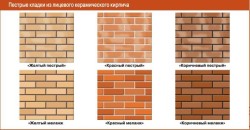

- Ceramic. The most stylish, attractive version of brick, presented in a huge assortment. Ceramic facing bricks for facades are divided into solid and hollow. All options are resistant to temperatures, not afraid sun rays, open flame, weakly absorb moisture. The surface is matte or glazed. The only partial drawback is that ceramic facade bricks are only made in various shades of brown or orange. The material is not presented in more original colors. The current price of clinker is from 15 rubles per piece.

Masonry options

How attractive is a facade made from one of the materials presented above? It all depends on the finishing procedure and the quality of the work performed.

The original masonry is here effective method make every 1m2 of material incredibly attractive on the walls of your home. Today experts advise choosing one of the following masonry options.

- Laying the path. The classic technology for installing facade bricks, where only the long sides of the material face the outside. Each top row has a certain offset of about half a block relative to the bottom;

- Block masonry. Here there is an alternation of long and short sides of the brick. Some joints coincide along the entire height;

- Cross. As with block masonry, short and long sides alternate. But the joints do not match. Every three rows are made so that the long part of the material in the central row creates a horizontal element of the cross, and the upper and bottom rows— vertical;

- Gothic. Short and long parts alternate not one after another. Each top row is offset from the bottom row by 1/2 of a short piece of material. This way, no joints are created between the long sides of the façade brick.

In fact, the list of masonry methods can be listed for quite a long time. There are a huge variety of them, so the choice should be made based on your own preferences, experience, and design features of the house. Some laying work is difficult for a beginner to carry out, so finishing is carried out using the simplest masonry options.

Brick requirements

When choosing facing bricks for the facade of your house, the finishing must meet certain requirements. There are various options on the market. But if price is not the main criterion for you, you will be able to competently consider all the types of materials presented, cut off unnecessary ones and purchase the optimal facade finishing.

So what requirements must a brick facade and the material used for work meet?

- High strength indicators. Choose bricks for which this parameter is 150-250 kg/cm2. Such material will be able to withstand impressive loads from the upper rows, thereby ensuring long service life for the exterior decoration of the house.

- Frost resistance. Frost resistance is an important selection criterion due to our climatic conditions. Nice brick must withstand at least 50 cycles of freezing and thawing, maintaining its external characteristics, strength, and structure.

- Water absorption. If the facade material absorbs a large amount of moisture and water, this will negatively affect the condition of the walls and foundation. Therefore, when choosing facade material for finishing the external walls of the house, make sure that the water absorption coefficient is no more than 13 percent.

- Color preservation. There are a number of materials that provide a superior appearance when finishing your home. But over time, the facade loses its attractiveness, which is due to the fading of the finish under the influence of sunlight and atmospheric phenomena. Facade bricks of the presented types perfectly resist exposure to the sun, without losing their attractiveness throughout almost their entire service life.

In many ways, the quality of facade bricks depends on the manufacturer. It is recommended to purchase material through trusted suppliers, company stores, and factory representative offices. This way you minimize the risk of getting a fake or low-quality product.

Insulation

To ensure that the work gives a more effective result, and not just an attractive appearance for the houses, a special technology for installing bricks is used. It requires the presence of a layer of insulation.

But what kind of insulation is suitable when finishing houses using facade bricks? There are several options:

- Minvata. Mineral wool widely used for working with facade facing bricks. She is able to maintain her performance characteristics within 10 years. Low cost, easy installation;

- Polyurethane foam. Perfectly combines affordable price and efficient operating parameters. External walls are sprayed, which provides reliable protection from moisture, cold, and mechanical influences;

- Styrofoam. Very light cheap material, which even a beginner can handle installing.

Each of the presented types of insulation perfectly copes with the role of an auxiliary layer under the facing facade brick. You won’t need to spend a lot of extra money on insulation, which once again proves that facade brick has an impressive list of advantages as a facing material for the exterior walls of a house. Lined facades one-story houses, brick facades of private buildings and imitation brick have their undeniable advantages. Looking at the photos of facades, you understand why many choose these particular cladding options. But photography cannot show everything. Therefore, if you want to cladding a brick house, first consult with specialists. Each facing brick must be selected competently and consistently, so as not to waste money.

Do not forget that façade technology brickwork requires the presence of ventilation gaps and openings. This allows you to maintain an optimal temperature between the cladding layer and the wall of your home. For ventilation, it is necessary to leave several rows of vertical seams without cement mortar, as well as create vents at the bottom and top of the cladding.

The facade is the calling card for every building, so it should look bright, beautiful and unusual. In addition, the front part ensures the wear and tear of the building, as well as comfortable indoor conditions. For this reason, it is important to especially carefully consider its cladding, and the façade facing brick, the options of which will be described below, has become Lately very popular. This cladding not only helps to improve the design of the house, but also protects it from external negative influences.

Facing brick for the facade has advantages and disadvantages. Among the positive qualities of a brick facade, it is worth highlighting the following characteristics:

- cladding face brick provides protection of buildings from the effects of precipitation, especially for wooden private houses, cottages and other outbuildings;

- this cladding gives a rich, monumental appearance. Makes the design richer and more unusual;

- provides additional protection of walls from destruction;

- If insulation is placed in the space between the walls and the brick, the insulation properties increase many times over. The brick retains all thermal properties indoors;

- low moisture permeability - there are types on sale that are intended specifically for cladding the facades of houses, the level of moisture permeability of which is only 14%;

- is not subject to constant sudden changes in temperature. Cladding material outside buildings have increased resistance to frost. It can easily withstand more than 50 winters without changing the quality of its structure;

- various shapes and a varied color palette. Some bricks can be used for windows, they match the shapes and complement every part of the structure. And the colors can be different - white, red, yellow and many others;

- increases the service life of the building many times over.

But, despite the presence of positive qualities, there are also negative properties:

- when installing bricks on the facade, additional pressure is observed on the foundation of the house, it begins to sag over time;

- if piles or pillars are used as the base, then after facing the facade with brick, these components simply collapse due to the pressure exerted on them;

- The facades of houses made of brickwork are quite an expensive pleasure, which not everyone can afford.

Types of bricks for facade cladding

Facades brick houses can be made from different materials. The best is brick. He can be different types, colors. In addition, you can find original substitutes for this material on sale; for example, facades made of artificial stone look beautiful. So, what material to choose for cladding the facade of a house? Let's look at popular types.

Classical

This material is also called sand-lime brick. It is often used in construction for the construction of various buildings. In addition, it is often used for cladding the outside of many private houses and windows.

Advantages of this material:

- provides excellent protection of the facade from negative external influences;

- has simple masonry - there are no difficulties during its installation;

- various colors - you can often see facades made of sand-lime brick, which have different colors - from light, from white brick, red brick and so on;

- low cost - this material has a low cost, so it is in high demand.

Hyper-pressed

Hyper-pressed the type is made from a moistened mixture of crushed stone, limestone and cement. Pigments for color are also added to this mixture; this process is carried out under increased pressure. During hyperpressing All elements are soldered at the molecular level, which makes it possible to obtain high strength of the material. The finished material can withstand load levels of up to 250 kg per 1 square meter.

Features of this material:

- hyper-pressed porous material is highly resistant to severe frost;

- increased moisture resistance - this type of brick does not allow liquid to enter the walls during rain or snow;

- has high strength and durability;

- the cost is not too high compared to the excellent qualities of the material;

- a wide range - on sale you can find material that imitates an artificial stone facade.

Modern hyper-pressed products may have unstable colors. The design of buildings made of yellow, red, or brown material looks quite beautiful. These products can also be used for window cladding.

It is worth noting that hyper-pressed material has a smooth surface, which makes it difficult to adhere to other materials. For this reason, the surface of products of this type must be treated with a water-repellent solution.

Ceramic

Ceramic finishing material is considered the most expensive, and it also poses certain difficulties during installation. But despite the fact that it belongs to the decorative varieties of stone, it is able to withstand loads of up to 150-200 kilograms per 1 square meter.

Positive qualities of the material:

- long service life - this material can last more than 20 years;

- has increased resistance to moisture, sunlight, and temperature changes. In addition, it does not collapse or fade;

- has a strong structure;

- The appearance design of ceramic bricks is attractive, so it is often used to decorate the exterior of a home;

- does not require increased care - in order to wash off all the dirt, just rinse everything with water from a hose.

Ceramic type material is available with various forms and surfaces – smooth, rough, wavy, even. It can be used for cladding wooden walls, as well as for decorating windows.

Clinker

Clinker bricks for facades are a type of material for construction and finishing. The strength of clinker finishing has long been proven by many European houses that were built several centuries ago.

It is worth highlighting the main advantages of this material:

- Due to the fact that during the production of this material traditional firing of clay bricks is used, its strength and wear are increased. 1 square meter of this material can withstand a load of almost 400 kg;

- high frost resistance, the material can withstand frosts down to – 150 degrees Celsius. For this reason, clinker brick cladding is used in northern regions with cold climates;

- has high moisture resistance - wall decoration made of this material can withstand heavy rains, snow and other precipitation;

- clinker material has a variety of textures, different color solutions, which allows it to be used for cladding walls with various architectural styles.

However, this imitation of brick has a very significant drawback - its high cost. Its cost is sometimes almost twice that of ceramic material.

Color scheme and choice of material shape

It's not enough to choose required material To cladding the facade, you need to select the appropriate shape and color of the brick. In this case, you can use tips on choosing this material:

- All products must be even. It is undesirable for them to have chips, otherwise the entire geometry of the structure will be disrupted;

- for a perfectly flat wall surface, you should use thin bricks that look like ceramic tiles;

- Some types of products may have unusual shapes that can be used for window cladding. Unusual shapes bricks will make the window more expressive and unusual;

- buildings can be faced with materials of different colors. The buildings made of red, white, brown brick. Also, yellow brick houses will become a bright decoration of your yard. Typically, for yellow brick houses, sand-lime brick cladding is used, which is painted. A cottage made of material with a red or brown color looks beautiful.

Painting brick facades

Painting walls with cladding is done to vary the appearance, as well as to protect against further damage. The paint protects against moisture, sunlight, frost and severe temperature changes.

When painting walls with cladding, you should adhere to the following important requirements:

- after the construction of the walls, at least 1 year must pass, after which work on the arrangement of the facade is carried out - cladding and painting;

- before painting the surface of the masonry, it should be cleaned of mold and fungal infections;

- after this, the wall should be rinsed with soapy water and dried for about a day;

- then the surface of the wall is treated with a primer mixture;

- at the end the wall is covered with paint. It is worth remembering that the paint must be vapor permeable.

Carrying out external finishing of the facade of brick houses, as a rule, is the final stage of all completed construction work. Facing allows you to give a finished and most neat look.

Carrying out external finishing of the facade of brick houses, as a rule, is the final stage of all completed construction work. Facing allows you to give a finished and most neat look.

This type of brick is weather-resistant, frost-resistant and has a decent appearance. Finishing a building built from facing or finishing bricks most often consists of decorating window slopes and doorways, as well as plastering or cladding the basement of the building.

Features of finishing a brick building

If simple brick was used in the construction of the house, then the facade of such a structure will definitely need exterior finishing. Not only is the appearance of such a building unattractive and unpresentable, but also quality characteristics leave much to be desired.

Houses built using sand-lime brick require the most attention. This type building material It is absolutely not suitable for outdoor work, due to its high ability to absorb excess moisture.

The most common option for finishing a house made of building or sand-lime brick is plastering the facade followed by painting. In addition, plastering the facade of a house can be quite easily combined with other finishing options, using, for example, natural or fake diamond, as well as porcelain stoneware or other modern finishing materials.

Decorative finishing options

The brick facade is almost ideal for finishing. For cladding the facade of a brick house, you can use a variety of options:

- any ;

- decorative;

- corrugated sheeting;

- sandwich panels.

Decorative plaster

Regardless of the type of façade surface and the type of material used to construct the walls, the technology for finishing with plaster is almost the same in all cases. However, you should remember some nuances:

- The facade of a building based on brickwork must be cleaned before finishing;

- before applying the plaster solution, it is necessary to moisten the surfaces of the walls using a spray bottle or a wide paint brush;

- all seams located between the bricks in the masonry should be cut out, maintaining a depth of one and a half centimeters, which will make the adhesion of the plaster layer to the base as reliable and high-quality as possible;

- if a thick layer of plaster is intended to be applied, then special guides in the form of beacons must be leveled;

- application decorative plaster is performed using standard technology, and the plaster layer is leveled from bottom to top using a special plaster rule;

- finishing plaster should be applied only after the main plaster layer has completely dried.

Things to remember: In order to obtain the highest quality adhesion of the plaster mixture to the wall surface, you should use a special plaster mesh. Such a mesh should be placed on top of the wall being treated and secured with dowels.

Ventilated facades

Quite often the need to produce exterior finishing associated with construction work. Such work is usually carried out on old buildings. However, recently, owners of new buildings also often carry out external insulation of houses with subsequent finishing.

If you plan to perform external insulation, then any version of sheet insulation should be strengthened on the wall surface. As a further finishing, plastering of the walls using a reinforcing mesh or a so-called device can be used.

The materials for creating ventilated facades are:

- façade cassettes;

- composite;

- porcelain stoneware;

- profiled flooring.

Insulation of the facade of a brick house (video)

Facing brick

Modern high-quality brick is not only an ideal material for capital construction, but is also widely used for finishing building facades. Stylish and bright facades based on facing bricks are characterized by beauty and durability.

This façade finishing is easy to install and reliable, and is also characterized by a high degree of resistance to moisture and mechanical impact. In many respects, facing bricks are superior to similar materials.

Currently, several types of facing bricks are produced, which differ not only in composition, but also in size and shape.

Hyperpressed facing brick

This type of brick is one of the leaders among materials for finishing brick buildings. A variety of shapes and a wide range of colors can satisfy the most demanding consumers.

Semi-dry bricks are used as raw materials in the manufacture of this type of brick. cement mixtures, as well as limestone and crushed stone rocks. When the feedstock is exposed to high pressure, it is possible to produce a kind of “welding” of all the components.

As a result, it is formed finishing material, with high levels of strength and reliability. The smooth version of this brick has dimensions of 25 x 12 x 6.5 cm. Facing bricks with a stone texture may be slightly shorter. In addition, “American” bricks with dimensions of 25 x 6 x 6.5 cm are popular.

Ceramic facing brick

The technological process for creating bricks of this type is much more complicated and is characterized by large time and energy costs, including very precise compliance temperature conditions during the firing process. Ceramic brick has internal voids or through holes, which lighten the weight of the structure and give the cladding additional heat-insulating qualities. The shapes and sizes of such voids vary.

Finishing brick facade can be varied: from plastering to facing with the appropriate type of brick. Its implementation is the final stage of all construction work, as well as external insulation work. Finishing provides the building with an attractive and aesthetic appearance.

Covering a brick house with siding (video)

![]()

What other façade work do you carry out?

In addition to wall work, we do terraces, canopies, fences, soffits, façade electrical, gutters, and anything related to the exterior of the house.

I need to complete the box at home

No. We only take on a house if it already has walls and a roof.

I need to make a terrace.

Yes. From general construction works we do terraces, winter gardens, entrance groups and awnings.

What's included in the price?

The price includes everything that will happen after the conclusion of the contract. Site visits - depending on the distance and complexity of the starting work (inspection of the house and territory, condition assessment, photographic recording of facades and their details, consultation on possible finishing materials, measurements, tool-free inspection of the house - from 2500 to 11000 rubles. Detailed calculation with selection materials, and price marketing - from RUB 5,000 to RUB 30,000. Remote consultations, assistance in drawing up technical specifications, preliminary cost estimates are free.

What is the payment scheme?

Payment in stages. The cost of work is divided into parts of 300-400 thousand rubles. taking into account individual stages. The purchase of materials in money is most often obtained according to the scheme 40% + 40% + 20% during the period of work.

What materials do you work with?

We have developments for different budgets with partner discounts. For example, QuickMix, Ceresit, Murexin, Knauf, Nichiha, Konoshima. These materials can be obtained at a price lower than the market price. We also work with any materials you are confident in.

How long does it take to finish the façade?

2-3 months. The deadlines are shorter if you have new house for finishing. Longer if you need to dismantle the old finish, repair the facade or strengthen the foundation.

What affects the cost?

Material load-bearing structure walls. Foundation structure and soil geology (the foundation can be movable). Number of style elements of the facade (stucco, fencing). Terraced areas. Window shape. Number of storeys. Configuration of architectural volumes and roofing. Remoteness of the object. And, of course, the type of finish you like.

Which insulation is better?

Conventionally, we can say that it is mineral. The choice of mineral insulation is extensive; you need to carefully select it in each case. In addition, in specific cases everything happens differently. For example, it is better to insulate foundations with extruded polystyrene - it does not absorb moisture. And there is also glass wool, polyurethane foam and many other exotic options. If you haven’t decided yet, we’ll help you choose the best one.