Facing brick indoors. Decorative facing bricks: types, application in the interior, installation rules

Despite the wide variety of finishing materials, decorative brick wall decoration is very popular today.

There are different designs and colors. The materials for its manufacture are also different.

What are decorative bricks for interior decoration? This is a material that is one of the varieties artificial stone.

It is made from:

- Plaster.

- Ceramics.

- Porcelain tiles.

- Acrylic and synthetic substance.

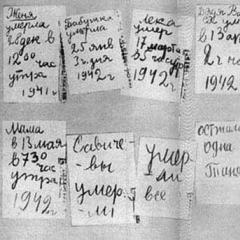

The photo shows examples of various color designs, including:

- White and red (standard shades).

- Brown with sand.

- Red with brown.

- White with sand or gray and so on.

Note.

Today, room design has become fashionable decorative brick aged, for interior decoration. It is used in antique stylistic directions of the interior.

Gypsum decorative brick

Brick for interior decoration made of gypsum is the most affordable material; it is made quite simply.

Material pretty:

- Practical.

- Reliable.

- Long lasting.

- Has a large selection of designs and sizes.

- It is not subject to deformation under the influence of temperature changes.

Note.

This cannot be said to be moisture resistant. Its surface does not absorb moisture only if it is covered with a layer of a special protective agent or varnish.

There are several options for gypsum brick surfaces:

- Matte (has no shine and is usually treated with a protective substance).

- Glossy with a sheen, varnished.

- Ragged, which does not have a flat top.

- Embossed.

- Convex or concave.

Characteristics:

- As for the sizes, they come in a variety of sizes and can reach the size of a standard double brick.

- The main advantage of this type of decorative brick is its price, which is several times lower compared to ceramic material.

There is another plus, this is self-production.

Production of gypsum decorative bricks

It is quite simple to make. There are certain instructions according to which all actions are carried out.

In order to make such a brick with your own hands you will need:

- Gypsum dough.

- Special shapes of different sizes.

- Mold lubricant.

- Hardener for gypsum mortar.

- Coloring pigments of the required shade.

Stages:

- Initially, gypsum dough is prepared, which is sold in bulk form. A certain amount of warm liquid is poured into the container and powder is gradually poured into it, which must be constantly stirred.

- You can use a construction mixer for such work; it will only speed up the process and save time.

- If you need a brick of a certain shade of one color range, then coloring pigments are added to this gypsum solution.

Advice. In order for there to be colored stains on the surface of the gypsum brick, the pigment is simply poured into the solution, but not thoroughly mixed. Glimpses of it should be visible in the solution itself.

- Or you can do it another way: after pouring the gypsum dough into well-greased special molds, pour the pigment directly into it and spend a little time in the solution with a wooden stick. This method has long been known to all masters.

- After the solution is poured into the molds, it needs to be allowed to stand for a while. As a rule, such a period will not take more than one day.

Then, using a rubber hammer, the finished gypsum bricks are removed.

Advice. It would be best to immediately coat them with varnish to protect the surface before installing the material.

Under brick using gypsum stone is becoming more and more popular every day. This is due not only to the low cost of the material, but also to its attractive appearance and ease of installation, since gypsum stone does not have much weight.

Ceramic decorative brick and its properties

Decorative ceramic bricks have been used for interior decoration for quite some time. He became the founder of the production of such finishing material.

All its properties are similar to ordinary ceramic tiles, which are used in finishing kitchen and sanitary areas.

He:

- Durable and reliable.

- Practical and durable.

- Does not absorb moisture and dirt.

- Does not deform under heavy loads.

- Able to withstand significant temperature changes.

- Frost-resistant, which makes it possible to use it not only in interior, but also in exterior work.

On the back side it has a perfectly flat surface, and on the other side it can be:

- Matte.

- Glazed.

- Embossed.

- Concave and convex.

Note. There are practically no torn external surfaces on ceramic bricks.

Porcelain stoneware decorative bricks for interior decoration

Porcelain stoneware decorative bricks for interior decoration are particularly durable. It's all in the process of making them.

If ceramic is produced using clay dough, which is exposed to high temperatures once or twice.

The material is made from:

- Clay dough.

- Granite chips.

- Binding solution.

Note. Porcelain tiles are also double fired, making them very durable.

Decorative artificial brick for interior decoration made of porcelain stoneware:

- Moisture resistant.

- Frost-resistant.

- Withstands temperature changes.

- Its surface does not absorb dirt, as it is coated with a protective agent.

- Easy to clean with a cleaning agent.

- Has a wide range of colors.

- There are different sizes of this material.

Peculiarities:

- It is also worth considering if you use porcelain stoneware bricks for exterior finishing, then it will not burn out and lose its original appearance.

- The average service life is at least 30-40 years.

Note.

It is used in the interior of the kitchen area, dining room, bathroom, hallway and other rooms. Due to its durability, it is often used as a floor covering.

Installation of decorative bricks

Decorative finishing with brick or ceramics begins with preparatory work on a surface. It should be smooth and clean.

Surface preparation: leveling and cleaning

Surface leveling can be done using this moment using a universal material - drywall.

There are different types:

- Wall.

- Ceiling.

Attention! Gypsum plasterboard of one type or another must be used strictly for its intended purpose.

It is mounted on a profile frame made of thin metal; for such actions you will need:

- Metal profiles.

- Self-tapping screws for metal.

- Screwdriver.

- Dowels.

- Hammer.

- Building level.

- A hacksaw or grinder for cutting the profile to the desired size.

Stages:

- The frame is assembled directly on the surface. To do this, the main guides are mounted on the surface using dowels.

Auxiliary profiles are attached to them, which form the cells of the frame. - On metal carcass Drywall sheets are mounted using self-tapping screws. This must be done very carefully so as not to damage the gypsum dough inside the material.

- The joints of the sheets are treated with putty and, after drying, with sandpaper.

- You can level the surface using plaster. But such a process is longer and more labor-intensive.

At the moment it is used quite rarely. The video shows the range of work with plaster and the tools used. - If the surface is smooth, then it will need to be thoroughly checked for defects. To do this, tap it with a rubber hammer or just with your hand.

If there are gaps in the plaster from the surface, they must be eliminated and the solution must be applied to these places again. If there is no plaster, then you can use putty.

The principle of its application is similar, only it dries faster. After this, you need to sand all places with sandpaper.

Advice. To ensure the strength of the finishing work, it is necessary to prime the surface with a special solution.

- If the surface has been painted, it will be difficult to attach decorative bricks to it. In order to facilitate the entire process of work, you need to use a hammer to make shallow holes in it, into which the cement or adhesive mortar will go and thereby provide a bond.

You can remove the painted layer using special means. them on today there are a large number.

After this, the surface is thoroughly washed and dried and only then primed.

The process of installing decorative bricks on the surface

Decorative brick finishing is done using:

- Cement or adhesive mortar.

- Level.

- Cross-shaped beacons.

- Tile cutter.

- Tape measures or rulers.

Installation:

- The cement mortar is prepared independently. This requires sand, water and cement.

It is advisable to use grade 400 cement, which has high strength after setting. - A tile cutter is used to cut to the desired size. Here you should follow safety standards and wear a protective mask when cutting the material.

- The adhesive solution is sold dry and liquid is added to give it a certain consistency.

Advice. Before such actions, you must carefully read the instructions on the package. In some products, not cold, but warm water is added.

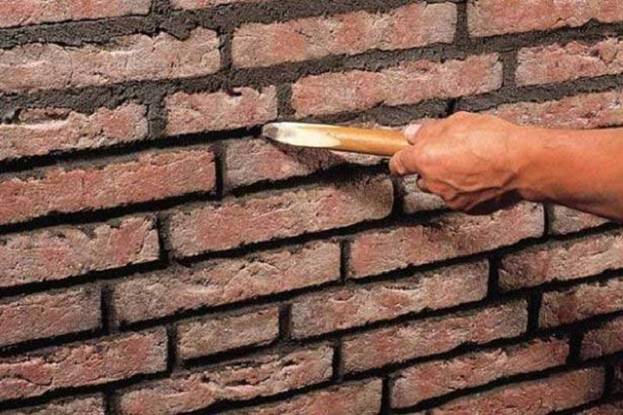

- The solution is applied to the surface and back side material using wavy movements using a special spatula. A uniform distance between each finishing element is ensured by cross-shaped beacons.

- After installation, all seams are treated with decorative putty. To avoid this, in glue or cement mortar Coloring pigments are added and thoroughly mixed with a construction mixer.

Decorative brick finishing in its principle and action is reminiscent of laying tiles on the surface. Each element is checked and leveled before fastening.

There is nothing complicated in the work and you can do it yourself.

Brickwork fills absolutely any interior with luxury, presentability and sophistication. That is why many apartment owners strive to use this decor in creating the design of their own homes. However, due to various circumstances, not everyone can afford to use natural brick and stone. Taking this fact into account, manufacturers began to produce artificial bricks, which made it possible to create an imitation of real masonry even in budget interiors.

Let's look at what types of this material can be found on the construction market, what are the features of each of them and what options are suitable for interior decoration.

Artificial brick: main varieties

Such finishing materials are made from a variety of raw materials, so each variety has its own characteristics. Some are made in the form of smooth and hard tiles, others are characterized by excellent flexibility, and others are made in the form of a large wall panel that covers most of the surface at once.

Artificial decorative bricks come in the following types:

Flexible tiles;

Plaster products;

Cement facing tiles;

Clinker brick;

MDF and PVC panels;

Fiberglass and cement panels.

To understand the advantages and disadvantages of each option, let’s look at all the products in more detail.

Flexible brick imitation

Artificial brick in the form of flexible tiles is suitable for cladding both internal and external surfaces. This innovative material, which appeared on the market not so long ago, has a number of positive features:

Has excellent decorative abilities;

Reliably protects walls from external factors;

Resistant to mechanical damage;

Characterized by good vapor permeability;

Available in a wide range of colors;

Not susceptible to colonization by bacteria and fungi;

UV resistant;

Quite easy to install.

Flexible tiles are ideal for covering uneven surfaces, as they easily bend around all external and internal corners premises. Artificial brick (of this variety) can be used as a finishing material for wall cladding in any room.

It is ideal for decorating round columns, fireplaces and various interior items of complex geometry. This cladding does not create additional load on the walls, which is why it is often used for finishing plasterboard structures.

The material is fixed to the surface using ordinary tile adhesive.

Gypsum facing brick

Artificial facing brick made of gypsum is considered the most economical option for creating an imitation

During its production, the cement-gypsum solution is poured into special relief molds, in which it remains until it hardens completely. After the bricks have completely hardened, they are carefully removed from the mold and dried.

The resulting product is quite beautiful, but fragile. However, it is quite suitable for cladding internal surfaces. Another disadvantage of gypsum brick is its high hygroscopicity, which does not allow its use in rooms with high humidity levels.

The light weight of the product makes the installation process quite easy, but in order for the tile to stay on the surface as long as possible, only gypsum-based glue should be used to fix it.

Cement facing brick

Artificial facing bricks made from cement are especially popular today because they are characterized by a huge variety of colors, textures and reasonable prices. In addition, the material is quite resistant to sudden temperature changes and can be used even in unheated rooms and rooms with high humidity.

This brick is made from a solution of Portland cement and sand. It is poured into silicone molds, where it hardens. Finished products are endowed with various shades and repeat the texture of natural stone.

Clinker brick

Artificial decorative brick made of clay is used in the interior much less frequently than its previous analogues, since in comparison with them it has a higher price tag. Excellent performance characteristics and resistance to external factors have made clinker tiles more popular in facade decoration. However, when it comes to decorative finishing of fireplaces and stoves, this imitation brick is considered the best option.

Artificial stone (brick) is made from highly plastic clay without any impurities, dyes or plasticizers, which allows us to talk about the absolute environmental friendliness of the material. The raw materials are pressed and fired at high temperatures, which gives the stone unsurpassed strength and durability. The resulting product is characterized by the following qualities:

High degree of wear resistance;

Resistance to low temperatures;

Fire safety;

Resistant to moisture and chemical influences.

The variety of textures allows the use of similar finishes in different styles interior design. It can have a completely flat, smooth, rough, glazed and untreated surface. The sizes and shapes of the elements are also very diverse, making this finish compatible with many finishing materials.

under brickwork

Artificial bricks for interior decoration in the form of panels are in great demand today.

This material can be made from a variety of raw materials, but the most common options are polyvinyl chloride and wood-fiber boards (PVC and MDF). The panels attract consumers due to their large size, which significantly reduces repair time.

It is also important that the material is quite simple to work with. Thanks to its light weight, it is easy to transport and mount on the wall. The panel is cut using a jigsaw or a regular construction knife.

To the positive features of wall decorative panels include the fact that before installation there is no need to level the surface. The product easily hides flaws, cracks, gouges and other defects in the base, and if they are installed on a pre-equipped frame, pipes, wires and other communications can be hidden behind them.

The color range of the panels is very diverse, while imitation bricks can have the most unusual and attractive textures.

With all the advantages of wall panels, they have one significant drawback - the inability to use on round and uneven surfaces.

Imitation brick made of glass fiber reinforced concrete

This type of artificial brick is made from cement to which glass fibers are added. The last component increases the strength of the cement product several times. The tile contains exclusively natural ingredients, which makes it safe for the environment.

Artificial brick for interior wall decoration with the addition of fiberglass reliably protects walls from moisture penetration, mechanical damage and radio emissions. The material is great for decoration interior walls, but is also quite often used in the exterior decoration of buildings. Its only drawback is its high cost, so not every homeowner can afford such decor.

Conclusion

Based on all the information above, we can conclude that modern manufacturers of finishing materials offer us a wide variety of products for decorating surfaces. brickwork. The quality of some options is so poor high level that even at close range it is difficult to distinguish the product from real brick or stone.

A wide variety of designs, reliefs, sizes of tiles and panels allows you to bring to life the most daring projects and choose the most suitable artificial brick for your interior. Photos of some surface finishing options can be seen in this article, which will help you get a general impression of each material.

To give the premises of a home comfort and a unique appearance, many finishing materials have now been invented, such as plaster, wallpaper, various kinds of panels and other types of wall coverings. But what to do if the interior involves the presence of brickwork in the design? For these purposes, there is decorative brick, which will help to accurately imitate the masonry inside the house, without putting a large load on the load-bearing capacity of the walls. In this article we will highlight the types of decorative bricks for interior decoration, their features, as well as the rules for installing the coating.

Assortment of decorative bricks

In all the variety of finishing materials, decorative brick is most often used to imitate real brickwork. This is due to its natural appearance and a large selection of existing material designs.

Manufacturers offer several options for decorative bricks. Previously there were much fewer of them, but now this list has expanded significantly. Each variety has its own characteristics and characteristics. Moreover, the elements can be both rigid and flexible.

Flexible tiles

This imitation of brickwork is perfect for both interior and exterior decoration. This material is not only beautiful in appearance, but also has a mass positive characteristics, including vapor permeability, resistance to various types of influences, including biological ones, ease of installation and maintenance with your own hands, as well as immunity to changes due to ultraviolet radiation.

Important! Using flexible bricks, you can decorate not only straight surfaces, but also create corners and roundness in the interior.

This cladding will look appropriate both on walls and as a decoration for fireplaces, columns and other architectural forms. Moreover, the design does not depend on the shape of the surface, as mentioned earlier, which makes the work as simple and convenient as possible.

The tiles can be attached to the wall with glue in a single color or combined several colors at once. Manufacturers offer many shades of this finishing material, so choosing the right one will not be difficult.

Hard tiles

This material is obtained from several solutions. It can be made from gypsum, clay, cement with the addition of plasticizers, dyes and special additives. Laying such tiles on the wall is as easy as flexible ones, but we’ll talk about that later. Now we will give a description of each of the options for such facing material.

Gypsum brick

This decorative material is the most affordable both in terms of range and cost. Decorative gypsum brick is lightweight, which makes it easy to attach it to the wall using gypsum-based adhesive. The tile does not have protective coating, therefore, such cladding is not used in rooms with high humidity to avoid water absorption.

But there is a more expensive decorative brick made of gypsum with a moisture-repellent coating and special additives to reduce hygroscopicity. It is successfully used as decoration for bathrooms and even the facade of a house.

It is very convenient that such tiles are produced not only in a straight version, but with the presence of corner elements. They help make brick areas look neater and protect them from chipping.

To decorate walls with such decorative bricks, you will need not only the material itself and the adhesive composition, but also a special grout to process the seams and create a single sealed surface.

Gypsum decor on its surface can be:

- matte, that is, one that has no shine.

- glossy, with an even beautiful shine. In this case, the gypsum is coated with varnish, due to which this shine appears.

- torn, characterized by an uneven surface with an asymmetrical arrangement of chips and corners.

- relief, which is a surface with different relief.

- concave or convex, which is represented by unusual shapes surfaces.

This material is very easy to do with your own hands, thanks to which you can save a lot.

Decorative cement brick

Cement brick tiles have many advantages, including a variety of assortments, low cost, and resistance to temperature changes, so the tiles can be used even in unheated rooms in winter.

To make such a brick design, tiles are created from Portland cement and sand diluted with water. Typically used brands are M400 and M500. You can make this decorative material yourself if you have ready-made molds for pouring. To do this, the solution is poured into molds and left there until it hardens completely. It can be given a tint immediately by adding dye, or painted after installation on the wall.

Clinker tiles

This type of decorative brick is more suitable for exterior decoration, but sometimes it is also used for interior decoration. The tiles are expensive, but their characteristics are quite good.

Important! Clinker tiles will be a good choice for cladding a fireplace or stove.

Clinker tiles are produced from high-quality clays without the use of artificial additives. The already formed material is fired in an oven at a temperature of 1120 degrees until completely hardened. Thanks to this treatment, clinker tiles are an environmentally friendly material with unique technical characteristics, which only multiply during the installation process. This material is resistant to any influences, including low moisture absorption, high wear resistance and frost resistance, and resistance to chemical influences.

Clinker tiles are available in such a variety that you can choose the right design option for finishing your home to suit any interior style. The outer surface can be rough, smooth, glazed or untreated. To reproduce the most daring design ideas, tiles are presented in different shapes and sizes.

Ceramic brick

This version of this material is the founder of the entire production, since the production of decorative bricks began precisely from ceramics. Such bricks are no different from ordinary ceramic tiles, which have been used for many years in a row to cover bathrooms and to construct kitchen backsplashes. Just like gypsum decorative bricks, ceramic ones can have several options for the outer surface. These include matte, glossy, concave or convex effects.

Decorative brick made of porcelain stoneware

The most durable and reliable coating is decorative bricks made of porcelain stoneware. It is no longer possible to make such material yourself, since the technology can only be followed in production conditions.

Unlike ceramic bricks, granite chips are added to this material. Finished elements are double fired in a special oven.

Among the positive properties of this decorative brick are:

- Moisture resistance and frost resistance.

- Elimination of contamination absorption due to the protective layer. Maintenance of this finish will be minimal - wet cleaning with a soft cloth.

- Variety of choices in construction stores.

- Various size options for brick tiles.

Important! The service life of porcelain stoneware bricks, according to the manufacturer, is 30 - 40 years.

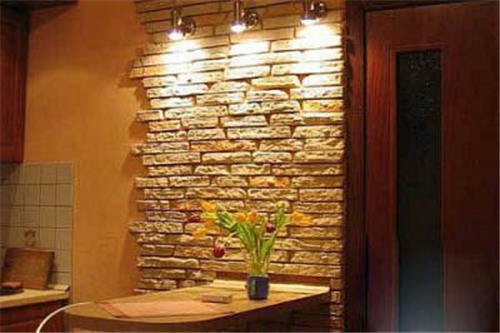

Options for laying decorative bricks for interior decoration on the wall can be seen in the photo:

Self-installation of decorative bricks

The work of laying decorative bricks on walls is similar to each other; there are almost no differences in technology. But there are some nuances regarding the laying of flexible and rigid material.

Installation of flexible bricks

You don’t need complex tools for this DIY finishing. You will only need spatulas - a smooth one designed for mixing the glue and a serrated one for applying it, a level, a ruler, a marking cord, a marker and construction scissors, a brush for leveling the mortar in the seams.

In addition to tools, you will need materials. These are: the tile itself, tile adhesive and primer for preparing the walls.

Before installation begins, the wall is prepared in any case. To do this, its surface is cleaned, leveled and coated with an antiseptic primer. After the surface has dried, you can begin laying decorative bricks.

Important! Work on the interior decoration of walls with decorative bricks can only be carried out at a temperature not lower than +5 degrees, so that the adhesion of the material does not decrease.

Installation of the coating is carried out according to the following algorithm:

Advice! Before starting installation, it is better to remove all the elements from the packages and mix them together to achieve a natural distribution of the shade.

Installation of hard bricks

As mentioned earlier, the finishing work is almost the same as with flexible tiles. But to cut the material you will need a jigsaw or a circular saw.

The difference in finishing lies in the specific placement of the material. A layer of adhesive for hard tiles is needed a little thicker than in the previous case. It will be approximately 3 - 4 mm. Usually, the packaging with brick tiles contains instructions for its installation, and you should follow them.

During the process, you should check how evenly each layer is laid using a building level. To create perfectly even distances between tiles, you can use special calibrators - an analogue of cross-shaped inserts when installing ceramic tiles. After finishing works they are removed.

The main difference is the need to seal the seams after the adhesive has dried. This is done with special grouts using ready-made guns different types or a homemade syringe from plastic bag. The grout must have plasticity in order to completely fill the seams.

Conclusion

Now the construction market presents a variety of materials with which you can create an ideal imitation of brickwork. For the interior decoration of houses, it is possible to choose the cladding that will suit all the characteristics and will be able to create the design that needs to be achieved in the end. Moreover, most of the materials are not expensive, which will help you make modern repairs at minimal cost with your own hands.

An affordable, practical and aesthetic way to decorate the interior is to line the walls with brick. With the help of brickwork, designers add a certain style to the entire room. Decorative material much lighter and thinner than natural, so load-bearing walls there will be no additional load.

Types of decorative bricks

Imitation brick for interior decoration is used not only for cladding the entire room, but also for individual accents that characterize a certain style. The popularity of this decorative masonry is increasing every year due to its unusual texture, corrugated surface, natural lines, and rich color palette. The modern construction market today offers many options for artificial stone. Let's look at the most popular types of decorative bricks for interior decoration.

Clinker

Clinker bricks for interior decoration are baked from refractory clay in high-temperature ovens over 1000 °C. This is an extremely reliable and convenient facing material that does not corrode and does not react to moisture. The service life of clinker bricks is unlimited, and it can only be damaged by physical impact. Decorating a room with this type of material is an expensive pleasure.

To improve the thermal insulation properties, the clinker brick is made hollow inside. As for the tint palette, it is available in a wide range of colors that are easy to choose in accordance with the color of the room. This became possible thanks to the use of different temperature conditions and the special composition of the clay. The average sizes of clinker bricks are from 250*60*60 to 250*65*80.

Gypsum brick for interior decoration

When installing, gypsum decorative bricks for interior decoration are very convenient and the most affordable in price. Its decorative qualities and appearance are almost indistinguishable from expensive analogues. Due to its light weight, the material can be used on any surface, so flexible gypsum finishes are attached to both walls and ceilings. Gypsum brick has the following characteristics:

- resistance to temperature changes;

- a huge selection of colors, sizes, textures;

- durability;

- versatility and practicality.

Low moisture resistance is the only flaw of gypsum, which imposes some restrictions on its use. In rooms with high dampness (baths, saunas, kitchens, bathrooms, showers), gypsum elements are used only after treatment with several layers of varnish or a special protective agent. The gypsum becomes denser because the porous holes close, and moisture can no longer penetrate into the material.

Wall decoration with porcelain stoneware

Porcelain stoneware bricks are made from a clay mixture to which a special binding solution and a certain amount of granite chips are added. The formed elements are then exposed to very high temperatures twice, after which they gain strength. Porcelain stoneware decorative bricks for interior decoration not only play an artistic role, but also help maintain cleanliness, as they make surfaces easy to care for.

Advantages of ceramic cladding:

- Durability. The service life reaches 40 years.

- Frost resistance. Widely used for unheated rooms.

- Does not deform. Withstands high loads and shifts temperature regime.

- Moisture resistance. It is used for interior decoration even in open spaces (balconies, terraces, loggias).

Construction stores offer different porcelain stoneware surfaces: with a glazed sheen, soft matte finish, uniform relief or natural chips. Such cladding has become a decorative element of many styles, giving status even classic interior. When choosing porcelain stoneware, designers recommend paying attention to natural shades. Particularly popular white brick, which is ideal both on its own and in combination with elements of any color.

Brick-like facing tiles for interior decoration

Decorative brick tiles are made in a mold from several rows of masonry as a whole panel. This type of cladding is made from a polymer mixture or ceramics and is a cheap type of material for interior decoration. One panel 2-3 stones long covers a large area, which saves effort and time during installation. The imitation in this case is incomplete because the elements are too similar to each other.

Laying tiles is carried out using adhesives or screws, and the cost of such interior finishing is affordable for any consumer. Decorative brick panels are very easy to cut, which provides an excellent opportunity to design complex surfaces of joints and corners. The negative qualities of tiles include the fragility of the material during finishing work.

Imitation brick in the interior

When there is brickwork in the room, the interior becomes warm and cozy at home. It is not necessary to lay bricks on the wall for this effect. This is not only inappropriate in an apartment, but also fraught with trouble. Decorative brick in the interior helps to achieve the desired result when creating many modern styles. With its help, arches, niches, columns, partitions can be easily erected, and fireplaces can be lined. Decorative bricks for interior decoration are made much thinner than the original, so they help save space.

In English style

When a large room is made in the English style, brick cladding of all walls is allowed. For a small room it is better to decorate decorative tiles one wall or area. An English-style living room decoration is ideal, especially if there is a fireplace lined with Gothic-style brickwork. The area around the home theater, decorated with individual brick fragments, will look great.

Many people like brickwork in the kitchen interior, especially if it is made in the English style. In this case, the brick should be painted to match the overall design concept. For English style The design is typically done in light colors, so the brickwork is tinted with white or the most natural pigment possible. As a rule, decor is used to decorate the area above the work surface, so clinker material is used that is not susceptible to moisture and temperature changes.

Aged brick

This material has less strength because it was not subjected to high-temperature firing during manufacturing. Aged properties are achieved by adding wood flour to the clay or impregnating it with a special polymer composition. Often this type of decoration can be seen in country style rooms. The peculiarity of the interior is country life, presented as rustic, French Provence, Alpine chalet.

Antique brick fits perfectly into a bedroom or hallway that is designed in a country style. On a plastered wall, a smooth or rough brick area with uneven edges looks stylish when it looks like the plaster has fallen off. Reddish-colored finishes are more often used, but if the room is small, then white aged brick will create the illusion of a large space.

Loft style

The interior of the loft uses rough, brutal brickwork. When decorating, the walls are completely covered to make the style look as realistic as possible. Loft is the absence of divided space, therefore it is used on large areas. The interior decoration harmoniously combines ultra-modern materials (glass, steel) and outdated ones (painted brick, beams, uneven plaster).

Since zoning of space occurs without walls, brickwork is an ideal solution for conditional division residential areas. The brickwork near the head of the bed looks interesting. Moreover, painting can be done in a natural tone or in contrast. Loft perfectly combines the minimalism of high-tech style with the carelessness and lightness of the classics.

Colored brick

Using colored brickwork is the most creative solution for creating stylish interior decoration. Modern technologies brought the process of creating cladding to perfection, producing decorative bricks of different colors and shapes. The design possibilities are expanded by a flat or embossed polymer coating, which is decorated with different patterns. Colored brick is especially relevant for decorating children's rooms and bathrooms.

Video: finishing walls with brickwork