We are building a house ourselves. Construction of country houses: design and installation of basic elements

Services construction companies The number of people promising to build a house is simply off the charts, and buying an apartment without a mortgage is available to only 2-3% of families. What to do and how to provide yourself with housing? if you have country cottage area or a piece of land, it is much more profitable to build a house with your own hands. Naturally, not everyone has experience in such work, and our article will partially introduce you to the basics of construction. About the stages of work, necessary materials And approximate estimate read with us.

Where to start construction?

You can’t just go ahead and build a house; you’ll initially need a project. Ready project You can find it on the Internet or, with minimal experience, work in special computer programs.

Interesting to know! A professional architect will charge about $50/1 sq.m. for the work. m. plan.

The project is necessary not only for planning the architectural form, but also for calculating materials and evenly distributing the load on the foundation. The original project along with the application is submitted to the government agency, because you need to obtain a construction permit. Attached to the project:

1. Calculation of the architectural part with drawings and internal layout.

2. Addition for the engineering part, which includes electricity, sewerage, water supply and heating.

After the approved project and received permission, a trailer is installed on the construction site in which you will spend the night and store your tools. The second step is a fence, which can be quickly erected from the following materials:

1. Picket fence.

2. Profiled sheet.

3. Croaker.

Laying the foundation: types and features

The first step in the actual construction of a house is laying the foundation. Here you need to carefully approach the issue of choice, because a fragile foundation will lead to the slow destruction of the entire structure:

1. For easy summer house A brick foundation is also suitable for greenhouses.

3. Expensive, but monolithic, high-quality foundation is suitable for non-standard houses above the 1st floor.

4. If you want to save money, then your choice is a shallow foundation that is durable.

5. In case of groundwater, make a foundation from asbestos cement pipes. It's designed for the lungs frame houses and greenhouses.

6. Filled strip foundation, suitable for light cottages. It costs much less than a full foundation.

7. For peat “floating” soils, a slab foundation is ideal.

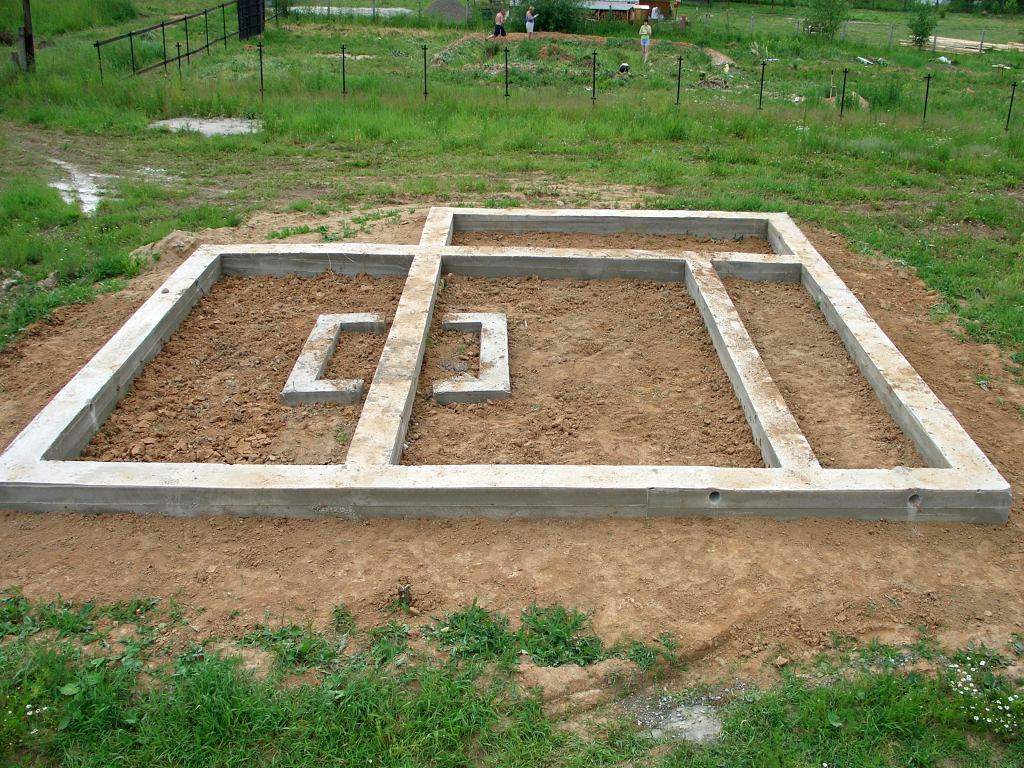

How is the foundation laid?

In do-it-yourself house building, strip, slab, and column are most often used. How to make a strip foundation can be seen in the video.

Laying a slab foundation is difficult and expensive: it is laid on a bulk cushion in such a way that it moves along with the soil. Tape base laid along the lines of the building design, concrete is poured and crushed stone is laid. Strip foundation strong enough, so you can dig a cellar, garage, etc. under an already built house.

The columnar foundation is the lightest, so it is most often used in home construction. But we note that laying the foundation is the most expensive pleasure in building a house, taking up about 20% of the budget.

Advice! The total cost of laying the cheapest foundation (equipment, materials, transportation costs) is about 500 thousand rubles.

An unusual way to build walls

Recognized and popular materials for the construction of walls are bricks and concrete blocks, thanks to which buildings are created “for centuries”. Remember that the wall may not be thick, but in this case you will have to lay a layer of insulation, for example, mineral wool, which will bring additional costs. You can learn how to make a brick house with your own hands from the following video.

So, to install the walls, the foundation layer is covered with roofing felt, building the first level brickwork. The first plinth row reaches 40 cm in height; load-bearing supports are erected at the corners of the masonry with constant level measurements. The supports are installed around the perimeter of the building according to the drawing; make sure that the support does not block the space for the future window or door.

In order to save money, the space between the supports is filled with inexpensive material such as hollow gypsum blocks. You will not lose quality, and the house will be well insulated.

Interesting to know! If, after all, insulation is carried out mineral wool, then you need to place anchors under it in advance (5-6 per 1 sq. m.). There may be fewer anchors, but this will negatively affect the quality.

Roof structure

The roof can be of 3 types:

1. Single-pitch.

2. Gable.

3. Three-slope.

Advice! In more complex architectural forms, they practice creating a mansard or multi-pitched roof. It looks beautiful, but if you have little experience in construction work, it is better to give preference to a single or gable structure.

Straw can also be used to cover the roof, but with a variety of modern and inexpensive materials, it is worth choosing from the best offers:

1. Soft tiles, which have a low price. If you want the tiles to last 50 years, then purchase products costing more than 500 rubles/m2. There are offers for 220 rubles, but they will last you less than 15 years.

2. Euro tiles (ondulin), characterized by low weight. The cost starts from 250 rubles. per sheet.

3. Classic slate, the cost of which is 150-200 rubles. per sheet.

The type of construction depends on your financial capabilities, but it is worth sticking to simple way with wooden rafters and lathing. Do not skimp on the choice of coating material, because if moisture or Sun rays penetrate the roof, it becomes deformed. You will learn how to make a roof with your own hands from the video.

We install windows and doors in openings

Double-glazed windows come in fixed and opening types, the latter are more expensive. Walk around the house or check the design to understand which windows you will open and which you will not. Thus, you can save 20-30% on the purchase of windows.

Important! Wooden windows and doors, as practice shows, are more reliable, but plastic structures have a high percentage of heat retention. How to install plastic windows V wooden house You can find out for yourself by watching our video.

How to insulate a building?

Insulation can be of 2 types:

1. Ventilated façade covered with curtain panels.

2. Wet insulation, which is created using glue and a layer of insulation, covered with reinforcement and a layer of plaster.

We will talk about facade insulation with ordinary polystyrene foam, which is the cheapest type.

Cheap insulation with foam sheets on the facade

Necessary materials:

1. Primer with a primer, ensuring good adhesion in the insulation-wall pair.

2. To attach the insulation, choose a polymer-cement based adhesive, which is used to attach the foam and the reinforcing mesh.

3. Be sure to install profiles that will act as supports for insulating boards. The profile will also drain excess water; it is attached near the base.

4. For insulation, foam C 25 is selected, the thickness of which depends on your region. Typically, the thickness of the slab is taken from 10 to 150 mm, the latter option for the northern regions.

5. Dowels, of which 3 to 8 pieces are required. per square meter of facade area.

6. Reinforcing mesh (facade fiberglass mesh), the thickness of which is in the range of 140-160 g per square meter. m.

7. Plaster for facades.

8. Material for finishing, facade paint is most often used.

They begin work by installing the profile along the base line, then install the foam from the corner, having previously treated the walls with a primer.

Advice! Glue is applied to the edges of the slab, and the center is spot-smeared. This will ensure good adhesion and economy of glue itself.

The rows are attached with slight blending of seams horizontally to prevent tears and cold spots. After attaching all the foam sheets, they are left for 3 days for the glue to dry; after this period, the sheets are additionally secured with dowels. The final touch is attaching the fiberglass mesh.

The fiberglass mesh is secured by applying glue to the foam plastic board, then the fiberglass mesh is immersed in the glue, covered with glue again and leveled with a spatula. As a result, you get a smooth canvas with a barely visible mesh.

Allow the composition to dry for another 3 days, then apply the plaster according to the manufacturer's instructions. It is optimal to apply 2 layers to the facade; the tool used is a spray gun (high consumption of material!), a roller or a brush (long to apply!).

Advice! When applying the finishing paint, make vertical and horizontal strokes, which also contribute to the absence of cold spots. How to properly insulate the walls of a house is described in the following video.

Ceiling insulation

It is better to insulate the ceiling using rolled mineral wool, which is laid from the attic side. Don’t forget to install a vapor barrier layer inside; it is recommended to use foil insulation for it. You can cover the mineral wool with a mixture of clay and sawdust if you will not be using the attic in the future.

Floor construction

We are talking about economical construction of a house, so we make a movable floor. This is a layer of roofing material, covered with crushed stone on top and tightly compacted. Afterwards the waterproofing is spread, and the floor is covered with any available material. It could be natural wood, tiles and whatever is available for your budget.

Water supply is a priority issue

The installation of a primitive bathroom should be done at the stage of laying the foundation. Here it is enough to dig a drainage hole, but you need to be careful not to pollute the general water. If you do not have a specific project, then it is optimal to connect the plumbing unit to the septic tank. In home construction, septic tanks are made of several concrete rings; the contaminated water in them is processed by bacteria, gradually passing through natural filtration in the soil.

Drinking water is obtained from a well or well, of course, if the village is not connected to the central water supply. Initially, take a closer look at your neighbors’ houses, and don’t hesitate to ask where they get their water. It is more economical to dig a well from which you can run a water supply, but your own well will provide you with an autonomous water supply.

Important! The price of drilling a well is about 1.5 thousand rubles per meter, the depth and total cost depend on the region and location of the site.

Prices and the issue of savings

We have brought the most inexpensive materials, from which you can build a house with your own hands. Today there are many options for construction, but how much does a house, for example, made of wood, cost? Let's find out:

1. Leading the list of the most expensive is a brick house. It is popular, but the cost of 1 sq. m. such a house will cost at least 15 thousand rubles.

2. It is cheaper to build a house with a metal frame, lined with brick, which will cost approximately 112 thousand rubles / sq. m. m.

3. Houses made of wood are not much cheaper. So, a house made of a simple log will cost 12 thousand rubles. per sq. m., and from logs that were processed by hand, already 25 thousand.

4. A frame-panel house costs 9-10 thousand rubles/sq.m. m.

Important! Brick house it takes about 6 months to build, while the frame-panel version only takes 3. The latter is lightweight, so you can save a lot of money when laying the foundation.

Cost of internal and external works

There is another article on self-construction transport costs, equipment rental, it is rare that during construction you can do without an excavator. Let’s add here the cost of finishing, and the more rooms there are, the more impressive the number of zeros in the final estimate.

Is it really that cheap to build houses on your own? Average calculations show that the construction of a simple Canadian frame house costs 1 million rubles (area 110 sq. m.):

1. Foundation: about 35 thousand rubles for columnar foundation, at least 55 thousand rubles for strip foundation.

2. Frame and panel cladding - an average of 120 thousand rubles.

3. Insulation for walls, attic, ceilings - ecowool on average 70 thousand rubles, mineral wool and additional. materials start from 70 thousand rubles.

4. Roof area 120 square meters made of soft tiles will cost 70 thousand rubles.

5. Purchase and installation of wood windows - 50 thousand rubles, MP windows - 90 thousand rubles.

6. Exterior finishing about 70 thousand rubles, siding will cost only 40 thousand rubles.

To the above prices we will add electrical work, well drilling, gas installation, interior decoration, heating and we’ll get that notorious million. Of course, you can build a house with an area of 25-50 square meters, which will immediately reduce the cost by half.

Let's sum it up

The pros and cons of self-construction include:

1. Drawing up a plan and approving it yourself will cost less than working with an architect.

2. The cost of purchasing materials is much lower.

3. Work with electricity, heating and sewerage will have to be entrusted to a specialist.

4. Self-construction can last from 6 months to 4 years.

Building a house with your own hands without construction experience will not work quickly, and you will definitely attract helpers who specialize in a certain field. But the price of the box is for simple house, if you order construction from a company, it will be about 18 thousand rubles / sq. m. m., and this price is not for Moscow, but for distant Orel.

In order to gather strength and start building a house with your own hands, sometimes you need to look at photos of building a house with your own hands.

Types of affordable construction

One of the types of high-speed and simple construction is the construction of residential cottages from Teflon blocks. Such blocks consist of three layers: an inner polystyrene foam layer and two outer layers of concrete. The layers are fastened together with fiberglass pins. A wall built from such blocks is almost no different from the reinforced concrete version.

Building a house with your own hands without construction experience is also possible using the universal monolith method. In this case, the reinforced concrete frame has a very rigid coupling, which ensures high strength and reliability of the entire structure. Here you can experiment with the layout, installing walls according to your personal choice.

Timber frame house

The construction of a wooden frame house using Canadian technology will allow the builder to move into a cozy cottage within 3-4 months. At the same time, the method has its fundamental advantages and critical aspects.

Today, the price of a do-it-yourself house without construction experience using this technology is the most affordable. It is important that financial feasibility is achieved not through the use of low-quality materials, but thanks to unique the latest technologies aimed at democratizing prices. Favorable reviews from many owners of frame-panel houses inspire them to start construction.

Such designs are easy to assemble, allow any finishing option, and are characterized by good thermal properties. The buildings are environmentally friendly buildings.

Among the disadvantages of the method that need to be studied before starting construction work: the need to periodically change the insulation, the flammability of materials, and greater audibility.

Stages of building a house

So, regardless of whether you have experience building your own house or not, a frame-panel house can be erected with due diligence.

To build a one-story wooden house, you need to draw up a plan and drawing. It is recommended to order the drawing from a professional architect. You should not skimp on specialist calculations, as their correctness is of great importance.

At the second stage of work, the site is prepared. If there are trees or plants on the territory that will interfere with construction operations, then they need to be eliminated. It is also important to decide how the cottage will be located and where the entrance will be. And think about the placement of all utilities.

The experience of building a house with your own hands suggests that next you need to start digging a pit, cesspool and laying the foundation. The basis for the foundation is bricks, concrete slabs, and processed wood. The foundation should be protected with special impregnation to avoid moisture penetration. During this period, electricity is also carried out.

At the third stage of construction, wooden plates are installed and the floor is formed. Having prepared special grooves, the beams are fastened. Afterwards, the structure is covered with floor beams and plywood is nailed. This measure is necessary to ensure that the floor is safe and durable.

The fourth stage involves laying logs. Based on the drawing, the prepared logs are connected to each other. To protect the house from the aggressive influence of the environment, tow is placed between the logs or the voids are filled. polyurethane foam. Afterwards, the supporting beams are insulated and laid.

More information about the construction of houses made of timber -. And this article discusses the features of construction from laminated veneer lumber.

The final stage is insulation and cladding of the house. The building is being prepared for internal work, namely installation of communications, cosmetic repairs, installation of plumbing.

Experts advise that before installing electrical wiring, be sure to familiarize yourself with the rules of this process for a wooden house.

In addition, when building for yourself, you should not skimp on the quality of materials, otherwise you will subsequently have to spend money on restoration work.

Build your own house yourself, without outside help and inexpensively... What could be more attractive! Your own home is the realization of a dream, and no one realizes our dreams better than ourselves. However, even country house This is a complex structure and when designing, it is necessary to take into account thousands of nuances. Each of them is quite difficult to consider, but the main points regarding construction own home, let's try to study it.

Where to start construction

Before you build a house with your own hands without experience in construction, you need to at least theoretically study the main stages and not be afraid possible difficulties and failures. Whoever owns the information owns the world. It is worth starting construction with information about the selected site. It is necessary to find out from future neighbors everything about groundwater, to understand the characteristics of the soil. Groundwater is important not only from the point of view of organizing the water supply system; the type of foundation of the future house will depend on the level of its occurrence.

Now it’s time to think about the project. This is a very important step even without design experience. building structures It's better not to take on this matter. Not only the price of the entire construction, but also the comfort of living and the speed of work on building a house depend on the quality and professionalism with which the project is completed. Therefore, you can go two ways - order individual project, or use a standard proven design that guarantees reliability and long-lasting construction.

We carry out a house project

Design work is a huge amount of work associated with both the architectural features of the building and the engineering part. And this part includes the calculation of electrical wiring, supplying the house with gas, water, calculation of ventilation, heating and sewerage. The average cost of a typical project may not reach hundreds of dollars, while an individual project can cost almost 6 thousand rubles per square meter.

During runtime design work You can prepare the site for future construction. In order to construction works took place smoothly and quickly, it is better to provide a temporary building, a construction car, a kung, any room where tools and at least some materials could be safely stored. Also in such a room you can take a break and change clothes.

Preparing the site for construction

At the same time, you need to think about constructing a fence. A fence is necessary because it will protect the area from prying eyes and uninvited guests. You can make at least a temporary fence from an unplaned board, from an inexpensive slab, you can make a fence from a picket fence, and if possible, it is better to take care of a more durable fence made from corrugated sheets or chain-link mesh.

What foundation to lay

In order to decide on the type of foundation, it is necessary to take into account a lot of points, but most likely this will be done at the stage of designing the house. Depending on the load and type of soil, the foundation can be like this:

- The foundation is strip. One of the most common types and suitable for the vast majority of buildings and types of soil.

- Brick foundation. This scheme is used extremely rarely, and only for light, possibly temporary buildings.

- Pile foundation. It may be the only possible option when it comes to building a house on heaving and unstable soils.

- Slab foundation. Also used for moving unstable soils.

- Rubble foundations can also be used in cases where construction is carried out on soil that is rich in groundwater with low burial depth.

- Foundation monolithic type may be useful when constructing a non-standard structure. Such foundations are reliable, but require serious expenses.

Materials for the construction of walls and roofs

After laying the foundation, it is isolated from moisture, insulated and the walls are laid out. There are a great variety of materials for walls, as well as technologies for their construction. When choosing a technology, not only the size of the budget is important, but also the climatic features of the area, and the material in each region may be different. In some places it is more profitable to build walls from shell rock or timber; in some regions brick is popular, but in others it is closer frame construction, as the fastest and least expensive, while some will prefer to build walls from foam blocks.

After the walls are erected, they begin to install the roofing system, which can also be very different. The type of roof can be either a classic gable or tri-slope, single-pitch or more complex shape and configuration, but it is important to consider roofing material, which will be laid on rafter system. Classic slate is used extremely rarely today; preference is mainly given to lightweight materials - soft tiles, rolled bitumen materials, some prefer classic tiles, while others decide to cover the roof with metal tiles.

It is important that the house fully corresponds to the owners’ idea of cozy nest, then any construction, no matter how long it lasts, will bring joy, and any work done from the heart will in any case be of high quality. Good luck with construction and making your dreams come true!