Houses lined with artificial stone. Conditions for work and preparation of stone for laying. For its manufacture, it is used

Artificial stone is a material obtained by mixing sand, cement, water, plasticizer and various dyes. It costs much less than its natural counterpart, although outwardly it is practically indistinguishable from it.

Increasingly popular, indoor and made of artificial stone is an economical way to decorate your home and spice up the interior. If you are also thinking about renovating a room or facing a facade, we suggest that you familiarize yourself with the methods of using decorative stone, its pros and cons, as well as installation technology.

The use of artificial stone

Facade decorationThe scope of application of artificial stone and panels from it is extensive. It has been successfully used as finishing material for walls, floors, fireplaces and the facade of the building, being an alternative to facing the house with natural stone.

Such popularity is due not only to cheapness. Due to the convenient shape and smooth back side, individual fragments are joined and attached to surfaces much easier than natural stone. Another advantage is durability and resistance to moisture, the decorative material is practically not affected by mold and fungi. In addition, it is easy to clean and low maintenance.

Wide color palette and ability to imitate various materials(brick, marble, granite, etc.) allows you to use decorative rock in any room. It looks appropriate in the kitchen as a finish for the area around the sink, successfully combined with the interior of the hallway or living room, designed in vintage and empire style. Artificial stone countertops are popular, they are scratch resistant, easy to care for, and they look just great! It is also suitable for decorating bathrooms, and fire resistance makes the material suitable for lining fireplaces.

Decorative stone in the interior

Decorative stone in the interior It is interesting to look in this design and doorways. Framing of crushed stone in the form of an arch, rectangle or fantasy pattern with uneven edges visually expands the room, and makes the interior interesting and original.

Interior wall cladding with decorative stone

Such a finish is more often used in combination with plaster or drywall, but wood panels, including the cladding of a house with a board, with the right choice of color and texture, also successfully harmonize with decorative stone.

Typically, stone is used to highlight functional areas in a room. For example, with its help they focus on the entrance, the area with a TV or a fireplace. The material for this is selected in contrasting colors, 2-3 tones darker (or lighter) than the main design of the room.

hallway decoration

hallway decoration If you plan to lay out the walls with stone completely, you should take care of additional lighting so that the room does not look too gloomy. If the result is unsatisfactory, you can correct the situation by adding mirrors and house plants. But still, for narrow, long rooms, this finishing option is not recommended, due to the visual narrowing of the space.

When using decorative stone for wall cladding in the hallway, it makes sense to place it around front door and near the shoe storage area. Being easy to care for (any dirt can be quickly cleaned from it), the material will simplify the cleaning of the room and prevent the appearance of indelible stains of dirt, which often happens with walls covered with wallpaper.

External decoration of the building with artificial stone

Not only indoors, artificial stone is used. This material is also popular for facing the facades and walls of the building from the outside. When choosing outdoor finishing materials for your home, you should pay attention to artificial stone. Its first advantage, which makes the material suitable for external cladding, is the ability to retain heat, due to which it will not only decorate the house, but also insulate it.

The second plus is soundproofing properties. Such sheathing will reduce the penetration of extraneous noise from the street into the building and will save on additional sound insulation.

The next advantage is the low weight of the decorative stone (1.5-2 times less than that of natural stone). By cladding with this material, you will not overload the walls, which means that strengthening the foundation is not required. This means that it is possible to choose such a cladding even after the completion of the main construction, while solving the issue of finishing natural material should be at the planning stage of the house.

Artificial stone will protect the basement of the building

Artificial stone will protect the basement of the building Artificial stone is also valued for its resistance to moisture. It does not need special impregnation, like a block house (front board for the exterior of the house). However, there is a downside - fragility. The material is easy to split by accidentally dropping it or hitting it too hard, however, this disadvantage is only important during transportation and installation. That is why it is important to pay attention to the integrity of the artificial stone when buying.

How to choose a decorative stone for the facade?

For the facade and basement of the building, the following types of material are used:

- Cast stone. It is produced using polyester resins, sand, natural stone chips and dyes. It has various colors and textures, does not fade under the influence of ultraviolet radiation and is resistant to temperature extremes. It is chosen mainly for finishing the house outside.

- Concrete products. They include cement, coloring pigment, plasticizers and reinforcing additives. The color is formed by adding a dye, but can also be achieved by coloring the surface. The material is durable and moisture resistant, can be used in bathrooms and kitchens.

- Porcelain tile. It is made from clay, sand and small stone chips by pressing and subsequent firing. Externally, the stone resembles glass or ceramics. Such products do not interact with chemicals and even tolerate the effects of acids. Facing the outer walls with porcelain stoneware guarantees the strength and durability of the coating.

decorative stone

decorative stone In addition to the materials of manufacture, the stone can vary in shape - tiles, brick imitation, chipped fragments. This parameter is selected individually, depending on the decorative effect to be achieved.

In order for the material to look harmoniously on the facade and not disappoint with the quality, use the following rules when buying:

- Choose products with color transitions, they look more natural and realistically imitate natural stone.

- To finish the plinth, purchase material that is not easily soiled - gray or brown.

- Give preference to domestic producers or those in countries whose climate is similar to yours.

- Pay attention to the surface of the product. Chips and too porous structure are a sign of low-quality products.

In order to provide for a certain amount of material that may be damaged during transportation and during operation, purchase the estimated amount of stone plus 10-15% of the total volume. In the event that excess material remains, the economical owner will find a use for it on the site.

Surface preparation

The next step after choosing the material is preparing the surface for finishing. If the walls are concrete, then they are leveled with plaster and treated grinder. Further, the surface is dedusted, covered with a deep penetration primer and waited for it to dry. The wooden facade is first inspected, interfering nails are removed and weak and rotten boards are replaced, if any. Then the surface is reinforced, plastered and primed.

Uneven surfaces must be sanded first.

Uneven surfaces must be sanded first. Note! For external walls with significant irregularities, stone finishing is not recommended; in this situation, cladding the facade of the house with wood-like panels or can be an alternative.

Mounting

Tools for the job

Tools for the job After preparing the surface, take care of necessary tools. To lay the material you will need:

- drill with a mixing nozzle;

- container for mixing the adhesive solution;

- roulette and level;

- a rope to control the horizontal rows;

- trowel, trowel and spatula;

- stitching tool;

- syringe gun for applying the jointing mixture;

- hard brush;

- rubber mallet.

The listed tools will simplify the installation process and allow you to perform work efficiently. It is also important to take into account weather. Produce cladding artificial stone not recommended in cold weather. If the temperature is below + 5 ° C, the mortar will not set well, but excessive heat also complicates the work.

Advice! In summer, to ensure a reliable connection, it is advisable to wet the walls and material with water before applying the adhesive mixture.

Although the tile for the exterior of the house already has a convenient shape and fits well on the prepared surface, it will be easier to assemble the pattern without errors if you practice laying it on the ground before installation. This is especially important for complex multi-color patterns or cladding made of different materials.

stone masonry

Stone laying begins from the corner of the building, mounting the bottom row first. To make the masonry even, for each row along the entire length of the wall, control marks are made, referring to the level.

The adhesive solution is applied in a thin layer, evenly distributing it with a comb spatula. So that the composition does not dry out ahead of time, it should not be covered simultaneously with areas of more than 1 m².

Installation of decorative stone

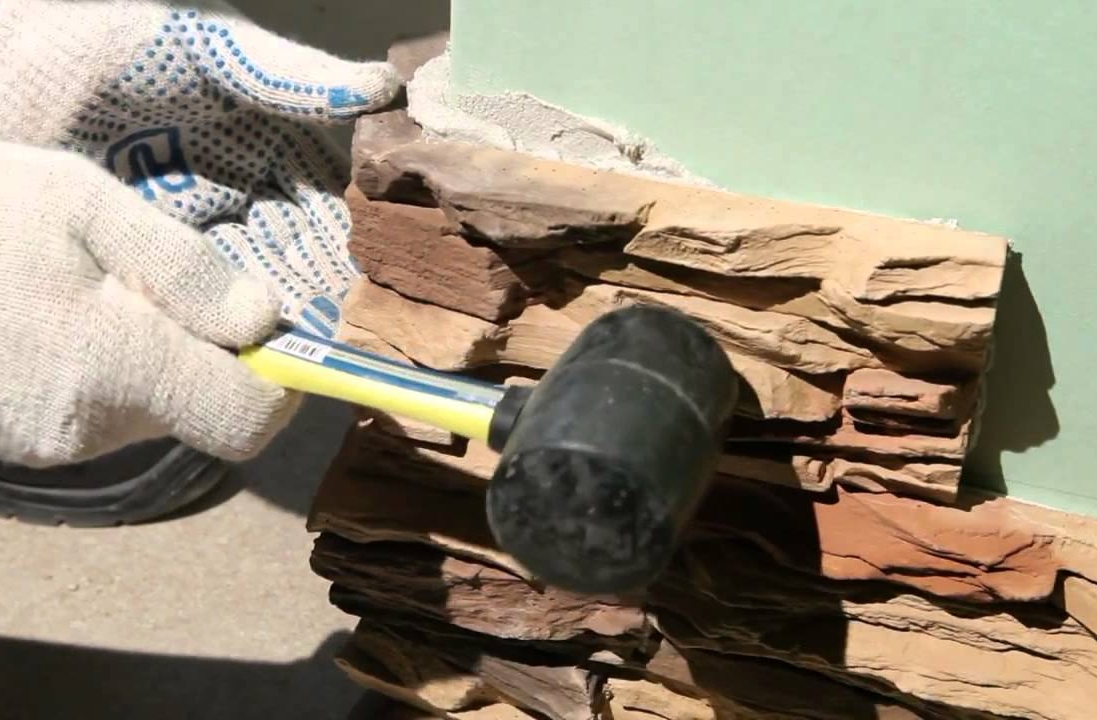

Installation of decorative stone Each fragment of the cladding is pressed against the surface until drops of the solution appear on the sides and tapped on it with a rubber mallet. At the same time, make sure that the glue that has come out does not stain the front side of the stone: it will not be easy to remove it.

Also, the exterior decoration of the house with tiles involves controlling the size of the seams. Usually they are made 8-10 mm thick. Templates of the appropriate size help to regulate the size of the space between the rows, which can be made in advance from plywood on your own or purchased ready-made.

We carry out masonry seams

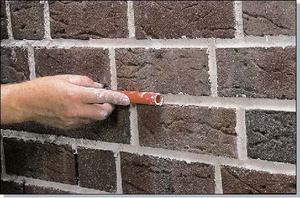

2-3 days after the end of the laying of the stone, rustication of the seams is performed. To do this, they are filled with a jointing mixture using a syringe gun. Sometimes coloring pigments are added to the mixture to give the seams a certain color.

Seam processing

Seam processing The resulting composition is smeared with all the vertical and horizontal spaces between the tiles. After waiting 30 minutes, the seams go through with a special spatula - stitching. The final stage is cleaning the surface with a stiff brush from excess mortar, it is done after the grout is completely dry and becomes crumbly.

Summing up, we can say that artificial stone for the exterior of a house is in no way inferior to natural, and even surpasses it with a variety of shades and affordability. In addition, the laying of the material is simple and, following the technology, you can do it yourself without any problems. We wish you a successful renovation!

What is a house facade? This is his calling card. Even a well-built house in a modern architectural project it will not look very good if its facade is simply painted. Therefore, manufacturers building materials offer a wide range of various kinds finishes that can satisfy the most demanding consumer.

In this article, we will be interested in facing facades with natural stone. This natural material has been used for facade decoration for a long time. The variety of stone rocks is huge, each has its own advantages and disadvantages. But it is the facade of the house made of stone that gives a certain nobility to the structure, unusualness and power.

Cladding technology

Like all construction and finishing works, facing a house with stone is divided into several main stages.

Stage No. 1 - settlement

First of all, it is necessary to calculate the amount of finishing material so that it is enough for the entire facade. A shortage is unacceptable, because delivering a stone is an unforeseen cost and an increase in the cost of finishing. Facing stone divided into two positions:

- Plate material. It is used specifically for finishing the area of \u200b\u200bthe facade of the house. Plates can have even geometric shapes or uneven in the form of natural chips. But in any case, the manufacturer sells them by area, that is, in square meters.

- corner elements. They are used to decorate the corners of the building. They are sold by the metre.

Advice! Experts with extensive experience in finishing using stone slabs recommend buying finishing material 10% more than the finished area of the building. Marriage during transportation, loading and unloading, as well as when cutting plates is a common thing.

The design norm of slab stone is determined by the area of the facade. The length of the corner elements is the sum of the height of the building and the number of corners themselves.

Stage number 2 - preparatory

You can veneer with stone houses built from different materials. That is, it can be a concrete, brick or wooden structure. But the preparation for them is different.

Houses made of brick and concrete must first be cleaned of dust and dirt. Notches should be applied to concrete surfaces. Then it is necessary to prime the facades. As a primer, a liquid bonding mortar is used, which is used for laying stone slabs. The solution is applied with any tool: brush, mop, roller or spatula. Training wooden houses slightly different:

Houses made of brick and concrete must first be cleaned of dust and dirt. Notches should be applied to concrete surfaces. Then it is necessary to prime the facades. As a primer, a liquid bonding mortar is used, which is used for laying stone slabs. The solution is applied with any tool: brush, mop, roller or spatula. Training wooden houses slightly different:

- First, the wooden facade must be waterproofed. For this, it is best to use bituminous waterproofing mastics. This layer will protect wooden surfaces from moisture, which is formed during the application of the adhesive composition.

- A metal mesh with cells of 30x30 mm is stuffed onto the wall, no less.

- The plaster is applied.

Advice! If the house is built of logs, then a crate of wooden slats is first stuffed onto its facade, which must be treated with an antiseptic composition. The fastening of the elements of the crate is done with self-tapping screws. Here it is important to install the rails closer to each other. This is expensive, but the strength of the crate is the key to the strength of the stone cladding, which is heavy.

And one more important point, which concerns mainly beginners without much experience. Experts recommend that before the main stage, that is, before facing, lay out the structure of the future decoration of the facade of the house on the ground.

Stage number 3 - the main

To finish the facade of the house, it is necessary to use special adhesives used for stone and for external work. You can knead the solution yourself on the basis of cement with the obligatory addition of plasticizers.

- The bonding composition is applied with a trowel to reverse side stone tiles, which are pressed against the facade with force.

- At the same time, excess cement mortar that appears from under the stone is removed.

- For alignment and for precise installation of the facing element in place, it is necessary to use a mallet (wooden hammer).

- All elements must be checked for evenness by setting the level.

Stone masonry is installed on the foundation. Its surface must be set horizontally.

Advice! Stone cladding of the facades of the house requires laying slabs with seams. To do this, intermediate elements are installed between adjacent finishing elements. In this case, you should not use standard crosses or other similar products. It is better to use the waste of the stone tile itself.

Stage number 4 - stitching

Designers advise adding a little color to the grouting mortar, which will emphasize the color of the stone. For example, for light tones of a stone color, it is better to choose a dark shade of embroidery. And vice versa.

Facing the facade of the house with stone is a very complex and time-consuming process. It takes a lot of time, you can not lift the finish high in one pass. The higher the laying height, the greater the load on the lower rows of tiles that cannot withstand it. Therefore, it is very important that the lower rows are well seized and the bonding solution is dry. It is better not to engage in this process if you are not an expert. The quality of the final result will depend on the qualifications of the contractor. Which, in the end, will affect the cost of the finishing process itself.

Facing the facade of the house with stone is a very complex and time-consuming process. It takes a lot of time, you can not lift the finish high in one pass. The higher the laying height, the greater the load on the lower rows of tiles that cannot withstand it. Therefore, it is very important that the lower rows are well seized and the bonding solution is dry. It is better not to engage in this process if you are not an expert. The quality of the final result will depend on the qualifications of the contractor. Which, in the end, will affect the cost of the finishing process itself.

If we look at the preserved old houses, then with 100% probability we will see that the outer walls of buildings must have a finish. It can be plaster, facing with granite, marble or other natural material. It is thanks to the external protection of the facades that ancient buildings delight us with their beautiful appearance. What to do today, how to make the facade of your house unique and at the same time protect the walls from external influences- wind, temperature changes, precipitation?

Today, there are many types of artificial stone on the market - from imitation brickwork to the "wild" stone. The house can be made to look like an old castle, lined with stone imitating rock, or you can emphasize the severity of the masonry using clinker bricks.

Pros and cons of artificial stone for facade cladding

Let's look at the pros and cons of artificial stone to make an informed decision. As a rule, several factors influence the choice:

- appearance;

- operational characteristics, i.e. durability;

- the cost of facing, i.e. the stone itself, glue, laying work 1 m².

Artificial stone is manufactured in compliance with technological standards and has the same characteristics and standardized size each tile, in contrast to the "wild" - natural stone. Thus, using artificial stone, you can be 100% sure that not a single tile will stand out from the overall picture, and the conceived facade will have perfect look.

The same can be said for performance. Factory production, strength and wear tests guarantee the stability of the quality of the stone throughout its service life.

The same can be said for performance. Factory production, strength and wear tests guarantee the stability of the quality of the stone throughout its service life.

The cost per unit area (1 m 2), lined with artificial stone, differs significantly down from facing with "wild" stone. The cost of materials directly - stone, cement glue for outdoor work - excluding the cost of laying work is as follows:

- stone from 500 to 1500 r / m2;

- glue for stone 500 - 700 Rr. per 25 kg (one bag). With a mixture consumption of 5-8 kg / m2, the cost per 1 m² will be slightly more than 100 r

In total, the cost of materials will not exceed 1,500 - 1,700 r / m 2.

Facade cladding technology

The cladding technology is not difficult if you follow the recommendations for preparing the surface for laying and the sequence of actions during work.

Surface and tool preparation

This is a very important stage of work. It is necessary to remove drips and traces of cement mortar from the walls, remove dust and prime the surface. You need to use a deep penetration primer, carefully monitor that there are no gaps when applying it.

We are waiting for the primer to dry and you can begin work on marking the surface and laying the stone.

For work you will need the following tools:

- drill mixer for mixing the adhesive composition;

- spatula, trowel, trowel for applying and distributing glue on the wall surface;

- rubber mallet;

- level;

- roulette;

- cord for horizontal marking;

- "Bulgarian" with a disc for cutting stone;

- brushes for cleaning seams;

- construction gun-syringe;

- "joint" - a special narrow spatula for leveling filled joints.

The right tool will help you get the job done quickly and efficiently. eliminate errors during the laying of the stone.

Conditions for work and preparation of stone for laying

For work Not recommended choose a cold season with sharp changes in temperature and humidity. These indicators greatly affect the quality of the adhesive mixture, the moisture content and consistency of which must be stable. Recommended for hot weather wet the walls and the stones themselves before applying the solution.

For work Not recommended choose a cold season with sharp changes in temperature and humidity. These indicators greatly affect the quality of the adhesive mixture, the moisture content and consistency of which must be stable. Recommended for hot weather wet the walls and the stones themselves before applying the solution.

In order for the facade to retain its appearance for a long time, you need to follow the installation recommendations. Each type of stone has its own nuances. For example, flagstone should be laid with a gap on seams from 12 to 25 mm; rectangular stones and bricks - with a gap of up to 12 mm. Compliance with the thickness of the seams will compensate natural movement of stones with seasonal fluctuations in temperature and humidity.

First, the stone must be selected as it will be laid on the wall, draw up a laying plan. To do this, we lay out about 1-2 m 2 on a flat surface, selecting stones in such a way that the difference in shades of color and texture looks organic and beautiful. Next, we lay the stones, observing this laying scheme.

Laying stone on the walls

We start laying from below. We mark the horizontal of the first row and apply several control marks along the entire height of the wall. In the process of laying, these marks must be controlled using a tape measure row height. Additionally, after several rows, it is worth checking the horizontal with a level.

We start laying from below. We mark the horizontal of the first row and apply several control marks along the entire height of the wall. In the process of laying, these marks must be controlled using a tape measure row height. Additionally, after several rows, it is worth checking the horizontal with a level.

We apply the solution on the wall with a trowel and with a spatula-comb, distribute it to the desired area, as a rule, by 2-3 rows in height. We start laying from the corner piece. We apply the stone and press it, moving it left and right, you can additionally tap it with a rubber mallet. The subsequent stones are laid in the same way. It is necessary to ensure that the vertical seams of adjacent rows did not fall one over the other. If necessary, you need to saw off the stones at the beginning of the row with a grinder, make halves out of them.

When laying, you need to immediately decide with seam thickness. For example, for brickwork, a seam of 8-12 mm is required - this seam thickness is organically combined with the traditional brick size. Small pieces of plywood of the right thickness are ideal for control, so you should saw them in sufficient quantities in advance.

Processing masonry joints

A few hours after laying, and preferably after two or three days, when the glue has set sufficiently, you can start filling the joints grout mixture. To apply the mixture, you can use a syringe gun with a nozzle desired diameter. We mix the grout mixture according to the instructions, add pigment, if a special color of the seams is required, fill the gun and carefully we smear all vertical and horizontal seams.

A few hours after laying, and preferably after two or three days, when the glue has set sufficiently, you can start filling the joints grout mixture. To apply the mixture, you can use a syringe gun with a nozzle desired diameter. We mix the grout mixture according to the instructions, add pigment, if a special color of the seams is required, fill the gun and carefully we smear all vertical and horizontal seams.

Among all the possible types of exterior finishes, a special place is occupied by the facing of building structures with artificial stone. This type of finishing is offered by our company represented by experienced professionals. Houses with a facade made of such material look very respectable and original. Compared to natural stone, man-made materials are much cheaper and come in a wide range of shapes, sizes and colors. Modern artificial stone practically does not differ in properties and appearance from natural, which makes it one of the most the best materials used in the decoration of wooden houses.

Benefits of decorating a house with artificial stone in our company

It is necessary to choose this particular material for finishing the facade for a number of reasons:

- Low price (especially in comparison with natural analogues). With the help of artificial stone, you can create a unique design of the house, give it a luxurious appearance for affordable money.

- Low installation cost. Compared to natural stone, artificial stone is much lighter (approximately 1.5 times), which greatly facilitates the finishing process. We offer the most affordable prices for the complex finishing of facades with artificial stone.

- Wide range of applications. Unlike natural, artificial stone is suitable for facing any coatings and structures.

- Great opportunities for the designer. A variety of shades, shapes and sizes of this decorative material allows you to create unique projects for every taste.

- Possibility of combination with other finishing materials.

The installation itself is technologically simpler than facing with natural stone. But in its implementation it is necessary to follow a number of rules. Entrusting the process of facing a house with artificial stone requires professionalism and skills, so it is better to entrust it to our specialists. We offer the most profitable terms cooperation, a guarantee of the quality of work and the implementation of the agreed deadlines.

Nowadays, even the most nondescript buildings have a chance to acquire an expressive appearance. Furthermore, wooden houses now they try on stone clothes, and frame cottages indistinguishable from brick mansions. Such reincarnations became possible due to the emergence of an amazing decorative material - artificial stone. True, in order for the new “suit” to look like a glove, you need to try very hard. To begin with, carefully read the manufacturer's instructions.

Artificial (decorative) stone is a mixture of cement, quartz sand, fillers, active additives and coloring pigments. In other words, this is the most concrete, but concrete is special. The material reliably imitates all kinds of rocks, different types brickwork, as well as complex elements of artistic decor. At the same time, unlike natural analogues, it does not create a serious additional load on the walls and, as a result, on the foundation of the house. In addition, artificial stone has a very accommodating character. They can be used on almost any wall. After proper preparation, of course. And, finally, with all the aesthetic and technical advantages, an artificial stone is much cheaper than a natural prototype.

The success of the material is based on the quality of the components and modern technology manufacturing. Each manufacturer has their own proprietary recipes. Only one thing can be said for sure: artificial stone is made by vibrocasting in flexible forms. The prepared mixture is compacted on a vibrating table, and then sent to drying chambers with elevated temperature and humidity. As a result, products with impeccable geometry are obtained, which, in some respects, are not only not inferior to natural stone, but even surpass it.

The material in demand on the market cannot but attract unscrupulous manufacturers. Artificial stone is "sculpted" by all and sundry - in semi-handicraft conditions, with gross violations of technological norms and rules. As a result, the reputation of the material suffers, and the consumer receives a product that is not what he expected. How to recognize a fake?

High-quality artificial stone is painted over the entire thickness of the tiles, all the details are precisely worked out. If the material is made roughly, has a gray concrete underside and even an impressive weight, then nothing good can be expected from it. The paint will soon be washed away by rain, and the colored stone facade will turn into a monotonous gray. Another alarming indicator is the defiantly low cost. A noteworthy premium class artificial stone is offered in one price category, which is due to the use of expensive imported raw materials and technological costs. If prices are reduced compared to the average market by 20-30%, then they saved either on important components or on production technology.

Leading manufacturers of artificial stone offer a fairly wide range of services. For example, right at the point of sale, the consumer can get expert advice on any issue related to the acquisition and use of the material. If necessary, the consultant goes to the site to help the owners decide on the choice of a particular model or to properly prepare the walls for cladding. However, detailed instructions on the installation of artificial stone can be read directly on the packages related materials (glue, jointing). Unfortunately, consumers often act at their own risk. Let's say they knead the whole package of jointing at once. And after the time of use, the thickened mixture is diluted with water, which is unacceptable. Or take a small amount of"Loose", but when kneading, add more water than required. As a result, the quality of filling the seams is sharply reduced.

Pledge of durability of facade cladding

The durability of artificial stone cladding directly depends on the condition of the base. The brick walls of operated houses are cleaned of old paint, peeling, crumbling plaster, and dirt. Weak areas are strengthened with a special primer. Plastered facades should be carefully checked. If, when tapped, the plaster makes a characteristic dull sound (“bumps”), then it has peeled off the wall or voids and internal cracks have formed in it. Defective areas should be removed and the plaster restored. In order for the artificial stone cladding to look perfect, the surface of the wall must be even. Deviation from the vertical and horizontal, exceeding 2 mm per 2 linear meters. m is unacceptable. Finishing alignment and additional strengthening of the base are provided by applying a mineral adhesive composition intended for fixing artificial stone.

By the way, glue should not be applied to wet plaster. The moisture content of the base must not exceed 5%, otherwise the adhesion of the adhesive to the plastered surface will be weakened. At the same time, an overdried surface draws water out of the adhesive mass, which also impairs the fastening of the artificial stone. In order for the hardening process to proceed normally, the too dry base is slightly moistened. For the same reason, an excessively porous substrate is recommended to be treated with a deep penetration primer. Facing work can be performed no earlier than two hours after the primer has dried.

When finishing new buildings, plaster is applied on a special (plaster) steel mesh, which is attached to the wall with special dowels. If it is decided to clad the facades with light-colored tiles with jointing, then it is recommended to use a galvanized mesh. By the way, smooth brick walls can not be plastered. It is enough to attach a plastic mesh, apply a layer of glue, and then lay an artificial stone using the same glue.

Before finishing the basement or, say, a concrete fence, you need to check the condition of the horizontal waterproofing of the foundation. If the walls are not protected from capillary suction ground water, stone cladding is in serious trouble. Soon, ugly greenish-whitish stains will appear on it - efflorescence, and this is an even lesser of evils. Dampness is a real paradise for mold, fungi, algae and other harmful vegetation. In addition, in winter, when water freezes, it expands, which leads to the gradual destruction of the wall.

New concrete surfaces should be sandblasted to remove the "wax" film. If you decide to decorate an old fence, you need to clean it of moss and mold and cover it with a bactericidal composition.

It is recommended to clad facades with artificial stone at an air temperature of +5 ... +25 °С. As is known. cement glue is kneaded on water, that is, its normal setting and hardening is possible only with positive thermometer readings. In frosty weather, finishing work is suspended. However, if the temperature fluctuates around zero, the facade cladding can be continued using a special frost-resistant adhesive. However, in hot weather do not attach decorative stone to sunny side. The glue will dry before it has time to set, and the lining will peel off. During installation, it is necessary to work with adhesive and grout compositions very carefully. A dirty front surface is extremely difficult to clean. In addition, when facing work, it is necessary to follow safety rules: sawing and cutting a stone in special goggles, gluing - in work gloves.

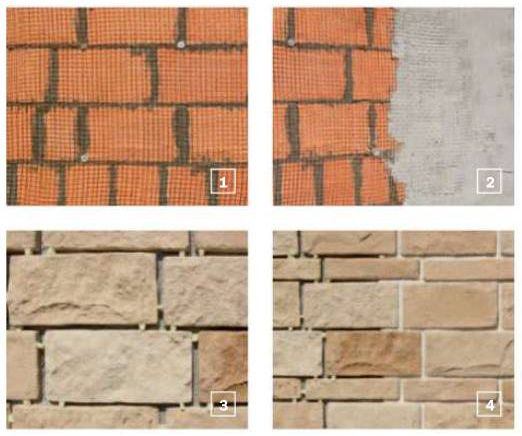

1. On brick wall fix the plaster mesh. 2. The wall is plastered with cement glue. 3. Laying artificial stone. The thickness of the seams is controlled by plastic inserts. 4. The seams are filled with a colored grout.

Finishing wooden houses with artificial stone

Wooden houses are also not alien to stone decor in recent times they are increasingly trimmed with artificial stone. That's just sticking tiles directly on the walls of timber or logs is impossible. An artificial stone is placed on a special screen. First, a frame is mounted on the walls - guides from a bent steel profile. The waterproof sheet material is then screwed on. The best option- cement-bonded particle boards (DSP) or glass-magnesite sheets (SML). So between wooden wall and a ventilation gap appears on the screen, which is blown through by air currents (for the entry and exit of this “wind”, you need to leave holes at the bottom and top of the wall). Thanks to constant ventilation, moisture does not accumulate under the decorative structure, and the tree remains safe and sound for a long time. Needless to say, the wooden base must be treated with an antiseptic compound. A layer of mineral glue is applied to a screen made of DSP or LSU over a polymer mesh. When this screed dries, proceed to facing work.

Facades of the house glued laminated timber lined with artificial stone with a characteristic rocky texture (seamless laying). "Rocks" are glued to a hinged screen made of CSP, which is attached to the walls with the help of guides made of bent steel profile.

In passing, we note that this method of finishing is directly related to the insulation system, known as the "ventilated facade". This technology is often used in the reconstruction and modernization of old houses from solid timber. The walls are insulated with mineral wool boards. And then a protective and decorative screen is mounted, which is lined with artificial stone.

Artificial stone for frame houses

Artificial stone radically changed fate frame houses. Now they are subject to any architectural styles. And no one will guess that a Gothic castle or a Russian Empire-style manor rests on a wooden frame structure, and the walls of a respectable building are filled with mineral wool insulation.

Facing made of artificial stone is attached either to the wall sheathing or to the external thermal insulation. In the second case, the frame walls are insulated from the outside with special facade thermal insulation - slabs of basalt wool or extruded polystyrene foam. On top of the insulation, a special plaster layer is created from cement glue, reinforced with a plaster polymer mesh. Next, glue the artificial stone.

1. View frame walls with external insulation made of expanded polystyrene. 2. The walls are plastered with a proprietary cement composition on a plaster polymer mesh. 3. Facades are faced with stone with dressing and jointing. 4. View of the house with cladding.

Caring for artificial stone cladding

Stone cladding needs care and attention. First of all, it is necessary to install a gutter system to remove precipitation from the roof. Unorganized runoff of rain and melt water can provoke delamination and destruction decorative finishes facades. In addition, mosses and lichens will one day settle on damp walls, which are not so easy to get rid of. However, problems can arise with exemplary home improvement. In order to correct the situation in time, it is necessary to regularly inspect the facades for cracks and other defects.

Artificial stone is recommended to be treated with silicone water repellents. They create an invisible water-repellent film on the surface of the cladding, which protects the material from moisture, ultraviolet radiation and other aggressive environmental influences. The silicone shell repels dirt and even "refreshes" the stone decor.

Depending on the texture of the artificial stone, laying can be carried out close (without grouting) or with grouting (recommended width 1-1.5 cm). The seams must be carefully sealed, that is, filled with a special grout. Otherwise, water will flow under the lining. In winter, it will turn into ice, which will cause the material to peel off. Typically, cladding elements with bandaging of seams are attached according to the principle of brickwork.

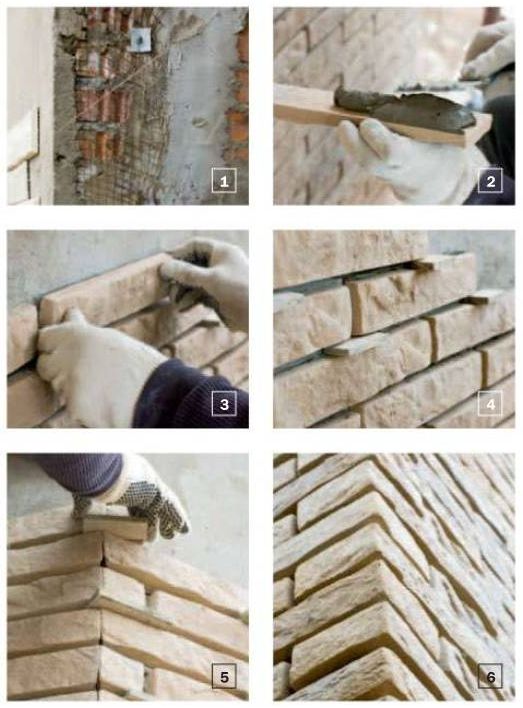

1. Laying artificial stone begins with marking the wall with beacons and twine. Previously, the plaster was treated with a primer and a layer of cement glue was applied.2. Cement adhesive is applied to the reverse side of the tile.3. The tile is attached to the wall with light pressure so that the glue squeezes out a little from under the stone.4. Pre-prepared stone spacers are inserted between the tiles.5. Facing of indirect corners is performed using trimmed tiles.6. Right angles are laid out with special corner elements. After completion of laying, the seams are filled with grout.