With longitudinal and transverse carriers. Definition of a load-bearing wall in a house, its thickness, difference from a partition

It is necessary to start developing the layout of the apartment from the exact definition of the load-bearing walls. They, as you know, cannot be dismantled: if the main walls are removed, then the building may collapse. Also note that when redeveloping the main walls, you will need to order a new project from the appropriate authority and coordinate it with the designer of this building. However, in Lately on the Internet, there are many options for redesigned premises, where the authors of the project quite easily dismantle the load-bearing walls, not paying attention to the illegality of such decisions and the collapse of the building. We suggest that you familiarize yourself with the description, which will help you correctly identify the load-bearing walls in a house or apartment.

The easiest definition bearing wall is a measurement of its thickness.

1. Main walls in a panel house

Initially via the Internet or website construction company you should find the characteristics of the series of your house, from which you will find out the thickness of both load-bearing walls and internal partitions.

As a rule, in houses made of panels, the thickness of the partitions is 80-100 mm, the main walls - 140-200 mm. In many panel buildings, the partitions are made of gypsum concrete, the thickness of which is 80 mm. Bearing walls made of reinforced concrete have a thickness of 140 mm or 180 or even 200 mm. In some old panel houses load-bearing walls are 120 mm. So, measure the thickness of the wall: if it is less than 120 mm, then this is an internal partition, if more, then the load-bearing wall, from which it is excluded. Keep in mind that finishing a wall with wallpaper or plaster can change its thickness, but in panel buildings, as a rule, the finish is no more than 50 mm. But, if you want to make an accurate measurement of the wall, then the layer of plaster will need to be removed.

2. Bearing walls in brick buildings

The thickness of the wall in a brick building is determined based on the thickness of the brick, that is, 120 mm and plus 10 mm per mortar. Therefore, brick walls are 120 and 250 mm thick, 380 mm, 510 and 640 mm thick with an addition of a finishing layer. In brick buildings, the main walls correspond to a thickness of 380 mm. In most residential brick houses partitions between rooms are made of bricks 120 mm thick or plasterboard panels 80 mm thick. Between the apartments, brick walls should be 250 mm thick, double panels with a gap of 200 mm, and load-bearing walls made of bricks with a thickness of 380 or 510 mm, as well as 640 mm. So, if your wall thickness is less than 380 mm, then it is a partition wall.

Brick buildings that are built in series are much smaller than panel houses, for this reason it is not easy to find a description of them. But many brick houses in big cities - these are the so-called "Khrushchev", as well as "Stalinka", they have similar layouts.

The main walls in "Khrushchev" and "Stalinka"

The design of a typical "Khrushchev" consists of three longitudinal load-bearing and transverse walls with special stiffening diaphragms, they create the strength of the longitudinal load-bearing walls (do not allow them to roll over). The transverse walls on the landings are designed to ensure the reliability of the longitudinal load-bearing walls, and also provide support for flights of stairs, in fact, also turn out to be carriers.

Support for ceilings from slabs between floors are longitudinal load-bearing walls, it can also be their transverse types of reinforced concrete and rectangular beams (with a cross section, as a rule, 200x600 mm). Such beams stand on longitudinal load-bearing walls.

It should be noted that the latter option was used much more often. In this case, the transverse structures serve to provide rigidity, as well as load-bearing walls, since they are the support for the intermediate floors. In which direction the slabs were laid can be determined by their joints (rusts). As a rule, partitions, both inter-apartment and inter-room, are placed under reinforced concrete beams so that they are not too noticeable.

The layout of the apartment, the number of rooms, the distance between the beams, and the like may differ, but the construction scheme still remains unchanged.

Everything that was mentioned earlier regarding the "Khrushchev" can also be attributed to the "Stalin". They should also highlight a structure with three longitudinally located load-bearing walls, but of a more complex architectural approach, therefore, the design schemes of stairs and elevator spans, wall rotation are also difficult to implement.

Often, in "Stalinka", brick columns are placed partially on the inner walls, reinforced concrete beams are installed on them.

3. Buildings-monoliths

Monolithic houses are the most diverse in terms of both architectural and constructive solutions. V monolithic buildings, intended for housing, columns and pylons (columns with a rectangular section), beams and load-bearing walls-monoliths are mainly used. Often, pylons are built into external walls and internal partitions. Monolithic internal main walls and pylons were made with a thickness of 200 mm, 250 and 300 mm. The thickness of the columns was even greater. So, if you made measurements of the thickness of the wall, and it is less than 200 mm, then this will be a partition. But, if you measured a wall, and its thickness is 200 mm, this does not mean that it is a carrier, since in monolithic buildings the thickness of the partitions can be more than 200 mm (for example, from a foam block).

If you live in a new monolithic house, then the easiest way is to get data on the load-bearing walls of your housing through the management company, or find your floor plan in architectural project Houses. As a rule, this is not difficult. On the plan, you can easily determine the internal load-bearing walls, as well as partitions and find out their dimensions.

Of course, there are other defining indicators of load-bearing walls, but this already requires professional skills, knowledge and experience in the construction industry, so we do not propose to consider them here. I hope this article was helpful to you.

Effective operation of buildings, i.e., constant qualified care for them, periodic assessment of their technical condition (damage diagnostics) and prevention of the onset of damage development, timely preventive and remedial repairs are possible only with knowledge of the structures of the structure, the features of its construction and operation, operational requirements and the degree of their actual satisfaction, the ability to identify vulnerabilities from which the development of damage is possible, etc. That is why the employees of the maintenance service must carefully study the design of the building; if it is being built, then during construction they control the quality of all work, study the as-built drawings and instructions for the operation of the building received from the builders, maintain a passport for each structure, a technical condition register (ZhTS) and other documents necessary during the operation of buildings and structures.

Despite the large differences between buildings for various purposes, due to the processes taking place in them, they all consist of a limited number of structural elements that perform the same functions in any structure. These are bases, foundations, walls or a frame, a roof or covering, ceilings, partitions, stairs, as well as external elements - entrance platforms, balconies, light galleries or pits at basement windows, etc. Structural schemes buildings for various purposes are also common: one-, two-, three- and multi-span. However, their specific design implementation may be different in civil and industrial buildings, which is caused by their dimensions in plan and in height, loads, etc.

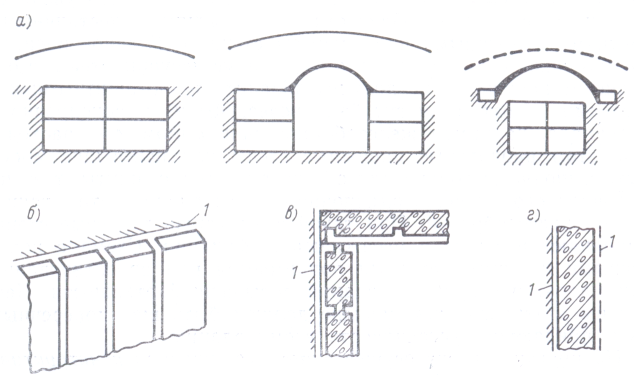

The combination of the main load-bearing elements of foundations, walls, supports, crossbars, ceilings and coatings can be reduced to four main structural schemes (Fig. 1.2):

with longitudinal load-bearing walls;

with transverse bearing walls or mixed - with longitudinal and transverse walls; with full frame - frame; with an incomplete frame.

Rice. 1.2. Structural schemes of buildings

a - with longitudinal load-bearing walls; b - with transverse load-bearing walls; and - with a common frame; g - with an internal load-bearing frame

In a structural scheme with longitudinal load-bearing walls, the loads from the roof and ceilings are transferred to the foundations and foundations by the longitudinal walls. They are the defining structural elements in ensuring the stability of the building, which is complemented by rigidity and reliable connection with their ceilings, when anchoring ceilings into walls, as well as the connection of longitudinal walls with staircases, with internal tie walls. The thickness and free length of the walls are determined by the calculation of strength, stability and heat-shielding qualities. The number of longitudinal walls can be from two to four or more, depending on the purpose and layout of the building. The walls can be brick, block, large-panel, and the height of buildings with such a core should not exceed nine floors.

With a structural scheme of a building with transverse load-bearing walls, spatial rigidity and loads from overlying parts on the foundation and base are transferred by transverse internal walls, reinforced, if necessary, to increase rigidity and stability by ceilings, stairwells, external longitudinal walls. The main advantage of such a scheme is that internal load-bearing walls, unlike external ones, should not have heat-shielding properties and therefore can be built from high-strength material, such as reinforced concrete, at low consumption. At the same time, the longitudinal outer walls, as non-bearing ones, can only be made to provide thermal protection, i.e., from low-strength thermal insulation material which is also very useful. With such a scheme, only the end walls perform load-bearing and enclosing functions. The scheme with transverse load-bearing walls is adopted in the design of both low-rise and buildings elevated number of storeys. The larger the number of storeys, the smaller should be the step of the transverse walls, which give stability to the entire building.

In practice, a mixed structural scheme is often carried out, in which both longitudinal and transverse walls are load-bearing.

The frame scheme (Fig. 1.2, c) is a system consisting of foundations, columns, horizontal elements - crossbars, beams, ceilings and stiffeners. The spatial rigidity of a building with such a scheme is determined either by a rigid connection of vertical and horizontal elements, or by the installation of special connection elements that perceive horizontal loads acting on the building.

The main advantage of the frame scheme is that the frame perceives all types of loads, and the walls perform only the functions of a fence, which makes it possible to rationally use the most effective for them. Construction Materials: for the frame - metal or reinforced concrete, for walls - materials with high heat-shielding qualities, such as lightweight concrete, layered structures.

The frame scheme is widely used in industrial buildings with large spans and significant crane loads. High-rise buildings for residential and service purposes are also erected as frame buildings; their structural elements can be completely unified, which ensures the high industrial character of their construction.

In buildings with a frame scheme, you can easily change the internal layout by rearranging the partitions, which greatly prolongs the moral durability of such buildings.

A scheme with an incomplete, or internal frame (Fig. 1.2, d), is also widely used, which is a system consisting of foundations, longitudinal external walls, one or more longitudinal rows of internal columns connected by crossbars, ceilings and a coating. The spatial rigidity and stability of such a scheme is ensured by the rigid connection of the columns with the foundations, transverse connection walls, stairwells, ceilings and roofing.

In buildings with an incomplete or internal frame, the layout can be largely achieved by means of light partitions, which, if necessary, can be rearranged according to the new purpose of the building, i.e. buildings with such a scheme are modernized at a lower cost than buildings with load-bearing longitudinal and transverse walls .

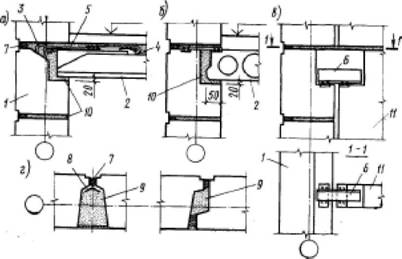

Design schemes and types load-bearing structures buried structures are shown in fig. 1.3.

Fig 1.3. Structural schemes of buried structures (a) and their structures: prefabricated (6), precast-monolithic (c) and monolithic (d) 1 - external waterproofing

When designing buildings, in particular when choosing their supporting structural scheme, all factors characterizing the construction of an object are examined: the purpose and dimensions of the building in terms of and in height, the capabilities of the production base, climatic, hydrogeological and other (including durability) factors, and as well as the possibility of modernization when changing the technological process.

The general requirement for the mentioned three types of buildings and structures when using any of the above load-bearing structural schemes is the maximum introduction of factory house-building methods. Each of these schemes allows for a high degree of industrialization and can be fully implemented in the construction of any of the three types of structures. Construction by individual projects carried out only as an exception.

In the upper floors of the building, it is possible to replace some of the transverse walls with transverse beams and create large spaces for the operating room and other rooms. The transverse walls provide good stability to the building.

Single-family houses of this design have two short facade walls. The transverse walls are internal and adjacent to neighboring ones.

The longitudinal and transverse walls of the building, together with the ceilings, form a spatial box that works to absorb all the loads acting on the building. To ensure the joint work of the horizontal parts of the building (floor) with walls and pillars, they are connected to each other using anchors.

Timber floors are made up of wooden beams, rolling and backfilling. Beams are laid on longitudinal or transverse walls. In addition to conventional wooden beams, glued I-beams are used, as they are more economical.

Window and door frames are installed in the process of concreting, lintels above the openings are reinforced or made prefabricated. To ensure transverse rigidity, transverse walls or vestibules are arranged simultaneously with longitudinal ones. Expansion joints are left in walls longer than 30 m. Such walls are erected from large-porous concrete, cinder block, lime-sand concrete and soil concrete, depending on the presence of one or another local aggregate. The thickness of the walls is determined by thermal calculation. Such buildings are cheap, but their construction is laborious and requires manual labor, although highly skilled labor is not required.

Ceilings consist of a supporting structure that receives loads from people in the building, equipment and the floor. In addition, ceilings are horizontal diaphragms that perceive the wind load acting on the building and transfer it to the transverse walls.

The transverse stiffness of a residential building is usually achieved by transferring horizontal loads to the walls of the stairwells and to the transverse end walls. The horizontal load arising from the action of the wind is perceived by the outer walls with the help of horizontal discs interfloor floors and is transferred to the transverse walls of the house. In order to ensure load transfer in this way, it is necessary to design interfloor floors so that the individual floor slabs are well connected to each other at the seams.

Hanging loggias protrude from the plane of the walls to the entire height of the building. On the first floor, the transverse walls are replaced by columns, which makes it possible to freely accommodate public service premises. The outer fence of the first floor has continuous glazing.

The frameless scheme is adopted in the design of residential and civil buildings with a height of no more than 16 floors. The spatial rigidity of such buildings is ensured by the joint work of walls, partitions and ceilings, interconnected by welding embedded parts and monolithic seams. The design solution is based on the principle of transferring the load from the ceilings to the longitudinal or transverse walls.

The interaction of transverse and longitudinal walls and floor slabs, forming the spatial system of the building, under the influence of a horizontal load occurs as follows. The horizontal load arising from the action of the wind and applied directly to the outer walls is transmitted through the horizontal diaphragms of the intermediate floors to the transverse walls. Due to the high rigidity of interfloor ceilings in their plane for bending, these ceilings can be considered fixed supports on which the outer walls rest. The transverse walls, which in this case are bracing diaphragms, should be considered as beam-type elements that receive loads from intermediate floors. If there are sufficient connections between the transverse and longitudinal walls in the form of tied seams brickwork walls or welded embedded parts of panel walls, then a part of the longitudinal walls is involved in the work, and the cross section of such a cantilever beam can be taken in the form of an I-beam.

The main load-bearing elements (foundations, walls, etc.) together form the supporting frame of the building, which perceives all the loads acting on the building and transfers them to the base, and also ensures the spatial immutability (rigidity) and stability of the building. The structural scheme of the supporting frame of the building is subdivided: frameless, frame and with an incomplete frame.

residential and public buildings, as a rule, they are built from bricks, ceramic or concrete stones and small blocks, as well as from large-sized parts and elements: large-block, large-panel and volume-block.

Frameless buildings made of bricks and small stones and blocks they are usually erected with longitudinal load-bearing (Fig. 2, a) external and internal walls. Transverse walls in such buildings are arranged mainly in stairwells, in places where smoke and ventilation ducts pass, as well as in the spaces between them to give greater stability to the longitudinal walls and buildings as a whole. In buildings with transverse load-bearing walls (Fig. 2, b), the longitudinal outer walls are self-supporting, and the ceilings rest on the transverse walls. Frameless buildings are also being erected, in which both transverse and longitudinal walls are load-bearing. In such buildings, floor panels the size of a room rest on all four sides on transverse and longitudinal walls.

Rice. 2. Structural schemes of frameless buildings with load-bearing walls:

a - longitudinal, b - transverse

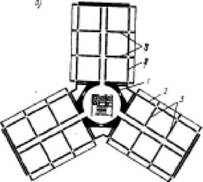

Frameless large-block buildings with walls made of concrete and other blocks have structural schemes with transverse and longitudinal load-bearing walls (Fig. 3). Public high-rise buildings are often erected with longitudinal load-bearing walls. At the same time, depending on the width of the building, there may be not one, but two internal longitudinal walls.

Rice. 3. Structural scheme of a large-block building with transverse and longitudinal load-bearing walls:

1 - corner block, 2 - wall, 3 - window sill, 4 - lintel, 5 - block of the inner wall, 6 - floor panels

Frameless large-panel buildings there are: with three longitudinal load-bearing walls: with transverse load-bearing walls-partitions, installed with a small or large step (distance) from each other.

In houses with transverse load-bearing partition walls (Fig. 4), all the main elements are load-bearing: transverse partition walls, internal longitudinal and external walls. Floor panels are supported on four sides. At the same time, external wall panels 1, which differ little from the outer panels in houses with longitudinal load-bearing walls, are also considered load-bearing. Partition panels 4 and panels of the inner longitudinal wall in such houses are made of heavy (constructive) concrete. Exterior wall panels are made of lightweight concrete. They are three-layer: made of heavy concrete with heat-insulating liners.

Rice. 4. Structural scheme of a large-panel house with load-bearing partition walls:

1 - external wall panels, 2 - sanitary cabins, 3 - load-bearing partitions, 4 - internal load-bearing transverse walls (partitions), 5 - floor panels, 6 - plinth panels, 7 - foundation blocks

It has its own characteristics and the solution of external walls. They are hinged, of increased length - up to 7 ... 11m. Loggias are hinged. The skeleton of the first floor is made of frame. A similar constructive system of transverse walls was adopted in the construction of 16-storey residential buildings built in Northern Chertanov and other districts of Moscow. The pitch of the transverse walls is 7.2 m, which further expanded the planning possibilities.

The main disadvantages of a structural system with a wide pitch of transverse load-bearing walls compared to a structural scheme with a narrow pitch are the labor intensity of construction increased by 25 ... 30%, the consumption of steel and cement increased by 15 ... 20%; this limits the use of wide pitch in construction.

Structural system with longitudinal bearing walls. Attempts to free the internal spaces from load-bearing structures led to the use of a system with three longitudinal load-bearing walls. The spatial rigidity of such buildings is ensured by the joint work of longitudinal and transverse intersection walls, as well as floors. Ceilings made of hollow-core floorings with interlocked joints are horizontal stiffening disks that transfer wind loads to the walls of the stairwells.

In principle, such an arrangement of load-bearing structures with spans of 5.4 ... 6 m to the greatest extent frees the area of \u200b\u200bthe house from internal walls. However, this decision conflicts with the constructive expediency: with single-layer structures of fences made of expanded clay concrete, the maximum height of the house, determined by the strength of the material and technical and economic indicators, is limited to nine floors.

External expanded clay walls are made in this case with a thickness of 40 cm, from expanded clay concrete class - 4-J-J-

Rice. XV.4. Large-panel 17-storey residential building with a wide pitch of transverse walls. Structural scheme:

/ - transverse load-bearing panels; 2-longitudinal wall panel; 3 - external tape wall panels: 4 - end reinforced concrete three-layer panels

sa B 5 with a density of 1200 kg/m3. Longitudinal internal wall made of concrete panels 27 cm thick. In the construction of brick and block residential buildings, the same structural system is used up to 12 floors high.

The structural system with cross-bearing walls in high-rise buildings has found limited use, and this is no coincidence. In the presence of transverse load-bearing walls, it is not advisable to arrange the front panels as load-bearing ones in order to support floor slabs on them. This solution makes sense only for small buildings up to 6 ... 9 floors. For more tall buildings it is logical to strive for all-round lightening of the outer walls, using only the inner ones for loading with plates (supported on three sides, including the inner longitudinal one). For building heights over 10…12" stories, a curtain wall solution is optimal.

Bearing frame of stone buildings. Houses with load-bearing stone walls still make up a significant share in the housing and civil construction of cities, although they are gradually being replaced by industrial and, above all, large-panel systems.

Despite the laboriousness of manual laying, stone structures will be used in the construction of various buildings and structures, including residential and public, due to architectural advantages and operational advantages.

The stone walls of the building are erected from clay and silicate bricks, ceramic hollow blocks, from artificial and natural stones of the correct form on lime-sand - vat-cement or sand-cement - solutions. There are stones for "one-handed" masonry: bricks (clay and silicate, solid and hollow) weighing up to 4.5 kg and stones for "two-handed" masonry - ceramic hollow stones with a density of up to 1200 kg / m3, from autoclaved cellular concrete with a density of up to 800 kg /m3. Stones for two-handed masonry have a mass of 8 ... 16 kg. Wall masonry techniques, see sec. II.

To improve the technical, economic and thermal performance, brick walls are made of efficient lightweight masonry, also discussed in Sec. II. In lightweight masonry, the upper 3 ... 5 floors are erected.

The load-bearing framework systems of multi-storey stone buildings do not differ from those discussed above for panel buildings: load-bearing frameworks with longitudinal or transverse load-bearing walls are used; also wireframes with self-supporting stone exterior walls.

With transverse load-bearing walls, longitudinal stone walls - self-bearing - perform only the functions of a building envelope. In addition, the longitudinal outer walls in this case are stiffening elements, providing, together with the staircases, the longitudinal stability of the supporting frame. The spatial rigidity of the building is ensured by the reliable connection of the longitudinal and transverse walls at their intersection and the connection of the walls with the ceilings.

The free length of the longitudinal walls within the limits between the cross braces according to the norms of SNiP with prefabricated reinforced concrete floors can reach up to 48 m.

The stability of buildings with longitudinal load-bearing walls is ensured by transverse walls - end, inter-apartment, and in some cases - special transverse stiffening walls.

An incomplete frame is used in order to save wall materials. An incomplete frame is also used if there are shops and other public service enterprises on the lower floors, the layout of which does not allow the construction of frequently located walls. With an incomplete frame, the floor panels are supported by crossbars laid along the columns of the frame.

Stone materials with a high density have a high thermal conductivity, and therefore, for thermal reasons, the outer walls have to be made of considerable thickness - from 38 to 77 cm.

The thickness of the walls in the lower floors of houses above 6 floors is increased to provide the necessary bearing capacity, and in some cases, for this purpose, special local wall thickenings (pilasters) are arranged in the lower floors or they are reinforced with reinforced concrete working together with masonry (the so-called "complex masonry"). ").

An increase in the bearing capacity of stone walls and pillars can also be achieved by using high-strength materials in the lower floors and reinforcing the masonry joints with horizontal wire meshes with a diameter of 4 ... 5 mm.

The thickness of the bearing internal walls is taken in the lower floors 640 mm (2.5 bricks) and 770 mm (3 bricks), and in the upper floors - 380 mm. (1.5 bricks). The thickness of the outer load-bearing walls in the lower floors is 640 ... 770 mm, in the upper floors for the climatic conditions of the middle zone, for example, Moscow, '- from hollow brick or ceramic stones 510 mm thick.

Decorative properties of brick walls are given by the device of a facade row of facing bricks or ceramic stones with jointing or facing with embedded ceramic or concrete slabs, which are installed along the masonry. For unique buildings, cladding with natural stone slabs is used.

The crowning part of the stone wall - a cornice or parapet - is decided in accordance with the roof structure adopted in the project and the drainage system (external or internal).

Interfloor floors of multi-storey buildings with stone walls are made of prefabricated reinforced concrete multi-hollow slabs. The skeletons of stone buildings with a height of 10 ... 14 floors are usually solved according to the principle of a wall skeleton with an incomplete frame, with floor slabs resting on the outer brick walls and on the longitudinal beams of the frame.

A certain advantage of such a constructive solution is the exclusion of a heavily loaded internal brick wall, which reduces the complexity of construction and creates the possibility of more flexible planning solutions. Such decisions were made in a number of cases for houses up to 14 floors high. A further increase in the number of storeys is not economically feasible, as it requires an increase in the thickness of the outer brick walls to increase their bearing capacity. Therefore, the limit of expediency of using a structural scheme with carriers (usually longitudinal) brick walls count as 14 floors.

|

|

Rice. XV.6. Details of joints of large-block walls:

a, 6 - adjoining floors to the outer walls: c - interface with the block of the inner wall; g - vertical joint; / - jumper block; 2 - flooring; 3 - lifting loop of the wall block; 4 - the same, flooring; 5 - steel anchor; 6 - steel corner; / - sealing mastic on a gernite tourniquet; 8 - pasting with rolled waterproofing material; 9 - lightweight concrete; Ш - cement mortar; // - inner wall block

XV. Load-bearing skeletons of civilian buildings

Multi-storey large-block buildings repeat the structural schemes of brick houses (Fig. XV.5, XV.6).

The outer walls are made of light-weight concrete blocks with two-row cutting, in the system of which the main ones are wall blocks and lintel blocks. On deaf (windowless) sections of walls, belt blocks are used instead of lintels. The thickness of lightweight concrete blocks of external walls is 400, 500, 600 mm, depending on the climatic conditions of construction. Internal wall blocks are made of heavy concrete with vertical round voids 400 and 500 mm thick, depending on the height of the house, i.e., on the magnitude of the acting forces.

At the intersections of the inner and outer walls, the banding of the belt blocks is provided and the embedded steel parts of the blocks are welded. To ensure reliable spatial operation of the building, the ceilings are anchored in the walls.

In terms of the level of industrialization, large-block systems occupy an intermediate position and are, as it were, transitional between brick and large-panel systems. In the future, as the base of large-panel housing construction develops, block structures will give way to more industrial and advanced systems - large-panel systems.

The choice of constructive systems for high-rise residential buildings.

The complexity of the economic comparison of the considered buildings, made according to various structural systems, is determined by the influence of a number of factors - the difference in volumetric planning decisions, the choice of materials and structures for individual elements, the individual approach of a designer to the design of elements. The influence on the cost of only planning factors can reach 20%. For buildings with a height of up to 16 ... 17 floors among building systems - large-block, frame-panel and large-panel - large-panel has advantages in terms of basic indicators. Most strongly in favor panel houses they say the indicators of labor intensity, which turns out to be 2.5 ... 3 times lower for panel houses than for frame houses.

The given indicators determine the expediency for 16 ... 25-storey residential buildings of frameless load-bearing frames.

Studies show that the most economical types of buildings in terms of steel, cement and concrete consumption, labor and cost are large-panel houses with a structural system in the form of transverse load-bearing walls located with a narrow step. That is why such a system is most widely used in construction.

Increasing the number of storeys of large-panel houses from 5 to 9, then to 12 and, finally, to 17 and 25 floors within a single structural system does not lead to a sharp increase in material consumption and labor intensity.

New directions for the development of multi-storey industrial housing construction. As the practice of building high-rise panel houses shows, conventional panel structures can be used in houses no higher than 25 floors. Already at such a height, additional and rather significant complications arise in the structures of panel houses, associated with the difficulties of ensuring spatial rigidity.

The most expedient method of increasing the rigidity of buildings is the layout of a panel house plan with transverse walls developed over its entire width, which in this case will have sufficiently high rigidity and in buildings up to 16 ... 17 floors high it is relatively easy to perceive horizontal loads.

Another direction in the search for new constructive solutions for high-rise panel buildings is also associated with the use of monolithic reinforced concrete. One of the possible structural schemes is a monolithic reinforced concrete shaft, from which powerful reinforced concrete cantilever hollow slabs are “released” at several levels, which are, as it were, platforms for supporting block houses of any panel structure (Fig. XV.7).

A variation of this system is prefabricated-monolithic reinforced concrete structure, in which the spatial system of diaphragms in the form of a stiffness core is made in monolithic reinforced concrete (for example, in the same movable formwork) and a prefabricated panel structure is “attached” to this core, which works here only for vertical loads (Fig. XV.8). Panel houses of this design can be built up to 30 ... 35 floors high.

Typification methods in large-panel housing construction. At the first stage of large-panel housing construction, the object of typification was a typical residential building. This led to monotony, to the impossibility of achieving diversity in the building architecture. The next method was block-sectional, in which block-sections were the finished object of typing, from the set of which a volumetric-spatial composition of the building was created. For a variety of compositional solutions, latitudinal and meridional block sections, straight and angular ones, with a shift in plan, rotary inserts, etc. have been developed. This method is most widely used in mass construction in our country.

The search for diversity in individual construction led to the development of the block-apartment method, in which the apartment was the object of typification. However, it did not find practical application due to the instability of factory production of parts and the need in each case to develop, in essence,

individual projects of panel houses.

A new method was the method of layout space-planning elements (KOPE) developed at Mosproekt No. 1, in which fragments (structural-planning cells) of a residential section with a height from the foundation to the roof became the object of typing, capable of interlocking with other similar fragments of the system according to certain rules, creating thereby different in terms of compositional, demographic and other conditions of space-planning

final solutions for residential buildings with a height of 18 ... 22 floors (Fig. XV.9).

The advantage of the method is a high degree of repeatability of typical industrial products due to the rigid unification of planning parameters in various fragments and in such elements of the building as stair-lift units, zero-cycle structures, an attic, etc.

The method assumes an open system of typification of facade panels, thus creating additional means for the diversity of building architecture.

Structures of load-bearing walls and floor support units. Most Ra

|

|

From the point of view of the whole complex of requirements - strength, technological, economic - the rational structures of load-bearing walls are transverse walls made of flat load-bearing reinforced concrete panels. This decision has become, in essence, the only one for high-rise buildings. Currently, flat panels for buildings with a height of 9 ... 12 floors are made with a thickness of 16 cm. This thickness is dictated not only by strength conditions, but also by the requirements of sound insulation from airborne noise.

It can be recommended to increase the thickness of the inter-apartment wall panels to 18 cm. When the number of storeys of houses with a narrow step increases, for example, to 16 ... 17 floors, the transition to a wall thickness of 18 cm is determined not only by sound insulation conditions, but also by strength, as well as fire safety requirements. For heavy loads, for example, in systems with a wide spacing of load-bearing walls, in houses with a height of 16 floors and more, it is advisable to increase the thickness of the transverse walls to 20 cm.

Abroad, in most cases, internal walls are also used in the form of flat panels the size of a room made of class B20 concrete with a thickness of 15 ... 20 cm.