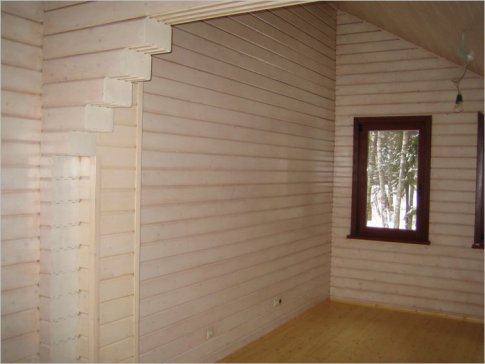

Photos of the interiors of houses made of laminated veneer lumber. Interiors of houses made of laminated veneer lumber

Construction modern houses, or rather, known technologies make it possible to build houses from a wide variety of building materials.

For example, houses made of laminated veneer lumber are very popular. If you like this building material, then rest assured that the finished house will have a beautiful, attractive appearance.

In this article we will discuss the issue that the interiors of houses made of laminated veneer lumber can be very different. When developing it, you can use a variety of elements and techniques. We invite you to consider this issue in detail. The article also contains many photographs showing ready-made solutions.

Features of buildings

Of course, a well-thought-out interior of a house made of laminated veneer lumber will make it attractive not only from the inside, but also from the outside. It is immediately worth noting that the material used itself has a number of positive aspects. For example, the main advantage is environmental friendliness.

Glued laminated timber is absolutely safe for others. As for the design of the house itself, this material has a special appeal. For this reason, to create beautiful interior it doesn't take much effort. Among the advantages, one can also highlight the fact that such a house has good sound and thermal insulation.

Considering the specificity of the entire building, the creation of the interior of the house should also be approached in an extraordinary way. There are several original solutions to give the overall appearance some originality:

- Painting the walls. Under a layer of paint, the timber will be better preserved. Plus, you can brighten up the interior.

- Wall finishing with plasterboard or other building material. Plus, you can combine certain solutions, as can be seen in the photo in this article.

It is important to remind you that when designing the interior of a house made of laminated veneer lumber, you should not adhere to a certain template and rigid framework. You may decide to use certain decorative elements. Everything is completely up to you. So, now we will look in detail at the individual elements of the interior, as well as how it can be decorated.

Timber processing

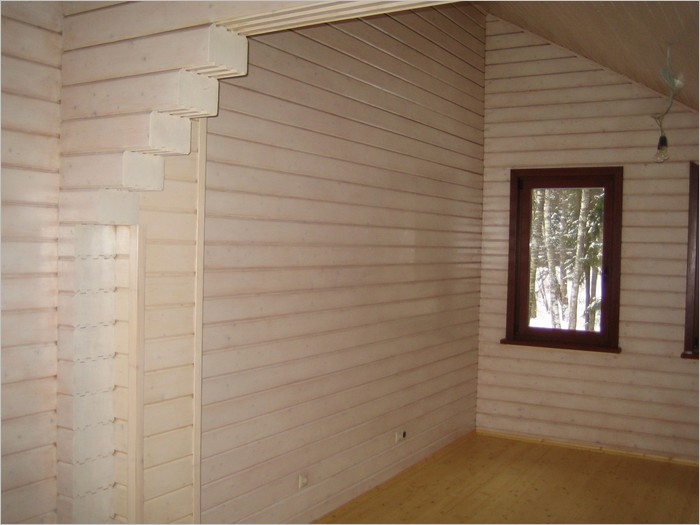

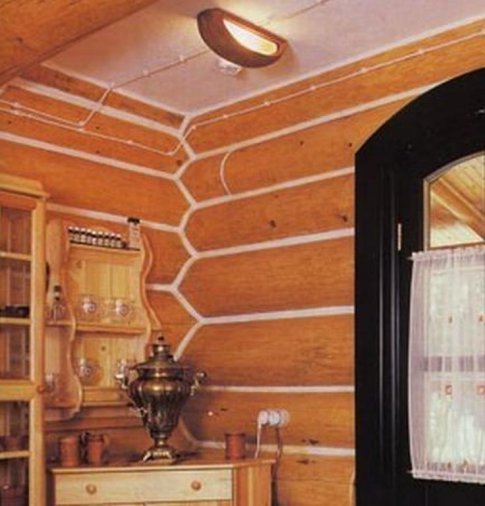

It is also worth noting the fact that purchased laminated veneer lumber requires processing after installation. It is covered with stain, varnish or paint. In the case of using stain and varnish, the structure of the wood can be emphasized. In the photo you can see the interior of the house, where the material is varnished.

Ceiling and floor treatment

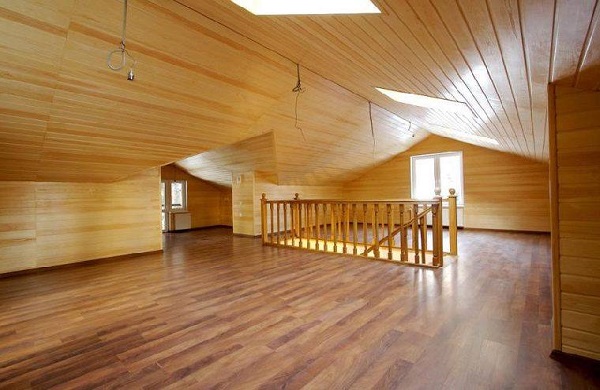

What is the best way to treat the floor in a house made of laminated veneer lumber? IN general style The interior will look original with wooden floors, ceramic tiles, stone and similar materials. You can also lay laminate flooring with a wood pattern. In the photo you can see how this floor fits perfectly into the overall design of the entire house.

As for the ceiling, there is also a considerable selection of original solutions. For example, you can attach wooden beams. Plus, you can mount wooden or plastic lining.

Decor elements

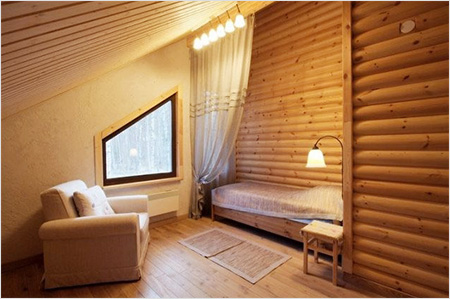

It is equally important to pay attention to decorative elements that can decorate the entire interior of a house made of laminated veneer lumber. It's important not to overdo it here. Remember, decorative elements should only be an addition and not play a key role in the interior of the entire house.

So, in combination with laminated timber, animal skins on the walls and floor, carpets, trophy antlers, guns, paintings or framed photos will look great. If the choice fell on a painting, then choose it so that it is at least somehow in harmony with the general idea of the design.

Advice! Beautiful lamps will also decorate the walls. Although it is part of the lighting, but beautiful wooden lamps can also be classified as decorative elements.

Change the interior slightly finished house from laminated veneer lumber you can do it yourself. For dramatic changes in the interior, those who have reached the finishing stage of a house under construction will most likely need a design project.

Stages and timing of creating a design project

A design project is not only an idea of the appearance of the room. It contains a whole package of documents, including various options for planning solutions, drawings, 3D floor plans, detailed cost calculations and other important documentation according to which the work will be carried out.

- Technical task. A standalone product consisting of several pages of descriptions and examples of what you like.

- Preliminary design. Development planning solution, according to the Technical Specifications with mandatory connection to existing utility networks. Development of the concept of the facility, in accordance with the Technical Specifications. At this stage, work is underway on the style and color palette, references are selected for each of the premises, including bathrooms and technical rooms, and finishing materials are pre-selected

- 3D visualization. Visualization will show exactly what your interior will look like after implementation.

- Working draft. Drawings: plans, developments, layouts, components, technical maps, furniture sketches. Pictures and drawings are good, but it’s still better to build according to the drawings.

- Selection of furniture and equipment.

Time frame for creating an interior design project: 2 months.

Examples finished design project: design project for the interior of a house made of laminated veneer lumber.

When do you need an interior design project?

We are often asked about this. In such cases, we ask for clarification. Are you ready to actively participate: in creating the layout of the premises of your home, in determining the configuration of the heating system, in designing low current systems, in the arrangement and selection of plumbing and lighting fixtures, independently purchasing ceramic tiles, laminate or parquet board, paints, wallpaper and doors? And finally, do you have a final sketch and 3D model of the interior?

You can go this route yourself, or contact our company to get an original interior without annoying surprises and mistakes.

The works of our designers are at your service. As you understand, their task is not just to draw beautiful pictures, but a professional approach to the technical and creative organization of the process, so that every day in good mood you were aiming for only one place—your home.

So, the house kit was delivered to the site. Then the professional team of the Russian West gets to work. And now on the site in all its glory.

The walls of the house look impressive. But to bring them to perfection, .

Let's leave the argument that you can do without finishing work. This hackneyed phrase was born because it is a unique building material made of natural wood that looks incredibly impressive. But this is not enough; competent and professional treatment of the walls is needed.

Suffice it to say that the degree of protection of the wood, its spectacular appearance, and even ease of maintenance depend on the quality of the finish.

Even at the factory, the timber is treated on all sides with a transport septic tank, and its ends are treated with special wax. But such treatment is just temporary protection of the timber.

Fully finishing the walls in a house made of laminated veneer lumber is a serious job that consists of several stages. In the Russian West company, each stage of finishing is strictly regulated, the best are found, optimal materials, the sequence of work is determined, specialists are involved and control is carried out.

The Russian West company does as external, so internal finishing of walls made of laminated veneer lumber.

Exterior finishes include:

- grinding the surface of the timber;

- protection with special compounds;

- removing wax from end surfaces;

- grinding and protection of end surfaces;

- intermediate and final coating.

The first stage is grinding. For this we use a set of grinding equipment. We have at our disposal a selection of grinding equipment for any design and configuration of houses.

Wood is a material that needs to be fully protected. After professional work We guarantee wood protection from:

- fires;

- precipitation, dampness, rain;

- rotting;

- exposure to harmful insects and wood-damaging fungi.

Next, we treat the timber with a special composition for wood, which gives the laminated timber a characteristic shade (tone). In addition, thanks to the vapor-permeable coating, micropores are formed, through which the humidity in the room is regulated.

Important point- protection of end surfaces. First, the varnish is removed from them, which is applied during production and performs protective functions during transportation to the site. Mandatory protection of the end surface in the Russian West company is due to the specifics of wood as a material: the overwhelming amount of moisture penetrates through the end cuts. But, after treatment with a special sealant, moisture is prohibited from entering!

Interior decoration

This stage also involves sanding and painting the walls. In this case, a vapor-permeable composition with a different formula is used (compared to what is used for exterior decoration). And here we are guided by high safety standards, since we are finishing the walls inside the house where people will live. Chemicals used for interior works less aggressive in composition, and, therefore, more harmless to people.

As a result of complex finishing, the walls are protected from damage and can even absorb unwanted odors!

Decoration Materials

All finishing materials that we use to finish laminated timber walls can be divided into two main types: tinting and protective.

Toning coatings are needed to impart the shade of the wood surface. The substances they contain penetrate into several layers of wood.

Tinted coatings do not provide a hard surface and may even be slightly tacky to the touch. Therefore, according to technology, the surface on which tinting coatings are applied must also be coated with a protective composition. Otherwise, dust will accumulate on them.

In its turn, protective coatings , unlike tinting ones, do not penetrate deep into the wood. They create a neat, attractive, smooth surface. And this surface remains clean.

Both protective and tinting surfaces contain various oils.

Clients are interested in what materials we use for the exterior and interior decoration of houses made of laminated veneer lumber?

Naturally, we choose compounds that have passed strict certification. We only use best materials world famous company Tikkurila- impregnations, varnishes, sealants and paints. Various materials allow us to provide a range of wall finishing solutions.

Very often, clients want to give their home a unique look. We offer a large selection of all kinds color solutions. And our designers give advice on choosing colors and combining shades.

The richness of colors and shades is a guarantee that the house will sparkle with colors, become bright and stand out against the general background.

Helpful information

Thanks to modern standards and new technologies, new finishing materials have appeared - water-based. All of them contain components that protect wood from ultraviolet radiation. They are ideal for natural wood tones.

Both paints and impregnations can have different densities, be glossy and matte.

Before applying the material to the walls, a test sample is required. You need to start with lighter tones - after all, it’s easier to make a wooden surface darker than to lighten it!

If the finishing is done correctly, in two or three layers, interior walls the houses will not need repairs for a very long time. Particular attention should be paid to areas around windows and glass doors: the casing and window sill must be treated with a wear-resistant compound.

The latest trend is to finish the inner surface with mastics based on natural materials(wax and the like).

Having completed the construction of a log house, you should not think that all the work is finished. On the contrary, the most interesting things are just ahead! To create a cozy atmosphere you need interior decoration houses made of timber, which requires more detailed attention.

And how to carry it out correctly, read this article.

Interior work in a wooden house - an integrated approach

If you have not yet come across the term “interior decoration of houses made of timber”, then it is worth explaining that this is a whole set of tasks, which includes:

- Laying communications (heating, water supply, sewerage, electricity);

- Impregnation of wooden walls with antiseptics and fire-resistant compounds; (see also article)

- Thermal insulation and waterproofing of walls, floors, ceilings (if necessary);

- Installation of partitions and other structures;

- Preparation of walls, ceilings, floors decorative finishing(leveling, installation of a frame for fastening cladding material, etc.);

- Finishing cladding of walls, ceilings, floors;

- Installation interior doors, switches, lighting fixtures.

Advice!

If you have never done any of the work listed above before, it is better to entrust it to qualified specialists.

Well, let it take more money than originally planned.

But this way you can be sure that everything is done efficiently and reliably.

This is especially true for communications.

It’s quite possible to handle the remaining tasks on your own.

Interior decoration of a house made of profiled timber is a responsible undertaking. Therefore, before starting it, it would be good to draw up a design project in which all the nuances will be clearly spelled out. In particular, the location of heating pipes, electrical networks, sewerage and much more.

That is, you need to clearly consider all the previously mentioned points: from rough materials to decorative coatings - their type, required quantity, cost, color, texture, etc.

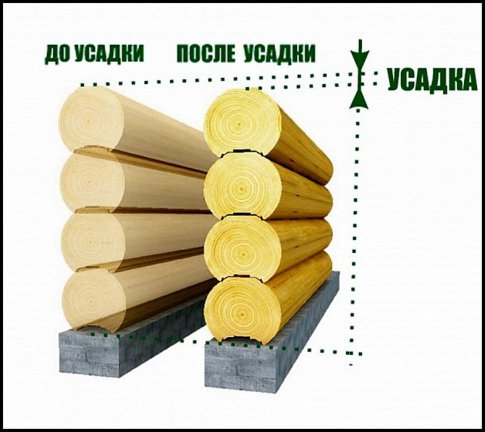

Another important point to be aware of is that all wooden buildings experience shrinkage.

This process can be divided into two stages:

- Primary shrinkage - in most cases continues during the first 2 years due to drying of the wood. Due to the fact that at this time there is a decrease in the gaps between the beams under the weight of the roof, cracks of various sizes may appear outside and inside the room. In addition, the ceiling and walls may shrink by 2-3 centimeters.

In view of this, experts do not recommend using rigid structures (for example, plasterboard, plastic panels) when finishing walls and ceilings until the shrinkage of the house is completed. - Secondary – associated with fluctuations in humidity and temperature of wood. As a rule, it is insignificant and is unlikely to have any negative impact on internal cladding coatings.

Then, what could the interior decoration of a house made of laminated veneer lumber or profiled timber look like in the first years after construction?

The best thing to do here is:

- Plaster bearing structures and cover them with special paints and varnishes that protect the wood from mold and rot;

- Install a two-layer subfloor;

- Leave the ceiling as it is or use a stretch fabric.

| Product | YUNIS TEPLON plaster white (30 kg) MIXTER plaster (30 kg) STARATELI plaster gray gypsum (30 kg) Gypsum plaster RUSEAN TERMOPLAST / Thermoplast (30 kg) Cement leveling plaster OSNOVIT BIGWELL T-22 (25 kg) Cement-lime forged leveling plaster OSNOVIT STARTWELL T-21 (25 kg) Gypsum plaster OSNOVIT GIPSWELL MN T-26 (30 kg) Gypsum plaster OSNOVIT GIPSWELL T-25 white (30 kg) Gypsum plaster OSNOVIT GIPSWELL T-25 gray (30 kg) Light plaster OSNOVIT FLYWELL T-24 (20 kg) Thin-layer cement plaster OSNOVIT SLIMWELL PC23 (T-23) (25 kg) Cement mortar LITOKOL LITOPLAN RAPID / LITOKOL LITOPLAN RAPID (25 kg) Plaster mixture LITOKOL LITOGIPS / LITOKOL LITOGIPS (30 kg) Decorative cement plaster KERAFLEX BARK BEARD (25 kg) Decorative cement plaster KERAFLEX SUBA (25 kg) Plaster KERAFLEX S20 Basic ( 25 kg) KERAFLEX plaster C23 Gray (30 kg) Plaster KERAFLEX C27 Machine (30 kg) Plaster VOLMA LAYER Universal (30 kg) Plaster VOLMA CANVAS (30 kg) Plaster mixture VILIS gypsum (30 kg) Plaster PERFEKTA / PERFECTA GIPSTAR WHITE (30 kg) Plaster plaster PERFEKTA / PERFECTA GIPSTAR GRAY (30 kg) Lightweight gypsum plaster PERFEKTA / PERFECTA GREEN LINE ECOSIDE (30 kg) Gypsum plaster for machine and hand application PERFEKTA / PERFECTA GIPSTAR WHITE (30 kg) Gypsum plaster for machine and hand application PERFEKTA / PER FECTA GYPSTAR GRAY (30 kg) Decorative plaster PERFEKTA / PERFECTA BARK BEETLE (25 kg) Decorative plaster PERFEKTA / PERFECTA SHUBA (25 kg) Facade plaster PERFEKTA / PERFECTA LEVELING (25 kg) Facade plaster PERFEKTA / PERFECTA LEVELING WINTER (25 kg) Easy machine applied facade plaster PERFEKTA / PERFECTA FRONTPRO LIGHT (30 kg) Lightweight machine-applied facade plaster PERFEKTA / PERFECTA FRONTPRO LIGHT WINTER (30 kg) Lightweight machine-applied facade plaster PERFEKTA / PERFECTA FRONTPRO (30 kg) Reinforced facade plaster PERFEKTA / PERFECTA THIN-LAYER (25 kg) Plaster KNAUF ROTBAND / KNAUF ROTBAND White (30 kg) Plaster KNAUF ROTBAND Gray (25 kg) Plaster KNAUF ROTBAND Gray (30 kg) Plaster KNAUF UNTERPUTZ Facade (25 kg) Plaster gypsum BERGAUF Bau Putz Gi ps / BERGAUF Bau Putz Gypsum for walls and ceilings (30 kg) Gypsum plaster BERGAUF Easyband (30 kg) Gypsum plaster BERGAUF Prima Putz Gips (30 kg) Cement plaster BERGAUF Bau Putz Zement Cement for facades (25 kg) |

| Surface area m2 | |

| Layer thickness, mm. | |

Rough and finishing floor

First of all, the subfloor is raised from timber into the home. We recommend choosing a double floor structure - it will best retain heat indoors.

How's that for a double subfloor? That is, special logs are constructed, between which insulation with a waterproofing layer is laid (for example, mineral wool). Then the whole thing is covered with boards, followed by a final floor covering. Perhaps this is the simplest, most economical and effective option in terms of heat conservation and sound insulation.

But it is very popular to use the following materials as a finishing floor covering in timber houses:

- Planed tongue and groove board.

It has many advantages, of which I would especially like to note the following:

- this is a 100% environmentally friendly material, which, thanks to its natural properties and special impregnations, “breathes” and has excellent resistance to moisture;

- strength and durability are another advantage of tongue and groove boards (besides, such a floor is very convenient and easy to care for);

- modern variations in the processing and tinting of the surface of the boards make it possible to harmoniously fit them into almost any interior;

- If necessary, the floor covering can always be updated by sanding or regular sanding of the boards.

- But if a water or infrared “warm floor” system is used as additional heating, then you can forget about the floorboard. The fact is that a decent portion of the heat will be spent on heating the sheet pile.

In this case, laminate or parquet boards are most often used to lay the finished floor.

Important!

When choosing parquet/laminate for floor heating with heating, pay attention to the presence of appropriate markings, which should indicate that the coating has good heat conductivity.

Wall cladding options

As mentioned above, interior decoration of the walls of a house made of timber involves their preparation (puttying, insulation, moisture and vapor barrier, etc. work) and further covering with finishing material/coating.

Advice!

Before finishing wall structures, answer yourself the question: “for what purposes will the constructed house be used?”

If it was built to spend exclusively weekends and summer holidays, then you can safely save on insulation.

After all, no one will live here in winter.

But if it’s the other way around (that is, this is the main dwelling), then it’s simply necessary to insulate the walls.

As for finishing the walls, there are many interesting solutions. True, when the house is shrinking (remember, the first 2 years after construction), it is better to limit yourself to paints, varnishes or simple stain.

This treatment is notable for the fact that the natural texture of the wood is preserved. After all, the tree itself has unique patterns, which are drawn by the most talented artist - nature. Why hide this beauty? This technique is especially effective if the walls of the house are built from valuable timber.

Attention!

When choosing paints and varnishes, give preference to those that contain as few substances as harmful to health as possible.

For your information!

Modern paint comes in matte, semi-gloss and glossy – also take this into account when purchasing it.

In the event that shrinkage no longer threatens, interior decoration wooden house timber can be made using sheet materials.

Let's look at the most fashionable of them:

- Isotex wall panels. They are usually made from wood without the addition of glue, so they are excellent environmental friendliness and hypoallergenic. The advantages here also include good thermal insulation characteristics, sound-absorbing properties and easy installation.

The outer covering of the panels is vinyl wallpaper or linen fabric. In specialized stores you will certainly find a rich assortment of these products, made in various color scheme and texture.

- Drywall is widely used everywhere for interior work. And this is not surprising, because you can use it to create any architectural creations (in particular arches)! In addition, it has a low specific gravity, is easy to process and is an environmentally friendly material. Oh, yes, the price for it is very, very pleasant, despite the many useful qualities.

The installation instructions for plasterboard sheets suggest attaching them to metal or wooden frame, which is pre-built on wall structures. This system is convenient in that the timber and gypsum board will not come into contact with each other - this will preserve both load-bearing walls, and the casing from the formation of cracks.

Behind the sheet material, in the frame, you can conveniently hide electrical wiring, plumbing, and other communications (not to mention the insulating layer).

- Interior wall decoration with imitation timber - siding, lining, block house, MDF panels. Many of our compatriots like real Russian log huts, but, alas, this is a very expensive pleasure. Therefore, it is necessary to build from cheaper material - profiled or laminated veneer lumber, which has a rectangular cross-section. (see article for more details)

Interior decoration with imitation timber allows you to give a timber house that missing nobility, and without spending a lot of money, time and effort. A room with such cladding is difficult to distinguish from natural logs.

The main advantages include:

- Environmental friendliness - the room will always maintain a favorable microclimate. And if you use panels made of pine or larch, the air in the house will become truly healing! (see article for more details)

- Wide range of applications - such panels can also be used for interior finishing of a bathhouse made of timber with your own hands or external cladding of buildings. And that's thanks to unique properties material: resistance to moisture, temperature changes, ultraviolet radiation and other harmful influences.

- Simplified installation - a convenient groove fastening system not only facilitates the cladding process, but also makes decorative coating monolithic and durable.

As you can see, the interior decoration of houses made of laminated veneer lumber can be very diverse and original, matching the chosen style of room decoration.

Since we started the renovation, let’s not forget about the ceiling

Here, again, you need to proceed from whether shrinkage occurs at the time of finishing work or not. If there is no longer any shrinkage, you can implement any ideas using any existing materials.

And in a newly completed house, it is more rational to choose one of the two solutions below:

- Leave the ceiling open. It would be great if the interior of the room corresponds to this approach. An unlined ceiling can harmoniously fit in and emphasize the country or Provence style, for example.

- Do suspended ceiling, which will perfectly cover the ceiling hole and at the same time will not interfere with the shrinkage of the house.

Conclusion

Any interior decoration (not just timber buildings) is a complex undertaking that simultaneously solves several important problems. Therefore, it must be taken seriously. Only then will the desired coziness, comfort and warmth reign in the house!

And in the video posted in this article there is visual information on the topic we touched on.

The term interior decoration includes a set of works on laying communications that provide heat, electricity, water supply, sewage system, etc. In addition, interior decoration involves creating an interior. Interior decoration in timber houses has a number of features.

Features of interior decoration of a house made of timber

In principle, the same materials are used for interior decoration of houses made of timber as for finishing, for example, brick house. But wood has a number of features that need to be taken into account when performing finishing work:

- houses made of timber are characterized by significant shrinkage, which can last for 5-6 years after completion of construction.

Shrinkage is due to the fact that the beam dries out and decreases somewhat in volume; in addition, due to the action of a constant load, the gaps between individual beams also decrease. As a result, by the end of 5-6 years of operation, the height of the floor may well decrease by 2-3 cm. Such deformation can have a detrimental effect on the appearance of the wall (cracks may appear in the plaster, the tiles may partially fall off or crack).

The use of laminated veneer lumber partially solves this problem. In this case, the shrinkage of the house is completed by the end of the year after operation.

- Another feature of houses made of timber is that wood, compared to other building materials, reacts especially strongly to changes in humidity. But changes in floor height for this reason are insignificant and rarely exceed 1% of its height.

Materials for finishing the interior of a timber house

Wood itself is an excellent finishing material, therefore, if the surface of the walls inside does not have obvious flaws, then it is quite possible to leave the walls without additional finishing. It will only be enough to saturate the wood with the appropriate composition to give it the required shade.

But wooden walls do not always correspond to the owner’s requests; wall finishing options; in this case, there are many finishing options.

Regardless of the chosen finishing method, the wood must be impregnated with an antipyretic and antiseptic. Otherwise, the wooden elements will quickly become unusable.

The finishing method depends on the age of the house and the purpose of the room. So, for houses whose age exceeds 5-6 years, there are no restrictions. For houses whose shrinkage has not yet been completed, it is not recommended to use low-deformation finishing materials, such as tiles.

In general, the following options for finishing a house made of timber inside are possible:

- Painting. The advantage of painting walls is that the layer of paint will serve as an additional protective layer for the wood.

- You can just plaster the inside of the house. In this case Special attention attention should be paid to waterproofing wooden surfaces. Plastering work is not recommended to begin earlier than a year after completion of construction.

- Finishing with block house or clapboard. This option is used when the walls inside have an unsightly appearance, but the owner wants to preserve the wooden surfaces inside the house. This finishing method is recommended to be used only after the house has settled. First you need to create a frame that will slightly reduce the usable area of the room.

- Wood tinting. To do this, the wood only needs to be cleaned of dust and impregnated with the composition in order to obtain the required shade.

- Plasterboard finishing. Perhaps a universal option for interior decoration of a house made of timber. Then, after puttying, you can stick wallpaper on the drywall and paint it. You can even lay tiles on drywall. To decorate rooms with high humidity, plasterboard is also most often used; for this it is recommended to use a moisture-resistant type of plasterboard (sheets of a greenish tint).

An important advantage of finishing a house made of timber with plasterboard is the ease of laying communications. Wires and pipes can be routed into the space between the wall surface and the drywall sheets. The disadvantage of this finishing method is some loss of usable space.

Plasterboard finishing can be combined with wall insulation.

When finishing the ceiling, quite often the ceiling beams are not masked, but act as an element of the interior. As for finishing the ceiling using traditional methods, for example, plastering, it is not recommended to do this in the first 5-6 years. The fact is that shrinkage of the house causes a redistribution of efforts in ceiling beams. A compromise option could be finishing the ceiling with plasterboard or installing a stretch ceiling.

Separately, it is worth mentioning sealing; these works can also be attributed to the interior decoration of a house made of timber. Of course, the house must “breathe,” but air circulation should occur through ventilation, and not through natural cracks and gaps between boards and beams. In the past, tow or moss was used to seal the joints between logs.

Traditional methods of sealing (filling cracks with moss or tow) have been replaced by new materials - special sealants. Despite their high elasticity, they provide 100% tightness and can act as an interior element.

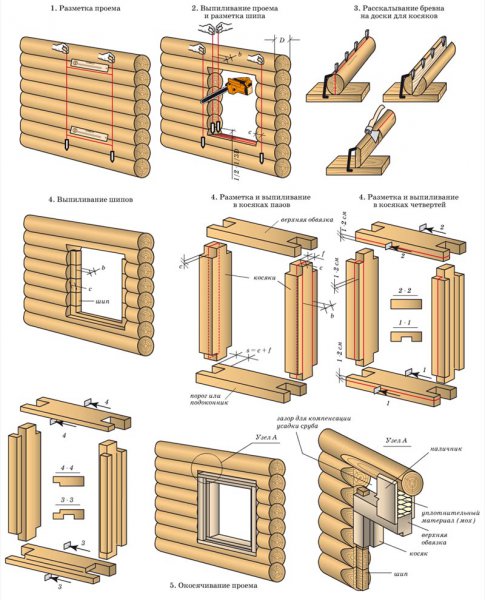

Significant wall deformations require attention when installing doors and windows. To prevent the beams from crushing the frame or door frame, so-called jambs are installed at a distance of up to 15 cm from the logs. At finishing works the space between them and the logs must be filled with elastic materials, otherwise, when deformed, the beams will simply crush the door frame or window frame.

In principle, the interior decoration of a house made of timber is not very different from the decoration of a house made of other materials, for example, brick or concrete. You just need to take into account the increased settlement of the house and the susceptibility of wood to moisture.

Video - Decorating the inside of a wooden house with water-based glaze