Monolithic construction of a private house by hand. Monolithic works and walls: how to build a monolithic house yourself. Lapping the concrete to a finish - grinding

Monolithic technology means construction directly on site by pouring concrete into the formwork. This technology, like any other, has its advantages and disadvantages.

So, the advantages of monolithic construction of houses:

- monolithic construction implies the integrity and unity of the entire structure, which increases the strength characteristics of the house as a whole;

- the absence of seams makes the house much warmer;

- construction monolithic houses can be produced at any time of the year on different types soil;

- economy; high speed of construction of structures;

- the possibility of erecting structures of any shape; walls can be finished with various materials; the shrinkage of the building will be uniform, and this will exclude the appearance of cracks.

There are also disadvantages that accompany monolithic construction:

It is ideally seeded with a concrete mix. The strength, durability and frost resistance of concrete formwork are properties that predispose to the formation of the landscape and the construction of retaining walls. More specifically, to remain constant in it. The big advantage of this technology is that it saves time and money. Especially because there is no need to remove the woodworking, and also because the preparation of the formwork often requires highly skilled joinery or assembly work. In addition, the formwork does not remain in the structure without use, but contributes to its load-bearing function, even it can provide the building with other necessary properties, depending on what the lost formwork consists of.

pouring cement requires a concrete pump, which is quite expensive; mandatory grounding of the entire house is required, since the walls are made of reinforced concrete with conductive reinforcement.

Thus, we can say that monolithic construction is, in general, an excellent option for any person who has decided to build a house with his own hands. It is worth talking about this in more detail.

Vibration-insulated concrete or lamp-bonded concrete fittings are most commonly used, but can also be made of insulating material. Or it can be made from cement slabs, which have the advantage of being highly variable in possible use. They can be used to create sloped walls, sloped ceilings, etc. in addition to vertical and horizontal structures, etc. a closed interior space is created from fittings or plates, which, if necessary, are filled with concrete after the reinforcement is applied.

DIY construction of a monolithic house

However, nothing is impossible, so a monolithic house can be built on your own. Project monolithic house you can do it yourself, or you can download it from the Internet or order it from a special design bureau. In any case, it will be necessary to calculate the strength of the bearing walls and the load on them, as well as required thickness pouring the solution and the amount of insulation.

Hollow concrete blocks filled with concrete mixes have a high load capacity, and we can also use them for the construction of support pillars. Therefore, it is logical that it is useful to use a clever idea here and it is more logical to create formwork, a form, only from concrete, which is associated with its strength and resistance to the foundation and the ideal of underground construction. For these purposes, prefabricated thin-walled fittings are used, which are assembled dry and filled with cast concrete. In vertical joints, locks are attached to them, which fit into each other.

After the project is completely ready, you can start working with the foundation. If construction is planned basement floor, then the foundation can be made tape. Most often, a pile-strip foundation is erected and waterproofed. Next, the construction of a monolithic house with your own hands with removable formwork will be described, since this option is considered the best today. It is possible to build houses with fixed formwork.

They are profiled in such a way that they can be embedded in horizontal and vertical reinforcement. In addition, the basics are easier to measure, the implementation itself is less labor intensive and more accurate. The use of formwork formwork is not limited to underground structures, but it is also possible to build perimeter walls for which we do not require high heat resistance, such as garages or workshops.

Or we need to provide additional insulation for the load-bearing wall. They are set to "dry", the ends of the blocks form a special fixing lock, into which a free piece of thermal insulation is inserted. After filling the cavity with concrete, the wall forms a solid and even base for internal and external plaster.

The formwork itself is made of boards, which have a size of 30 to 50 millimeters. If the temperature in the region where the construction is carried out is below -30 degrees, then it is better to choose a larger thickness of the boards.

- At the bottom, metal ties with bolts are installed. This is done so that the shields are not ripped apart after pouring the mortar. From above, all shields must be fixed with wooden plates or the same steel ties.

- Further, depending on the project, a reinforcing mesh or frame is inserted into the formwork.

- Now you can start making sawdust concrete.

- To do this, take 8 parts of dry sawdust, one part of cement, two parts of sand and three parts of lime.

- The cement is mixed with the sand.

- Separately, you need to mix and lime with sawdust.

- Only then can both mixtures be thoroughly mixed together.

- In this case, it is necessary to gradually add water to the mixture. As a result, there should be enough water so that it does not flow out of the solution.

- Now the resulting solution can be poured into the formwork with a layer of 20 centimeters. The entire mixture is thoroughly mixed with a vibrator and pierced with rods to thoroughly tamp the solution. After tamping, the solution remains for hardening for about a day.

- Then you can fill in the next layer in the same way. This is done until the formwork is practically filled.

- To simplify further work, it is worth leaving a distance of 10-15 centimeters on top. Above, the formwork can be rearranged only after about 3-5 days. The solution should harden all this time. In this case, the formwork must be protected from the sun and rain.

- After all the walls have been erected, the concrete must be given about a month to fully harden. Only after that, further work is carried out related to the arrangement of floors and roofs. All ceilings should go beyond the walls by at least 20 centimeters.

- When the sawdust concrete is completely dry, you can, if necessary, insulate the walls from the outside. For these purposes, warm plaster is ideal, which can be applied in a layer of up to 50 millimeters. It is an excellent waterproofing and heat insulator, and at the same time it perfectly permeates steam to the outside.

Thus, the construction of a monolithic house with your own hands can be considered completed. As you can see, there is nothing supernatural in this process. Many have long preferred to engage in this kind of construction without the involvement of third-party organizations and individuals.

We can grow our pods and fences easily and quickly. In some cases, it is not necessary to fill the cavity of the blocks with concrete, but it can be filled with a dry, free-flowing mixture such as gravel. The forms of the lost formwork are connected to the drywall by bandaging, or the structure is reinforced with horizontal or vertical reinforcement. Self-washing is carried out using a thin concrete mixture in a layer, but up to three to five layers of formwork at a time.

However, if we want to improve the thermal insulation, we need to add another layer of thermal insulation. A ridiculous solution is to form the formwork, mold, fitting from a material that insulates better than concrete. The material was wood waste associated with cement. We know this solution is mostly unchanged with us under different trade names. Walls and ceilings are concreted into the precast formwork of wood-cement boards or fittings, which, after the concrete has hardened, remain a permanent part of the structure.

Do-it-yourself monolithic house construction technology

Removable formwork is always designed individually for the house or cottage. This is done due to the fact that monolithic houses can be of various shapes... The formwork must exactly repeat all the outlines of the building. Most often, wood or metal is used to create formwork. You can find options that will be made of plastic, plywood. This does not change the meaning of the work.

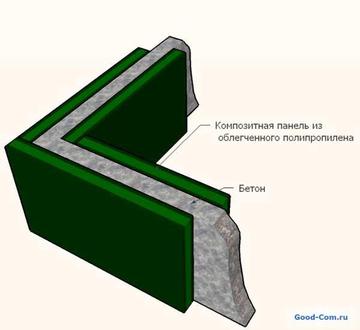

To improve the thermal insulation properties, boards or fittings can already be added to the insulation with a layer of thermal insulation, usually polystyrene. Thanks to the concrete core, exceptional storage capacity in the house is guaranteed, of course, high strength, fire resistance, excellent acoustic insulation and low diffusion resistance, i.e. easy penetration of water vapor. As with concrete parts, the perimeter and / or internal masonry is exposed to the panels and the prepared cavity is filled with concrete.

Another possible material from which formwork blocks are made is polystyrene. Their advantage is their lightness and excellent isolation capabilities. Blocks of precision locks are simply assembled into formwork, which, after spraying with concrete, create a massive, durable structure with double-sided thermal insulation.

In this case, the width of the empty layer that forms between the formwork should be equal to the width of the wall. This thickness depends on many different factors. The most important are the region of construction and the thermal conductivity of the concrete mixture.

Formwork panels are fastened with various fasteners. The optimal solution is nuts, washers and studs. In order to make it easier to remove the formwork after work, you need to put on special corrugated tubes on the studs, which should not come into contact with concrete.

How to choose the right building system for passive houses? What are the advantages and disadvantages of individual solutions? These are questions for the Expert Forum, a unique meeting format organized by the Passive House Center. The building system is one of the most important elements not only of the passive, but of the whole house in general. There are many materials and systems on the market. Each of them has its own pros and cons, and especially the features that must be observed during design and implementation. That is why Mass Construction Systems was chosen as one of the experts of the passive house center that took place in Brno Mai.

The construction of a monolithic house implies pouring not only ordinary cement mortar, but also the possibility of using other mixtures that have lower thermal conductivity. These include: expanded clay concrete, slag concrete, sawdust concrete and so on. All these materials are also widely used in the construction of houses and cottages of this kind.

Effective solution for massive structures for passive houses

What did you come when you didn’t come? A feature of heavy chain structures is that they are conductive materials. Therefore, it is important to follow a few basic design principles. Sufficient and uninterrupted thermal insulation. Minimum 250 mm without loosening with support elements. ... Design without thermal bridges.

Structural connection details outdoor structure thermally separated, no thermal insulation. Continuous plastering connection with other structures of sealed installation and penetration. Author of the drawing: Jiří Čech. Typical values for the heat transfer coefficient for low energy and passive houses. Shown including approximate insulation thickness. These are, of course, approximate values. Achieving passive standard house always accompanied by comprehensive design and optimization for individual conditions.

In the case of using one of them, walls are obtained that have good indicators of heat conservation and vapor permeability. However, there are also disadvantages to using such substitutes. Walls cannot withstand too heavy loads.

Reinforcement of the walls is a very important point. For these purposes, you can use ordinary reinforcing mesh, but it is best if it is a reinforcing frame.

It is also important to remember the details and solutions of thermal bridges. They can have a large impact on both the heat loss of the entire building and the quality of the indoor environment and the risk of structural damage. An example of connecting a ceiling structure to a perimeter wall. Obviously, with some design systems, the thermal bridging solution is seamless, and complete elimination of the thermal bridging is nearly impossible.

The interconnection of the individual structures is also related to the non-breathability of the entire building. This, of course, also depends on the materials used, on the suitability of their combination and on the adherence to technological requirements and procedures. The combination of high precision design including custom parts, high quality construction and meticulous inspections results in a successful blower test and a quality home. The so-called pencil rule serves to define the airtight layer in a simple and unambiguous manner.

You do not need to pour more than 50 centimeters of concrete at a time. Only after the first layer has set can you continue pouring. Concrete compaction is best done using borehole vibrators. Particular attention should be paid to the corners of the building.

After the concrete has hardened, the formwork must be moved higher. This is done until all the walls have been erected. In order for the concrete to fully harden, it needs to stand for about 4 to 5 weeks. This is followed by work on the insulation and decoration of the house or cottage.

Types, implementation and economics of mass building systems for passive houses

Possibilities of fixing thermal insulation

An ideal anchorage is one that does not interrupt the thermal insulation shell and therefore the system thermal bridges. Schemes represent three main types of mounts. The main advantages of this system are high load-bearing capacity, no thermal bridges, cost and labor savings. This fastening method can also help reduce the airtightness of the shell. However, some principles must be followed: only polystyrene or mineral wool with perpendicular fibers can be glued.

Any of these materials can now be purchased without any problems in specialized hardware stores. The choice of a specific one depends on the desires of the person and on his financial capabilities. For those who want to save money, the best fit mineral wool, and for those who love comfort and aesthetics - expanded polystyrene.

Tips for building passive houses correctly

If, however, it is necessary to use mechanical anchors, it is advisable to use an anchor with the possibility of installing a concealed assembly in combination with thermal insulation plugs, thereby preventing the anchors from being pierced on the façade. When designing a home, a foundation is best suited to interrupt the home's thermal insulation. However, it must be borne in mind that static construction is always superior, so we must take into account the individual building construction conditions. Another criterion when choosing a fund is to optimize the price of the measure.

You can also use a variant of the so-called well facade. When using it, an indent is made outside the concrete wall, then everything is lined with bricks or tiles. After that, all the free space is covered with insulation. In this case, ecowool or expanded clay can be used as insulation.

The advantage of this technology is that the monolithic house turns out to be as environmentally friendly and breathable as possible. Minus - fuss with the assembly and disassembly of the formwork. For those who do not want to spend too much time on this, a technology has been created for the construction of a monolithic house with fixed formwork. However, this option is not ideal either. The choice in each case will depend on the preferences of the person and his experience in construction work.

There are three main options for creating a passive house with a massive support structure. In order to achieve the required quality of construction and individual structures on site, it is necessary to adhere to separate technological executive rules. First of all, the correct execution of details regarding the functions of waterproofing, thermal insulation, static, airtightness, as well as coordination of actions on site.

In particular, when performing masonry. However, when calculating, it is always necessary to assess the complexity, the complexity of execution, the complexity of structural parts and associated structures, or increased requirements for accuracy of execution. The additional cost to achieve a passive standard is around 5-10% compared to today's construction. These additional costs are now covered by the New Green Savings Grant Program.

Monolithic house do it yourself video

Concrete is a building material made up of crushed stone, sand, water and cement. Preparation of concrete involves thorough mixing of the ingredients and pouring it into containers, where the subsequent hardening of the concrete solution is carried out. For construction warm home special fillers are added to the mixture, which improve the quality of concrete. The concrete composition for the construction of houses has many advantages, one of them is the ability to prepare a solution and build a structure with your own hands.

Presentation of selected systems presented at the Expert Forum

This is the most commonly used solid construction. High thermal conductivity - the need to separate the thermal bridges of the thin construction of the assembly lines. Morning: Jiří Cech, Michal Hučík.

Precast precast concrete panels

Availability - need for local solutions for the installation of concrete plants needs an external support. Author: Jiří Čech, Juraj Hazuha.Compliance with the requirements of a passive house. Due to its characteristics, this system is primarily intended for use in energy efficient buildings. Applicants can choose from three main options. Optimal wall structure, ensuring variability of the insulating parts. The attachment of non-supporting parts with removable plastic partitions creates a lost formwork.

When working with a concrete house, the following advantages are distinguished:

- quick installation;

- reliability;

- longevity;

- high strength of the structure;

- relatively small financial costs;

- in the House monolithic structure there are no gaps through which cold passes;

- sound insulation of the room;

- the ability to use any finishing material on top of concrete;

- the ability to build buildings with your own hands;

- concrete has various geometric shapes, which simplifies the installation process;

- with even pouring of the solution, the formation of cracks is reduced;

- the use of light mixtures in the composition does not require deepening the foundation.

DIY concrete houses have the following disadvantages:

Subsequent filling of the concrete mix results in a monolithic reinforced concrete core. After the concrete has hardened, the wall is ready for surface treatment. Greater insulating ability to distribute thermal insulation due to reduced fire load on the outside. Lost formwork wall system made of thermal insulation of non-support and fiber-cement boards. Optimal wall structure for accumulation in the concrete core of the wall. Lost formwork is created by joining non-supporting parts and CFB using removable plastic partitions.

- the need for additional equipment for high-altitude work;

- due to the metal reinforcement of the walls, the house will need grounding;

- when using fixed formwork, it is necessary to provide ventilation of the room so that the house can breathe;

- welding the frame will require large labor costs, which are also needed when possible;

- a warm house can only be after proper insulation;

- if the structure provides for a permanent formwork, polystyrene is used, and when it burns, it releases toxic substances that are harmful to human health.

Tools and materials for work

When erecting buildings and structures made of concrete, you cannot do without the following tools and equipment:

When erecting buildings and structures made of concrete, you cannot do without the following tools and equipment:

- mixer for connecting concrete components;

- do-it-yourself containers for mixing concrete mixture;

- reinforcement;

- trolley for transferring the solution;

- construction hair dryer;

- puncher;

- a knife to cut styrofoam;

- various tools;

- nippers;

- roulette;

- wire;

- hammer;

- sand;

- fittings;

- cement;

- concrete mixer;

- crushed stone;

- formwork.

Construction methods

Concrete houses are erected in two ways: using removable formwork and non-removable. The removable method implies an individual formwork layout, the purpose of which is to accurately repeat the contours of the future structure. Removable formwork is made of plastic, metal or wood. This method carries out the pouring of a mortar from concrete with minimal heat transfer, which allows you to save heat in the room. The non-removable method makes the walls thin, but at the same time retains all its structural properties. This formwork has an insulating layer and built-in fittings.

With fixed formwork

Fixed formwork for the foundation.

Fixed formwork for the foundation. The fixed formwork method has the following types of construction: angular, longitudinal, above-window, window-sills. This method of wall construction has an internal layer of thermal insulation, which saves on heating costs. It simplifies the installation of the structure due to its lightness and creates a different configuration of the premises.

Thermal insulation of the material is especially important for buildings and structures, because its absence requires the construction of walls of great thickness. Of the shortcomings, the formation of danger is observed as a result of the release of toxins into the atmosphere, which appear during a fire in buildings.

Construction technology

The formwork is placed on a waterproofing layer and fixed in the grooves, this technology creates a strong concrete grout, as a result of which there is no leakage of the mixture in the joints. When pouring the formwork, it is forbidden to use heated mortars, they can form condensation in large quantities, which will increase the humidity of the room. Using permanent formwork, a house with a good thermal insulation layer is provided, which will only require covering the expanded polystyrene plates with facing material.

With removable

Using removable formwork, methods of its insulation are chosen. One of the options is to insulate the gap with warm plaster, the second method is the well facade. The well facade is a brick cladding monolithic wall, and the gap between them is closed with insulation. The well facade is the optimal solution for insulation, which provides the walls with breathable qualities. Thus, the house in the summer is resistant to overheating and will keep the room cool, and in the cold season it will keep warm and resist freezing.

Construction technology

The technological process consists of casting the formwork in several stages. Begin laying the mortar no more than 50 centimeters of concrete. The mixture is left to dry, the next layer is applied after the final hardening of the previous one. After pouring the solution, it is tamped using a deep vibrator. Next, the shape is shifted upward after the solution has completely hardened.

The concrete mixture is laid until the required wall height is reached. To make the structure strong, a reinforcing mesh is installed in the walls. Wall decoration and installation of thermal insulation material is carried out one and a half months after laying the concrete solution, waiting for the final strength of the structure. Heat insulating material may be:

- Styrofoam;

- mineral wool;

- warm plaster;

- extruded polystyrene.

The removable mold is made of wood, metal or plastic. When using a plywood sheet, it is cut with a fine-toothed file and drilled on both sides, this method eliminates the destruction of the coating. When storing plywood at the bottom of the formwork, they provide protection against moisture penetration onto its surface. So that the disassembly of the formwork does not cause difficulties, the plywood is covered with a special mixture and fasteners are fixed on it.

Conclusion

Concrete is a unique building material, thanks to which various architectural solutions are embodied in reality. The popularity of concrete is due to its large number of positive qualities. It gives buildings and structures strength, reliability and longevity. Therefore, concrete is often used for the construction of houses and load-bearing structures.

An important advantage of durable building material is the possibility of one-hand preparation and use in the process of erecting structures.