External walls of a frame house. Selection and calculation of materials for frame houses

There is a certain difficulty in calculating materials when frame housing construction. It lies in the fact that the structure of enclosing structures can be very diverse; it is thanks to invariance that a house can be built at minimal cost. Therefore, it is very important to have a project on hand, regardless of whether you decide to purchase a ready-made house kit or a future cottage - this is a bouquet of your ideas.

Surely, while carrying out a simplified economic cost analysis, you have already encountered questions that in one way or another relate to the selection and calculation of material. Of course, finding the optimal balance between price, quality and ease of installation is not an easy task.

But, nevertheless, having disassembled the structure element by element, you can figure out which option is best for you. It is more convenient to make calculations according to the stages of construction, i.e.

- Foundation

- First floor covering

- Construction of the frame

- Roof installation

- Sheathing with thermal insulation material

this sequence is typical for Scandinavian house building

technologies when wall insulation is carried out only after the roof is erected.

If the consumption of materials for arranging the foundation is more or less known, since typical types of foundation are often used, such as shallow strip, pile or columnar, then you will have to work hard with the selection and calculation of lumber and insulation. Although if you understand key moment process, there is nothing complicated about it, you just need attention and patience.

In order to make the task as easy as possible, they start by selecting the material according to the drawings. For convenience, we advise you to draw a block of the structure, for example a load-bearing frame, and make a development for each component part (floor, wall, etc.). You can also make calculations using detailed drawings.

I would immediately like to note that for frame house construction, lumber must be dry and pre-treated with various antiseptic compounds. Otherwise, the assembled structure may shrink, which will inevitably lead to various kinds of distortions in the structure and, as a result, the formation of cracks and other defects. The impregnation must penetrate approximately 10 mm into the wood; only in this case can a long service life be guaranteed. Surface application of antiseptics will protect structural elements for a maximum of two to three years, after which re-treatment of the wooden parts of the house will be required.

Undoubtedly, wood dried and processed under industrial conditions is much more more expensive than that, which can be purchased at construction sites. If you still decide to save money and purchase lumber of natural moisture, then after it is delivered to the site you will need to stack it. Each row is laid on slats to prevent the boards from touching each other and to ensure natural ventilation. Although this method of removing moisture does not guarantee against corroding, the main drawback of wood.

Calculation of materials for the construction of a frame house

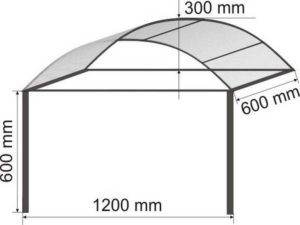

To construct a power frame, softwood lumber is often used. For tying the lower belt, a regular beam of 150x150 mm is used; this section is suitable for corner posts, if the building has two levels. The required quantity is calculated based on the perimeter of the building, i.e. we will need width (a), length (b), according to the simplest mathematical formulas we will find out the required volume of timber, (a + b) x 2 = N is the total value of the material in linear meters. To convert to cubic meters V = N * 0.15 * 0.15 = 0.0225 * N (m 3 ). We carry out calculations for racks in a similar way, with the only difference that instead of the length and width of the house, we will need other values, the number of supports (n) and the height (h) of the floor or house, if the project provides for their end-to-end arrangement. According to the project, we determine the required volume of lumber for other structural elements. However, I would like to draw attention to some points. As for the intermediate posts, their cross-section should be commensurate with the thickness thermal insulation material.When choosing a step (distance) between them, they are guided by two conditions: the calculated load and the standard size of the material used. Agree, it is not logical to place supports at a distance of 950 mm, if you know that the sheet of plasterboard with which you plan to cover the inner surface has a standard width of 600, 800 and 1200 mm. Therefore, by choosing, for example, a pitch of 800 mm, you can easily calculate the number of boards (M) for installing intermediate posts. To do this, take the perimeter of the house and divide it by the set step, N / 0.8 = M, from this value we subtract the number of main racks of the power frame and we get how many racks in pieces are required for one floor. This figure can also be expressed in cubic meters, knowing geometric parameters board used (usually 100x50mm), we apply the same formula as for timber, V = (M – f)*0.15*0.05 = 0.0075 * (M – f) m 3, where f – number of main racks.

A very interesting and functional alternative to a lattice structure made of timber and boards in frame housing construction can be called one that has recently appeared on Russian market- I-beam, which is made entirely of wood.

It serves as a ready-made cell for laying thermal insulation material. It consists of two beams connected to each other by a jumper, which is made of OSB board. The I-beam shelf is easily adjusted by the size of the base and is matched to the calculated thickness of the thermal insulation. Using this structural element, the thermal uniformity of enclosing structures is improved and the risk of shrinkage deformations of the frame is reduced.

To calculate other materials, in most cases, surface area will be required, this applies to waterproofing (roofing felt, roofing felt), subfloor, interior and exterior finishing. Everything is simple here, we take the dimensions of the space that we need and, using simple mathematical operations, carry out the calculations.

Along with the material for the load-bearing frame, the choice of thermal insulation is very important. Disputes on this issue not only do not subside, but as new representatives appear in this sector, they only flare up. First of all, it is worth noting that there are two main types of heat and sound insulation materials: soft and hard. Soft materials include basalt wool and fiberglass insulation. Expanded polystyrene and its new modification can be considered rigid - extruded polystyrene. Each of them has very low thermal conductivity and has its own pros and cons.

The main advantage of mineral wool mats is their excellent physical and mechanical properties, thanks to which thermal properties are maintained for a long time. This material is chemically and biologically resistant, non-hygroscopic, absolutely environmentally friendly and resistant to deformation. It has been proven over time that mineral wool practically does not shrink, which eliminates the occurrence of “cold bridges” during operation.

The water-repellent ability of this material prevents moisture from penetrating inside the slab, and its excellent breathability makes it possible to create a comfortable microclimate in the room through natural ventilation. Another undoubted advantage is the fire resistance of mineral wool; according to the fire safety classification, it belongs to the NG group (non-combustible material). In order for the insulation to “work” fully, it must be provided during installation correct styling. The size of the mat should be 10 - 30 mm wider than the cell, this will avoid unnecessary gaps and unnecessary cracks, which guarantees minimal heat loss.

What else do you need to know about mineral wool slabs? The thermal insulation properties of a material are determined by its thickness, but if during the installation process you happened to have 100 mm of insulation, you had to compact it to 80 mm, then its quality characteristics will correspond to its final state, that is, 80 mm. That is why it is so important to maintain the size of the timber, which determines the parameters of the cell for laying the insulation.

In many respects, glass wool is less attractive. Even if we ignore all the difficult aspects of working with this material, it is still inferior to the previous insulation. The fact is that fiberglass is subject to shrinkage, which over time leads to the appearance of “cold bridges” and heat loss. The relatively high rate of water absorption, which can reach 13–15%, does not have the best effect on the thermal insulation properties.

What can we say about foam plastics? Undoubtedly, it has almost the lowest thermal conductivity coefficient, low volumetric weight and a number of other advantages that exceed the parameters of mineral wool. However, along with many positive qualities, there are a number of significant disadvantages that force developers to abandon this material in favor of others. The rigid structure does not allow the insulation to be installed using the “expanded” technology, which inevitably entails a loose connection in the cells and, as a result, additional heat loss. The absolute airtightness of the material creates the effect of a “thermos”, which is also not a plus. Unscrupulous manufacturers often use low-quality, cheap raw materials for the production of polystyrene foam, which further undermines confidence in this type of insulation. But the most important thing that stops many builders from using polystyrene is its flammability. Moreover, under the influence of high temperatures, toxic substances are released that are harmful and dangerous to human health. And this not very unpleasant list ends with the fact that polystyrene foam is a favorite place for rodents to live, and this is not a very comfortable neighborhood to live in.

The amount of heat-insulating material that will be required to insulate a house will largely depend on the calculated thickness and overall dimensions of the workpieces. Experts recommend making the required insulating layer in stacks, for example, an estimated thickness of 150 mm; it is advisable to assemble it from three mats of 50 mm each or two mats of 100 and 50 mm in height. This type of insulation is considered more effective because it has additional air layers.

After you make a step-by-step selection of material for the entire structure, similar items are summed up, and as a result you will receive a complete breakdown of costs in cubic meters, pieces, rolls, liters and kilograms. For clarity, you can summarize all the figures in one table; by the way, in this way it will be easier to calculate the upcoming costs in monetary terms. In order not to lose sight of this or that material, sketch out a schematic layer-by-layer structure of the floor, walls, ceilings, and ceilings.

You should have approximately the following list:

main and intermediate racks

sheathing

insulation

vapor barrier material

overlap of the lower and upper chords

hydro, windproof membrane

finishing material

waterproofing

Also, do not forget that during construction you will need antiseptic compounds, polyurethane foam, fastening elements (nails, screws, perforated metal corners). Do not forget that when purchasing materials, it is worth adding 10–12% to the calculated volumes, since waste is inevitable in construction. Although some argue that this is the percentage that remains if door and window openings are not taken into account.

If you have completed construction frame house, then we still have to think about its interior decoration. This is the only way you will be able to achieve coziness and comfort in the premises.

Technology

Such work takes place in two stages, the first of which involves rough manipulations, while the second involves finishing. Initially, the surface of the walls, ceiling and floor should be prepared; such measures mean removing the old coating, as well as preparing and leveling the surfaces. represents final stage when surfaces are subject to wallpapering, installation of facing materials or painting.

Selection of material for rough finishing

May take several months external finishing frame house. carried out during the same period. By visiting a hardware store, you can choose a material that will fit your allocated budget and certain characteristics. For rough finishing, OSB or plasterboard is most often used. The advantage in these cases is the ability to hide wall imperfections with the help of smooth sheets. Such canvases can be installed on untreated or curved surfaces. With the help of gypsum boards you can create complex design compositions. IN short time you will be able to cover the walls, preparing them for further work.

Disadvantages of using gypsum board and OSB for rough work

If you purchased a newly built frame house, you can do the interior finishing with plasterboard yourself. However, this material has some disadvantages, which will be expressed in a reduction in the area of the room when installing sheets on uneven walls. If there are any, then first you have to install a frame system, which will be somewhat removed from the base. This also applies to OSB, which has a more impressive thickness. If you use this material, it will be very difficult to do without additional devices for lifting sheets.

However, sometimes the solutions described are the only correct ones.

Pros and cons of using wallpaper

Considering Options interior decoration frame house, you can pay attention to the traditional wallpapers that are presented on modern market in a wide variety, they can be paper, acrylic, vinyl, fiberglass and non-woven. Each of these types of finishes has its own positive and negative features. For example, paper wallpaper Although they are low in cost, they are extremely unstable to low temperatures and moisture, and even without this they are very short-lived. They can be used as a temporary solution.

The interior decoration of a frame house, the photo of which is presented in the article, can be done using vinyl or acrylic wallpaper that is resistant to mechanical damage and are durable. The latter are characterized by durability and moisture resistance. Owners of private houses who want to diversify the interior choose a non-woven type of covering, which is made from foamed vinyl; it can be used as a basis for further decorative painting.

The worst enemy of frame wooden houses- fire. If you want to make your home more fireproof, you should purchase fiberglass wallpaper, which, along with mechanical strength, is flame resistant. At the same time, they can be successfully used for coloring.

Positive and negative features of lining

Quite often in Lately The interior finishing of a frame house is carried out using clapboards. This is no coincidence, since this material is able to bring home comfort and a natural look. Wood will give the walls higher sound and heat insulation. Depending on the available funds allocated for repairs, you can choose a lining that will belong to a certain grade.

There will be no defects on the surface of the elements if you prefer top-class lining. Consumers who are not afraid of chips and stains choose grade A finish. The material is designated grade B if there are several cracks and knots on one of the slats.

When considering the materials for the interior decoration of a frame house, you can choose plastic lining, which you can install yourself, since it is quite easy to install. This finish is low cost and is not exposed to harmful bacteria. With the help of plastic slats, it is unlikely that you will be able to achieve comfort in the room, and the artificiality of the material will be immediately visible. In terms of sound and heat insulation characteristics, PVC is inferior to models made of natural wood, but it can be installed in rooms with high level humidity.

Finishing walls with plasterboard

Technology must be followed when finishing a frame house. Interior decoration, as mentioned above, may involve the use of plasterboard. With its help, you can hide any unevenness, which will eliminate the labor-intensive leveling of the base. The paintings are fixed on metal carcass, which speeds up manipulations. The resulting free space between the main wall and the sheet can be filled with insulating material, and electrical wiring and other communications can also be laid there.

The low weight of drywall will not create additional load on the floor, so you can build arbitrarily complex geometric structures, which sometimes represent

Initially, the master will have to carry out the markings, strengthening the starting UD profiles with self-tapping screws, then the wiring will be laid in special plastic boxes or corrugated polyvinyl chloride pipes. Drywall sheets must be laid on the profile and secured with metal screws. The fastener head should be recessed by 1 millimeter. Even an inexperienced craftsman can finish a frame house. Interior finishing using plasterboard will be completed in a matter of days. Carrying out these manipulations does not require the master to have special skills.

The seams formed between the sheets must be filled with putty; the tool will need to get rid of excess material, aligning the seams. Afterwards, fine-grained sandpaper comes into play, which will smooth out the joints in order to prepare the sheets for finishing.

Using OSB boards

The technology for installing such canvases is almost no different from that used with the only difference is the impressive weight of OSB. For this reason, you will need to use more reliable and durable fasteners. To fix the panels to the wooden frame, use 50mm spiral nails. At the connection points, fasteners are installed in increments of 15 centimeters. It is necessary to leave centimeter gaps along the edges of the walls, but the distance between the slabs that do not have a connection should be two millimeters. If you plan to use OSB to form a floor covering, then you need to lay the sheets, placing them perpendicular to the joists.

The installation of sheets does not involve the entire finishing of a frame house. Interior finishing involves sanding the surface. After this, the slabs are varnished in 3 layers, each of which must be thoroughly dried. This coating acts as a protection for the structure of the material from moisture penetration. If you decide to cover the surface of such a rough base with plaster or paint, then you must first apply a primer.

Advantages of using imitation timber in interior decoration

Over time, imitation timber is becoming more and more popular, especially when compared with lining. After finishing work, the premises turn out warm and aesthetically attractive. All the advantages of this material are associated with quality characteristics, which are expressed in the absence of shrinkage. Over time, the lamellas do not crack, as they are equipped with grooves to relieve stress inside the products. During installation, time and labor costs will be minimal. The advantage is that this finish is not afraid of exposure to ultraviolet rays.

If you choose certain types of wood, they will not be negatively affected by moisture. The cost of such material is significantly lower compared to full-fledged profiled or laminated timber. And if you carry out high-quality installation, then appearance such walls will hardly differ from a natural log house. The interior decoration of a frame house with imitation timber is not afraid of exposure to high and low temperatures.

The main disadvantages of imitation timber

Despite the fact that products during the manufacturing process are treated with various anti-flammable compounds and antiseptics, they do not cease to be fireproof. During operation, you have to process the wood once a year, otherwise it will become cracked, change color, and catch fire when exposed to fire. If you do the interior decoration of a frame house with your own hands using imitation timber, then you will have to take care of the wood throughout its entire service life, covering the surface of the walls with protective agents and paints and varnishes.

It is impossible not to note another disadvantage, which is expressed in expensive components such as internal corners, decorated elements and external consumables. If you don’t want the walls to resemble, then you need to use panels whose width starts at 90 millimeters.

Disadvantages of imitation pine timber

If finishing interior walls frame house will be made from imitation timber, it is important to choose the right one. For example, pine has some disadvantages, including resin, which indicates an increased fire hazard. Before installation work, despite the fact that the material was treated with fire retardants at the factory, a fire-retardant compound must be applied. It is worth remembering that the smell of pine lingers for a very long time, after a certain time it can begin to irritate. That is why this feature must be taken into account when decorating living rooms.

Conclusion

Interior decoration of a frame house OSB boards produced most often when there is no shortage of free space. Otherwise, it is best to choose sheets of drywall.

Finishing is the final stage of building a frame house. By doing finishing works there are no small things. Negligence in the future will result in additional financial costs for rework and correction of errors.

Before you start decorating, you need to imagine future interior home: where partitions, plumbing, electrical appliances and Appliances; what materials and types of coatings will be used for walls, ceilings and floors; make a furniture arrangement plan. With drawings in hand, you can begin rough finishing.

Rough work on interior finishing

The result of all repairs depends on the quality of the rough finishing of the interior, so it must be carried out with special care.

Rough repairs include:

- installation of heating, sewerage and water supply systems at home;

- laying electrical wiring and installing distribution boards;

- hydro-, heat- and sound insulation of premises;

- installation of floors, installation of a “warm floor” system, if it was planned in the project;

- installation of partitions made of timber with plasterboard finishing;

- elimination of uneven walls and ceilings.

Rough finishing of walls with plasterboard

Finishing the interior walls of a frame house should begin by securing a film vapor barrier membrane with a stapler over the entire area. Sheets of plasterboard are laid on top of the film on a metal or wooden frame from slats or timber.

Plasterboard sheets installed on the walls will slightly reduce the area of the room, but the gap between the sheet and the wall will allow you to cover the cable channels and avoid the need for gating the walls.

You can do the installation of plasterboard panels yourself:

- mark the sheet with a marker on the front side;

- use a knife to cut the workpieces of the required size, taking into account that the size of the workpiece should be 5-7 mm smaller than the plane to which it will be attached;

- lay the sheet on a metal profile or timber frame pre-fixed on the wall, attach it with self-tapping screws in increments of up to 20 cm, starting from the center of the sheet, recessing the caps into the sheet by about 1 mm;

- apply putty to the seams in several steps, removing excess with a spatula, after drying each new layer;

- sand the joints and the surface covered with plasterboard using fine sandpaper.

Options for finishing walls

Traditional materials for wall decoration are wallpaper: paper, acrylic and vinyl, foam wallpaper on a paper and non-woven basis, photo wallpaper, paintable wallpaper.

Using glass wallpaper

A relatively new wall covering material is fiberglass wallpaper.

They are ideal for interior wall decoration in frame house due to its unique fire-fighting properties, since the coating applied to the wall does not burn and does not spread fire.

Glass threads are made from natural materials: clay, soda, quartz sand and limestone. After making glass fiber on a loom, it is impregnated with a composition based on modified starch. The woven structure, which is an imitation of canvas, allows air to pass through and does not collect dust, so mold and mildew will never appear in the house. Pets will not be able to damage freshly papered walls, since glass wallpaper is durable and resistant to damage.

To paint fiberglass fabric, it is better to use latex paints or water-based paints, such as acrylics. Applied in a thin layer, they will add relief to the wallpaper pattern and will not disrupt its breathable structure.

Walls covered with fiberglass will retain their fresh appearance for a long time; if you need to completely update the interior, you just need to repaint them in a different color, more suitable for the new design solution.

Water-based decorative plaster (acrylic or PVA-based) will add originality to the decoration of a kitchen or bathroom, as it is not afraid of exposure to moist air and does not absorb foreign odors. Imitations of different textures made with plaster mortar decorate the walls of corridors and hallways.

With your own hands using decorative plaster You can create unique patterns on the wall that will complement the interior of the living room. To do this, use shaped spatulas, rubber rollers, ordinary rags with different textures, sponges and cellophane.

A more traditional solution is to use ceramic tiles for the walls of the kitchen and bathroom, finishing the horizontal surfaces entirely or combining them with other materials. It is best to mount the tiles on moisture-resistant drywall.

Plastic panels are a cheap and easy-to-assemble wall covering option for rooms with high humidity. They can be mounted either on a timber frame or directly on drywall.

Original wall decoration in interior spaces is obtained by using various kinds imitations: stone, brick, timber.

The use of timber for interior decoration of a frame house is suitable for lovers of natural materials.

Panels with imitation timber are made from cedar, larch, aspen, linden and other types of wood. Each type of wood has its own characteristics - pattern, resistance to temperature changes, and the ability to absorb foreign odors. For interior decoration, timber up to 21 mm thick and up to 150 mm wide is suitable. Finishing bars less than 100 mm will lose their charm and will look like lining. If the walls are pre-sheathed with plasterboard, then wooden panels imitating timber are attached directly to the wall, without sheathing, using screws, nails or self-tapping screws.

The options for preparing the ceiling surface are varied, as are the materials that are offered for these purposes.

A flat ceiling will be provided by plasterboard slabs arranged in a checkerboard pattern. The sheets are attached to the ceiling in the same way as to the walls. The frame in this case consists of floor beams with timber slats installed between them. Plasterboard blanks are reinforced along the ceiling, starting from the center of the room. The joints between them are puttied and cleaned. Drywall is indispensable when modeling a complex multi-level ceiling.

Lovers of sophisticated interiors will be attracted by the coffered ceilings. In the classic version, they are formed by ceiling beams and wood panels, which are attached to a timber frame. Coffered ceilings are an imitation of coffered ceilings; they can be made with your own hands using false beams made of polyurethane and overlays that are imitation of wood and stucco decorations. The beauty of a ceiling with coffers is in their symmetry, so it is very important not to make mistakes when marking the ceiling. First, false beams are fixed on the ceiling, and then decorative decorations.

In non-residential premises of a frame house, plastic ceilings will serve well. Plastic panels for the ceiling are mounted on a wooden frame made of slats, timber or metal profiles.

Stretch ceilings do not require rough surface preparation. Manufacturers offer a variety of suspended ceiling structures with imitation mosaics, suede, and wooden surfaces, the main thing is that they match the overall design of the room.

After preparatory work, the ceiling is painted, glued, covered with plastic or wooden panels.

Installation of floors in a frame house

The installation of floors in a frame house begins with laying the subfloor on which they lay waterproofing material and light insulation, most often mineral wool 50 mm thick. Mineral wool It allows air to pass through well, and good ventilation is the key to the durability of floors. A finished floor is laid on top of the insulation.

When choosing flooring for a frame house, it is important to take into account the load-bearing capacity of the wooden structure. It is better to give preference to lighter materials such as floorboards, parquet or cork.

Wooden plank floors and their imitation

A floor made of wooden tongue-and-groove or edged boards retains heat well inside the house, thanks to the low thermal conductivity of wood, looks beautiful and has a long service life. This floor will be appreciated by supporters of environmentally friendly materials. After assembly, the floors are treated with a protective compound and varnished to protect the boards from external influences and emphasize decorative properties, inherent natural wood. Over time, the boards dry out, begin to creak, and cracks appear in the floor, but this will not happen soon.

Wood floors are easy to repair.

Plywood or plasterboard laid on top of the finished floor will provide additional leveling of the surface if for finishing Decorative coverings will be used on the floors.

Parquet floor

Parquet or parquet board as decorative covering The floor will harmoniously fit into any interior if you choose it by color. There are several classic ways of laying parquet - deck laying, herringbone, diamond or square laying. In order to lay parquet, imitating wicker with inserts, you will have to first mark the floor. After installation, the parquet is sanded with a special apparatus, then tinted and varnished at least three times, taking four-hour breaks to dry each layer. With proper care, parquet floors retain their attractive appearance for a long time. You can update the appearance of parquet with your own hands using sanding equipment, and then re-varnish it.

Cork is not the most common material for decorative finishing flooring, but its popularity is growing as more people choose natural materials for their homes.

Despite its good durability, cork flooring is not suitable for all rooms in the house. It must be taken into account that it can be damaged by sharp objects or prolonged point loading. In rooms with significant load, in order not to violate the integrity of the solution, you can get by with imitation cork covering.

There are two options for cork flooring: prefabricated cork panels and adhesive flooring.

Interlocking panels made of cork (they are also called cork laminate) are easy to assemble; they can be assembled and, if necessary, disassembled with your own hands, since the cork floor is not attached to the base. They look great and will add a touch of originality to the decoration of the house, being an imitation of exotic material.

Cork coverings, which are attached with glue, are tiles similar to tiles. This coating requires careful preparation of the base, because the slightest unevenness on the floor will be clearly visible. But combinations of cork tiles of different colors and textures can be used to zone a room.

The ideal solution is cork flooring in the bedroom.

It is pleasant to walk on cork with bare feet, as it has a slight springiness. It has excellent thermal insulation properties and retains heat in the room, and its porous structure will provide additional sound insulation of the room.

Weaknesses of cork flooring - relative fragility, color change with prolonged exposure sun rays, high price.

A budget alternative to parquet, wooden boards and cork are laminate and linoleum. They are also successfully used as decorative floor finishing, which you can do yourself. There is a laminate, which is a fairly accurate imitation of natural wood coverings.

After completing the final finishing of the frame house, all that remains is to arrange the furniture and celebrate the housewarming.

Large population of regions Russian Federation dreams of building his own house in which he and his family would live permanently.

In addition, they plan to build their own houses quite soon, according to a sociological survey. Also, a significant part of the population intends to build and country houses, in other words, dachas where they will spend their leisure time in the summer. Only a small percentage of the population surveyed is completely satisfied with their living in city apartments.

But sometimes dreams do not come true, or their implementation is extended over a long period due to the fact that those who dream of building their own home simply do not have enough financial resources or time. Therefore, to avoid such troubles, you must first carefully calculate the amount the required material and make an estimate for the construction of a frame house.

Distinctive feature frame houses– they are low cost and small in size, which means their installation is quite simple to perform. Due to their size, they do not require high costs for building materials, which means that in relation to houses built using other technologies, frame buildings are distinguished by their low cost. For example, the average amount financial costs for building materials necessary for the construction of a house with an area of 100 m2 will be equal to 0.5 million rubles.

What necessary building materials will be contained in the kit needed to build such houses?

This kit will consist of the following items:

The future structure is the main factor in the selection and calculation building materials, namely, to carry out these calculations, its dimensions will be used, which can be found in the design documentation.

To obtain a more accurate and correct calculation, it is necessary to know exactly the dimensions of the structure’s frame, specifying the sections of the materials used and the spacing of their location. It is also advisable to draw up a plan that reflects all the components of the building and takes into account all the necessary nuances.

Despite the fact that after all the calculations there is 100% confidence in the amount of necessary building materials obtained, it is necessary to purchase them in slightly larger quantities. This will allow you not to interrupt the construction process and will allow you to complete the project on time, even in the event of a shortage of materials or any discrepancies in size. In addition, such materials may not be in warehouses, and it will be necessary to wait for them to be delivered from the sawmill, and this will delay the construction time.

Algorithm for calculating sections of building materials for a frame house

The basis of frame houses is only lumber, which is previously cleared of bark and various deposits and sawn in the form of boards, bars or slats having a standard length of 3-5 meters, but if necessary, you can order at a sawmill for individual measurements (and 1, 5 m, and even 6 m).

It is not recommended to save money on such materials; they guarantee a longer and more efficient service for the future home, so be sure to purchase the required quantities.

You should also correctly calculate the values of the following frame components: materials for the top and bottom trim and racks.

Lower and upper framing of the frame - calculation of the necessary building materials

Lower and upper framing of the frame - calculation of the necessary building materials

In building materials used for tying the bottom and top of the frame, much attention is paid to the length and cross-sectional dimensions, as well as fasteners. These components are the main ones.

The size of the cross-section directly depends on the insulating material used for construction. For example, if the insulation is 15 cm thick, the cross-section of the building material must be the following values: width 15 cm, height 10 cm. The best option It will be possible to use a solid block of this size, but it is possible to assemble it from 2 bars of smaller dimensions. The length of the timber required for tying the bottom of the building frame is directly dependent on dimensional indicators foundation.

It is attached to the foundation base using anchor bolts having a diameter of 3-3.2 cm. Also, instead of these elements, you can use threaded studs, the diameter of which corresponds to the above fastening materials, which are inserted into the foundation until it hardens. The studs are selected in such a size that, after being immersed in the concrete foundation structure, top part protruded to a height of 15 cm. Therefore, the minimum length of the hairpin should be equal to 30-35 cm. To tie the lower one, having an area of 100 m2, use no more than 3 hairpins.

To fasten the strapping, it is necessary to connect the bars together. This is done using nails and pins. All corner joints are fixed with nails having a length of 15 cm and a diameter of 0.5 cm.

The upper part of the building frame is tied with the same number of building materials as in the lower part, and all dimensional dimensions of these lumber are also observed. The only difference is that the trim of the upper part is not connected to the foundation.

Operations for calculating materials for house racks

Of great importance when installing the frame of a building are racks, for the construction of which timber, boards and bars are used. Moreover, such materials should have the following dimensions:

The height of the building affects the length of the racks. The standard height between the floor and the ceiling is taken to be 2.5 m; in specialized rooms (toilet, bathroom) this distance can be reduced, but not more than 0.5 m.

Therefore, to calculate the length of the racks, you need to take the resulting distance and add to it the height of the floor itself, including the thickness of its covering, joists and ceiling cladding material.

That is, the final height of the racks should be 2.7-2.8 m (where 20-30 cm is the additional height obtained from adding the height of the floors and ceiling covering).

When installing these parts of a frame house, you should remember that a certain distance must be maintained between them, calculated between the axes and the center of the racks, and not between the outer ribs. To determine the step size, exact indicators of the sizes of OSB sheets and insulation materials that will be used on the walls of the house are used, but it is still impossible to determine a perfectly accurate calculation of the step. It should also be taken into account that in the locations of window and doorways, the racks will be located according to a completely different principle.